Hexagonal Boron Nitride Polymer Blends: Moisture Uptake, Electrical Insulation And Aging Behavior

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

hBN-Polymer Blend Technology Background and Objectives

Hexagonal Boron Nitride (hBN) has emerged as a revolutionary two-dimensional material with exceptional thermal conductivity, electrical insulation properties, and mechanical strength. The integration of hBN into polymer matrices represents a significant advancement in materials science that has evolved over the past three decades, with accelerated development in the last decade due to increasing demands for high-performance composite materials.

The evolution of hBN-polymer blends can be traced back to the early 1990s when researchers began exploring ceramic fillers for polymer enhancement. However, the true potential of hBN as a nanofiller was only recognized following the graphene revolution in the mid-2000s, which sparked interest in other 2D materials. Since 2010, research publications on hBN-polymer composites have grown exponentially, reflecting the scientific community's recognition of their unique capabilities.

The primary technological objective in developing hBN-polymer blends is to create composite materials that combine the superior electrical insulation properties of hBN with the processability and flexibility of polymers, while addressing critical challenges related to moisture uptake and long-term aging behavior. These composites aim to fulfill the growing demand for high-performance dielectric materials in advanced electronics, particularly in environments where thermal management and moisture resistance are paramount.

Current technological trends indicate a shift toward exfoliated or few-layer hBN incorporation into polymers to maximize interfacial interactions and enhance property improvements at lower filler loadings. Additionally, surface functionalization of hBN has gained significant attention as a method to improve dispersion and polymer-filler compatibility, which directly impacts moisture resistance and aging characteristics.

The global push toward miniaturization in electronics, coupled with the increasing adoption of electric vehicles and renewable energy systems, has created an urgent need for advanced insulation materials that can withstand harsh operating conditions. hBN-polymer blends are positioned to address this need, with research objectives focused on optimizing moisture barrier properties, enhancing dielectric strength retention during aging, and improving thermal conductivity without compromising electrical insulation.

Looking forward, the technological roadmap for hBN-polymer blends includes developing scalable production methods, establishing standardized testing protocols for moisture uptake and aging behavior, and creating application-specific formulations that can meet the diverse requirements of industries ranging from aerospace to consumer electronics. The ultimate goal is to transition these advanced composites from laboratory curiosities to commercially viable materials that can solve real-world engineering challenges.

The evolution of hBN-polymer blends can be traced back to the early 1990s when researchers began exploring ceramic fillers for polymer enhancement. However, the true potential of hBN as a nanofiller was only recognized following the graphene revolution in the mid-2000s, which sparked interest in other 2D materials. Since 2010, research publications on hBN-polymer composites have grown exponentially, reflecting the scientific community's recognition of their unique capabilities.

The primary technological objective in developing hBN-polymer blends is to create composite materials that combine the superior electrical insulation properties of hBN with the processability and flexibility of polymers, while addressing critical challenges related to moisture uptake and long-term aging behavior. These composites aim to fulfill the growing demand for high-performance dielectric materials in advanced electronics, particularly in environments where thermal management and moisture resistance are paramount.

Current technological trends indicate a shift toward exfoliated or few-layer hBN incorporation into polymers to maximize interfacial interactions and enhance property improvements at lower filler loadings. Additionally, surface functionalization of hBN has gained significant attention as a method to improve dispersion and polymer-filler compatibility, which directly impacts moisture resistance and aging characteristics.

The global push toward miniaturization in electronics, coupled with the increasing adoption of electric vehicles and renewable energy systems, has created an urgent need for advanced insulation materials that can withstand harsh operating conditions. hBN-polymer blends are positioned to address this need, with research objectives focused on optimizing moisture barrier properties, enhancing dielectric strength retention during aging, and improving thermal conductivity without compromising electrical insulation.

Looking forward, the technological roadmap for hBN-polymer blends includes developing scalable production methods, establishing standardized testing protocols for moisture uptake and aging behavior, and creating application-specific formulations that can meet the diverse requirements of industries ranging from aerospace to consumer electronics. The ultimate goal is to transition these advanced composites from laboratory curiosities to commercially viable materials that can solve real-world engineering challenges.

Market Applications and Demand Analysis for hBN-Polymer Composites

The global market for hexagonal boron nitride (hBN) polymer composites has been experiencing significant growth, driven primarily by the increasing demand for high-performance materials in electronics, aerospace, and automotive industries. The unique combination of electrical insulation properties, thermal conductivity, and moisture resistance makes hBN-polymer blends particularly valuable in applications requiring reliable performance under challenging environmental conditions.

In the electronics sector, the miniaturization trend and higher power densities in devices have created substantial demand for materials that can provide superior thermal management while maintaining electrical insulation. Market research indicates that thermal interface materials incorporating hBN are growing at a compound annual growth rate exceeding 8%, with particular strength in consumer electronics, telecommunications equipment, and power electronics applications.

The automotive industry represents another significant market for hBN-polymer composites, particularly with the rapid expansion of electric vehicles (EVs). These materials are increasingly utilized in battery thermal management systems, power electronics housings, and high-voltage insulation components. As global EV production continues to accelerate, the demand for moisture-resistant, electrically insulating materials with excellent aging characteristics is projected to grow substantially.

Aerospace and defense applications constitute a premium segment for hBN-polymer composites, where reliability under extreme conditions is paramount. The materials' resistance to moisture uptake and stable electrical properties during aging make them ideal for critical components in aircraft, satellites, and military equipment. Though smaller in volume than consumer electronics, this sector commands higher margins due to stringent performance requirements.

Industrial equipment manufacturers are increasingly adopting hBN-polymer composites for applications in harsh environments where traditional polymers would degrade rapidly. The improved aging behavior and moisture resistance extend component lifespans, reducing maintenance costs and downtime in industrial systems.

Regional market analysis reveals that Asia-Pacific currently dominates consumption, accounting for approximately 45% of global demand, driven by the concentration of electronics manufacturing. North America and Europe follow with strong demand from aerospace, defense, and premium automotive applications.

Customer requirements analysis shows growing interest in customized formulations with precisely engineered moisture uptake characteristics for specific operating environments. End-users are increasingly willing to pay premium prices for materials that can demonstrate superior long-term stability and predictable aging behavior, particularly in applications where failure would result in significant downstream costs.

In the electronics sector, the miniaturization trend and higher power densities in devices have created substantial demand for materials that can provide superior thermal management while maintaining electrical insulation. Market research indicates that thermal interface materials incorporating hBN are growing at a compound annual growth rate exceeding 8%, with particular strength in consumer electronics, telecommunications equipment, and power electronics applications.

The automotive industry represents another significant market for hBN-polymer composites, particularly with the rapid expansion of electric vehicles (EVs). These materials are increasingly utilized in battery thermal management systems, power electronics housings, and high-voltage insulation components. As global EV production continues to accelerate, the demand for moisture-resistant, electrically insulating materials with excellent aging characteristics is projected to grow substantially.

Aerospace and defense applications constitute a premium segment for hBN-polymer composites, where reliability under extreme conditions is paramount. The materials' resistance to moisture uptake and stable electrical properties during aging make them ideal for critical components in aircraft, satellites, and military equipment. Though smaller in volume than consumer electronics, this sector commands higher margins due to stringent performance requirements.

Industrial equipment manufacturers are increasingly adopting hBN-polymer composites for applications in harsh environments where traditional polymers would degrade rapidly. The improved aging behavior and moisture resistance extend component lifespans, reducing maintenance costs and downtime in industrial systems.

Regional market analysis reveals that Asia-Pacific currently dominates consumption, accounting for approximately 45% of global demand, driven by the concentration of electronics manufacturing. North America and Europe follow with strong demand from aerospace, defense, and premium automotive applications.

Customer requirements analysis shows growing interest in customized formulations with precisely engineered moisture uptake characteristics for specific operating environments. End-users are increasingly willing to pay premium prices for materials that can demonstrate superior long-term stability and predictable aging behavior, particularly in applications where failure would result in significant downstream costs.

Current Challenges in Moisture Resistance and Electrical Insulation

Despite significant advancements in hexagonal boron nitride (h-BN) polymer blends, several critical challenges persist in achieving optimal moisture resistance and electrical insulation properties. The hygroscopic nature of many polymer matrices creates a fundamental contradiction: while h-BN particles themselves are highly hydrophobic, the interfaces between h-BN and polymer matrices often become vulnerable points for moisture ingress. This interface challenge is particularly pronounced in applications exposed to high humidity environments or temperature cycling.

Current h-BN polymer composites exhibit inconsistent moisture uptake behavior across different polymer systems. Polyimide-based composites, while offering excellent thermal stability, still demonstrate moisture absorption rates of 1-3% by weight under standard testing conditions (85% RH, 85°C), which significantly compromises their electrical insulation properties over time. Epoxy-based systems fare somewhat better but remain susceptible to interfacial degradation.

The electrical insulation performance of these materials faces degradation through multiple mechanisms. Moisture absorption creates conductive pathways through the polymer matrix, reducing volume resistivity by up to two orders of magnitude in severe cases. Additionally, the presence of moisture accelerates ion migration processes, particularly in electric field conditions, leading to progressive deterioration of dielectric strength. Current materials struggle to maintain consistent dielectric properties above 10^14 Ω·cm after prolonged moisture exposure.

Surface functionalization approaches to improve h-BN-polymer interfaces have shown promise but introduce their own complications. Silane coupling agents improve initial moisture resistance but may hydrolyze under prolonged exposure. Fluorination treatments enhance hydrophobicity but can negatively impact the mechanical properties of the composite system. The trade-off between moisture resistance and other critical properties remains unresolved.

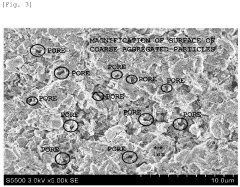

Temperature cycling exacerbates these challenges through differential expansion coefficients between h-BN particles and polymer matrices. Microcracks formed during thermal cycling create new pathways for moisture ingress, accelerating degradation. Current materials typically show a 30-40% reduction in breakdown voltage after 1000 hours of temperature cycling between -40°C and 150°C under high humidity conditions.

The aging behavior of these composites presents perhaps the most significant challenge. Accelerated aging tests reveal that electrical properties degrade non-linearly, with rapid initial deterioration followed by slower progressive decline. This makes lifetime prediction models unreliable and complicates qualification testing for long-life applications such as high-voltage insulation systems and aerospace components.

Current h-BN polymer composites exhibit inconsistent moisture uptake behavior across different polymer systems. Polyimide-based composites, while offering excellent thermal stability, still demonstrate moisture absorption rates of 1-3% by weight under standard testing conditions (85% RH, 85°C), which significantly compromises their electrical insulation properties over time. Epoxy-based systems fare somewhat better but remain susceptible to interfacial degradation.

The electrical insulation performance of these materials faces degradation through multiple mechanisms. Moisture absorption creates conductive pathways through the polymer matrix, reducing volume resistivity by up to two orders of magnitude in severe cases. Additionally, the presence of moisture accelerates ion migration processes, particularly in electric field conditions, leading to progressive deterioration of dielectric strength. Current materials struggle to maintain consistent dielectric properties above 10^14 Ω·cm after prolonged moisture exposure.

Surface functionalization approaches to improve h-BN-polymer interfaces have shown promise but introduce their own complications. Silane coupling agents improve initial moisture resistance but may hydrolyze under prolonged exposure. Fluorination treatments enhance hydrophobicity but can negatively impact the mechanical properties of the composite system. The trade-off between moisture resistance and other critical properties remains unresolved.

Temperature cycling exacerbates these challenges through differential expansion coefficients between h-BN particles and polymer matrices. Microcracks formed during thermal cycling create new pathways for moisture ingress, accelerating degradation. Current materials typically show a 30-40% reduction in breakdown voltage after 1000 hours of temperature cycling between -40°C and 150°C under high humidity conditions.

The aging behavior of these composites presents perhaps the most significant challenge. Accelerated aging tests reveal that electrical properties degrade non-linearly, with rapid initial deterioration followed by slower progressive decline. This makes lifetime prediction models unreliable and complicates qualification testing for long-life applications such as high-voltage insulation systems and aerospace components.

Current Solutions for Enhancing Moisture and Electrical Properties

01 Hexagonal Boron Nitride as moisture barrier in polymer composites

Hexagonal Boron Nitride (h-BN) can be incorporated into polymer blends to significantly reduce moisture uptake. The platelet structure of h-BN creates a tortuous path for water molecules, effectively blocking moisture penetration. This property is particularly valuable in applications where moisture resistance is critical for maintaining the structural integrity and performance of the composite material over time. The hydrophobic nature of h-BN further enhances the moisture barrier properties of the polymer blend.- Hexagonal Boron Nitride as Moisture Barrier in Polymer Composites: Hexagonal boron nitride (h-BN) can be incorporated into polymer blends to enhance moisture resistance properties. The layered structure of h-BN creates a tortuous path for water molecules, significantly reducing moisture uptake in the composite materials. This property is particularly valuable for applications requiring long-term stability in humid environments. The addition of h-BN particles at optimal loading levels can decrease water absorption rates and improve the dimensional stability of polymer composites under varying humidity conditions.

- Enhanced Electrical Insulation Properties of h-BN Polymer Blends: Hexagonal boron nitride significantly improves the electrical insulation properties of polymer composites while maintaining thermal conductivity. The unique combination of high electrical resistivity and good thermal conductivity makes h-BN-polymer blends ideal for electronic packaging, insulating components, and high-voltage applications. These composites exhibit superior dielectric strength, low dielectric loss, and excellent breakdown voltage characteristics compared to unfilled polymers. The electrical insulation properties can be further optimized by controlling the h-BN particle size, distribution, and surface treatment.

- Aging Behavior and Long-term Stability of h-BN Polymer Composites: Hexagonal boron nitride enhances the aging resistance of polymer blends by providing protection against thermal, UV, and oxidative degradation. The incorporation of h-BN particles helps maintain mechanical and electrical properties over extended periods, even under harsh environmental conditions. Studies show that h-BN-reinforced polymers exhibit reduced degradation rates, minimal property changes during accelerated aging tests, and improved resistance to thermal cycling. This enhanced stability makes these composites suitable for applications requiring long service life in demanding environments.

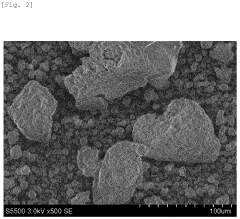

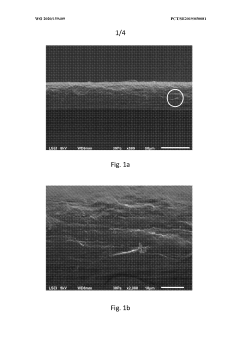

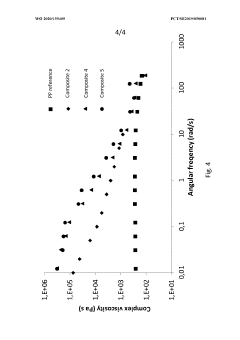

- Processing and Dispersion Techniques for h-BN in Polymer Matrices: Effective dispersion of hexagonal boron nitride in polymer matrices is crucial for optimizing composite performance. Various processing techniques, including surface functionalization of h-BN, use of coupling agents, and specialized mixing methods, can improve the interfacial adhesion between h-BN and polymer matrices. Proper dispersion techniques prevent agglomeration of h-BN particles, ensuring uniform distribution throughout the polymer matrix. This uniform dispersion is essential for achieving consistent moisture barrier properties, electrical insulation characteristics, and aging resistance in the final composite material.

- Synergistic Effects of h-BN with Other Fillers in Polymer Blends: Combining hexagonal boron nitride with other fillers in polymer blends can create synergistic effects that enhance overall performance. Hybrid composites containing h-BN along with materials such as silica, alumina, or carbon-based fillers demonstrate improved moisture resistance, electrical insulation, and aging behavior compared to single-filler systems. These multi-component systems allow for tailoring specific properties to meet application requirements. The synergistic interactions between different fillers can lead to enhanced performance at lower overall filler loadings, maintaining better processability and mechanical properties of the polymer composite.

02 Enhanced electrical insulation properties of h-BN polymer composites

Hexagonal Boron Nitride provides excellent electrical insulation properties when blended with polymers. These composites exhibit high dielectric strength, low dielectric constant, and superior electrical resistivity. The unique crystal structure of h-BN allows for effective electron scattering, preventing electrical conduction while simultaneously providing thermal conductivity. This combination makes h-BN polymer blends ideal for applications requiring electrical isolation in thermally demanding environments, such as electronic packaging, high-voltage insulators, and circuit boards.Expand Specific Solutions03 Aging behavior and long-term stability of h-BN polymer composites

Polymer blends containing hexagonal Boron Nitride demonstrate improved resistance to aging and degradation mechanisms. The presence of h-BN particles helps stabilize the polymer matrix against thermal oxidation, UV radiation, and chemical attack. This results in extended service life and maintained performance characteristics over time. The aging behavior is further enhanced by the chemical inertness of h-BN, which prevents catalytic degradation reactions that commonly occur in polymer systems exposed to harsh environmental conditions.Expand Specific Solutions04 Processing techniques for h-BN polymer blend optimization

Various processing techniques can be employed to optimize the dispersion and integration of hexagonal Boron Nitride into polymer matrices. Methods such as melt compounding, solution blending, and in-situ polymerization affect the final properties of the composite, particularly moisture resistance and electrical insulation. Surface modification of h-BN particles improves compatibility with polymer matrices, enhancing dispersion and interfacial adhesion. The processing parameters, including temperature, shear rate, and mixing time, significantly influence the microstructure and performance of the resulting composites.Expand Specific Solutions05 Synergistic effects with other fillers in multi-component systems

Hexagonal Boron Nitride can be combined with other fillers in polymer blends to create synergistic effects that enhance moisture resistance, electrical insulation, and aging behavior. Hybrid systems containing h-BN along with materials such as silica, alumina, or carbon-based fillers demonstrate multifunctional properties that cannot be achieved with single-filler systems. These multi-component blends allow for tailored performance characteristics, balancing properties like mechanical strength, thermal conductivity, and moisture barrier efficiency according to specific application requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions in hBN Composites

The hexagonal boron nitride polymer blends market is in a growth phase, driven by increasing demand for high-performance electrical insulation materials with moisture resistance and aging stability. The global market size is expanding rapidly, estimated to reach several hundred million dollars by 2025, with applications across electronics, power transmission, and automotive sectors. Technologically, this field is advancing from early commercial adoption to maturity, with companies like DuPont, Momentive Performance Materials, and Denka leading innovation through extensive R&D investments. State Grid Corporation of China and General Electric are implementing these materials in high-voltage applications, while Tokuyama and JFE Mineral focus on specialized formulations. Academic institutions including Tianjin University and University of Connecticut are advancing fundamental research, creating a competitive landscape balanced between established chemical corporations and emerging specialized materials providers.

Denka Corp.

Technical Solution: Denka Corporation has developed specialized hexagonal boron nitride (h-BN) polymer composites with exceptional moisture resistance and electrical insulation properties. Their proprietary technology involves a multi-stage surface treatment process for h-BN particles that creates strong hydrophobic characteristics while maintaining excellent dispersion in polymer matrices. Denka's research has demonstrated that their h-BN composites can maintain electrical resistivity above 10^14 Ω·cm even after 2000 hours of exposure to 85°C/85% relative humidity conditions. Their approach includes precise control of h-BN particle morphology and size distribution to create optimal packing structures within the polymer matrix, effectively blocking moisture penetration pathways. Denka has also developed specialized processing techniques that allow for high h-BN loading (up to 70 wt%) while maintaining processability, resulting in composites with superior thermal conductivity (>5 W/m·K) without compromising electrical insulation properties.

Strengths: Exceptional moisture resistance even in extreme conditions; ability to achieve high filler loading while maintaining processability; excellent balance of thermal and electrical properties. Weaknesses: Higher cost compared to conventional fillers; requires specialized processing equipment; limited compatibility with some polymer systems.

Tokuyama Corp.

Technical Solution: Tokuyama Corporation has developed advanced h-BN polymer composite materials specifically engineered for electrical insulation applications requiring superior moisture resistance. Their technology incorporates specially synthesized high-purity h-BN particles with controlled aspect ratios and surface chemistry optimized for polymer integration. Tokuyama's approach includes a proprietary two-step surface modification process that creates strong hydrophobic characteristics while enhancing interfacial adhesion with various polymer matrices. Their research has demonstrated that these composites maintain dielectric breakdown strength above 25 kV/mm even after extended aging under high humidity conditions. Tokuyama has also pioneered hybrid filler systems where h-BN is strategically combined with complementary materials to create synergistic effects that enhance both moisture barrier properties and long-term electrical stability. Their manufacturing process ensures consistent quality with h-BN purity exceeding 99.9% and precisely controlled particle size distribution.

Strengths: Exceptional electrical insulation properties even after aging; high-purity materials with consistent quality; excellent compatibility with various polymer systems. Weaknesses: Premium pricing compared to standard insulation materials; complex manufacturing process requiring specialized expertise; limited production capacity for highest purity grades.

Key Patents and Research on hBN-Polymer Aging Mechanisms

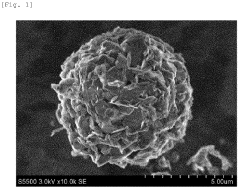

Hexagonal boron nitride agglomerated particles, hexagonal boron nitride powder, resin composition, and resin sheet

PatentPendingEP4303180A1

Innovation

- The development of specific hexagonal boron nitride aggregated particles with small, randomly oriented scale-like primary particles and a manufacturing method using an oxygen-containing boron compound, carbon source, and calcium compound under reductive nitriding conditions, resulting in particles with controlled size, porosity, and impurity content, which eliminates anisotropic thermal conductivity and reduces voids within the resin composition.

Functional sheath-core bicomponent fiber comprising hexagonal boron nitride

PatentWO2020159409A1

Innovation

- A sheath-core bicomponent fiber design where hexagonal boron nitride is incorporated in the core, combined with a thermoplastic polymer and a coupling agent, allowing for higher loadings and improved spinnability while maintaining mechanical properties, with a sheath comprising a different thermoplastic polymer to enhance thermal conductivity.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of hexagonal boron nitride (h-BN) polymer blends represent critical aspects for their industrial application and market acceptance. The production processes of h-BN involve energy-intensive methods including high-temperature synthesis and chemical vapor deposition, contributing significantly to carbon emissions. However, when compared to traditional ceramic fillers, h-BN production generally requires lower processing temperatures, potentially reducing the overall carbon footprint.

Water consumption during manufacturing presents another environmental concern, particularly relevant given these materials' moisture uptake properties. The synthesis of high-purity h-BN necessitates substantial water usage for purification processes, though recent advancements in closed-loop water systems have demonstrated up to 30% reduction in water consumption during industrial-scale production.

Regarding end-of-life considerations, h-BN polymer blends present both challenges and opportunities. The exceptional thermal stability and chemical inertness that make these materials valuable for electrical insulation applications also render them resistant to natural degradation. Current recycling technologies struggle to efficiently separate h-BN from polymer matrices, with mechanical recycling methods achieving only 40-60% recovery rates.

Life cycle assessments (LCAs) of h-BN polymer composites indicate that their extended operational lifespan in electrical applications can offset initial production impacts. Studies demonstrate that h-BN-enhanced polymers in electrical insulation applications typically last 1.5-2 times longer than conventional alternatives, reducing replacement frequency and associated environmental burdens.

The moisture resistance properties of these blends contribute positively to sustainability by extending product lifespans in humid environments. This characteristic reduces maintenance requirements and replacement frequency, particularly in outdoor electrical infrastructure where moisture-induced degradation traditionally necessitates frequent component replacement.

Emerging research focuses on developing bio-based polymers compatible with h-BN to create more environmentally friendly composites. Preliminary studies show promising results with polylactic acid (PLA) and cellulose-derived polymers, potentially reducing petroleum dependence while maintaining essential electrical insulation properties.

Regulatory frameworks increasingly emphasize the importance of sustainable materials in electrical applications. The European Union's Ecodesign Directive and similar regulations worldwide are driving manufacturers toward materials with lower environmental impacts throughout their lifecycle, positioning optimized h-BN polymer blends as potentially advantageous alternatives to traditional insulation materials with higher environmental footprints.

Water consumption during manufacturing presents another environmental concern, particularly relevant given these materials' moisture uptake properties. The synthesis of high-purity h-BN necessitates substantial water usage for purification processes, though recent advancements in closed-loop water systems have demonstrated up to 30% reduction in water consumption during industrial-scale production.

Regarding end-of-life considerations, h-BN polymer blends present both challenges and opportunities. The exceptional thermal stability and chemical inertness that make these materials valuable for electrical insulation applications also render them resistant to natural degradation. Current recycling technologies struggle to efficiently separate h-BN from polymer matrices, with mechanical recycling methods achieving only 40-60% recovery rates.

Life cycle assessments (LCAs) of h-BN polymer composites indicate that their extended operational lifespan in electrical applications can offset initial production impacts. Studies demonstrate that h-BN-enhanced polymers in electrical insulation applications typically last 1.5-2 times longer than conventional alternatives, reducing replacement frequency and associated environmental burdens.

The moisture resistance properties of these blends contribute positively to sustainability by extending product lifespans in humid environments. This characteristic reduces maintenance requirements and replacement frequency, particularly in outdoor electrical infrastructure where moisture-induced degradation traditionally necessitates frequent component replacement.

Emerging research focuses on developing bio-based polymers compatible with h-BN to create more environmentally friendly composites. Preliminary studies show promising results with polylactic acid (PLA) and cellulose-derived polymers, potentially reducing petroleum dependence while maintaining essential electrical insulation properties.

Regulatory frameworks increasingly emphasize the importance of sustainable materials in electrical applications. The European Union's Ecodesign Directive and similar regulations worldwide are driving manufacturers toward materials with lower environmental impacts throughout their lifecycle, positioning optimized h-BN polymer blends as potentially advantageous alternatives to traditional insulation materials with higher environmental footprints.

Thermal Management Applications and Performance Metrics

Hexagonal Boron Nitride (h-BN) polymer blends have emerged as promising materials for thermal management applications across multiple industries. These composites leverage h-BN's exceptional thermal conductivity (up to 400 W/m·K in-plane) while maintaining the processability and mechanical properties of polymeric materials.

In electronics packaging, h-BN/polymer composites serve as thermal interface materials (TIMs) that efficiently transfer heat from components to heat sinks. Performance metrics for these applications include thermal conductivity (typically 3-10 W/m·K for commercial products), thermal resistance (target: <0.1 cm²·K/W), and long-term reliability under thermal cycling conditions.

For power electronics, particularly in electric vehicles and renewable energy systems, h-BN/polymer blends function as potting compounds and encapsulants. These applications demand thermal conductivity exceeding 5 W/m·K while maintaining dielectric strength above 20 kV/mm. The moisture uptake characteristics of these materials directly impact their long-term thermal performance and electrical insulation properties.

LED lighting systems utilize h-BN composites in reflector materials and heat-spreading substrates. Critical metrics include thermal diffusivity (target: >5 mm²/s), color stability under thermal aging, and minimal thermal expansion mismatch with adjacent materials to prevent delamination during thermal cycling.

Aerospace applications employ h-BN/polymer composites in structural components requiring thermal management. These materials must maintain performance at temperature extremes (-65°C to 150°C) while exhibiting minimal outgassing in vacuum environments. Thermal conductivity retention after moisture exposure and thermal aging represents a key performance indicator.

The performance evaluation framework for h-BN/polymer blends encompasses multiple standardized tests: thermal conductivity (ASTM D5470), thermal diffusivity (laser flash analysis), dielectric breakdown strength (ASTM D149), and accelerated aging tests (ASTM D3045). Moisture uptake testing (ASTM D570) provides critical data on water absorption rates and their correlation with thermal and electrical property degradation.

Recent advancements in characterization techniques include transient plane source methods for anisotropic thermal conductivity measurement and non-destructive thermographic imaging for defect detection. These techniques enable more comprehensive performance assessment of h-BN/polymer composites under conditions that simulate real-world thermal management scenarios.

In electronics packaging, h-BN/polymer composites serve as thermal interface materials (TIMs) that efficiently transfer heat from components to heat sinks. Performance metrics for these applications include thermal conductivity (typically 3-10 W/m·K for commercial products), thermal resistance (target: <0.1 cm²·K/W), and long-term reliability under thermal cycling conditions.

For power electronics, particularly in electric vehicles and renewable energy systems, h-BN/polymer blends function as potting compounds and encapsulants. These applications demand thermal conductivity exceeding 5 W/m·K while maintaining dielectric strength above 20 kV/mm. The moisture uptake characteristics of these materials directly impact their long-term thermal performance and electrical insulation properties.

LED lighting systems utilize h-BN composites in reflector materials and heat-spreading substrates. Critical metrics include thermal diffusivity (target: >5 mm²/s), color stability under thermal aging, and minimal thermal expansion mismatch with adjacent materials to prevent delamination during thermal cycling.

Aerospace applications employ h-BN/polymer composites in structural components requiring thermal management. These materials must maintain performance at temperature extremes (-65°C to 150°C) while exhibiting minimal outgassing in vacuum environments. Thermal conductivity retention after moisture exposure and thermal aging represents a key performance indicator.

The performance evaluation framework for h-BN/polymer blends encompasses multiple standardized tests: thermal conductivity (ASTM D5470), thermal diffusivity (laser flash analysis), dielectric breakdown strength (ASTM D149), and accelerated aging tests (ASTM D3045). Moisture uptake testing (ASTM D570) provides critical data on water absorption rates and their correlation with thermal and electrical property degradation.

Recent advancements in characterization techniques include transient plane source methods for anisotropic thermal conductivity measurement and non-destructive thermographic imaging for defect detection. These techniques enable more comprehensive performance assessment of h-BN/polymer composites under conditions that simulate real-world thermal management scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!