Hexagonal Boron Nitride In Power Modules: Substrate Integration, CTE Matching And Package Integrity

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

h-BN Power Module Background and Objectives

Hexagonal Boron Nitride (h-BN) has emerged as a revolutionary material in power electronics, offering unique properties that address critical challenges in power module design and performance. The evolution of power electronics has been marked by continuous demands for higher power density, improved thermal management, and enhanced reliability under extreme operating conditions. Traditional materials used in power modules have increasingly shown limitations in meeting these escalating requirements.

The historical development of power module substrates has progressed from simple ceramic bases to complex multi-material solutions. Initially, aluminum oxide (Al2O3) dominated the market, followed by aluminum nitride (AlN) and silicon nitride (Si3N4). Each iteration brought improvements in thermal conductivity and mechanical strength, yet challenges persisted in coefficient of thermal expansion (CTE) matching and thermal cycling reliability.

h-BN represents the next significant advancement in this technological progression. With its hexagonal crystal structure similar to graphene, h-BN offers an exceptional combination of high thermal conductivity (up to 400 W/m·K in-plane), excellent electrical insulation properties (bandgap ~5.9 eV), and remarkable chemical stability at high temperatures. These characteristics position h-BN as an ideal candidate for next-generation power module substrates.

The primary technical objective of incorporating h-BN in power modules is to overcome the thermal management bottleneck that currently limits power density in semiconductor devices. By enabling more efficient heat dissipation, h-BN substrates could potentially allow for significant miniaturization of power modules while maintaining or improving reliability metrics.

Another critical objective is addressing the CTE mismatch between different materials in power module assemblies. The CTE of h-BN can be engineered through composite formulations to closely match that of silicon, silicon carbide, or gallium nitride semiconductors, thereby reducing thermomechanical stress during thermal cycling and improving long-term reliability.

Package integrity represents the third major objective in h-BN power module development. The mechanical properties of h-BN, particularly its flexibility and strength, offer potential solutions for reducing delamination and cracking issues that plague current power module designs during thermal cycling and power cycling tests.

The integration of h-BN into commercial power modules aims to support the broader industry trend toward wide bandgap semiconductors operating at higher voltages, frequencies, and temperatures. As silicon carbide and gallium nitride devices become more prevalent, the substrate materials must evolve to accommodate their unique thermal and electrical requirements. h-BN technology development aligns with the industry roadmap for more efficient power conversion in electric vehicles, renewable energy systems, and industrial applications where size, weight, and reliability are paramount concerns.

The historical development of power module substrates has progressed from simple ceramic bases to complex multi-material solutions. Initially, aluminum oxide (Al2O3) dominated the market, followed by aluminum nitride (AlN) and silicon nitride (Si3N4). Each iteration brought improvements in thermal conductivity and mechanical strength, yet challenges persisted in coefficient of thermal expansion (CTE) matching and thermal cycling reliability.

h-BN represents the next significant advancement in this technological progression. With its hexagonal crystal structure similar to graphene, h-BN offers an exceptional combination of high thermal conductivity (up to 400 W/m·K in-plane), excellent electrical insulation properties (bandgap ~5.9 eV), and remarkable chemical stability at high temperatures. These characteristics position h-BN as an ideal candidate for next-generation power module substrates.

The primary technical objective of incorporating h-BN in power modules is to overcome the thermal management bottleneck that currently limits power density in semiconductor devices. By enabling more efficient heat dissipation, h-BN substrates could potentially allow for significant miniaturization of power modules while maintaining or improving reliability metrics.

Another critical objective is addressing the CTE mismatch between different materials in power module assemblies. The CTE of h-BN can be engineered through composite formulations to closely match that of silicon, silicon carbide, or gallium nitride semiconductors, thereby reducing thermomechanical stress during thermal cycling and improving long-term reliability.

Package integrity represents the third major objective in h-BN power module development. The mechanical properties of h-BN, particularly its flexibility and strength, offer potential solutions for reducing delamination and cracking issues that plague current power module designs during thermal cycling and power cycling tests.

The integration of h-BN into commercial power modules aims to support the broader industry trend toward wide bandgap semiconductors operating at higher voltages, frequencies, and temperatures. As silicon carbide and gallium nitride devices become more prevalent, the substrate materials must evolve to accommodate their unique thermal and electrical requirements. h-BN technology development aligns with the industry roadmap for more efficient power conversion in electric vehicles, renewable energy systems, and industrial applications where size, weight, and reliability are paramount concerns.

Market Demand Analysis for Advanced Power Module Materials

The power electronics market is experiencing unprecedented growth, with a projected CAGR of 8.7% from 2023 to 2028, reaching approximately $29 billion by the end of the forecast period. This growth is primarily driven by the rapid expansion of electric vehicles, renewable energy systems, and industrial automation applications that require increasingly efficient power management solutions.

Within this expanding market, power modules represent a critical component segment, with particular demand for materials that can enhance thermal management, reliability, and power density. The transition toward wide bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) has intensified the need for advanced packaging materials that can withstand higher operating temperatures and voltage levels.

Hexagonal Boron Nitride (h-BN) has emerged as a promising material for next-generation power modules due to its exceptional thermal conductivity (up to 400 W/mK in-plane), electrical insulation properties (bandgap ~5.9 eV), and chemical stability at high temperatures. Market research indicates that the thermal interface materials segment, where h-BN plays a significant role, is growing at 11.2% annually, outpacing the broader power electronics market.

The automotive sector represents the largest demand driver for advanced power module materials, accounting for approximately 35% of the market share. Electric vehicle manufacturers are actively seeking solutions that can improve power density while maintaining reliability under harsh operating conditions. The coefficient of thermal expansion (CTE) matching capabilities of h-BN composites address a critical pain point in this application space.

Renewable energy systems, particularly solar inverters and wind power converters, constitute the second-largest application segment at 28% market share. These applications benefit significantly from the enhanced thermal management and reliability offered by advanced substrate materials like h-BN composites.

Regional analysis reveals that Asia-Pacific dominates the market with 45% share, led by manufacturing powerhouses in China, Japan, and South Korea. North America and Europe follow with 25% and 22% respectively, with particularly strong demand in regions with aggressive electrification initiatives.

Customer surveys indicate that power module manufacturers prioritize three key material attributes: thermal performance (cited by 87% of respondents), long-term reliability (82%), and cost-effectiveness (76%). The ability of h-BN to address the first two priorities while offering potential for cost optimization through reduced cooling requirements positions it favorably in the competitive landscape.

Within this expanding market, power modules represent a critical component segment, with particular demand for materials that can enhance thermal management, reliability, and power density. The transition toward wide bandgap semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) has intensified the need for advanced packaging materials that can withstand higher operating temperatures and voltage levels.

Hexagonal Boron Nitride (h-BN) has emerged as a promising material for next-generation power modules due to its exceptional thermal conductivity (up to 400 W/mK in-plane), electrical insulation properties (bandgap ~5.9 eV), and chemical stability at high temperatures. Market research indicates that the thermal interface materials segment, where h-BN plays a significant role, is growing at 11.2% annually, outpacing the broader power electronics market.

The automotive sector represents the largest demand driver for advanced power module materials, accounting for approximately 35% of the market share. Electric vehicle manufacturers are actively seeking solutions that can improve power density while maintaining reliability under harsh operating conditions. The coefficient of thermal expansion (CTE) matching capabilities of h-BN composites address a critical pain point in this application space.

Renewable energy systems, particularly solar inverters and wind power converters, constitute the second-largest application segment at 28% market share. These applications benefit significantly from the enhanced thermal management and reliability offered by advanced substrate materials like h-BN composites.

Regional analysis reveals that Asia-Pacific dominates the market with 45% share, led by manufacturing powerhouses in China, Japan, and South Korea. North America and Europe follow with 25% and 22% respectively, with particularly strong demand in regions with aggressive electrification initiatives.

Customer surveys indicate that power module manufacturers prioritize three key material attributes: thermal performance (cited by 87% of respondents), long-term reliability (82%), and cost-effectiveness (76%). The ability of h-BN to address the first two priorities while offering potential for cost optimization through reduced cooling requirements positions it favorably in the competitive landscape.

h-BN Integration Challenges and Technical Barriers

Despite the promising properties of hexagonal Boron Nitride (h-BN) for power module applications, significant technical barriers impede its widespread integration. The primary challenge lies in the manufacturing processes required to incorporate h-BN into substrate materials while maintaining its beneficial properties. Current deposition techniques, including chemical vapor deposition (CVD) and physical vapor deposition (PVD), struggle to produce uniform, defect-free h-BN layers at scales necessary for commercial power module production.

The interface quality between h-BN and other materials in the power module stack presents another substantial hurdle. Poor adhesion between h-BN and metal contacts or semiconductor layers can lead to delamination under thermal cycling, negating the thermal management benefits. Surface functionalization techniques to improve adhesion often compromise h-BN's thermal conductivity or electrical insulation properties, creating a difficult engineering trade-off.

Coefficient of Thermal Expansion (CTE) matching, while theoretically advantageous with h-BN, faces practical implementation challenges. The anisotropic nature of h-BN means its CTE varies significantly between in-plane and out-of-plane directions. This anisotropy complicates the design of composite substrates that must maintain dimensional stability across wide temperature ranges experienced in power electronics applications.

Cost considerations present perhaps the most immediate barrier to h-BN adoption. Current synthesis methods for high-quality h-BN remain expensive, with costs approximately 8-10 times higher than traditional substrate materials like aluminum nitride or silicon nitride. The economic viability of h-BN integration depends on either significant cost reductions in production or demonstrating performance improvements that justify the premium price point.

Quality control and standardization issues further complicate h-BN integration. The lack of established industry standards for h-BN quality, thickness uniformity, and defect density makes it difficult for manufacturers to ensure consistent performance across production batches. Variations in h-BN quality can lead to unpredictable thermal and electrical behavior in the final power module.

Scalability remains problematic as current laboratory-scale production methods for high-quality h-BN have not been successfully transferred to industrial-scale manufacturing. The transition from small research samples to wafer-scale or larger production faces yield issues, quality consistency problems, and equipment limitations that must be overcome before commercial viability can be achieved.

Finally, long-term reliability data for h-BN in power module applications remains limited. Without comprehensive understanding of aging mechanisms, failure modes, and lifetime performance under various operating conditions, manufacturers remain hesitant to adopt this novel material despite its theoretical advantages. Accelerated life testing protocols specific to h-BN-based power modules need development to provide confidence in long-term reliability.

The interface quality between h-BN and other materials in the power module stack presents another substantial hurdle. Poor adhesion between h-BN and metal contacts or semiconductor layers can lead to delamination under thermal cycling, negating the thermal management benefits. Surface functionalization techniques to improve adhesion often compromise h-BN's thermal conductivity or electrical insulation properties, creating a difficult engineering trade-off.

Coefficient of Thermal Expansion (CTE) matching, while theoretically advantageous with h-BN, faces practical implementation challenges. The anisotropic nature of h-BN means its CTE varies significantly between in-plane and out-of-plane directions. This anisotropy complicates the design of composite substrates that must maintain dimensional stability across wide temperature ranges experienced in power electronics applications.

Cost considerations present perhaps the most immediate barrier to h-BN adoption. Current synthesis methods for high-quality h-BN remain expensive, with costs approximately 8-10 times higher than traditional substrate materials like aluminum nitride or silicon nitride. The economic viability of h-BN integration depends on either significant cost reductions in production or demonstrating performance improvements that justify the premium price point.

Quality control and standardization issues further complicate h-BN integration. The lack of established industry standards for h-BN quality, thickness uniformity, and defect density makes it difficult for manufacturers to ensure consistent performance across production batches. Variations in h-BN quality can lead to unpredictable thermal and electrical behavior in the final power module.

Scalability remains problematic as current laboratory-scale production methods for high-quality h-BN have not been successfully transferred to industrial-scale manufacturing. The transition from small research samples to wafer-scale or larger production faces yield issues, quality consistency problems, and equipment limitations that must be overcome before commercial viability can be achieved.

Finally, long-term reliability data for h-BN in power module applications remains limited. Without comprehensive understanding of aging mechanisms, failure modes, and lifetime performance under various operating conditions, manufacturers remain hesitant to adopt this novel material despite its theoretical advantages. Accelerated life testing protocols specific to h-BN-based power modules need development to provide confidence in long-term reliability.

Current h-BN Integration Solutions for Power Modules

01 h-BN as thermal interface material for CTE matching

Hexagonal boron nitride (h-BN) is utilized as a thermal interface material in electronic packaging due to its excellent thermal conductivity and coefficient of thermal expansion (CTE) matching capabilities. When formulated into composites, h-BN helps bridge the CTE mismatch between different package components, reducing thermal stress and improving package integrity. These materials can be tailored to match the CTE of various substrates including silicon, ceramics, and metals, preventing delamination and cracking during thermal cycling.- h-BN as thermal interface material for CTE matching: Hexagonal boron nitride (h-BN) is utilized as a thermal interface material in electronic packaging due to its excellent thermal conductivity and coefficient of thermal expansion (CTE) matching capabilities. When formulated into composites, h-BN helps bridge the CTE mismatch between different package components, reducing thermal stress and improving package integrity during thermal cycling. The platelet structure of h-BN allows for effective heat dissipation while maintaining dimensional stability.

- h-BN filled polymer composites for package sealing: Polymer composites filled with hexagonal boron nitride particles are developed for package sealing applications. These composites combine the flexibility and processability of polymers with the thermal stability and CTE control provided by h-BN fillers. By adjusting the h-BN loading percentage and particle size distribution, the composite's CTE can be tailored to match surrounding materials, ensuring hermetic sealing and package integrity under thermal stress conditions. These materials are particularly valuable in microelectronic packaging where reliability during thermal cycling is critical.

- Oriented h-BN structures for enhanced CTE control: Advanced manufacturing techniques enable the creation of oriented hexagonal boron nitride structures where the h-BN platelets are aligned in specific directions. This orientation allows for anisotropic control of coefficient of thermal expansion, providing directional CTE matching capabilities. Such oriented structures can be strategically implemented in package designs to manage thermal expansion in critical directions, enhancing overall package integrity. The alignment process typically involves techniques such as magnetic field alignment, shear force application, or specialized deposition methods.

- h-BN coatings for interface protection and CTE management: Thin coatings of hexagonal boron nitride are applied at critical interfaces within electronic packages to manage CTE mismatch and protect underlying components. These coatings serve as buffer layers that accommodate thermal expansion differences while providing thermal conductivity. The h-BN coatings can be deposited through various methods including chemical vapor deposition, sputtering, or spray coating, depending on the substrate requirements. The thickness and crystallinity of these coatings can be optimized to achieve the desired CTE matching properties.

- Multi-layer h-BN structures for package integrity: Multi-layered structures incorporating hexagonal boron nitride at different concentrations and configurations are designed to create gradual CTE transitions between dissimilar materials in electronic packages. These engineered structures prevent abrupt CTE mismatches that could lead to delamination or cracking during thermal cycling. The gradual transition layers distribute thermal stress more evenly, significantly improving package reliability and integrity. Such multi-layer approaches often combine h-BN with other fillers or matrix materials to achieve precise CTE control throughout the package assembly.

02 h-BN filled polymer composites for package sealing

Polymer composites filled with hexagonal boron nitride particles are developed for package sealing applications. These composites combine the flexibility and processability of polymers with the thermal stability and CTE control provided by h-BN. The addition of h-BN to polymeric matrices creates materials with tailored CTE values that can maintain package integrity under thermal stress. These composites can be formulated as adhesives, sealants, or molding compounds that provide hermetic sealing while accommodating thermal expansion differences between package components.Expand Specific Solutions03 Oriented h-BN structures for anisotropic CTE control

Oriented or aligned hexagonal boron nitride structures are engineered to provide anisotropic control of coefficient of thermal expansion in packaging materials. By aligning h-BN platelets in specific directions, the thermal expansion behavior can be tailored differently along various axes, allowing for more precise CTE matching with adjacent materials. This approach is particularly valuable in complex electronic packages where different components have varying expansion characteristics. The orientation can be achieved through various processing techniques including magnetic alignment, shear forces, or directional solidification.Expand Specific Solutions04 h-BN surface treatments for improved adhesion and package integrity

Surface modification of hexagonal boron nitride particles enhances their compatibility with matrix materials and improves interfacial adhesion in packaging applications. Various treatments including silane coupling agents, plasma processing, and chemical functionalization can be applied to h-BN surfaces to promote stronger bonding with polymers, ceramics, or metals. These treatments improve the mechanical integrity of packages by preventing delamination at interfaces while maintaining the beneficial CTE matching properties of h-BN. Enhanced interfacial strength results in more reliable packages that can withstand thermal cycling without failure.Expand Specific Solutions05 Multi-layer packaging structures with h-BN gradient layers

Multi-layer packaging structures incorporating gradient concentrations of hexagonal boron nitride provide gradual transitions in coefficient of thermal expansion between dissimilar materials. These gradient structures minimize stress concentration at interfaces by creating a smooth CTE transition from one component to another. The h-BN concentration can be systematically varied across layers to create a tailored CTE profile that accommodates the expansion differences between package components such as dies, substrates, and heat spreaders. This approach significantly enhances package reliability under thermal cycling conditions by distributing thermal stresses more evenly throughout the structure.Expand Specific Solutions

Leading Companies in h-BN and Power Module Industry

The hexagonal boron nitride (h-BN) power module market is in a growth phase, with increasing adoption driven by demands for high-performance thermal management solutions in power electronics. The market is expanding rapidly as power module manufacturers seek materials with superior thermal conductivity and electrical insulation properties. Technologically, h-BN integration is advancing through innovations from key players across multiple sectors. Materials specialists like Denka, Tokuyama, and Resonac are developing high-purity h-BN formulations, while electronics giants Samsung and Rogers Corporation are focusing on substrate integration techniques. Research institutions including Shenzhen Institutes of Advanced Technology and Rice University are pioneering CTE matching solutions. The technology is approaching commercial maturity with specialized manufacturers like BNNT Materials commercializing advanced applications, though challenges in cost-effective mass production and standardization remain.

Rogers Corp.

Technical Solution: Rogers Corporation has pioneered the development of h-BN enhanced power electronics substrates through their advanced materials engineering approach. Their technology centers on a proprietary process that incorporates hexagonal boron nitride into ceramic-filled PTFE and other high-performance polymer systems. The company's RO-LINX PowerCircuit solutions utilize h-BN as a critical component to achieve thermal conductivity values exceeding 45 W/m·K while maintaining excellent electrical isolation properties. Rogers has developed a unique particle size distribution control method that optimizes the packing density of h-BN platelets within the polymer matrix, creating a network structure that enhances heat dissipation pathways. Their substrates feature precisely engineered CTE values (typically 10-14 ppm/K) that can be adjusted based on the specific semiconductor devices being packaged. The company has also developed specialized surface treatment techniques for h-BN that improve adhesion to both metallic layers and encapsulation materials, enhancing overall package integrity and reliability under thermal cycling conditions.

Strengths: Excellent balance of thermal, electrical, and mechanical properties; proven reliability in high-power applications; established manufacturing infrastructure for consistent quality. Weaknesses: Higher cost compared to traditional substrate materials; limited flexibility in ultra-thin applications; requires specialized processing equipment for implementation.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed an innovative approach to integrating hexagonal boron nitride (h-BN) into power module substrates for their next-generation semiconductor devices. Their technology utilizes atomically thin h-BN layers grown via metal-organic chemical vapor deposition (MOCVD) that are subsequently transferred and stacked to create customizable thermal interface materials. Samsung's proprietary process enables precise control of h-BN layer thickness and orientation, resulting in thermal conductivity values exceeding 1800 W/m·K in the in-plane direction. For power module applications, Samsung has pioneered a hybrid substrate architecture where h-BN layers are sandwiched between ceramic layers (AlN or Si3N4) and copper heat spreaders, creating a composite structure with engineered CTE values between 4-8 ppm/K that closely match silicon carbide and gallium nitride semiconductors. Their latest innovation involves laser-patterned h-BN layers that create controlled thermal pathways while maintaining electrical isolation, addressing the thermal-electrical performance trade-off that has traditionally limited power module performance.

Strengths: Exceptional in-plane thermal conductivity; precise CTE matching capabilities; excellent electrical isolation properties; compatibility with advanced semiconductor materials. Weaknesses: Complex manufacturing process with high initial capital costs; challenges in scaling to very large substrate sizes; requires specialized handling and integration equipment.

Key Patents and Research on h-BN Substrate Technology

Method of manufacturing hexagonal boron nitride laminates

PatentInactiveUS20170239854A1

Innovation

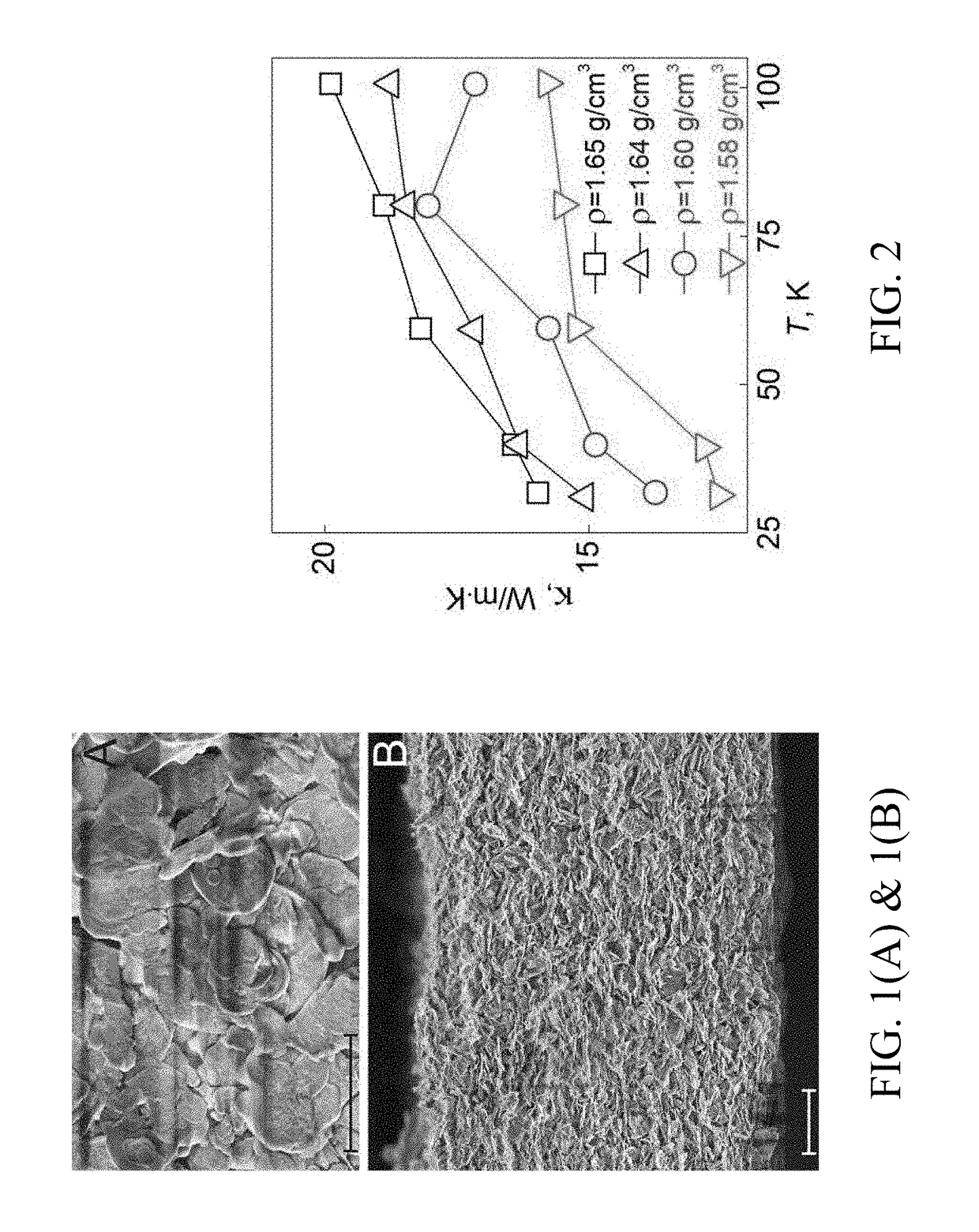

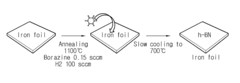

- A method of manufacturing hexagonal boron nitride laminates by dissolving dielectric polymers and mixing h-BN powder to form a coating slurry, which is coated on substrates, dried, and then processed to create free-standing or multi-layer h-BN films with adjustable thermal conductivity by varying mass density through roll-to-roll peeling and heat compression.

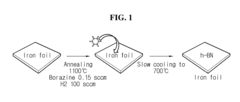

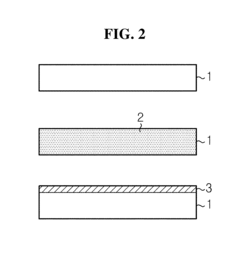

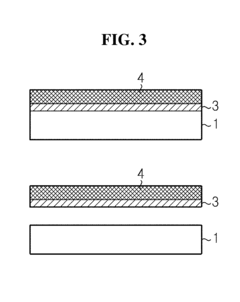

Formation method of hexagonal boron nitride thick film on a substrate and hexagonal boron nitride thick film laminates thereby

PatentActiveUS10113230B2

Innovation

- A method involving substrate heating, h-BN precursor supply, precursor dissolving, and cooling, followed by exfoliation and transfer of the h-BN thick film to another substrate using an aqueous solution and electrochemical separation, allowing for the formation of a large-thickness, uniform h-BN thick film laminate without damage to the substrate.

Thermal Management Strategies with h-BN Materials

Thermal Management Strategies with h-BN Materials

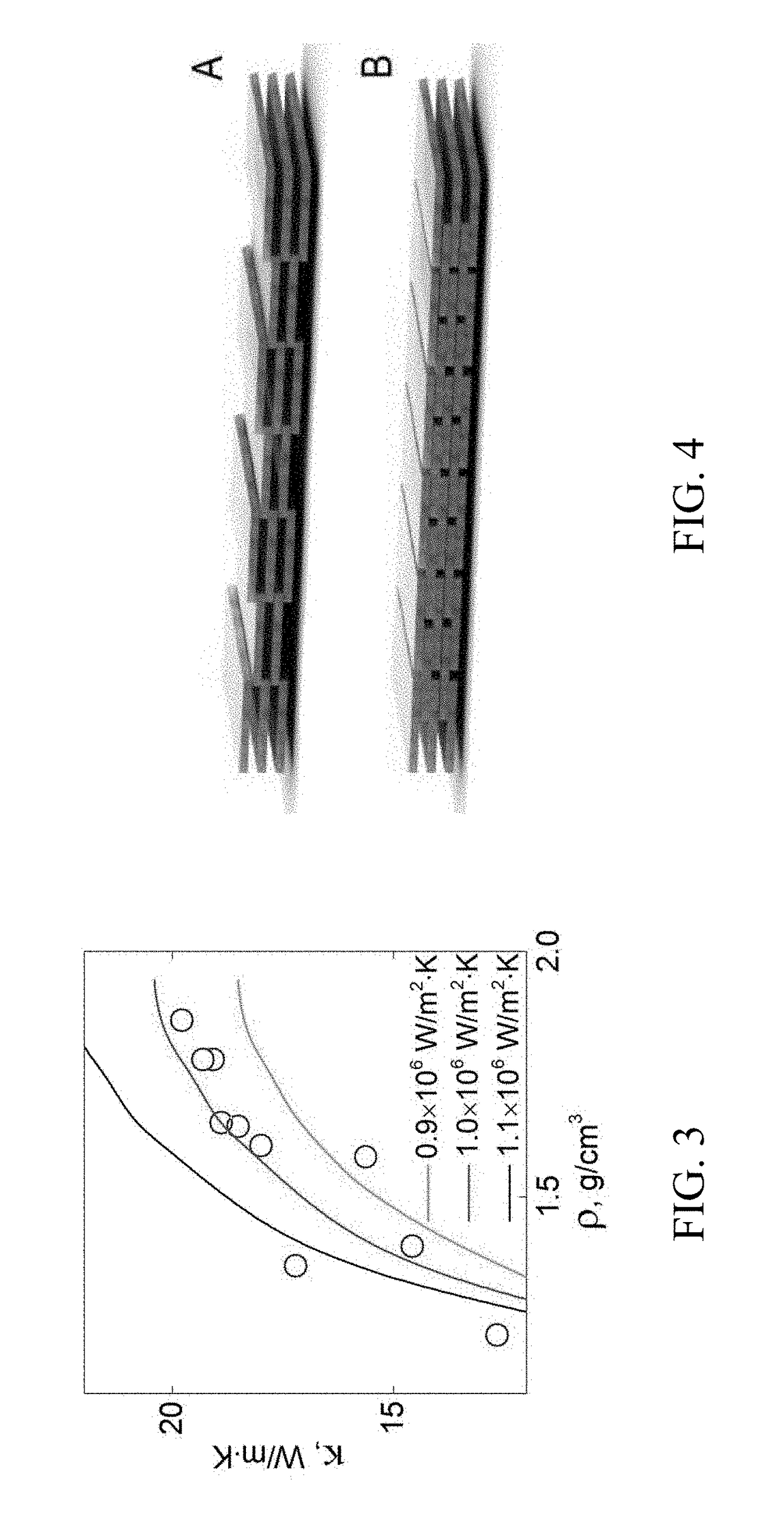

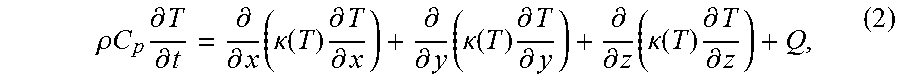

Hexagonal Boron Nitride (h-BN) offers exceptional thermal management capabilities that are increasingly vital for advanced power module designs. With thermal conductivity values ranging from 30 W/mK for amorphous films to over 400 W/mK for single-crystal structures, h-BN provides versatile solutions for heat dissipation challenges in high-power density applications.

The integration of h-BN as thermal interface materials (TIMs) represents a significant advancement over traditional silicone-based compounds. When formulated as composites with polymeric matrices, h-BN fillers can enhance thermal conductivity by 200-300% while maintaining electrical isolation properties critical for power electronics. These h-BN-enhanced TIMs demonstrate superior long-term reliability under thermal cycling conditions, with minimal degradation after 1000+ cycles compared to conventional alternatives.

Vertical thermal management strategies utilizing h-BN involve the creation of specialized heat dissipation pathways through the module structure. By incorporating h-BN layers between semiconductor dies and substrates, thermal resistance can be reduced by up to 30%, enabling more efficient heat transfer to cooling systems. This approach is particularly effective in silicon carbide (SiC) and gallium nitride (GaN) power modules where operating temperatures frequently exceed 175°C.

Lateral heat spreading techniques leverage h-BN's in-plane thermal conductivity, which can reach 600 W/mK in certain configurations. By strategically positioning h-BN layers parallel to heat-generating components, hotspot formation can be mitigated through improved heat distribution across larger surface areas. This strategy has demonstrated temperature reductions of 15-20°C in high-current switching applications.

The development of h-BN/ceramic composite substrates represents an emerging thermal management approach. By incorporating h-BN particles or layers within aluminum nitride (AlN) or aluminum oxide (Al₂O₃) substrates, manufacturers can create customized thermal conductivity profiles that address specific module requirements. These composites offer thermal conductivity improvements of 40-60% while maintaining mechanical integrity under thermal stress.

Recent innovations include 3D-printed h-BN structures that enable precise thermal management geometries previously unachievable with conventional manufacturing methods. These structures can be designed with variable density and orientation to create optimized thermal pathways that conform to complex module architectures, potentially reducing junction temperatures by up to 25% in next-generation power conversion systems.

Hexagonal Boron Nitride (h-BN) offers exceptional thermal management capabilities that are increasingly vital for advanced power module designs. With thermal conductivity values ranging from 30 W/mK for amorphous films to over 400 W/mK for single-crystal structures, h-BN provides versatile solutions for heat dissipation challenges in high-power density applications.

The integration of h-BN as thermal interface materials (TIMs) represents a significant advancement over traditional silicone-based compounds. When formulated as composites with polymeric matrices, h-BN fillers can enhance thermal conductivity by 200-300% while maintaining electrical isolation properties critical for power electronics. These h-BN-enhanced TIMs demonstrate superior long-term reliability under thermal cycling conditions, with minimal degradation after 1000+ cycles compared to conventional alternatives.

Vertical thermal management strategies utilizing h-BN involve the creation of specialized heat dissipation pathways through the module structure. By incorporating h-BN layers between semiconductor dies and substrates, thermal resistance can be reduced by up to 30%, enabling more efficient heat transfer to cooling systems. This approach is particularly effective in silicon carbide (SiC) and gallium nitride (GaN) power modules where operating temperatures frequently exceed 175°C.

Lateral heat spreading techniques leverage h-BN's in-plane thermal conductivity, which can reach 600 W/mK in certain configurations. By strategically positioning h-BN layers parallel to heat-generating components, hotspot formation can be mitigated through improved heat distribution across larger surface areas. This strategy has demonstrated temperature reductions of 15-20°C in high-current switching applications.

The development of h-BN/ceramic composite substrates represents an emerging thermal management approach. By incorporating h-BN particles or layers within aluminum nitride (AlN) or aluminum oxide (Al₂O₃) substrates, manufacturers can create customized thermal conductivity profiles that address specific module requirements. These composites offer thermal conductivity improvements of 40-60% while maintaining mechanical integrity under thermal stress.

Recent innovations include 3D-printed h-BN structures that enable precise thermal management geometries previously unachievable with conventional manufacturing methods. These structures can be designed with variable density and orientation to create optimized thermal pathways that conform to complex module architectures, potentially reducing junction temperatures by up to 25% in next-generation power conversion systems.

Reliability Testing Standards for h-BN Power Modules

Reliability testing standards for h-BN power modules must adhere to rigorous protocols to ensure performance under extreme conditions. The integration of hexagonal Boron Nitride (h-BN) in power modules necessitates specialized testing frameworks that address its unique material properties and integration challenges.

Industry standards such as JEDEC JESD22, AEC-Q101, and IEC 60747 provide foundational testing methodologies, but require adaptation for h-BN-specific characteristics. Temperature cycling tests (TCT) must be modified to account for h-BN's thermal stability up to 1000°C, with extended high-temperature dwelling periods to properly evaluate CTE matching performance between h-BN and adjacent materials.

High Temperature Operating Life (HTOL) testing for h-BN power modules typically requires 1000+ hours at temperatures exceeding 175°C, significantly more demanding than conventional module testing. This extended duration is essential to verify h-BN's long-term thermal stability and interface integrity with metallization layers and semiconductor dies.

Humidity-based reliability tests, including Temperature Humidity Bias (THB) and Highly Accelerated Stress Test (HAST), must be conducted at 85°C/85% RH for a minimum of 1000 hours to evaluate h-BN's moisture resistance properties. These tests are particularly critical for assessing the hydrophobic characteristics of h-BN and potential moisture ingress at material interfaces.

Mechanical stress testing protocols require modification to address h-BN's unique mechanical properties. Bend testing, vibration analysis, and shock testing must be calibrated to evaluate the structural integrity of h-BN substrates and their bonding interfaces. Standard test methods like ASTM D790 for flexural properties need adjustment for the anisotropic mechanical behavior of h-BN.

Electrical performance reliability testing must include high-voltage breakdown testing (up to 10 kV/mm), partial discharge measurements, and insulation resistance evaluation under various environmental conditions. These tests are essential to verify h-BN's superior dielectric properties in power module applications.

Accelerated aging tests combining multiple stressors (temperature, humidity, electrical bias, and mechanical stress) are necessary to simulate real-world operating conditions. Power cycling tests must be extended to 100,000+ cycles to properly evaluate the thermal management capabilities and CTE matching benefits of h-BN in high-power applications.

Failure analysis protocols for h-BN power modules should incorporate specialized techniques including scanning acoustic microscopy (SAM), cross-sectional analysis, and thermal imaging to detect delamination, cracking, or degradation at material interfaces. These analytical methods provide critical insights into failure mechanisms specific to h-BN integration.

Industry standards such as JEDEC JESD22, AEC-Q101, and IEC 60747 provide foundational testing methodologies, but require adaptation for h-BN-specific characteristics. Temperature cycling tests (TCT) must be modified to account for h-BN's thermal stability up to 1000°C, with extended high-temperature dwelling periods to properly evaluate CTE matching performance between h-BN and adjacent materials.

High Temperature Operating Life (HTOL) testing for h-BN power modules typically requires 1000+ hours at temperatures exceeding 175°C, significantly more demanding than conventional module testing. This extended duration is essential to verify h-BN's long-term thermal stability and interface integrity with metallization layers and semiconductor dies.

Humidity-based reliability tests, including Temperature Humidity Bias (THB) and Highly Accelerated Stress Test (HAST), must be conducted at 85°C/85% RH for a minimum of 1000 hours to evaluate h-BN's moisture resistance properties. These tests are particularly critical for assessing the hydrophobic characteristics of h-BN and potential moisture ingress at material interfaces.

Mechanical stress testing protocols require modification to address h-BN's unique mechanical properties. Bend testing, vibration analysis, and shock testing must be calibrated to evaluate the structural integrity of h-BN substrates and their bonding interfaces. Standard test methods like ASTM D790 for flexural properties need adjustment for the anisotropic mechanical behavior of h-BN.

Electrical performance reliability testing must include high-voltage breakdown testing (up to 10 kV/mm), partial discharge measurements, and insulation resistance evaluation under various environmental conditions. These tests are essential to verify h-BN's superior dielectric properties in power module applications.

Accelerated aging tests combining multiple stressors (temperature, humidity, electrical bias, and mechanical stress) are necessary to simulate real-world operating conditions. Power cycling tests must be extended to 100,000+ cycles to properly evaluate the thermal management capabilities and CTE matching benefits of h-BN in high-power applications.

Failure analysis protocols for h-BN power modules should incorporate specialized techniques including scanning acoustic microscopy (SAM), cross-sectional analysis, and thermal imaging to detect delamination, cracking, or degradation at material interfaces. These analytical methods provide critical insights into failure mechanisms specific to h-BN integration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!