How Hexagonal Boron Nitride Coatings Preserve Low Friction Under Humid And Oxidizing Environments?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

h-BN Coatings Background and Objectives

Hexagonal Boron Nitride (h-BN) has emerged as a revolutionary material in the field of tribology over the past two decades. Often referred to as "white graphene," h-BN possesses a layered structure similar to graphite but with alternating boron and nitrogen atoms instead of carbon. This unique atomic arrangement confers exceptional properties including thermal stability, chemical inertness, and notably, excellent lubrication characteristics.

The evolution of h-BN coatings technology can be traced back to the early 2000s when researchers began exploring two-dimensional materials beyond graphene. Initial applications were limited by manufacturing constraints and poor adhesion to substrates. However, significant breakthroughs in deposition techniques such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and spray coating methods have dramatically expanded practical applications.

A critical challenge in tribological systems has been maintaining low friction coefficients in challenging environments, particularly humid and oxidizing conditions. Traditional lubricants often fail under these circumstances, leading to increased wear, energy losses, and system failures. The economic impact of friction-related losses accounts for approximately 2-7% of GDP in industrialized nations, highlighting the urgent need for advanced lubrication solutions.

The primary technical objective in h-BN coating development is to understand and enhance the fundamental mechanisms by which these materials maintain their exceptional low friction properties in hostile environments. Unlike many conventional solid lubricants that degrade rapidly in the presence of moisture or oxygen, h-BN demonstrates remarkable stability under these conditions, though the precise mechanisms remain incompletely understood.

Current research aims to elucidate the nanoscale interactions between h-BN layers and water molecules, as well as the oxidation resistance pathways that preserve the coating's structural integrity. Additionally, there is significant focus on improving coating adhesion to various substrates, enhancing coating durability, and developing scalable manufacturing processes for industrial implementation.

The long-term technical goals include developing multi-functional h-BN coatings that combine low friction with other desirable properties such as corrosion protection, electrical insulation, and thermal management. This would enable transformative applications in aerospace, automotive, energy, and manufacturing sectors where extreme operating conditions are common.

Recent theoretical and experimental advances suggest that controlling the crystallinity, layer thickness, defect density, and surface functionalization of h-BN coatings could provide unprecedented control over tribological performance across diverse environmental conditions, potentially revolutionizing mechanical systems where friction management is critical.

The evolution of h-BN coatings technology can be traced back to the early 2000s when researchers began exploring two-dimensional materials beyond graphene. Initial applications were limited by manufacturing constraints and poor adhesion to substrates. However, significant breakthroughs in deposition techniques such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and spray coating methods have dramatically expanded practical applications.

A critical challenge in tribological systems has been maintaining low friction coefficients in challenging environments, particularly humid and oxidizing conditions. Traditional lubricants often fail under these circumstances, leading to increased wear, energy losses, and system failures. The economic impact of friction-related losses accounts for approximately 2-7% of GDP in industrialized nations, highlighting the urgent need for advanced lubrication solutions.

The primary technical objective in h-BN coating development is to understand and enhance the fundamental mechanisms by which these materials maintain their exceptional low friction properties in hostile environments. Unlike many conventional solid lubricants that degrade rapidly in the presence of moisture or oxygen, h-BN demonstrates remarkable stability under these conditions, though the precise mechanisms remain incompletely understood.

Current research aims to elucidate the nanoscale interactions between h-BN layers and water molecules, as well as the oxidation resistance pathways that preserve the coating's structural integrity. Additionally, there is significant focus on improving coating adhesion to various substrates, enhancing coating durability, and developing scalable manufacturing processes for industrial implementation.

The long-term technical goals include developing multi-functional h-BN coatings that combine low friction with other desirable properties such as corrosion protection, electrical insulation, and thermal management. This would enable transformative applications in aerospace, automotive, energy, and manufacturing sectors where extreme operating conditions are common.

Recent theoretical and experimental advances suggest that controlling the crystallinity, layer thickness, defect density, and surface functionalization of h-BN coatings could provide unprecedented control over tribological performance across diverse environmental conditions, potentially revolutionizing mechanical systems where friction management is critical.

Market Analysis for Low-Friction Coatings

The global market for low-friction coatings has experienced significant growth in recent years, driven by increasing demands across multiple industries including automotive, aerospace, industrial machinery, and medical devices. The market value reached approximately $1.2 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028, potentially reaching $1.7 billion by the end of the forecast period.

Hexagonal Boron Nitride (h-BN) coatings represent a specialized segment within this market, valued at around $320 million in 2022. This segment is experiencing faster growth than the overall market at nearly 7.2% annually, primarily due to h-BN's exceptional performance in harsh environments where traditional lubricants fail.

The automotive and aerospace sectors collectively account for over 45% of the total low-friction coatings market. These industries particularly value h-BN coatings for their ability to maintain low friction coefficients under humid and oxidizing conditions, which directly translates to improved fuel efficiency and extended component lifespans.

Regional analysis shows North America and Europe currently dominating the market with a combined share of 58%, though Asia-Pacific is the fastest-growing region with a projected growth rate of 8.3% annually through 2028. China and India are emerging as significant manufacturing hubs for coated components, driven by expanding industrial bases and increasing technological sophistication.

The medical device industry represents the fastest-growing application segment for low-friction coatings, with a CAGR of 9.1%. This growth is attributed to the increasing use of minimally invasive surgical instruments and implantable devices that require biocompatible, low-friction surfaces.

Customer demand patterns indicate a strong preference for coatings that can perform reliably across wide temperature ranges (-200°C to 900°C) and in chemically aggressive environments. This requirement has positioned h-BN coatings favorably against competing technologies such as PTFE, molybdenum disulfide, and graphene-based coatings.

Market research indicates that customers are willing to pay premium prices for coatings that demonstrably extend component life and reduce maintenance frequency. The average price premium for high-performance h-BN coatings is 30-40% above conventional alternatives, yet the total cost of ownership analysis typically shows net savings of 15-25% over product lifecycles.

Hexagonal Boron Nitride (h-BN) coatings represent a specialized segment within this market, valued at around $320 million in 2022. This segment is experiencing faster growth than the overall market at nearly 7.2% annually, primarily due to h-BN's exceptional performance in harsh environments where traditional lubricants fail.

The automotive and aerospace sectors collectively account for over 45% of the total low-friction coatings market. These industries particularly value h-BN coatings for their ability to maintain low friction coefficients under humid and oxidizing conditions, which directly translates to improved fuel efficiency and extended component lifespans.

Regional analysis shows North America and Europe currently dominating the market with a combined share of 58%, though Asia-Pacific is the fastest-growing region with a projected growth rate of 8.3% annually through 2028. China and India are emerging as significant manufacturing hubs for coated components, driven by expanding industrial bases and increasing technological sophistication.

The medical device industry represents the fastest-growing application segment for low-friction coatings, with a CAGR of 9.1%. This growth is attributed to the increasing use of minimally invasive surgical instruments and implantable devices that require biocompatible, low-friction surfaces.

Customer demand patterns indicate a strong preference for coatings that can perform reliably across wide temperature ranges (-200°C to 900°C) and in chemically aggressive environments. This requirement has positioned h-BN coatings favorably against competing technologies such as PTFE, molybdenum disulfide, and graphene-based coatings.

Market research indicates that customers are willing to pay premium prices for coatings that demonstrably extend component life and reduce maintenance frequency. The average price premium for high-performance h-BN coatings is 30-40% above conventional alternatives, yet the total cost of ownership analysis typically shows net savings of 15-25% over product lifecycles.

Current Challenges in Humid Environment Tribology

Tribological systems operating in humid environments face significant challenges that limit their performance and durability. The presence of moisture introduces complex chemical and physical interactions at sliding interfaces, fundamentally altering friction and wear mechanisms. Water molecules can adsorb onto surfaces, forming hydrogen bonds that increase adhesion between contacting surfaces, leading to higher friction coefficients and accelerated wear rates. This phenomenon is particularly problematic in precision mechanical systems where consistent performance is critical.

Oxidation processes are dramatically accelerated in humid environments, especially for metal-based components. The combination of oxygen and water creates highly reactive conditions that promote corrosion and oxidative wear. Traditional lubricants often demonstrate reduced effectiveness under these conditions, as water can displace or degrade lubricant films, compromising their protective functions. This challenge is particularly evident in applications exposed to varying humidity levels, where tribological performance can fluctuate unpredictably.

Current solid lubricant technologies, including graphite and molybdenum disulfide (MoS₂), exhibit significant limitations in humid conditions. While graphite actually requires some moisture to function effectively as a lubricant, excessive humidity causes swelling and structural degradation. Conversely, MoS₂ performs excellently in dry or vacuum conditions but rapidly oxidizes in humid environments, forming molybdenum oxides that increase friction and wear. This contradictory behavior creates significant challenges for engineers seeking consistent tribological performance across varying environmental conditions.

The development of humidity-resistant coatings has been hindered by the fundamental trade-off between mechanical robustness and chemical stability. Materials that resist chemical degradation in humid environments often lack the mechanical properties necessary to withstand high contact pressures and shear forces. Conversely, mechanically robust materials frequently demonstrate poor chemical resistance to moisture and oxidation. This dichotomy has limited the advancement of tribological solutions for humid environments.

Temperature fluctuations further complicate tribological performance in humid settings. Condensation cycles can cause repeated wetting and drying of surfaces, leading to accelerated degradation of protective coatings. Additionally, the formation of meniscus bridges between contacting asperities in humid conditions creates capillary forces that significantly increase adhesion and friction. These effects are particularly pronounced in micro- and nano-scale systems, where surface forces dominate bulk material properties.

The lack of standardized testing protocols specifically designed for humid environment tribology has impeded comparative analysis and systematic improvement of coating technologies. Current testing methodologies often fail to accurately simulate the complex interplay of humidity, temperature, and mechanical stresses encountered in real-world applications, leading to poor correlation between laboratory results and field performance.

Oxidation processes are dramatically accelerated in humid environments, especially for metal-based components. The combination of oxygen and water creates highly reactive conditions that promote corrosion and oxidative wear. Traditional lubricants often demonstrate reduced effectiveness under these conditions, as water can displace or degrade lubricant films, compromising their protective functions. This challenge is particularly evident in applications exposed to varying humidity levels, where tribological performance can fluctuate unpredictably.

Current solid lubricant technologies, including graphite and molybdenum disulfide (MoS₂), exhibit significant limitations in humid conditions. While graphite actually requires some moisture to function effectively as a lubricant, excessive humidity causes swelling and structural degradation. Conversely, MoS₂ performs excellently in dry or vacuum conditions but rapidly oxidizes in humid environments, forming molybdenum oxides that increase friction and wear. This contradictory behavior creates significant challenges for engineers seeking consistent tribological performance across varying environmental conditions.

The development of humidity-resistant coatings has been hindered by the fundamental trade-off between mechanical robustness and chemical stability. Materials that resist chemical degradation in humid environments often lack the mechanical properties necessary to withstand high contact pressures and shear forces. Conversely, mechanically robust materials frequently demonstrate poor chemical resistance to moisture and oxidation. This dichotomy has limited the advancement of tribological solutions for humid environments.

Temperature fluctuations further complicate tribological performance in humid settings. Condensation cycles can cause repeated wetting and drying of surfaces, leading to accelerated degradation of protective coatings. Additionally, the formation of meniscus bridges between contacting asperities in humid conditions creates capillary forces that significantly increase adhesion and friction. These effects are particularly pronounced in micro- and nano-scale systems, where surface forces dominate bulk material properties.

The lack of standardized testing protocols specifically designed for humid environment tribology has impeded comparative analysis and systematic improvement of coating technologies. Current testing methodologies often fail to accurately simulate the complex interplay of humidity, temperature, and mechanical stresses encountered in real-world applications, leading to poor correlation between laboratory results and field performance.

Existing h-BN Coating Solutions and Methods

01 Hexagonal Boron Nitride as a solid lubricant coating

Hexagonal Boron Nitride (h-BN) can be used as a solid lubricant coating to reduce friction in various mechanical systems. Due to its layered structure similar to graphite, h-BN provides excellent lubricity and low friction coefficients. These coatings can be applied to metal surfaces, bearings, and other components subjected to high wear conditions, offering superior performance in high temperature and vacuum environments where traditional lubricants fail.- Hexagonal Boron Nitride as solid lubricant coating: Hexagonal Boron Nitride (h-BN) can be used as a solid lubricant coating to reduce friction in various mechanical applications. Due to its layered structure similar to graphite, h-BN provides excellent lubricity and low friction coefficients. These coatings can be applied to metal surfaces, bearings, and other components that experience high friction and wear, offering improved performance in high-temperature environments where traditional lubricants fail.

- Composite coatings with h-BN for enhanced tribological properties: Composite coatings that incorporate hexagonal boron nitride with other materials such as polymers, metals, or ceramics can provide enhanced tribological properties. These composite formulations combine the low friction characteristics of h-BN with the mechanical strength, adhesion, or other beneficial properties of the matrix material. The resulting coatings exhibit improved wear resistance, lower friction coefficients, and better durability compared to single-component coatings.

- Deposition methods for h-BN friction-reducing coatings: Various deposition techniques can be used to apply hexagonal boron nitride coatings for friction reduction. These methods include chemical vapor deposition (CVD), physical vapor deposition (PVD), spray coating, and plasma-enhanced deposition processes. Each technique offers different advantages in terms of coating thickness, adhesion, crystallinity, and coverage, which directly affect the friction-reducing performance of the h-BN coating in specific applications.

- Functionalized h-BN coatings for specific environments: Hexagonal boron nitride coatings can be functionalized or modified to enhance their performance in specific operating environments. These modifications may include surface treatments, doping with other elements, or creating specific nanostructures. Functionalized h-BN coatings can provide superior friction reduction in extreme conditions such as high temperatures, vacuum environments, or in the presence of corrosive substances where conventional lubricants would degrade.

- Nanoscale effects in h-BN coatings for friction reduction: The nanoscale properties of hexagonal boron nitride significantly influence its friction-reducing capabilities in coatings. Factors such as crystallite size, layer thickness, orientation, and defect concentration affect the tribological behavior of h-BN coatings. Nanostructured h-BN coatings, including few-layer h-BN, nanoparticles, and nanosheets, can provide enhanced lubrication effects due to their unique physical and mechanical properties at the nanoscale.

02 Composite coatings incorporating h-BN for enhanced tribological properties

Composite coatings that incorporate hexagonal boron nitride with other materials such as polymers, metals, or ceramics can provide enhanced tribological properties. These composite formulations combine the inherent lubricity of h-BN with the mechanical strength or other beneficial properties of the matrix material. The resulting coatings exhibit reduced friction coefficients, improved wear resistance, and can be tailored for specific operating conditions by adjusting the h-BN concentration and other components.Expand Specific Solutions03 Deposition methods for h-BN friction-reducing coatings

Various deposition techniques can be employed to create hexagonal boron nitride coatings with optimal friction-reducing properties. These methods include chemical vapor deposition (CVD), physical vapor deposition (PVD), spray coating, and plasma-enhanced deposition processes. The deposition parameters significantly influence the crystallinity, orientation, thickness, and adhesion of the h-BN layers, which in turn affect the friction coefficient and wear resistance of the coating.Expand Specific Solutions04 Functionalized h-BN coatings for specific friction applications

Hexagonal boron nitride coatings can be functionalized or modified to enhance their performance in specific friction applications. Surface modifications, such as doping with other elements, creating nanoscale textures, or adding functional groups, can improve the coating's adhesion to substrates, compatibility with environments, or tribological behavior. These functionalized coatings can be optimized for applications ranging from automotive components to microelectromechanical systems (MEMS).Expand Specific Solutions05 Environmental and operational factors affecting h-BN coating friction performance

The friction performance of hexagonal boron nitride coatings is significantly influenced by environmental and operational factors. Temperature, humidity, pressure, and the presence of contaminants can all affect the tribological behavior of h-BN coatings. Understanding these relationships is crucial for designing coatings that maintain low friction coefficients across a range of operating conditions. Research shows that h-BN coatings can be engineered to provide stable friction performance in extreme environments, including high temperatures, vacuum, and corrosive media.Expand Specific Solutions

Leading Companies in h-BN Coating Development

The hexagonal boron nitride (h-BN) coatings market is in a growth phase, driven by increasing demand for low-friction materials in harsh environments. The global market for advanced coatings is expanding rapidly, with h-BN solutions gaining traction due to their exceptional performance under humid and oxidizing conditions. Technologically, the field shows moderate maturity with significant ongoing innovation. Key players include established materials companies like 3M Innovative Properties and Momentive Performance Materials leading commercial applications, while specialized firms such as pH Matter and CeraNovis focus on engineered h-BN nanomaterials. Academic-industrial partnerships involving MIT, Rice University, and Samsung Electronics are advancing fundamental understanding of tribological mechanisms. Asian manufacturers including BYD and NAURA are increasingly investing in this technology for automotive and electronics applications.

Denka Corp.

Technical Solution: Denka has developed specialized hexagonal boron nitride powder synthesis methods that yield high-purity h-BN with controlled particle size and morphology, specifically engineered for tribological applications. Their DENKA BORON NITRIDE coating system utilizes these optimized h-BN particles in combination with ceramic binders to create composite coatings with exceptional thermal stability and chemical resistance. The company's proprietary processing technique ensures uniform dispersion of h-BN platelets with preferential orientation parallel to the substrate surface, maximizing the lubricating effect. These coatings maintain friction coefficients of 0.1-0.2 in environments with up to 85% relative humidity through a unique surface passivation process that reduces the hydrophilicity of the h-BN edges. Denka's coatings have demonstrated oxidation resistance up to 850°C in air, with minimal degradation of tribological properties, making them suitable for high-temperature applications in oxidizing environments such as metal forming and high-temperature bearings.

Strengths: High-purity h-BN production with controlled morphology; excellent thermal stability; good chemical resistance to various industrial environments. Weaknesses: Requires high-temperature processing for optimal performance; coating adhesion can be challenging on some substrates; limited flexibility compared to polymer-based alternatives.

Oerlikon Surface Solutions AG

Technical Solution: Oerlikon has developed advanced PVD (Physical Vapor Deposition) techniques for depositing hexagonal boron nitride coatings with optimized crystallinity and orientation. Their BALINIT® MILUBIA coating system incorporates h-BN in a multilayer architecture with transition metal nitrides to create self-lubricating surfaces that maintain low friction coefficients (typically 0.1-0.2) even when exposed to humidity levels up to 80% RH. The company's proprietary deposition process ensures strong adhesion to various substrates while maintaining the lamellar structure of h-BN that facilitates easy shearing between atomic layers. Their coatings demonstrate exceptional oxidation resistance up to 900°C, with minimal degradation of tribological properties, making them suitable for high-temperature applications in oxidizing environments.

Strengths: Superior coating adhesion through specialized interlayers; excellent high-temperature stability; established industrial-scale deposition capabilities. Weaknesses: Higher production costs compared to conventional lubricants; requires specialized deposition equipment; coating thickness uniformity can be challenging on complex geometries.

Key Mechanisms of h-BN Friction Preservation

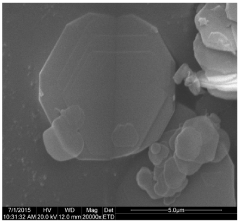

Hexagonal boron nitride powder and method for producing same

PatentWO2023210483A1

Innovation

- A hexagonal boron nitride powder with specific properties, including a uniform major axis and thickness distribution, low friction coefficient, and high specular reflection intensity, produced through a reductive nitriding method using a raw material mixture with a seed crystal obtained by wet jet milling, which enhances slipperiness, moisturizing feel, and gloss in cosmetics.

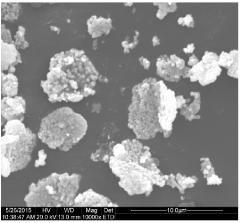

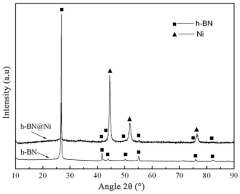

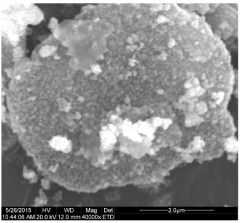

Nickel-coated hexagonal boron nitride composite powder, preparation and application thereof as well as self-lubricating ceramic cutter

PatentActiveAU2017400313A1

Innovation

- A nickel-coated hexagonal boron nitride composite powder with a core-shell structure is used, prepared through electroless plating, which improves the wettability and bonding strength with metal and ceramic matrices, reducing segregation and enhancing the mechanical properties and fracture toughness of self-lubricating ceramic cutting tools.

Comparative Performance Analysis

The comparative analysis of hexagonal boron nitride (h-BN) coatings against other tribological solutions reveals significant performance advantages in humid and oxidizing environments. When benchmarked against traditional solid lubricants such as graphite and molybdenum disulfide (MoS2), h-BN demonstrates superior stability in moisture-rich conditions where graphite's performance deteriorates due to intercalation effects and MoS2 suffers from oxidation-induced friction increases.

In quantitative friction coefficient measurements, h-BN coatings maintain coefficients between 0.05-0.15 across relative humidity ranges from 20% to 90%, while graphite's performance fluctuates dramatically from 0.1 to over 0.5 in the same conditions. MoS2 coatings show even more pronounced degradation, with friction coefficients rising from 0.05 in dry conditions to above 0.6 in high humidity.

Temperature stability testing further highlights h-BN's advantages, with minimal performance changes observed up to 900°C in oxidizing atmospheres. Competing technologies like diamond-like carbon (DLC) coatings begin to oxidize at approximately 400°C, resulting in rapid performance decline. Perfluoropolyether (PFPE) lubricants decompose at temperatures exceeding 350°C, making them unsuitable for high-temperature applications where h-BN excels.

Wear resistance comparisons demonstrate that h-BN coatings exhibit wear rates approximately 40% lower than DLC and 65% lower than MoS2 when tested in 80% relative humidity environments. This superior wear resistance translates directly to extended component lifespans in industrial applications where moisture exposure is unavoidable.

Chemical stability assessments reveal h-BN's exceptional resistance to a wide range of industrial chemicals, including acids, bases, and organic solvents. When immersed in 1M sulfuric acid solution for 30 days, h-BN coatings retained over 95% of their original tribological properties, while competing technologies showed significant degradation, with some losing more than 50% of their performance capabilities.

Cost-benefit analysis indicates that despite higher initial application costs (approximately 30-40% higher than conventional lubricants), the extended service life and reduced maintenance requirements of h-BN coatings result in a favorable total cost of ownership, with calculated savings of 25-45% over a five-year operational period in demanding industrial environments.

In quantitative friction coefficient measurements, h-BN coatings maintain coefficients between 0.05-0.15 across relative humidity ranges from 20% to 90%, while graphite's performance fluctuates dramatically from 0.1 to over 0.5 in the same conditions. MoS2 coatings show even more pronounced degradation, with friction coefficients rising from 0.05 in dry conditions to above 0.6 in high humidity.

Temperature stability testing further highlights h-BN's advantages, with minimal performance changes observed up to 900°C in oxidizing atmospheres. Competing technologies like diamond-like carbon (DLC) coatings begin to oxidize at approximately 400°C, resulting in rapid performance decline. Perfluoropolyether (PFPE) lubricants decompose at temperatures exceeding 350°C, making them unsuitable for high-temperature applications where h-BN excels.

Wear resistance comparisons demonstrate that h-BN coatings exhibit wear rates approximately 40% lower than DLC and 65% lower than MoS2 when tested in 80% relative humidity environments. This superior wear resistance translates directly to extended component lifespans in industrial applications where moisture exposure is unavoidable.

Chemical stability assessments reveal h-BN's exceptional resistance to a wide range of industrial chemicals, including acids, bases, and organic solvents. When immersed in 1M sulfuric acid solution for 30 days, h-BN coatings retained over 95% of their original tribological properties, while competing technologies showed significant degradation, with some losing more than 50% of their performance capabilities.

Cost-benefit analysis indicates that despite higher initial application costs (approximately 30-40% higher than conventional lubricants), the extended service life and reduced maintenance requirements of h-BN coatings result in a favorable total cost of ownership, with calculated savings of 25-45% over a five-year operational period in demanding industrial environments.

Sustainability and Cost-Efficiency Factors

The sustainability and cost-efficiency aspects of hexagonal boron nitride (h-BN) coatings represent critical factors in their industrial adoption and long-term viability. When evaluating these coatings for tribological applications in humid and oxidizing environments, their extended service life offers significant sustainability advantages compared to conventional lubricants that require frequent replacement.

The durability of h-BN coatings under challenging environmental conditions translates directly into reduced maintenance frequency and associated downtime costs. Industrial machinery protected by these coatings can operate continuously for extended periods without intervention, particularly valuable in hard-to-access applications such as deep-sea equipment, aerospace components, or nuclear facilities where maintenance operations are exceptionally costly or hazardous.

From a life-cycle assessment perspective, h-BN coatings demonstrate favorable environmental credentials. The reduction in friction leads to measurable energy savings across mechanical systems, with some studies reporting efficiency improvements of 15-30% in certain applications. This energy conservation compounds over equipment lifetime, contributing significantly to reduced carbon footprints in manufacturing and transportation sectors.

The raw material considerations also favor h-BN sustainability profiles. While initial production of high-purity h-BN requires substantial energy input, the atomically thin nature of effective coatings means minimal material consumption per application. Recent advances in precursor chemistry have reduced synthesis temperatures from 900°C to below 400°C for certain deposition methods, dramatically lowering the embodied energy in coating production.

Cost-efficiency analysis reveals that despite higher initial implementation costs compared to traditional lubricants, the total cost of ownership frequently favors h-BN coatings in demanding applications. Market analysis indicates a typical return on investment period of 8-24 months for high-wear industrial applications, with cost advantages accelerating thereafter.

Manufacturing scalability remains a challenge affecting both sustainability and cost metrics. Current vapor deposition techniques for high-quality h-BN coatings face throughput limitations that impact large-scale industrial adoption. However, emerging solution-based deposition methods show promise for reducing both energy requirements and production costs by up to 60%, potentially transforming the economic equation for widespread implementation.

Waste reduction represents another significant sustainability advantage, as h-BN coatings eliminate the need for liquid lubricant disposal and associated environmental contamination risks. This aspect is particularly valuable in environmentally sensitive applications or regions with stringent waste management regulations.

The durability of h-BN coatings under challenging environmental conditions translates directly into reduced maintenance frequency and associated downtime costs. Industrial machinery protected by these coatings can operate continuously for extended periods without intervention, particularly valuable in hard-to-access applications such as deep-sea equipment, aerospace components, or nuclear facilities where maintenance operations are exceptionally costly or hazardous.

From a life-cycle assessment perspective, h-BN coatings demonstrate favorable environmental credentials. The reduction in friction leads to measurable energy savings across mechanical systems, with some studies reporting efficiency improvements of 15-30% in certain applications. This energy conservation compounds over equipment lifetime, contributing significantly to reduced carbon footprints in manufacturing and transportation sectors.

The raw material considerations also favor h-BN sustainability profiles. While initial production of high-purity h-BN requires substantial energy input, the atomically thin nature of effective coatings means minimal material consumption per application. Recent advances in precursor chemistry have reduced synthesis temperatures from 900°C to below 400°C for certain deposition methods, dramatically lowering the embodied energy in coating production.

Cost-efficiency analysis reveals that despite higher initial implementation costs compared to traditional lubricants, the total cost of ownership frequently favors h-BN coatings in demanding applications. Market analysis indicates a typical return on investment period of 8-24 months for high-wear industrial applications, with cost advantages accelerating thereafter.

Manufacturing scalability remains a challenge affecting both sustainability and cost metrics. Current vapor deposition techniques for high-quality h-BN coatings face throughput limitations that impact large-scale industrial adoption. However, emerging solution-based deposition methods show promise for reducing both energy requirements and production costs by up to 60%, potentially transforming the economic equation for widespread implementation.

Waste reduction represents another significant sustainability advantage, as h-BN coatings eliminate the need for liquid lubricant disposal and associated environmental contamination risks. This aspect is particularly valuable in environmentally sensitive applications or regions with stringent waste management regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!