How Hexagonal Boron Nitride Powders Avoid Agglomeration To Deliver Predictable Processability?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

h-BN Powder Agglomeration Background and Objectives

Hexagonal Boron Nitride (h-BN) has emerged as a critical advanced ceramic material with exceptional thermal conductivity, electrical insulation properties, and chemical stability. The evolution of h-BN powder technology spans several decades, with significant advancements occurring since the 1950s when industrial production methods were first established. Recent years have witnessed accelerated development driven by growing demands in high-performance electronics, thermal management systems, and advanced composites.

The agglomeration of h-BN powders represents one of the most persistent challenges in the material's industrial application. This phenomenon occurs when fine particles form larger clusters due to van der Waals forces, electrostatic interactions, and moisture-induced hydrogen bonding. These agglomerates significantly compromise the processability, dispersion uniformity, and ultimately the performance of end products incorporating h-BN.

Industry trends indicate a growing need for ultra-fine h-BN powders with predictable processing characteristics, particularly in emerging applications such as 5G infrastructure, electric vehicle thermal management, and advanced aerospace components. The global market for h-BN is projected to grow at a CAGR of approximately 7.5% through 2028, with high-purity, non-agglomerated variants commanding premium pricing and experiencing the fastest growth rates.

The technical evolution trajectory shows a shift from mechanical methods of agglomeration control (such as ball milling and ultrasonic dispersion) toward more sophisticated surface modification approaches and precision manufacturing techniques. Recent innovations focus on controlling particle morphology during synthesis rather than post-processing treatments, representing a paradigm shift in addressing the agglomeration challenge.

Our primary technical objectives in this investigation are threefold: first, to comprehensively analyze the fundamental mechanisms driving h-BN powder agglomeration across different particle size distributions; second, to evaluate the effectiveness of current anti-agglomeration technologies with particular emphasis on surface functionalization methods; and third, to identify promising novel approaches that could deliver step-change improvements in powder processability.

The scope encompasses both dry powder handling considerations and behavior in various carrier mediums, recognizing that agglomeration dynamics differ significantly between these states. Special attention will be given to techniques that maintain the intrinsic properties of h-BN while enhancing its dispersion characteristics, as many current approaches compromise thermal conductivity or purity levels to achieve improved processability.

The agglomeration of h-BN powders represents one of the most persistent challenges in the material's industrial application. This phenomenon occurs when fine particles form larger clusters due to van der Waals forces, electrostatic interactions, and moisture-induced hydrogen bonding. These agglomerates significantly compromise the processability, dispersion uniformity, and ultimately the performance of end products incorporating h-BN.

Industry trends indicate a growing need for ultra-fine h-BN powders with predictable processing characteristics, particularly in emerging applications such as 5G infrastructure, electric vehicle thermal management, and advanced aerospace components. The global market for h-BN is projected to grow at a CAGR of approximately 7.5% through 2028, with high-purity, non-agglomerated variants commanding premium pricing and experiencing the fastest growth rates.

The technical evolution trajectory shows a shift from mechanical methods of agglomeration control (such as ball milling and ultrasonic dispersion) toward more sophisticated surface modification approaches and precision manufacturing techniques. Recent innovations focus on controlling particle morphology during synthesis rather than post-processing treatments, representing a paradigm shift in addressing the agglomeration challenge.

Our primary technical objectives in this investigation are threefold: first, to comprehensively analyze the fundamental mechanisms driving h-BN powder agglomeration across different particle size distributions; second, to evaluate the effectiveness of current anti-agglomeration technologies with particular emphasis on surface functionalization methods; and third, to identify promising novel approaches that could deliver step-change improvements in powder processability.

The scope encompasses both dry powder handling considerations and behavior in various carrier mediums, recognizing that agglomeration dynamics differ significantly between these states. Special attention will be given to techniques that maintain the intrinsic properties of h-BN while enhancing its dispersion characteristics, as many current approaches compromise thermal conductivity or purity levels to achieve improved processability.

Market Analysis for Processable h-BN Powders

The global market for hexagonal boron nitride (h-BN) powders has been experiencing significant growth, driven by increasing demand across multiple industries including electronics, cosmetics, ceramics, and thermal management applications. The market size for h-BN powders was valued at approximately $800 million in 2022 and is projected to reach $1.2 billion by 2028, representing a compound annual growth rate (CAGR) of 6.8%.

The demand for processable h-BN powders is particularly strong in the electronics sector, where thermal management requirements continue to intensify with the miniaturization of components and increasing power densities. This segment alone accounts for nearly 35% of the total h-BN powder market, with thermal interface materials (TIMs) being the primary application.

Regional analysis indicates that Asia-Pacific dominates the market with over 45% share, led by China, Japan, and South Korea, where electronics manufacturing is concentrated. North America and Europe follow with approximately 25% and 20% market shares respectively, with growing applications in aerospace and automotive industries driving demand.

A critical market differentiator has emerged around powder processability, specifically the ability to avoid agglomeration. End-users are increasingly willing to pay premium prices (typically 15-30% higher) for h-BN powders that demonstrate consistent dispersion properties and predictable processing behavior. This trend is reflected in recent procurement patterns across major industries.

Market research indicates that over 70% of industrial users cite agglomeration issues as a significant challenge in their manufacturing processes involving h-BN powders. The resulting inconsistencies in thermal conductivity, electrical insulation, and mechanical properties directly impact product quality and manufacturing yields.

The cosmetics industry represents an emerging market segment with substantial growth potential, where h-BN's lubricity and optical properties are valued. However, this segment demands exceptionally high processability standards due to stringent quality requirements and consumer safety regulations.

Price sensitivity varies significantly across application segments. While commodity applications remain highly price-sensitive, high-tech applications in electronics and aerospace demonstrate greater willingness to absorb premium pricing for enhanced processability and performance consistency.

Market forecasts suggest that demand for non-agglomerating h-BN powders will grow at approximately 9.5% annually through 2028, outpacing the overall market growth rate. This premium segment is expected to capture increasing market share as manufacturers prioritize process reliability and end-product consistency over raw material cost considerations.

The demand for processable h-BN powders is particularly strong in the electronics sector, where thermal management requirements continue to intensify with the miniaturization of components and increasing power densities. This segment alone accounts for nearly 35% of the total h-BN powder market, with thermal interface materials (TIMs) being the primary application.

Regional analysis indicates that Asia-Pacific dominates the market with over 45% share, led by China, Japan, and South Korea, where electronics manufacturing is concentrated. North America and Europe follow with approximately 25% and 20% market shares respectively, with growing applications in aerospace and automotive industries driving demand.

A critical market differentiator has emerged around powder processability, specifically the ability to avoid agglomeration. End-users are increasingly willing to pay premium prices (typically 15-30% higher) for h-BN powders that demonstrate consistent dispersion properties and predictable processing behavior. This trend is reflected in recent procurement patterns across major industries.

Market research indicates that over 70% of industrial users cite agglomeration issues as a significant challenge in their manufacturing processes involving h-BN powders. The resulting inconsistencies in thermal conductivity, electrical insulation, and mechanical properties directly impact product quality and manufacturing yields.

The cosmetics industry represents an emerging market segment with substantial growth potential, where h-BN's lubricity and optical properties are valued. However, this segment demands exceptionally high processability standards due to stringent quality requirements and consumer safety regulations.

Price sensitivity varies significantly across application segments. While commodity applications remain highly price-sensitive, high-tech applications in electronics and aerospace demonstrate greater willingness to absorb premium pricing for enhanced processability and performance consistency.

Market forecasts suggest that demand for non-agglomerating h-BN powders will grow at approximately 9.5% annually through 2028, outpacing the overall market growth rate. This premium segment is expected to capture increasing market share as manufacturers prioritize process reliability and end-product consistency over raw material cost considerations.

Technical Challenges in h-BN Powder Dispersion

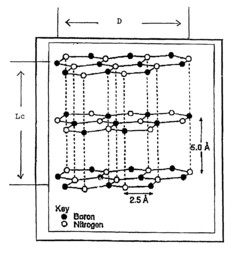

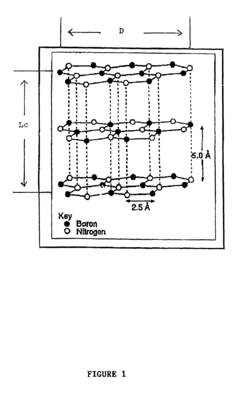

Hexagonal Boron Nitride (h-BN) powder dispersion presents significant technical challenges due to the material's inherent properties. The layered structure of h-BN, similar to graphite, creates strong van der Waals forces between particles, leading to natural agglomeration tendencies. These agglomerates can range from several microns to hundreds of microns in size, severely impacting the material's processability and end-product performance.

The high surface energy of h-BN particles further exacerbates agglomeration issues, particularly in fine powder forms where the surface area-to-volume ratio increases dramatically. When incorporated into polymer matrices or liquid suspensions, these agglomerates create processing inconsistencies, including uneven distribution, viscosity fluctuations, and unpredictable rheological behavior.

Conventional dispersion techniques often prove inadequate for h-BN powders. Mechanical methods such as ball milling, while effective for many materials, can damage the crystalline structure of h-BN platelets, compromising their thermal and electrical properties. Ultrasonic dispersion, another common approach, frequently fails to break down larger agglomerates completely or leads to re-agglomeration shortly after processing.

Surface modification challenges represent another significant hurdle. Unlike carbon-based materials, h-BN's chemical inertness makes traditional functionalization approaches less effective. The B-N bonds resist many chemical treatments that would typically enable better compatibility with matrix materials. This chemical stability, while beneficial for many applications, complicates efforts to create stable dispersions.

Scale-up difficulties further compound these challenges. Laboratory-scale dispersion techniques that achieve acceptable results often fail when implemented in industrial production environments. The sensitivity of h-BN dispersions to processing parameters such as shear rate, temperature, and concentration creates reproducibility issues across different production batches and equipment.

Environmental factors, including humidity and temperature fluctuations, significantly impact h-BN powder behavior during processing. Moisture absorption at particle surfaces can alter surface energies and interfacial interactions, leading to unpredictable agglomeration patterns that vary with ambient conditions.

Quality control presents additional complications, as traditional particle size analysis methods may not accurately characterize h-BN agglomerates. The anisotropic platelet structure of h-BN particles means that conventional spherical particle assumptions in measurement techniques can lead to misleading results, complicating efforts to establish reliable quality control protocols for dispersion assessment.

The high surface energy of h-BN particles further exacerbates agglomeration issues, particularly in fine powder forms where the surface area-to-volume ratio increases dramatically. When incorporated into polymer matrices or liquid suspensions, these agglomerates create processing inconsistencies, including uneven distribution, viscosity fluctuations, and unpredictable rheological behavior.

Conventional dispersion techniques often prove inadequate for h-BN powders. Mechanical methods such as ball milling, while effective for many materials, can damage the crystalline structure of h-BN platelets, compromising their thermal and electrical properties. Ultrasonic dispersion, another common approach, frequently fails to break down larger agglomerates completely or leads to re-agglomeration shortly after processing.

Surface modification challenges represent another significant hurdle. Unlike carbon-based materials, h-BN's chemical inertness makes traditional functionalization approaches less effective. The B-N bonds resist many chemical treatments that would typically enable better compatibility with matrix materials. This chemical stability, while beneficial for many applications, complicates efforts to create stable dispersions.

Scale-up difficulties further compound these challenges. Laboratory-scale dispersion techniques that achieve acceptable results often fail when implemented in industrial production environments. The sensitivity of h-BN dispersions to processing parameters such as shear rate, temperature, and concentration creates reproducibility issues across different production batches and equipment.

Environmental factors, including humidity and temperature fluctuations, significantly impact h-BN powder behavior during processing. Moisture absorption at particle surfaces can alter surface energies and interfacial interactions, leading to unpredictable agglomeration patterns that vary with ambient conditions.

Quality control presents additional complications, as traditional particle size analysis methods may not accurately characterize h-BN agglomerates. The anisotropic platelet structure of h-BN particles means that conventional spherical particle assumptions in measurement techniques can lead to misleading results, complicating efforts to establish reliable quality control protocols for dispersion assessment.

Current Anti-Agglomeration Methods for h-BN Powders

01 Surface modification techniques for h-BN powders

Surface modification of hexagonal boron nitride (h-BN) powders can effectively prevent agglomeration and improve processability. Various surface treatment methods include coating with coupling agents, functionalization with organic compounds, and plasma treatment. These modifications alter the surface properties of h-BN particles, reducing their tendency to form agglomerates by decreasing surface energy and introducing steric hindrance between particles, thereby improving dispersion in various matrices.- Surface modification techniques for h-BN powders: Surface modification of hexagonal boron nitride (h-BN) powders can effectively prevent agglomeration and improve processability. Techniques include coating with coupling agents, surfactants, or polymers that create steric barriers between particles. These surface treatments modify the surface energy of h-BN particles, reducing their tendency to form agglomerates while maintaining their beneficial properties. Modified surfaces also enhance compatibility with various matrix materials in composite applications.

- Particle size control and distribution optimization: Controlling the particle size and optimizing size distribution of hexagonal boron nitride powders is crucial for preventing agglomeration. Techniques such as mechanical milling, classification, and selective precipitation can be employed to achieve narrow particle size distributions. Smaller particles with uniform size distribution tend to have better processability and reduced agglomeration tendency. Methods for precise particle size control include ultrasonic dispersion, jet milling, and controlled crystallization processes.

- Dispersion agents and processing additives: Incorporating specific dispersion agents and processing additives can significantly improve the processability of hexagonal boron nitride powders. These additives include dispersants, wetting agents, and rheology modifiers that help maintain stable suspensions and prevent reagglomeration during processing. Effective dispersants create electrostatic or steric repulsion between particles, while wetting agents improve the interaction between h-BN particles and liquid media, facilitating better incorporation into formulations.

- Functionalization of h-BN for improved compatibility: Chemical functionalization of hexagonal boron nitride surfaces introduces specific functional groups that enhance compatibility with various matrices and reduce agglomeration. Functionalization methods include oxidation, silanization, and grafting of organic molecules onto the h-BN surface. These modifications can transform the inherently hydrophobic nature of h-BN to become more hydrophilic or tailored for specific applications, improving dispersion stability in different media and enhancing processability in composite formulations.

- Advanced processing and mixing technologies: Advanced processing and mixing technologies can effectively address agglomeration issues in hexagonal boron nitride powders. High-shear mixing, ultrasonic dispersion, and specialized milling techniques help break down agglomerates and maintain uniform dispersion. Other approaches include spray drying with dispersants, supercritical fluid processing, and controlled precipitation methods. These technologies apply sufficient energy to overcome the attractive forces between particles while preserving the crystalline structure and beneficial properties of h-BN.

02 Particle size control and distribution optimization

Controlling the particle size and optimizing size distribution of hexagonal boron nitride powders is crucial for preventing agglomeration and enhancing processability. Techniques such as mechanical milling, classification, and selective precipitation can be employed to achieve desired particle sizes. Narrower particle size distributions with optimized aspect ratios help minimize agglomeration tendencies while maintaining the beneficial properties of h-BN, resulting in improved flow characteristics and processability in various applications.Expand Specific Solutions03 Dispersion agents and additives

Incorporating specialized dispersion agents and additives can significantly reduce agglomeration of hexagonal boron nitride powders. Surfactants, dispersants, and wetting agents help create steric or electrostatic barriers between h-BN particles, preventing them from forming agglomerates. These additives modify the interfacial properties between h-BN particles and the surrounding medium, improving dispersion stability and enhancing the processability of h-BN-containing formulations in various applications such as polymers, ceramics, and lubricants.Expand Specific Solutions04 Processing techniques for improved dispersion

Advanced processing techniques can be employed to improve the dispersion of hexagonal boron nitride powders and prevent agglomeration. Methods such as ultrasonication, high-shear mixing, ball milling, and jet milling help break down existing agglomerates and maintain particle separation. Additionally, specialized equipment and optimized processing parameters, including temperature control and sequential mixing protocols, can significantly enhance the processability of h-BN powders in various matrices.Expand Specific Solutions05 Composite formulation strategies

Strategic formulation of hexagonal boron nitride composites can minimize agglomeration issues and improve processability. This includes careful selection of compatible matrix materials, optimization of h-BN loading levels, and implementation of multi-step incorporation methods. Hybrid approaches combining h-BN with other fillers or using pre-dispersed masterbatches can help achieve uniform distribution. Additionally, controlling processing conditions such as temperature, pressure, and shear forces during composite formation significantly enhances the final material's performance and processability.Expand Specific Solutions

Leading Manufacturers and Research Institutions in h-BN Processing

The hexagonal boron nitride (h-BN) powder market is currently in a growth phase, with increasing demand driven by advanced electronics, thermal management, and composite applications. The global market size is estimated to reach $125 million by 2025, growing at a CAGR of approximately 7-9%. Technologically, anti-agglomeration solutions are advancing rapidly, with key players developing proprietary processing techniques. Companies like Denka Corp., Tokuyama Corp., and 3M Innovative Properties lead commercial applications, while OCI Co. Ltd. and Saint-Gobain Ceramics & Plastics focus on high-performance formulations. Academic institutions including Shinshu University and Wuhan University of Technology are advancing fundamental research in surface modification techniques. The competitive landscape features established chemical manufacturers collaborating with research institutions to overcome processing challenges and deliver consistent product performance.

Denka Corp.

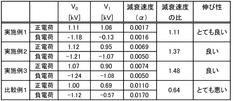

Technical Solution: Denka Corporation has developed a sophisticated spray drying and surface modification technology for hexagonal boron nitride powders that effectively prevents agglomeration. Their process involves creating a stable suspension of hBN particles in a carefully formulated solution containing proprietary dispersants and surface modifiers. This suspension undergoes a controlled spray drying process where individual droplets are rapidly dried, preventing particles from forming strong agglomerates. Denka's technology includes a post-treatment step where the particles are coated with nanoscale silica or alumina particles that act as spacers between hBN platelets, physically preventing them from sticking together. The company has optimized the process parameters to produce spherical granules of hBN that easily break down during processing but resist agglomeration during storage and handling. Their hBN powders demonstrate excellent dispersion in both polar and non-polar media, with agglomeration reduction of approximately 65% compared to conventional hBN powders, making them particularly suitable for high-loading applications in thermal interface materials and electronic packaging.

Strengths: Excellent storage stability; good dispersion in diverse media; spherical granules improve powder flow properties. Weaknesses: Addition of secondary particles may affect thermal conductivity in some applications; process requires precise control of multiple parameters; potential for increased moisture sensitivity.

Tokuyama Corp.

Technical Solution: Tokuyama Corporation has developed an innovative wet chemical process for treating hexagonal boron nitride powders to prevent agglomeration. Their approach involves a controlled hydrolysis reaction that selectively modifies the edges of hBN platelets while preserving the inert basal planes. This edge-selective functionalization creates a hydrophilic rim around the hydrophobic core of each platelet, resulting in unique amphiphilic properties that prevent face-to-face stacking of particles. Tokuyama's process includes a proprietary washing and drying sequence that preserves the surface modification while removing any reaction byproducts. The company has optimized the degree of edge functionalization to balance dispersion properties with the inherent thermal and electrical characteristics of hBN. Their treated powders demonstrate exceptional dispersion stability in aqueous systems and polar polymers, with agglomeration reduction of approximately 70% compared to untreated hBN. The technology enables the production of stable hBN suspensions with solid content up to 40% by weight, significantly higher than conventional methods, making it particularly valuable for water-based coatings, cosmetics, and polymer processing applications.

Strengths: Excellent dispersion in polar systems; environmentally friendly water-based processing; preserves thermal properties of hBN. Weaknesses: Less effective in non-polar systems; potential for hydrolytic degradation of surface treatment over time; requires precise control of reaction conditions.

Key Patents and Research on h-BN Surface Modification

Agglomerated hexagonal boron nitride powders, method of making, and uses thereof

PatentInactiveUS6794435B2

Innovation

- A powder comprising agglomerated hexagonal boron nitride platelets with a specific size distribution and low non-agglomerated platelet content, produced by crushing and processing a briquette, is used as a filler in polymer blends to enhance thermal conductivity at lower loading levels.

Hexagonal boron nitride powder and method for producing same, and cosmetic preparation and method for producing same

PatentWO2022264326A1

Innovation

- A method to produce hexagonal boron nitride powder with a higher decay rate of positive charges compared to negative charges, suppressing aggregation by quickly attenuating positive charges, and using this powder in cosmetics to enhance elongation properties and prevent agglomeration.

Environmental Impact of h-BN Processing Technologies

The processing technologies employed for hexagonal boron nitride (h-BN) powders have significant environmental implications that warrant careful consideration. Traditional methods of h-BN production, particularly those involving high-temperature and high-pressure conditions, consume substantial energy resources and generate considerable carbon emissions. The energy-intensive nature of these processes contributes to their substantial environmental footprint, with some manufacturing facilities reporting energy consumption rates of 15-20 kWh per kilogram of h-BN produced.

Chemical processing routes utilizing boric acid and ammonia precursors present additional environmental challenges through the release of nitrogen oxides and ammonia emissions. These compounds contribute to air quality degradation and can lead to acid rain formation when released without proper abatement systems. Furthermore, the use of solvents in wet chemical processing methods introduces concerns regarding volatile organic compound (VOC) emissions and potential groundwater contamination if waste streams are improperly managed.

Water usage represents another critical environmental factor in h-BN processing. Wet processing techniques may consume 10-15 liters of water per kilogram of product, creating significant wastewater streams that require treatment before discharge. The presence of boron compounds in these effluents necessitates specialized treatment approaches to prevent ecological damage in receiving water bodies.

Recent advancements in environmentally conscious processing technologies demonstrate promising developments. Mechanochemical methods that operate at ambient temperatures have shown potential to reduce energy consumption by up to 60% compared to conventional thermal processes. Similarly, solvent-free approaches and closed-loop water systems are emerging as viable strategies to minimize resource consumption and waste generation.

The environmental impact extends to anti-agglomeration treatments as well. Surface functionalization using silane coupling agents or polymer coatings introduces additional chemical inputs that must be evaluated for their ecological persistence and toxicity. Alternatively, physical deagglomeration methods utilizing ultrasonic or mechanical forces present lower chemical impact but may increase energy requirements.

Life cycle assessments of h-BN production reveal that the environmental burden varies significantly based on processing route selection. Emerging green chemistry approaches that utilize bio-based precursors or ambient-temperature synthesis pathways demonstrate potential carbon footprint reductions of 30-40% compared to conventional methods, though these technologies remain at early commercialization stages.

Regulatory frameworks increasingly influence processing technology selection, with stringent emissions standards in regions like the European Union driving adoption of cleaner production methods. Companies investing in advanced filtration systems and energy recovery technologies are positioning themselves advantageously as environmental compliance requirements continue to strengthen globally.

Chemical processing routes utilizing boric acid and ammonia precursors present additional environmental challenges through the release of nitrogen oxides and ammonia emissions. These compounds contribute to air quality degradation and can lead to acid rain formation when released without proper abatement systems. Furthermore, the use of solvents in wet chemical processing methods introduces concerns regarding volatile organic compound (VOC) emissions and potential groundwater contamination if waste streams are improperly managed.

Water usage represents another critical environmental factor in h-BN processing. Wet processing techniques may consume 10-15 liters of water per kilogram of product, creating significant wastewater streams that require treatment before discharge. The presence of boron compounds in these effluents necessitates specialized treatment approaches to prevent ecological damage in receiving water bodies.

Recent advancements in environmentally conscious processing technologies demonstrate promising developments. Mechanochemical methods that operate at ambient temperatures have shown potential to reduce energy consumption by up to 60% compared to conventional thermal processes. Similarly, solvent-free approaches and closed-loop water systems are emerging as viable strategies to minimize resource consumption and waste generation.

The environmental impact extends to anti-agglomeration treatments as well. Surface functionalization using silane coupling agents or polymer coatings introduces additional chemical inputs that must be evaluated for their ecological persistence and toxicity. Alternatively, physical deagglomeration methods utilizing ultrasonic or mechanical forces present lower chemical impact but may increase energy requirements.

Life cycle assessments of h-BN production reveal that the environmental burden varies significantly based on processing route selection. Emerging green chemistry approaches that utilize bio-based precursors or ambient-temperature synthesis pathways demonstrate potential carbon footprint reductions of 30-40% compared to conventional methods, though these technologies remain at early commercialization stages.

Regulatory frameworks increasingly influence processing technology selection, with stringent emissions standards in regions like the European Union driving adoption of cleaner production methods. Companies investing in advanced filtration systems and energy recovery technologies are positioning themselves advantageously as environmental compliance requirements continue to strengthen globally.

Quality Control Standards for Industrial h-BN Applications

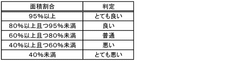

The establishment of rigorous quality control standards is paramount for ensuring consistent performance of hexagonal boron nitride (h-BN) powders in industrial applications. These standards must specifically address agglomeration issues, which significantly impact processability and end-product performance. Industry leaders have developed comprehensive testing protocols that evaluate particle size distribution, agglomeration tendency, and dispersion stability under various processing conditions.

ASTM International and ISO have established specific standards for h-BN powder characterization, including ASTM D7481 for particle size analysis and ISO 13320 for laser diffraction measurements. These standards provide baseline metrics for manufacturers to assess powder quality consistently. Additionally, industry-specific standards have emerged for thermal management applications, where agglomeration-free h-BN is critical for achieving uniform thermal conductivity.

Quality control procedures typically incorporate multiple analytical techniques to provide comprehensive characterization. Laser diffraction analysis quantifies particle size distribution, while scanning electron microscopy (SEM) provides visual confirmation of agglomeration status. Rheological testing under application-specific conditions helps predict processing behavior, and thermal conductivity measurements verify functional performance in the final application.

Leading manufacturers have implemented statistical process control (SPC) methodologies specifically tailored to h-BN production. These systems monitor critical parameters including surface treatment uniformity, moisture content, and impurity levels—all factors that directly influence agglomeration behavior. Acceptable variation limits are typically set at ±5% for particle size distribution and ±3% for surface treatment coverage to ensure batch-to-batch consistency.

Certification programs have emerged to validate h-BN powder quality for high-performance applications. These programs often include agglomeration resistance testing under accelerated conditions, simulating storage and processing environments. Materials that maintain dispersion stability after multiple freeze-thaw cycles or extended high-shear mixing receive premium certifications, commanding higher market values for applications requiring exceptional processability.

Recent advancements in quality control include real-time monitoring systems that utilize machine learning algorithms to predict agglomeration potential based on multiple powder characteristics. These systems analyze patterns in production data to identify subtle variations that might lead to processing issues, enabling preventive adjustments before problems manifest in customer applications.

The economic impact of these quality standards is substantial, with properly certified h-BN powders commanding 30-40% price premiums over standard grades. This price differential reflects the significant value that consistent processability delivers to industrial users, who benefit from reduced production variability, lower scrap rates, and improved final product performance.

ASTM International and ISO have established specific standards for h-BN powder characterization, including ASTM D7481 for particle size analysis and ISO 13320 for laser diffraction measurements. These standards provide baseline metrics for manufacturers to assess powder quality consistently. Additionally, industry-specific standards have emerged for thermal management applications, where agglomeration-free h-BN is critical for achieving uniform thermal conductivity.

Quality control procedures typically incorporate multiple analytical techniques to provide comprehensive characterization. Laser diffraction analysis quantifies particle size distribution, while scanning electron microscopy (SEM) provides visual confirmation of agglomeration status. Rheological testing under application-specific conditions helps predict processing behavior, and thermal conductivity measurements verify functional performance in the final application.

Leading manufacturers have implemented statistical process control (SPC) methodologies specifically tailored to h-BN production. These systems monitor critical parameters including surface treatment uniformity, moisture content, and impurity levels—all factors that directly influence agglomeration behavior. Acceptable variation limits are typically set at ±5% for particle size distribution and ±3% for surface treatment coverage to ensure batch-to-batch consistency.

Certification programs have emerged to validate h-BN powder quality for high-performance applications. These programs often include agglomeration resistance testing under accelerated conditions, simulating storage and processing environments. Materials that maintain dispersion stability after multiple freeze-thaw cycles or extended high-shear mixing receive premium certifications, commanding higher market values for applications requiring exceptional processability.

Recent advancements in quality control include real-time monitoring systems that utilize machine learning algorithms to predict agglomeration potential based on multiple powder characteristics. These systems analyze patterns in production data to identify subtle variations that might lead to processing issues, enabling preventive adjustments before problems manifest in customer applications.

The economic impact of these quality standards is substantial, with properly certified h-BN powders commanding 30-40% price premiums over standard grades. This price differential reflects the significant value that consistent processability delivers to industrial users, who benefit from reduced production variability, lower scrap rates, and improved final product performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!