Hexagonal Boron Nitride In Heat Spreaders: In-Plane vs Through-Plane Conductivity And Design Limits

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

h-BN Heat Spreader Technology Background and Objectives

Hexagonal Boron Nitride (h-BN) has emerged as a revolutionary material in thermal management solutions over the past decade. Initially discovered in the 1940s, h-BN gained significant attention in the 2000s when researchers identified its exceptional thermal conductivity properties. The layered structure of h-BN, often referred to as "white graphene," exhibits anisotropic thermal behavior that presents both opportunities and challenges for heat spreader applications.

The evolution of electronic devices toward higher power densities and miniaturization has created an urgent need for advanced thermal management solutions. Traditional materials like copper and aluminum are approaching their physical limits in heat dissipation capabilities, particularly in applications requiring electrical insulation properties. This technological gap has driven research interest in h-BN as a next-generation thermal management material.

h-BN's thermal conductivity can reach theoretical values of up to 2000 W/mK in-plane, while through-plane conductivity typically ranges from 2-20 W/mK. This stark anisotropy stems from its hexagonal crystal structure where strong covalent bonds exist within layers, but weak van der Waals forces connect the layers. Understanding and potentially manipulating this anisotropy represents a key objective in current research efforts.

The primary technical objectives in h-BN heat spreader development include optimizing the material's thermal conductivity, addressing the in-plane versus through-plane conductivity discrepancy, and developing scalable manufacturing processes. Researchers aim to enhance through-plane thermal conductivity without compromising the exceptional in-plane properties, potentially through techniques such as defect engineering, doping, or creating composite structures.

Another critical objective involves establishing design guidelines that account for h-BN's anisotropic nature. Current thermal management systems are typically designed around isotropic materials, necessitating new modeling approaches and design paradigms to fully leverage h-BN's unique properties. This includes determining optimal thickness, orientation, and integration methods for various electronic cooling applications.

The environmental stability of h-BN presents another advantage, as it maintains structural integrity and thermal performance at temperatures exceeding 1000°C in non-oxidizing environments. This characteristic makes it particularly valuable for high-temperature electronics and aerospace applications where traditional materials would degrade.

As we look toward future developments, research is increasingly focused on hybrid solutions that combine h-BN with other materials to create composites with tailored thermal properties. These efforts aim to overcome the inherent limitations of pure h-BN while maintaining its advantageous characteristics, ultimately enabling the next generation of thermal management solutions for advanced electronic systems.

The evolution of electronic devices toward higher power densities and miniaturization has created an urgent need for advanced thermal management solutions. Traditional materials like copper and aluminum are approaching their physical limits in heat dissipation capabilities, particularly in applications requiring electrical insulation properties. This technological gap has driven research interest in h-BN as a next-generation thermal management material.

h-BN's thermal conductivity can reach theoretical values of up to 2000 W/mK in-plane, while through-plane conductivity typically ranges from 2-20 W/mK. This stark anisotropy stems from its hexagonal crystal structure where strong covalent bonds exist within layers, but weak van der Waals forces connect the layers. Understanding and potentially manipulating this anisotropy represents a key objective in current research efforts.

The primary technical objectives in h-BN heat spreader development include optimizing the material's thermal conductivity, addressing the in-plane versus through-plane conductivity discrepancy, and developing scalable manufacturing processes. Researchers aim to enhance through-plane thermal conductivity without compromising the exceptional in-plane properties, potentially through techniques such as defect engineering, doping, or creating composite structures.

Another critical objective involves establishing design guidelines that account for h-BN's anisotropic nature. Current thermal management systems are typically designed around isotropic materials, necessitating new modeling approaches and design paradigms to fully leverage h-BN's unique properties. This includes determining optimal thickness, orientation, and integration methods for various electronic cooling applications.

The environmental stability of h-BN presents another advantage, as it maintains structural integrity and thermal performance at temperatures exceeding 1000°C in non-oxidizing environments. This characteristic makes it particularly valuable for high-temperature electronics and aerospace applications where traditional materials would degrade.

As we look toward future developments, research is increasingly focused on hybrid solutions that combine h-BN with other materials to create composites with tailored thermal properties. These efforts aim to overcome the inherent limitations of pure h-BN while maintaining its advantageous characteristics, ultimately enabling the next generation of thermal management solutions for advanced electronic systems.

Market Analysis for Advanced Thermal Management Solutions

The thermal management solutions market is experiencing robust growth, driven by increasing power densities in electronic devices and the miniaturization trend across industries. The global thermal management market was valued at approximately $8.6 billion in 2020 and is projected to reach $12.8 billion by 2025, growing at a CAGR of 8.2%. Within this market, advanced materials for heat spreading applications represent one of the fastest-growing segments.

Hexagonal Boron Nitride (h-BN) based heat spreaders are gaining significant traction in this landscape, particularly in high-performance computing, telecommunications, aerospace, and automotive electronics sectors. The demand for h-BN thermal solutions is primarily fueled by the material's exceptional thermal conductivity properties and electrical insulation characteristics, making it ideal for applications where both thermal management and electrical isolation are required.

The market for h-BN heat spreaders is segmented based on form factor (films, coatings, composites), application (electronics cooling, LED thermal management, power electronics), and end-use industry. Currently, the electronics cooling segment dominates the market share, accounting for approximately 42% of the total h-BN heat spreader applications.

Regional analysis indicates that Asia-Pacific holds the largest market share (38%), followed by North America (32%) and Europe (24%). This distribution correlates with the concentration of electronics manufacturing hubs and semiconductor industries. China, Japan, South Korea, and Taiwan are particularly significant markets within the Asia-Pacific region, while the United States leads in North America for advanced thermal management solutions.

Customer requirements are increasingly focusing on the directional thermal conductivity properties of h-BN, with growing awareness of the significant differences between in-plane and through-plane thermal performance. This has created market segmentation between applications requiring primarily lateral heat spreading (utilizing in-plane conductivity) versus those needing through-thickness heat transfer (through-plane conductivity).

Market research indicates that the price premium customers are willing to pay for h-BN solutions with optimized directional conductivity ranges from 15-30% above conventional thermal management materials, depending on the performance improvement achieved. This price sensitivity varies significantly across industries, with aerospace and high-performance computing showing the highest willingness to pay for premium thermal solutions.

Competitive analysis reveals that the market is currently fragmented, with several specialized material suppliers and a few large chemical companies competing for market share. Key players include Momentive Performance Materials, 3M, Saint-Gobain, and Denka Company, alongside emerging specialized manufacturers focusing exclusively on h-BN thermal solutions.

Hexagonal Boron Nitride (h-BN) based heat spreaders are gaining significant traction in this landscape, particularly in high-performance computing, telecommunications, aerospace, and automotive electronics sectors. The demand for h-BN thermal solutions is primarily fueled by the material's exceptional thermal conductivity properties and electrical insulation characteristics, making it ideal for applications where both thermal management and electrical isolation are required.

The market for h-BN heat spreaders is segmented based on form factor (films, coatings, composites), application (electronics cooling, LED thermal management, power electronics), and end-use industry. Currently, the electronics cooling segment dominates the market share, accounting for approximately 42% of the total h-BN heat spreader applications.

Regional analysis indicates that Asia-Pacific holds the largest market share (38%), followed by North America (32%) and Europe (24%). This distribution correlates with the concentration of electronics manufacturing hubs and semiconductor industries. China, Japan, South Korea, and Taiwan are particularly significant markets within the Asia-Pacific region, while the United States leads in North America for advanced thermal management solutions.

Customer requirements are increasingly focusing on the directional thermal conductivity properties of h-BN, with growing awareness of the significant differences between in-plane and through-plane thermal performance. This has created market segmentation between applications requiring primarily lateral heat spreading (utilizing in-plane conductivity) versus those needing through-thickness heat transfer (through-plane conductivity).

Market research indicates that the price premium customers are willing to pay for h-BN solutions with optimized directional conductivity ranges from 15-30% above conventional thermal management materials, depending on the performance improvement achieved. This price sensitivity varies significantly across industries, with aerospace and high-performance computing showing the highest willingness to pay for premium thermal solutions.

Competitive analysis reveals that the market is currently fragmented, with several specialized material suppliers and a few large chemical companies competing for market share. Key players include Momentive Performance Materials, 3M, Saint-Gobain, and Denka Company, alongside emerging specialized manufacturers focusing exclusively on h-BN thermal solutions.

Current Challenges in h-BN Heat Spreader Development

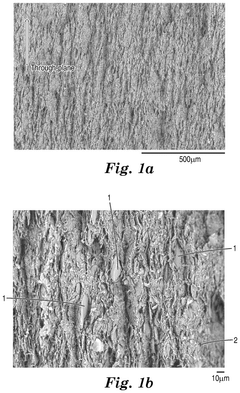

The development of hexagonal boron nitride (h-BN) heat spreaders faces several significant technical challenges that currently limit their widespread adoption and optimal performance. One of the most prominent issues is the anisotropic thermal conductivity of h-BN, with substantial differences between in-plane (200-300 W/m·K) and through-plane (2-20 W/m·K) directions. This anisotropy creates complex heat flow patterns that are difficult to predict and optimize in practical applications.

Manufacturing scalability presents another major hurdle. Current production methods for high-quality h-BN films and composites remain costly and difficult to scale. Techniques such as chemical vapor deposition (CVD) produce high-quality h-BN but are limited in terms of production volume and substrate size compatibility, while exfoliation methods struggle with consistency in flake size and thickness.

Interface thermal resistance significantly impedes heat transfer efficiency in h-BN-based thermal management systems. The contact between h-BN and adjacent materials often creates thermal bottlenecks due to phonon scattering at boundaries. This issue is particularly problematic in multilayer structures where multiple interfaces exist, potentially negating the benefits of h-BN's intrinsic thermal conductivity.

Defect engineering and control represent another critical challenge. Crystal defects, grain boundaries, and impurities dramatically reduce thermal conductivity in h-BN materials. While some research suggests that certain defects might be beneficial for specific applications, the precise control of defect type, concentration, and distribution remains elusive in current manufacturing processes.

The integration of h-BN into complex thermal management systems poses significant design challenges. Engineers must account for the material's anisotropic properties when determining optimal thickness, orientation, and configuration. Current simulation tools often lack accurate models for predicting the thermal behavior of h-BN in complex geometries and under various operating conditions.

Environmental stability concerns also exist, particularly regarding h-BN's performance under extreme conditions. While h-BN exhibits excellent thermal stability at high temperatures, questions remain about long-term reliability under thermal cycling, humidity, and in the presence of various chemicals in industrial environments.

Cost-effectiveness remains a significant barrier to widespread adoption. Current high-quality h-BN materials are expensive compared to traditional thermal management solutions, limiting their use to high-value applications where performance justifies the cost premium. Reducing production costs while maintaining thermal performance represents a critical challenge for commercial viability.

Manufacturing scalability presents another major hurdle. Current production methods for high-quality h-BN films and composites remain costly and difficult to scale. Techniques such as chemical vapor deposition (CVD) produce high-quality h-BN but are limited in terms of production volume and substrate size compatibility, while exfoliation methods struggle with consistency in flake size and thickness.

Interface thermal resistance significantly impedes heat transfer efficiency in h-BN-based thermal management systems. The contact between h-BN and adjacent materials often creates thermal bottlenecks due to phonon scattering at boundaries. This issue is particularly problematic in multilayer structures where multiple interfaces exist, potentially negating the benefits of h-BN's intrinsic thermal conductivity.

Defect engineering and control represent another critical challenge. Crystal defects, grain boundaries, and impurities dramatically reduce thermal conductivity in h-BN materials. While some research suggests that certain defects might be beneficial for specific applications, the precise control of defect type, concentration, and distribution remains elusive in current manufacturing processes.

The integration of h-BN into complex thermal management systems poses significant design challenges. Engineers must account for the material's anisotropic properties when determining optimal thickness, orientation, and configuration. Current simulation tools often lack accurate models for predicting the thermal behavior of h-BN in complex geometries and under various operating conditions.

Environmental stability concerns also exist, particularly regarding h-BN's performance under extreme conditions. While h-BN exhibits excellent thermal stability at high temperatures, questions remain about long-term reliability under thermal cycling, humidity, and in the presence of various chemicals in industrial environments.

Cost-effectiveness remains a significant barrier to widespread adoption. Current high-quality h-BN materials are expensive compared to traditional thermal management solutions, limiting their use to high-value applications where performance justifies the cost premium. Reducing production costs while maintaining thermal performance represents a critical challenge for commercial viability.

Existing h-BN Heat Spreader Design Approaches

01 Anisotropic thermal conductivity properties of h-BN

Hexagonal Boron Nitride (h-BN) exhibits significant anisotropic thermal conductivity, with in-plane thermal conductivity (along the a-axis) being substantially higher than through-plane conductivity (along the c-axis). This anisotropy is due to the layered crystal structure of h-BN, where strong covalent bonds exist within the hexagonal planes while weaker van der Waals forces connect the layers. The in-plane thermal conductivity can be 20-30 times greater than the through-plane value, making h-BN particularly valuable for applications requiring directional heat dissipation.- Anisotropic thermal conductivity properties of h-BN: Hexagonal boron nitride (h-BN) exhibits highly anisotropic thermal conductivity properties, with significantly higher thermal conductivity in the in-plane direction compared to the through-plane direction. This anisotropy is due to the layered crystal structure of h-BN, where strong covalent bonds exist within the planes while weak van der Waals forces connect the layers. The in-plane thermal conductivity can be 10-20 times higher than the through-plane value, making h-BN valuable for directional heat management applications.

- Methods to enhance h-BN thermal conductivity: Various methods have been developed to enhance the thermal conductivity of h-BN materials. These include controlling the crystallinity and orientation of h-BN flakes, reducing defects through high-temperature annealing processes, and optimizing particle size distribution. Additionally, surface functionalization and alignment techniques can be employed to maximize the exposure of the high-conductivity in-plane direction in composite materials, resulting in improved overall thermal performance.

- h-BN composites for thermal management applications: Hexagonal boron nitride is frequently incorporated into polymer, ceramic, or metal matrix composites to enhance thermal conductivity while maintaining electrical insulation properties. The orientation of h-BN particles within these composites significantly affects the thermal performance, with aligned h-BN showing superior heat dissipation capabilities. These composites are utilized in electronic packaging, thermal interface materials, and heat spreaders where directional heat transfer is desired.

- Measurement and characterization of h-BN thermal conductivity: Specialized techniques are employed to accurately measure the anisotropic thermal conductivity of h-BN materials. These include laser flash analysis, steady-state methods, and transient plane source techniques. For thin films and 2D materials, time-domain thermoreflectance and Raman spectroscopy are utilized to distinguish between in-plane and through-plane thermal properties. These measurements are crucial for understanding the structure-property relationships and optimizing h-BN for specific thermal management applications.

- h-BN film thickness and layer orientation effects on thermal conductivity: The thickness of h-BN films and the orientation of layers significantly impact thermal conductivity performance. As the number of layers decreases toward few-layer or monolayer h-BN, the in-plane thermal conductivity can increase due to reduced interlayer phonon scattering, while through-plane conductivity decreases. Controlling layer stacking and orientation during synthesis or processing allows for tailoring the thermal transport properties for specific applications, such as in microelectronics cooling or thermal interface materials.

02 Enhancement of h-BN thermal conductivity through structural modifications

Various structural modifications can enhance the thermal conductivity of h-BN materials. These include controlling the crystallinity, grain size, orientation, and thickness of h-BN layers. Single-crystal h-BN shows superior thermal conductivity compared to polycrystalline forms. Techniques such as hot pressing, chemical vapor deposition, and epitaxial growth can be employed to create highly oriented h-BN structures with maximized in-plane thermal conductivity. Additionally, reducing defects and impurities in the crystal structure significantly improves thermal performance.Expand Specific Solutions03 h-BN composites for thermal management applications

Incorporating h-BN into polymer, ceramic, or metal matrices creates composites with enhanced thermal conductivity. The orientation of h-BN platelets within these composites is crucial, as aligned platelets maximize the in-plane thermal conductivity. Various processing techniques, including extrusion, lamination, and magnetic field alignment, can be used to control h-BN orientation. These composites find applications in electronic packaging, thermal interface materials, and heat spreaders where directional heat transfer is desired.Expand Specific Solutions04 Measurement and characterization techniques for h-BN thermal conductivity

Specialized techniques are required to accurately measure the anisotropic thermal conductivity of h-BN. These include laser flash analysis, steady-state methods, 3-omega technique, and time-domain thermoreflectance. For in-plane measurements, samples with specific geometries are prepared to facilitate heat flow along the desired direction. Through-plane measurements often require thin films or carefully prepared bulk samples. Advanced microscopy and spectroscopy techniques help correlate the measured thermal properties with the material's microstructure and crystallographic orientation.Expand Specific Solutions05 Factors affecting the thermal conductivity ratio between in-plane and through-plane directions

Several factors influence the ratio between in-plane and through-plane thermal conductivity in h-BN. These include the number of layers, interlayer spacing, presence of defects, and temperature. Few-layer h-BN typically shows a higher anisotropy ratio compared to bulk h-BN. Surface functionalization and intercalation can modify the interlayer interactions, affecting the through-plane thermal conductivity. The anisotropy ratio generally decreases at higher temperatures due to increased phonon scattering. Understanding these factors allows for tailoring h-BN materials for specific thermal management applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in h-BN Technology

Hexagonal Boron Nitride (h-BN) in heat spreaders is currently in a growth phase, with the market expanding due to increasing thermal management demands in electronics. The technology demonstrates varying maturity levels across in-plane versus through-plane conductivity applications, with in-plane conductivity showing greater commercial adoption. Key players like Denka Corp., Momentive Performance Materials, and Resonac Holdings are advancing h-BN formulations, while companies such as Mitsubishi Electric, 3M, and Rogers Corp. are integrating these materials into thermal management solutions. Research institutions including Shenzhen Institutes of Advanced Technology and Electronics & Telecommunications Research Institute are addressing design limitations through novel composite structures and manufacturing techniques to overcome the inherent anisotropic thermal properties of h-BN.

Denka Corp.

Technical Solution: Denka Corporation has developed specialized hexagonal boron nitride (h-BN) materials for thermal management applications with a focus on controlling crystallinity and particle morphology to optimize thermal conductivity. Their technology involves proprietary synthesis methods that produce high-purity h-BN with controlled defect concentrations, which significantly impacts thermal performance. Denka's approach includes hot-pressing techniques that create dense h-BN structures with improved through-plane thermal conductivity while maintaining the naturally high in-plane conductivity. Their materials feature carefully engineered particle size distributions and aspect ratios to balance directional heat transfer properties. Denka has developed composite systems where h-BN is combined with ceramic matrices to create heat spreaders with thermal conductivity values reaching 120-180 W/m·K in-plane and 30-45 W/m·K through-plane. Their technology also addresses the challenge of thermal interface resistance through surface treatments that improve wetting and adhesion with various matrix materials.

Strengths: High-purity materials with excellent thermal stability; good balance between cost and performance; established manufacturing capabilities for consistent quality. Weaknesses: Lower maximum thermal conductivity compared to some competitors; limited customization options for specific applications; requires high processing temperatures for optimal performance.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed advanced thermal management solutions utilizing hexagonal boron nitride (h-BN) for power electronics applications. Their technology focuses on optimizing the balance between in-plane and through-plane thermal conductivity through controlled h-BN particle orientation and hybrid filler systems. Mitsubishi's approach involves specialized sintering processes that create dense h-BN structures with minimized interfacial thermal resistance. Their heat spreader designs incorporate gradient structures where h-BN concentration and orientation vary throughout the material to direct heat flow optimally. Mitsubishi has particularly focused on applications for high-power semiconductor devices, where their h-BN heat spreaders achieve in-plane thermal conductivity values of 250-350 W/m·K while maintaining through-plane values of 25-40 W/m·K. Their technology also addresses the challenge of thermal expansion mismatch between h-BN composites and semiconductor materials through carefully engineered intermediate layers and interface designs.

Strengths: Excellent thermal stability at high temperatures (>200°C); good compatibility with semiconductor manufacturing processes; optimized for power electronics applications with high heat flux. Weaknesses: Manufacturing complexity increases costs; performance in through-plane direction still significantly lower than in-plane; requires specialized design considerations for each application.

Key Patents and Research on Directional Thermal Conductivity

Boron nitride aggregated particles, thermal conductive resin composition, and heat dissipation member

PatentInactiveUS20220154059A1

Innovation

- Aggregated boron nitride particles with a specific surface area of 2 to 6 m2/g and a crushing strength of 5 MPa or more, along with a controlled particle diameter and aspect ratio, are used to enhance contact with the resin and prevent void formation, improving thermal conductivity and insulation breakdown strength.

Sheet comprising a composite material of a polymer and hexagonal boron nitride particles and processes for producing the same

PatentPendingUS20250188335A1

Innovation

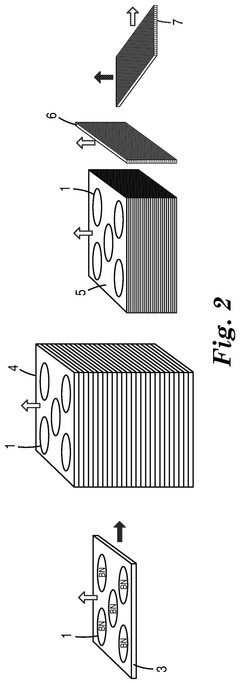

- A composite sheet material comprising a polymer and hexagonal boron nitride particles, where the hexagonal boron nitride particles are oriented perpendicular to the plane of the sheet, achieving a high through-plane thermal conductivity of more than 12 W/m*K.

Material Integration and Manufacturing Processes

The integration of hexagonal boron nitride (h-BN) into heat spreader applications requires sophisticated manufacturing processes that address the material's anisotropic thermal properties. Current integration methods focus on optimizing either in-plane or through-plane thermal conductivity, depending on the specific application requirements and heat flow directions.

Exfoliation techniques represent a primary approach for h-BN integration, where mechanical or liquid-phase exfoliation produces thin flakes that can be incorporated into polymer matrices. These methods typically preserve the high in-plane thermal conductivity of h-BN but require careful control of flake orientation during composite formation to maximize heat transfer efficiency.

Chemical vapor deposition (CVD) has emerged as a promising technique for producing high-quality h-BN films with controlled thickness and crystallinity. This process enables direct growth on various substrates, facilitating integration into electronic devices where thermal management is critical. CVD-grown h-BN films demonstrate superior in-plane thermal conductivity compared to exfoliated materials due to their larger crystal domains and fewer defects.

For applications requiring enhanced through-plane conductivity, specialized alignment techniques have been developed. These include magnetic field alignment, freeze-casting, and directional pressure application during composite formation. Such methods can reorient h-BN platelets perpendicular to the substrate, creating preferential heat conduction pathways in the through-plane direction.

Sintering processes represent another important manufacturing approach, particularly for bulk h-BN heat spreaders. Hot pressing and spark plasma sintering enable the production of dense h-BN structures with minimized interfacial thermal resistance. These techniques typically involve high temperatures (1500-2000°C) and pressures to achieve optimal thermal performance.

Interface engineering remains a critical challenge in h-BN integration. Surface functionalization methods, including plasma treatment and chemical modification, improve compatibility between h-BN and matrix materials, reducing interfacial thermal resistance. Additionally, the development of hybrid structures incorporating h-BN with other thermally conductive materials like graphene or aluminum nitride has shown promise in creating heat spreaders with optimized performance characteristics.

Scalable manufacturing represents a significant hurdle for widespread adoption. While laboratory-scale processes demonstrate excellent thermal performance, transitioning to industrial-scale production while maintaining material quality and thermal properties presents ongoing challenges. Recent advances in roll-to-roll processing and solution-based deposition methods offer potential pathways toward cost-effective, large-scale manufacturing of h-BN-based thermal management solutions.

Exfoliation techniques represent a primary approach for h-BN integration, where mechanical or liquid-phase exfoliation produces thin flakes that can be incorporated into polymer matrices. These methods typically preserve the high in-plane thermal conductivity of h-BN but require careful control of flake orientation during composite formation to maximize heat transfer efficiency.

Chemical vapor deposition (CVD) has emerged as a promising technique for producing high-quality h-BN films with controlled thickness and crystallinity. This process enables direct growth on various substrates, facilitating integration into electronic devices where thermal management is critical. CVD-grown h-BN films demonstrate superior in-plane thermal conductivity compared to exfoliated materials due to their larger crystal domains and fewer defects.

For applications requiring enhanced through-plane conductivity, specialized alignment techniques have been developed. These include magnetic field alignment, freeze-casting, and directional pressure application during composite formation. Such methods can reorient h-BN platelets perpendicular to the substrate, creating preferential heat conduction pathways in the through-plane direction.

Sintering processes represent another important manufacturing approach, particularly for bulk h-BN heat spreaders. Hot pressing and spark plasma sintering enable the production of dense h-BN structures with minimized interfacial thermal resistance. These techniques typically involve high temperatures (1500-2000°C) and pressures to achieve optimal thermal performance.

Interface engineering remains a critical challenge in h-BN integration. Surface functionalization methods, including plasma treatment and chemical modification, improve compatibility between h-BN and matrix materials, reducing interfacial thermal resistance. Additionally, the development of hybrid structures incorporating h-BN with other thermally conductive materials like graphene or aluminum nitride has shown promise in creating heat spreaders with optimized performance characteristics.

Scalable manufacturing represents a significant hurdle for widespread adoption. While laboratory-scale processes demonstrate excellent thermal performance, transitioning to industrial-scale production while maintaining material quality and thermal properties presents ongoing challenges. Recent advances in roll-to-roll processing and solution-based deposition methods offer potential pathways toward cost-effective, large-scale manufacturing of h-BN-based thermal management solutions.

Sustainability and Cost Analysis of h-BN Heat Spreaders

The sustainability and economic viability of h-BN heat spreaders represent critical factors in their widespread adoption across various industries. When evaluating hexagonal boron nitride as a thermal management solution, environmental impact and cost considerations must be thoroughly assessed alongside technical performance metrics.

From a sustainability perspective, h-BN offers several advantages compared to traditional metallic heat spreaders. The material's chemical stability results in longer product lifespans, reducing replacement frequency and associated waste. Additionally, h-BN is non-toxic and environmentally inert, presenting minimal ecological risks during both manufacturing and end-of-life disposal phases.

However, current h-BN production methods present sustainability challenges. The high-temperature synthesis processes required for high-quality h-BN consume significant energy, contributing to considerable carbon footprints. Chemical vapor deposition (CVD) methods, while producing superior quality h-BN films with enhanced in-plane thermal conductivity, are particularly energy-intensive and utilize hazardous precursors that require careful handling and disposal.

Cost analysis reveals that h-BN heat spreaders currently command premium pricing compared to conventional alternatives. Raw material costs remain high due to limited production scale and specialized purification requirements. The manufacturing complexity increases substantially when optimizing for specific thermal conductivity orientations - particularly when maximizing the superior in-plane thermal properties that make h-BN attractive for next-generation electronics.

Economic barriers are especially pronounced for large-format h-BN heat spreaders, where production challenges compound with increasing dimensions. The cost differential between in-plane and through-plane optimized designs is significant, with the former typically commanding higher prices due to more stringent crystallographic alignment requirements during fabrication.

Market projections suggest economies of scale will gradually reduce costs as production volumes increase. Several manufacturers are developing more efficient synthesis methods that promise to lower energy requirements and production expenses. Recycling initiatives for h-BN materials are also emerging, though technical challenges in separating h-BN from composite structures remain.

The cost-performance ratio of h-BN heat spreaders varies considerably across application domains. In high-value electronics where thermal management directly impacts device performance and reliability, the premium for h-BN solutions is often justified despite higher initial costs. Conversely, mass-market consumer applications remain price-sensitive, limiting current adoption to premium product segments where thermal performance commands priority over cost considerations.

From a sustainability perspective, h-BN offers several advantages compared to traditional metallic heat spreaders. The material's chemical stability results in longer product lifespans, reducing replacement frequency and associated waste. Additionally, h-BN is non-toxic and environmentally inert, presenting minimal ecological risks during both manufacturing and end-of-life disposal phases.

However, current h-BN production methods present sustainability challenges. The high-temperature synthesis processes required for high-quality h-BN consume significant energy, contributing to considerable carbon footprints. Chemical vapor deposition (CVD) methods, while producing superior quality h-BN films with enhanced in-plane thermal conductivity, are particularly energy-intensive and utilize hazardous precursors that require careful handling and disposal.

Cost analysis reveals that h-BN heat spreaders currently command premium pricing compared to conventional alternatives. Raw material costs remain high due to limited production scale and specialized purification requirements. The manufacturing complexity increases substantially when optimizing for specific thermal conductivity orientations - particularly when maximizing the superior in-plane thermal properties that make h-BN attractive for next-generation electronics.

Economic barriers are especially pronounced for large-format h-BN heat spreaders, where production challenges compound with increasing dimensions. The cost differential between in-plane and through-plane optimized designs is significant, with the former typically commanding higher prices due to more stringent crystallographic alignment requirements during fabrication.

Market projections suggest economies of scale will gradually reduce costs as production volumes increase. Several manufacturers are developing more efficient synthesis methods that promise to lower energy requirements and production expenses. Recycling initiatives for h-BN materials are also emerging, though technical challenges in separating h-BN from composite structures remain.

The cost-performance ratio of h-BN heat spreaders varies considerably across application domains. In high-value electronics where thermal management directly impacts device performance and reliability, the premium for h-BN solutions is often justified despite higher initial costs. Conversely, mass-market consumer applications remain price-sensitive, limiting current adoption to premium product segments where thermal performance commands priority over cost considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!