How Hexagonal Boron Nitride Composites Maintain Interface Integrity Under Thermal Shock?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

h-BN Composites Background and Thermal Stability Goals

Hexagonal Boron Nitride (h-BN) composites have emerged as critical materials in high-temperature applications due to their exceptional thermal stability, chemical inertness, and mechanical properties. The evolution of these materials spans several decades, beginning with the initial synthesis of h-BN in the mid-20th century and progressing to today's sophisticated composite formulations engineered for extreme thermal environments.

The structural similarity of h-BN to graphite—often referred to as "white graphite"—provides a layered hexagonal lattice arrangement that contributes to its remarkable thermal properties. Unlike carbon-based materials, h-BN maintains structural integrity at temperatures exceeding 1000°C in oxidizing environments, making it invaluable for applications where thermal shock resistance is paramount.

Recent technological advancements have focused on enhancing the interface integrity of h-BN composites under thermal shock conditions. This development trajectory has been driven by increasing demands in aerospace, electronics, and energy sectors, where materials must withstand rapid temperature fluctuations without degradation or delamination at critical interfaces.

The primary technical goals in h-BN composite development center on maintaining interface integrity during thermal cycling. These objectives include: minimizing coefficient of thermal expansion (CTE) mismatch between h-BN and matrix materials; enhancing interfacial bonding mechanisms that remain stable under thermal gradients; developing surface functionalization techniques that promote adhesion without compromising thermal conductivity; and creating multi-scale reinforcement architectures that distribute thermal stresses effectively.

Industry trends indicate a growing emphasis on tailored h-BN composite systems designed for specific thermal shock profiles. The aerospace sector requires materials capable of withstanding rapid heating during atmospheric re-entry, while electronics applications demand composites that can dissipate heat spikes from high-power components without interface failure.

The evolution of manufacturing techniques has paralleled material development, with advances in chemical vapor deposition, hot pressing, spark plasma sintering, and additive manufacturing enabling more precise control over h-BN composite microstructures. These processing innovations have been crucial in addressing the fundamental challenge of creating strong interfaces between the inherently inert h-BN particles and various matrix materials.

Looking forward, the technical trajectory points toward multi-functional h-BN composites that not only maintain interface integrity under thermal shock but simultaneously deliver enhanced electrical insulation, neutron absorption, or tribological properties. This convergence of performance characteristics represents the next frontier in h-BN composite development, with significant implications for next-generation thermal management systems in critical applications.

The structural similarity of h-BN to graphite—often referred to as "white graphite"—provides a layered hexagonal lattice arrangement that contributes to its remarkable thermal properties. Unlike carbon-based materials, h-BN maintains structural integrity at temperatures exceeding 1000°C in oxidizing environments, making it invaluable for applications where thermal shock resistance is paramount.

Recent technological advancements have focused on enhancing the interface integrity of h-BN composites under thermal shock conditions. This development trajectory has been driven by increasing demands in aerospace, electronics, and energy sectors, where materials must withstand rapid temperature fluctuations without degradation or delamination at critical interfaces.

The primary technical goals in h-BN composite development center on maintaining interface integrity during thermal cycling. These objectives include: minimizing coefficient of thermal expansion (CTE) mismatch between h-BN and matrix materials; enhancing interfacial bonding mechanisms that remain stable under thermal gradients; developing surface functionalization techniques that promote adhesion without compromising thermal conductivity; and creating multi-scale reinforcement architectures that distribute thermal stresses effectively.

Industry trends indicate a growing emphasis on tailored h-BN composite systems designed for specific thermal shock profiles. The aerospace sector requires materials capable of withstanding rapid heating during atmospheric re-entry, while electronics applications demand composites that can dissipate heat spikes from high-power components without interface failure.

The evolution of manufacturing techniques has paralleled material development, with advances in chemical vapor deposition, hot pressing, spark plasma sintering, and additive manufacturing enabling more precise control over h-BN composite microstructures. These processing innovations have been crucial in addressing the fundamental challenge of creating strong interfaces between the inherently inert h-BN particles and various matrix materials.

Looking forward, the technical trajectory points toward multi-functional h-BN composites that not only maintain interface integrity under thermal shock but simultaneously deliver enhanced electrical insulation, neutron absorption, or tribological properties. This convergence of performance characteristics represents the next frontier in h-BN composite development, with significant implications for next-generation thermal management systems in critical applications.

Market Applications and Demand for Thermally Resistant Materials

The global market for thermally resistant materials has experienced significant growth in recent years, driven by increasing demands across multiple high-temperature application industries. Hexagonal Boron Nitride (h-BN) composites have emerged as critical materials in this landscape due to their exceptional thermal shock resistance and interface integrity maintenance capabilities.

Aerospace and defense sectors represent primary markets for h-BN composites, where components must withstand extreme temperature fluctuations during operation. The aerospace industry alone is projected to grow at a compound annual rate of 5-7% through 2028, with thermal management materials comprising a substantial segment of this expansion. Aircraft engine components, hypersonic vehicle thermal protection systems, and rocket nozzle linings all require materials that maintain structural integrity under rapid thermal cycling.

Electronics manufacturing constitutes another major market driver, particularly with the miniaturization trend increasing thermal management challenges. The thermal interface materials market, where h-BN composites excel, continues to expand as power densities in electronic devices increase. Semiconductor processing equipment manufacturers specifically seek materials that can withstand repeated thermal cycling while maintaining dimensional stability and thermal conductivity.

Energy sector applications represent a third significant market segment, encompassing both traditional and renewable energy systems. Gas turbines, solid oxide fuel cells, and concentrated solar power systems all operate under conditions of thermal cycling that challenge material interfaces. The transition toward hydrogen energy infrastructure further expands potential applications, as h-BN composites demonstrate compatibility with hydrogen environments while maintaining thermal shock resistance.

Industrial manufacturing processes involving high-temperature furnaces, metal casting, and glass production represent established markets with growing demands for improved thermal shock resistance. These industries seek materials that reduce maintenance cycles and extend equipment lifespans, directly impacting operational economics.

Market analysis indicates regional variations in demand patterns. Asia-Pacific leads consumption growth, driven by electronics manufacturing and industrial expansion in China, Japan, and South Korea. North America and Europe maintain strong demand from aerospace, defense, and specialized industrial applications, with emphasis on performance over cost considerations.

Customer requirements increasingly focus on multifunctional properties beyond thermal shock resistance alone. Materials that combine thermal management with electrical insulation, chemical stability, and mechanical strength command premium positions in the market. This trend favors advanced h-BN composites engineered with tailored interface characteristics.

Aerospace and defense sectors represent primary markets for h-BN composites, where components must withstand extreme temperature fluctuations during operation. The aerospace industry alone is projected to grow at a compound annual rate of 5-7% through 2028, with thermal management materials comprising a substantial segment of this expansion. Aircraft engine components, hypersonic vehicle thermal protection systems, and rocket nozzle linings all require materials that maintain structural integrity under rapid thermal cycling.

Electronics manufacturing constitutes another major market driver, particularly with the miniaturization trend increasing thermal management challenges. The thermal interface materials market, where h-BN composites excel, continues to expand as power densities in electronic devices increase. Semiconductor processing equipment manufacturers specifically seek materials that can withstand repeated thermal cycling while maintaining dimensional stability and thermal conductivity.

Energy sector applications represent a third significant market segment, encompassing both traditional and renewable energy systems. Gas turbines, solid oxide fuel cells, and concentrated solar power systems all operate under conditions of thermal cycling that challenge material interfaces. The transition toward hydrogen energy infrastructure further expands potential applications, as h-BN composites demonstrate compatibility with hydrogen environments while maintaining thermal shock resistance.

Industrial manufacturing processes involving high-temperature furnaces, metal casting, and glass production represent established markets with growing demands for improved thermal shock resistance. These industries seek materials that reduce maintenance cycles and extend equipment lifespans, directly impacting operational economics.

Market analysis indicates regional variations in demand patterns. Asia-Pacific leads consumption growth, driven by electronics manufacturing and industrial expansion in China, Japan, and South Korea. North America and Europe maintain strong demand from aerospace, defense, and specialized industrial applications, with emphasis on performance over cost considerations.

Customer requirements increasingly focus on multifunctional properties beyond thermal shock resistance alone. Materials that combine thermal management with electrical insulation, chemical stability, and mechanical strength command premium positions in the market. This trend favors advanced h-BN composites engineered with tailored interface characteristics.

Current Challenges in h-BN Interface Integrity

The interface integrity of hexagonal boron nitride (h-BN) composites under thermal shock conditions represents one of the most significant challenges in advanced materials engineering. Despite h-BN's exceptional thermal stability and electrical insulation properties, maintaining robust interfaces between h-BN and matrix materials during rapid temperature fluctuations remains problematic. The primary issue stems from the substantial coefficient of thermal expansion (CTE) mismatch between h-BN (approximately 2-4 × 10^-6/K) and common matrix materials such as polymers (50-200 × 10^-6/K) or metals (10-25 × 10^-6/K).

This mismatch creates severe interfacial stresses during thermal cycling, leading to delamination, crack formation, and ultimately, catastrophic failure of the composite structure. Recent studies have documented interface degradation occurring at temperature gradients as low as 50°C/min in polymer-based h-BN composites, significantly limiting their application in environments requiring thermal cycling.

Surface chemistry compatibility presents another critical challenge. The inherently inert basal plane of h-BN lacks reactive functional groups, resulting in weak interfacial bonding with most matrix materials. While edge functionalization offers some improvement, achieving uniform and stable chemical bonding across the entire h-BN surface remains elusive. Current chemical modification approaches often compromise the intrinsic properties of h-BN or create inconsistent bonding sites that become stress concentration points during thermal shock.

Moisture sensitivity at the interface compounds these challenges. Research has shown that even trace amounts of moisture can penetrate h-BN interfaces, particularly in polymer composites, creating hydrolytic degradation pathways that accelerate under thermal shock conditions. This moisture-induced degradation mechanism has been observed to reduce interfacial shear strength by up to 40% after just 10 thermal shock cycles in epoxy-based h-BN composites.

Scale-up and manufacturing consistency represent significant hurdles for industrial implementation. Laboratory-scale successes in interface engineering often fail to translate to production environments due to processing variability. The orientation and dispersion of h-BN platelets, critical for interface performance, become increasingly difficult to control in larger production volumes, resulting in inconsistent thermal shock resistance across manufactured batches.

Recent investigations have also revealed microstructural evolution at h-BN interfaces during thermal shock events. High-resolution transmission electron microscopy studies have documented the formation of nanoscale voids and phase transformations at interfaces subjected to rapid temperature changes, suggesting complex degradation mechanisms beyond simple mechanical failure. These evolving microstructural features create progressive weakening that may not be immediately detectable but leads to premature failure under continued thermal cycling.

This mismatch creates severe interfacial stresses during thermal cycling, leading to delamination, crack formation, and ultimately, catastrophic failure of the composite structure. Recent studies have documented interface degradation occurring at temperature gradients as low as 50°C/min in polymer-based h-BN composites, significantly limiting their application in environments requiring thermal cycling.

Surface chemistry compatibility presents another critical challenge. The inherently inert basal plane of h-BN lacks reactive functional groups, resulting in weak interfacial bonding with most matrix materials. While edge functionalization offers some improvement, achieving uniform and stable chemical bonding across the entire h-BN surface remains elusive. Current chemical modification approaches often compromise the intrinsic properties of h-BN or create inconsistent bonding sites that become stress concentration points during thermal shock.

Moisture sensitivity at the interface compounds these challenges. Research has shown that even trace amounts of moisture can penetrate h-BN interfaces, particularly in polymer composites, creating hydrolytic degradation pathways that accelerate under thermal shock conditions. This moisture-induced degradation mechanism has been observed to reduce interfacial shear strength by up to 40% after just 10 thermal shock cycles in epoxy-based h-BN composites.

Scale-up and manufacturing consistency represent significant hurdles for industrial implementation. Laboratory-scale successes in interface engineering often fail to translate to production environments due to processing variability. The orientation and dispersion of h-BN platelets, critical for interface performance, become increasingly difficult to control in larger production volumes, resulting in inconsistent thermal shock resistance across manufactured batches.

Recent investigations have also revealed microstructural evolution at h-BN interfaces during thermal shock events. High-resolution transmission electron microscopy studies have documented the formation of nanoscale voids and phase transformations at interfaces subjected to rapid temperature changes, suggesting complex degradation mechanisms beyond simple mechanical failure. These evolving microstructural features create progressive weakening that may not be immediately detectable but leads to premature failure under continued thermal cycling.

Current Interface Engineering Solutions

01 Interface modification techniques for h-BN composites

Various surface modification techniques can be applied to hexagonal boron nitride (h-BN) to improve its interface integrity with matrix materials. These techniques include chemical functionalization, plasma treatment, and coupling agents that create strong chemical bonds between h-BN and the surrounding matrix. These modifications reduce interfacial defects and enhance load transfer across the interface, resulting in improved mechanical properties and thermal stability of the composite.- Interface modification techniques for h-BN composites: Various surface modification techniques can be applied to hexagonal boron nitride (h-BN) to improve interface integrity in composite materials. These include chemical functionalization, plasma treatment, and coupling agents that create strong chemical bonds between h-BN and the matrix material. These modifications enhance wettability, reduce interfacial defects, and improve load transfer across the interface, resulting in superior mechanical properties and thermal stability of the composite.

- Polymer-h-BN composite interface engineering: Engineering the interface between hexagonal boron nitride and polymer matrices involves specific strategies to overcome the inherent incompatibility between the inorganic filler and organic matrix. This includes incorporating compatibilizers, using block copolymers as interfacial agents, and developing gradient interphase regions. These approaches minimize interfacial voids, enhance adhesion, and improve stress transfer, leading to composites with enhanced thermal conductivity while maintaining electrical insulation properties.

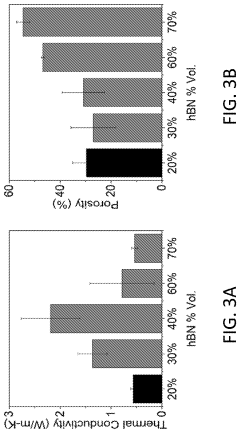

- Thermal management applications of h-BN composites: Hexagonal boron nitride composites are engineered for thermal management applications by focusing on interface integrity to maximize heat transfer. This involves controlling the orientation of h-BN platelets, optimizing filler concentration, and creating continuous thermal pathways through the matrix. Interface design techniques include using sintering aids, high-pressure processing, and thermal treatment to reduce interfacial thermal resistance, making these composites suitable for electronic packaging and heat dissipation applications.

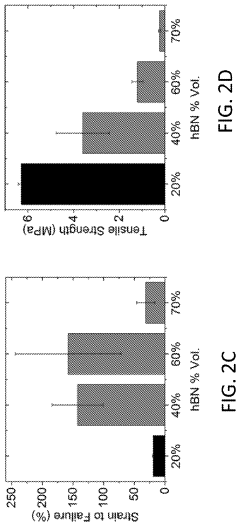

- Mechanical reinforcement through h-BN interface control: Controlling the interface between hexagonal boron nitride and the matrix material enables significant mechanical reinforcement in composites. Techniques include creating hierarchical structures, developing core-shell architectures, and implementing nano-scale interlocking mechanisms. These approaches prevent interfacial delamination, enhance crack deflection, and improve energy dissipation during mechanical loading. The resulting composites exhibit improved tensile strength, fracture toughness, and resistance to fatigue and environmental degradation.

- Advanced characterization of h-BN composite interfaces: Advanced characterization techniques are essential for understanding and optimizing hexagonal boron nitride composite interfaces. These include high-resolution transmission electron microscopy, atomic force microscopy, X-ray photoelectron spectroscopy, and nanomechanical testing methods. These techniques provide insights into interfacial bonding mechanisms, chemical interactions, nanoscale morphology, and local mechanical properties. This information guides the development of interface engineering strategies to enhance overall composite performance and durability.

02 Polymer-h-BN composite interface engineering

The interface between hexagonal boron nitride and polymer matrices can be engineered to improve compatibility and bonding. Methods include incorporating compatibilizers, using functionalized h-BN with polymer-reactive groups, and developing gradient interphase regions. These approaches minimize interfacial voids, improve stress transfer, and enhance the overall mechanical properties of the composite while maintaining thermal conductivity advantages of h-BN.Expand Specific Solutions03 Thermal interface materials with h-BN

Hexagonal boron nitride is incorporated into thermal interface materials to enhance thermal conductivity while maintaining interface integrity. The two-dimensional structure of h-BN allows for efficient heat transfer pathways while specialized formulations ensure good contact with adjacent surfaces. Various binding agents and processing techniques are used to minimize thermal boundary resistance and ensure long-term stability of the interface under thermal cycling conditions.Expand Specific Solutions04 Ceramic matrix composites with h-BN interfaces

Hexagonal boron nitride serves as an effective interface material in ceramic matrix composites, providing weak interfaces that enhance toughness while maintaining structural integrity. The layered structure of h-BN allows for controlled crack deflection and energy dissipation. Processing techniques such as chemical vapor infiltration and hot pressing are optimized to create stable h-BN interfaces that maintain their properties at high temperatures and under oxidizing conditions.Expand Specific Solutions05 Nanostructured h-BN for enhanced interface properties

Nanostructured forms of hexagonal boron nitride, including nanotubes, nanosheets, and nanoparticles, offer unique interface characteristics in composite materials. These nanostructures provide increased surface area for matrix interaction and can be precisely engineered for specific interface requirements. Advanced processing techniques ensure uniform dispersion and orientation of the nanostructures, resulting in composites with enhanced mechanical strength, thermal conductivity, and interface integrity across multiple applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The hexagonal boron nitride (h-BN) composites market is in a growth phase, with increasing applications in thermal management solutions across electronics, aerospace, and automotive sectors. The global market size for h-BN composites is expanding rapidly due to rising demand for high-performance materials capable of withstanding thermal shock. Technologically, the field is advancing from basic research to commercial applications, with companies like 3M Innovative Properties, Samsung Electronics, and Momentive Performance Materials leading industrial implementation. Research institutions such as MIT, KAIST, and Harbin Institute of Technology are driving fundamental innovations in interface integrity mechanisms. Denka Corp., Tokuyama Corp., and JFE Steel are developing specialized manufacturing processes, while Rogers Corp. and Kaneka Corp. focus on application-specific formulations that maintain structural integrity under extreme thermal cycling conditions.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced hexagonal boron nitride (h-BN) composite materials with engineered interfaces that maintain integrity under thermal shock conditions. Their technology incorporates a multi-layer interface design where h-BN platelets are surface-modified with silane coupling agents to create strong covalent bonds with polymer matrices. This chemical functionalization improves interfacial adhesion while maintaining the thermal conductivity benefits of h-BN. 3M's composites utilize a gradient structure where the concentration and orientation of h-BN particles vary across the material thickness, creating stress-dissipation zones that prevent crack propagation during thermal cycling. Their proprietary manufacturing process includes controlled cooling rates and thermal pre-conditioning treatments that minimize residual stresses at the interfaces, allowing the composite to withstand temperature fluctuations exceeding 300°C without delamination or mechanical failure.

Strengths: Superior interfacial bonding through chemical functionalization; established manufacturing infrastructure; extensive experience in thermal management materials. Weaknesses: Higher production costs compared to conventional composites; potential limitations in extreme temperature applications above 500°C; proprietary nature of technology limits broader adoption.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed sophisticated h-BN composite materials specifically engineered to maintain interface integrity under the thermal shock conditions encountered in advanced electronics. Their technology utilizes vertically aligned h-BN structures embedded within a polymer matrix containing thermally conductive ceramic nanoparticles that create multiple heat dissipation pathways. This architecture maximizes through-plane thermal conductivity while maintaining flexibility at interfaces. Samsung's approach incorporates a proprietary interface modification technique where h-BN surfaces are treated with plasma-enhanced chemical vapor deposition to create nanoscale anchoring sites for the polymer matrix, significantly enhancing adhesion during thermal cycling. Their composites feature a multi-layer design with gradient filler concentrations that distribute thermal stresses and prevent delamination. Samsung has implemented these materials in high-performance electronics where thermal management is critical, demonstrating sustained performance through thousands of thermal cycles between -40°C and 150°C. Their manufacturing process includes precision-controlled dispersion techniques that prevent h-BN agglomeration, a common cause of interface weakness and thermal conductivity reduction in composite materials.

Strengths: Optimized for electronics applications with proven field performance; excellent through-plane thermal conductivity; established manufacturing capabilities for mass production. Weaknesses: Primarily focused on moderate temperature electronics applications rather than extreme environments; proprietary nature limits broader adoption; potential cost concerns for non-premium applications.

Key Patents and Research on h-BN Thermal Shock Resistance

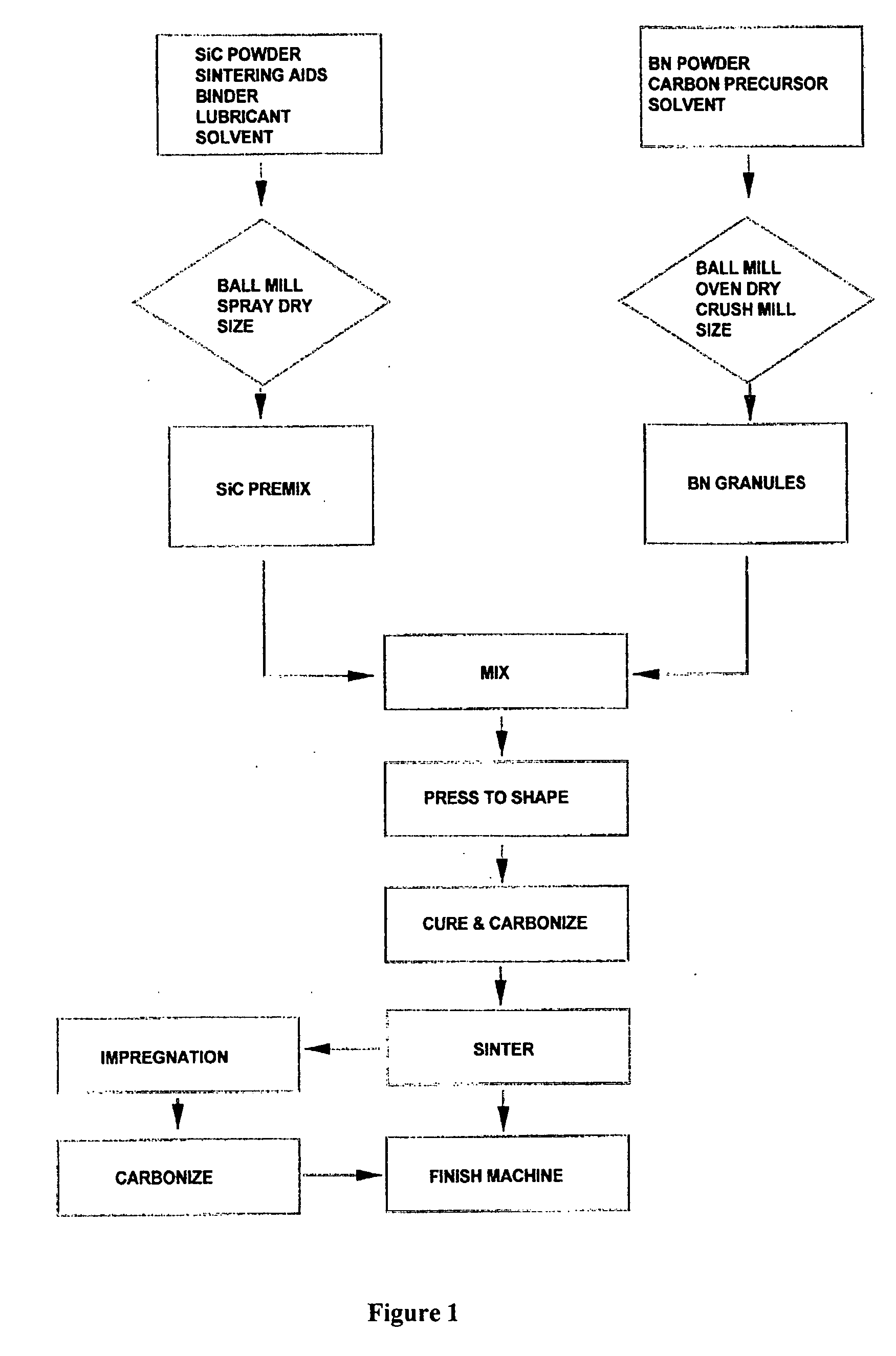

Ceramic composite body of silicon carbide/boron nitride/carbon

PatentInactiveUS20060154800A1

Innovation

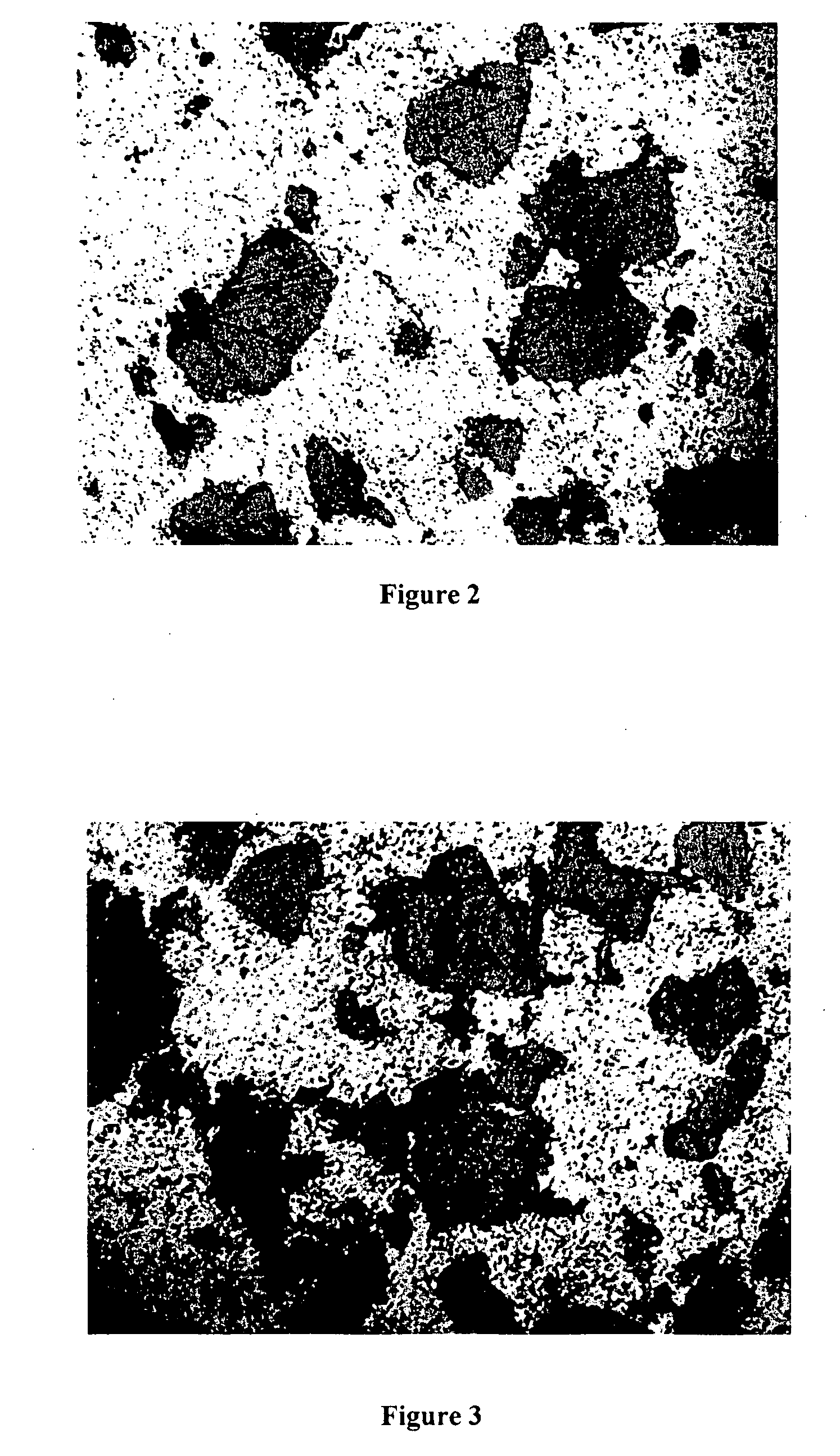

- A dense silicon carbide composite body is produced using pressureless sintering with hexagonal phase boron nitride granules bonded by glassy carbon, allowing high boron nitride loadings up to 30 weight percent, and the use of glassy carbon precursors to enhance bonding and retain boron nitride inclusions, achieving high density and self-lubricity.

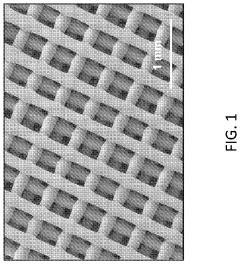

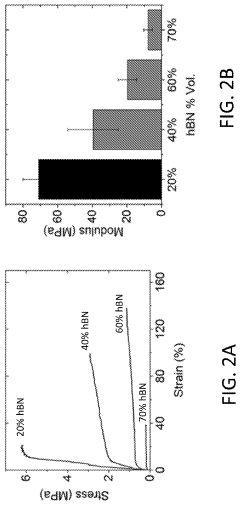

Flexible hexagonal boron nitride composites for additive manufacturing applications

PatentActiveUS11850327B2

Innovation

- Development of composite materials with hexagonal boron nitride particles dispersed in a biocompatible elastomeric polymer binder, enabling 3D extrusion printing of thermally conductive, electrically insulating, and cytocompatible scaffolds for thermal management in implantable medical devices, while maintaining high mechanical flexibility and stretchability.

Environmental Impact and Sustainability Factors

The environmental impact of hexagonal boron nitride (h-BN) composites extends beyond their thermal performance characteristics. As these materials gain prominence in high-temperature applications, their ecological footprint throughout the lifecycle becomes increasingly relevant. The production of h-BN involves energy-intensive processes, particularly during the synthesis phase where temperatures exceeding 1500°C are often required. This energy consumption contributes significantly to carbon emissions when non-renewable energy sources are utilized.

Material extraction represents another environmental consideration. Boron mining operations can lead to habitat disruption, soil degradation, and water contamination if not managed responsibly. The chemical processes involved in purifying boron compounds may generate hazardous byproducts requiring specialized disposal protocols to prevent environmental contamination.

From a sustainability perspective, h-BN composites offer several advantages that partially offset their production impacts. Their exceptional thermal stability and resistance to thermal shock significantly extends component lifespans in extreme environments, reducing replacement frequency and associated resource consumption. This durability factor translates to substantial material conservation over time, particularly in aerospace, electronics, and industrial applications where component failure can trigger cascading replacement needs.

Recyclability presents both challenges and opportunities. While pure h-BN is theoretically recyclable, its integration into complex composite structures often complicates end-of-life recovery. Current recycling technologies struggle to efficiently separate h-BN from polymer matrices or metallic substrates without degrading its valuable properties. Research into advanced separation techniques and designing composites with disassembly considerations could substantially improve recyclability metrics.

Water usage during manufacturing represents another environmental factor. The production and processing of h-BN composites typically requires significant water resources for cooling, cleaning, and chemical processing. Implementing closed-loop water systems and water-efficient manufacturing techniques can mitigate this impact considerably.

Recent innovations in green synthesis pathways show promise for reducing the environmental footprint of h-BN production. Biomass-derived precursors, lower-temperature synthesis routes, and solvent-free processing methods are emerging as more sustainable alternatives to conventional manufacturing approaches. These developments align with growing regulatory pressures and market demands for environmentally responsible materials that maintain exceptional thermal shock resistance while minimizing ecological impact.

Material extraction represents another environmental consideration. Boron mining operations can lead to habitat disruption, soil degradation, and water contamination if not managed responsibly. The chemical processes involved in purifying boron compounds may generate hazardous byproducts requiring specialized disposal protocols to prevent environmental contamination.

From a sustainability perspective, h-BN composites offer several advantages that partially offset their production impacts. Their exceptional thermal stability and resistance to thermal shock significantly extends component lifespans in extreme environments, reducing replacement frequency and associated resource consumption. This durability factor translates to substantial material conservation over time, particularly in aerospace, electronics, and industrial applications where component failure can trigger cascading replacement needs.

Recyclability presents both challenges and opportunities. While pure h-BN is theoretically recyclable, its integration into complex composite structures often complicates end-of-life recovery. Current recycling technologies struggle to efficiently separate h-BN from polymer matrices or metallic substrates without degrading its valuable properties. Research into advanced separation techniques and designing composites with disassembly considerations could substantially improve recyclability metrics.

Water usage during manufacturing represents another environmental factor. The production and processing of h-BN composites typically requires significant water resources for cooling, cleaning, and chemical processing. Implementing closed-loop water systems and water-efficient manufacturing techniques can mitigate this impact considerably.

Recent innovations in green synthesis pathways show promise for reducing the environmental footprint of h-BN production. Biomass-derived precursors, lower-temperature synthesis routes, and solvent-free processing methods are emerging as more sustainable alternatives to conventional manufacturing approaches. These developments align with growing regulatory pressures and market demands for environmentally responsible materials that maintain exceptional thermal shock resistance while minimizing ecological impact.

Characterization Methods for Interface Integrity Assessment

The assessment of interface integrity in hexagonal boron nitride (h-BN) composites under thermal shock conditions requires sophisticated characterization methods that can detect and quantify changes at the micro and nanoscale. Scanning Electron Microscopy (SEM) with Energy Dispersive X-ray Spectroscopy (EDS) provides high-resolution imaging of interface morphology and elemental distribution, enabling researchers to identify delamination, cracking, or chemical changes resulting from thermal stress.

Transmission Electron Microscopy (TEM) offers atomic-level resolution for examining the crystalline structure at interfaces, revealing lattice distortions or phase transformations induced by thermal shock. This technique is particularly valuable for understanding how the hexagonal structure of BN interacts with matrix materials during rapid temperature changes.

Fourier Transform Infrared Spectroscopy (FTIR) and Raman spectroscopy serve as complementary techniques for analyzing chemical bonding at interfaces. These methods can detect shifts in vibrational modes that indicate changes in bonding characteristics or the formation of new compounds at the interface region after thermal cycling.

X-ray Diffraction (XRD) provides critical information about crystalline phases and their transformations, helping researchers monitor structural integrity and potential phase changes at interfaces during thermal shock events. Residual stress analysis using XRD is particularly useful for quantifying mechanical stresses accumulated at interfaces.

Thermal analysis techniques, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), enable the measurement of thermal properties and phase transitions at interfaces. These methods help establish correlations between thermal behavior and interface stability.

Advanced acoustic techniques such as Scanning Acoustic Microscopy (SAM) offer non-destructive evaluation of interfaces, detecting delamination or void formation without sample destruction. This is particularly valuable for monitoring interface integrity over multiple thermal shock cycles.

Nanoindentation testing provides quantitative measurements of mechanical properties at interfaces, including hardness, elastic modulus, and interfacial adhesion strength. Changes in these properties after thermal shock can indicate degradation of interface integrity.

Digital Image Correlation (DIC) techniques allow for real-time monitoring of strain fields during thermal shock events, providing insights into deformation mechanisms and stress distribution at interfaces. This method is particularly valuable for understanding the dynamic response of interfaces to rapid temperature changes.

Transmission Electron Microscopy (TEM) offers atomic-level resolution for examining the crystalline structure at interfaces, revealing lattice distortions or phase transformations induced by thermal shock. This technique is particularly valuable for understanding how the hexagonal structure of BN interacts with matrix materials during rapid temperature changes.

Fourier Transform Infrared Spectroscopy (FTIR) and Raman spectroscopy serve as complementary techniques for analyzing chemical bonding at interfaces. These methods can detect shifts in vibrational modes that indicate changes in bonding characteristics or the formation of new compounds at the interface region after thermal cycling.

X-ray Diffraction (XRD) provides critical information about crystalline phases and their transformations, helping researchers monitor structural integrity and potential phase changes at interfaces during thermal shock events. Residual stress analysis using XRD is particularly useful for quantifying mechanical stresses accumulated at interfaces.

Thermal analysis techniques, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), enable the measurement of thermal properties and phase transitions at interfaces. These methods help establish correlations between thermal behavior and interface stability.

Advanced acoustic techniques such as Scanning Acoustic Microscopy (SAM) offer non-destructive evaluation of interfaces, detecting delamination or void formation without sample destruction. This is particularly valuable for monitoring interface integrity over multiple thermal shock cycles.

Nanoindentation testing provides quantitative measurements of mechanical properties at interfaces, including hardness, elastic modulus, and interfacial adhesion strength. Changes in these properties after thermal shock can indicate degradation of interface integrity.

Digital Image Correlation (DIC) techniques allow for real-time monitoring of strain fields during thermal shock events, providing insights into deformation mechanisms and stress distribution at interfaces. This method is particularly valuable for understanding the dynamic response of interfaces to rapid temperature changes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!