High-Entropy Alloys in Additive Manufacturing Processes

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEA Development and AM Integration Goals

High-Entropy Alloys (HEAs) represent a paradigm shift in metallurgical science, moving beyond conventional alloy design principles that typically focus on one principal element with minor additions. HEAs consist of five or more principal elements in near-equiatomic proportions, creating unique microstructures and properties through high configurational entropy. The development trajectory of HEAs has evolved from theoretical conceptualization in the early 2000s to practical applications in extreme environments due to their exceptional mechanical properties, corrosion resistance, and thermal stability.

The integration of HEAs with Additive Manufacturing (AM) processes presents a synergistic opportunity to overcome traditional manufacturing limitations. AM technologies such as Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Directed Energy Deposition (DED) enable the fabrication of complex geometries with minimal material waste, while HEAs provide enhanced material performance. This convergence aims to revolutionize industries including aerospace, biomedical, and energy sectors.

The primary technical goals for HEA development in AM contexts include establishing reproducible processing parameters to ensure consistent microstructural control. This involves optimizing laser power, scanning speed, layer thickness, and powder characteristics to achieve desired solidification rates and cooling trajectories. Additionally, researchers aim to develop computational models that can accurately predict phase formation and microstructural evolution during the rapid solidification inherent to AM processes.

Another critical objective is to expand the compositional design space of printable HEAs. Current efforts focus on creating composition-specific processing windows that maintain the beneficial multi-phase structures while avoiding detrimental intermetallic compounds or excessive porosity. This includes developing specialized pre-alloyed powders with optimized flowability, particle size distribution, and chemical homogeneity for AM processes.

From an application perspective, the goals extend to demonstrating functional superiority of AM-fabricated HEA components in specific use cases. This includes developing HEAs with tailored properties such as gradient compositions, lattice structures, or embedded functionality that can only be realized through AM techniques. The ultimate aim is to establish design methodologies that leverage both the compositional complexity of HEAs and the geometric freedom of AM to create next-generation materials with unprecedented performance characteristics.

Long-term objectives include standardization of HEA-AM processes, comprehensive property databases, and integrated computational materials engineering (ICME) frameworks that enable rapid alloy development and qualification. These goals collectively work toward establishing HEAs as mainstream engineering materials in advanced manufacturing ecosystems.

The integration of HEAs with Additive Manufacturing (AM) processes presents a synergistic opportunity to overcome traditional manufacturing limitations. AM technologies such as Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Directed Energy Deposition (DED) enable the fabrication of complex geometries with minimal material waste, while HEAs provide enhanced material performance. This convergence aims to revolutionize industries including aerospace, biomedical, and energy sectors.

The primary technical goals for HEA development in AM contexts include establishing reproducible processing parameters to ensure consistent microstructural control. This involves optimizing laser power, scanning speed, layer thickness, and powder characteristics to achieve desired solidification rates and cooling trajectories. Additionally, researchers aim to develop computational models that can accurately predict phase formation and microstructural evolution during the rapid solidification inherent to AM processes.

Another critical objective is to expand the compositional design space of printable HEAs. Current efforts focus on creating composition-specific processing windows that maintain the beneficial multi-phase structures while avoiding detrimental intermetallic compounds or excessive porosity. This includes developing specialized pre-alloyed powders with optimized flowability, particle size distribution, and chemical homogeneity for AM processes.

From an application perspective, the goals extend to demonstrating functional superiority of AM-fabricated HEA components in specific use cases. This includes developing HEAs with tailored properties such as gradient compositions, lattice structures, or embedded functionality that can only be realized through AM techniques. The ultimate aim is to establish design methodologies that leverage both the compositional complexity of HEAs and the geometric freedom of AM to create next-generation materials with unprecedented performance characteristics.

Long-term objectives include standardization of HEA-AM processes, comprehensive property databases, and integrated computational materials engineering (ICME) frameworks that enable rapid alloy development and qualification. These goals collectively work toward establishing HEAs as mainstream engineering materials in advanced manufacturing ecosystems.

Market Analysis for AM-HEA Applications

The global market for High-Entropy Alloys (HEAs) in Additive Manufacturing (AM) processes is experiencing significant growth, driven by increasing demand for advanced materials with superior properties in critical applications. Current market estimates value the AM-HEA segment at approximately $320 million in 2023, with projections indicating a compound annual growth rate of 18.7% through 2030, potentially reaching $1.2 billion by the end of the decade.

Aerospace and defense sectors currently represent the largest market share for AM-HEAs, accounting for roughly 42% of total applications. These industries particularly value the exceptional high-temperature performance, corrosion resistance, and strength-to-weight ratios that HEAs offer for components operating in extreme environments. Commercial aviation manufacturers are increasingly exploring AM-HEAs for turbine components, structural elements, and heat shields.

The medical device industry has emerged as the fastest-growing application segment, with 24.3% annual growth anticipated over the next five years. Biocompatible HEAs produced through AM processes show promising results for orthopedic implants, dental applications, and surgical instruments, offering enhanced durability and reduced rejection rates compared to traditional alloys.

Energy sector applications, particularly in oil and gas, nuclear, and renewable energy, collectively represent approximately 18% of the current market. These industries leverage AM-HEAs for components requiring exceptional corrosion resistance, thermal stability, and mechanical performance in harsh operating conditions.

Regionally, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate, driven by significant investments in advanced manufacturing capabilities in China, Japan, and South Korea, along with expanding aerospace and medical device manufacturing bases.

Market penetration faces several challenges, including high material costs, limited standardization, and insufficient performance data for long-term applications. The average cost premium for AM-HEAs remains 2.5-4 times higher than conventional alloys, restricting widespread adoption to high-value applications where performance benefits justify the increased expense.

Customer adoption patterns indicate a two-tiered market: early adopters in specialized high-performance applications willing to pay premium prices, and a growing segment of industrial users awaiting cost reductions and standardization before broader implementation. Market forecasts suggest a potential inflection point around 2026-2027 when improved manufacturing efficiencies and increased competition may drive costs down sufficiently to enable wider industrial adoption.

Aerospace and defense sectors currently represent the largest market share for AM-HEAs, accounting for roughly 42% of total applications. These industries particularly value the exceptional high-temperature performance, corrosion resistance, and strength-to-weight ratios that HEAs offer for components operating in extreme environments. Commercial aviation manufacturers are increasingly exploring AM-HEAs for turbine components, structural elements, and heat shields.

The medical device industry has emerged as the fastest-growing application segment, with 24.3% annual growth anticipated over the next five years. Biocompatible HEAs produced through AM processes show promising results for orthopedic implants, dental applications, and surgical instruments, offering enhanced durability and reduced rejection rates compared to traditional alloys.

Energy sector applications, particularly in oil and gas, nuclear, and renewable energy, collectively represent approximately 18% of the current market. These industries leverage AM-HEAs for components requiring exceptional corrosion resistance, thermal stability, and mechanical performance in harsh operating conditions.

Regionally, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate, driven by significant investments in advanced manufacturing capabilities in China, Japan, and South Korea, along with expanding aerospace and medical device manufacturing bases.

Market penetration faces several challenges, including high material costs, limited standardization, and insufficient performance data for long-term applications. The average cost premium for AM-HEAs remains 2.5-4 times higher than conventional alloys, restricting widespread adoption to high-value applications where performance benefits justify the increased expense.

Customer adoption patterns indicate a two-tiered market: early adopters in specialized high-performance applications willing to pay premium prices, and a growing segment of industrial users awaiting cost reductions and standardization before broader implementation. Market forecasts suggest a potential inflection point around 2026-2027 when improved manufacturing efficiencies and increased competition may drive costs down sufficiently to enable wider industrial adoption.

Current Challenges in HEA Additive Manufacturing

Despite the promising potential of High-Entropy Alloys (HEAs) in additive manufacturing (AM), several significant challenges currently impede their widespread industrial adoption. The primary obstacle remains the limited understanding of process-structure-property relationships specific to HEAs in AM environments. Unlike conventional alloys, HEAs exhibit complex solidification behaviors and phase transformations during rapid heating and cooling cycles typical in AM processes, making predictive modeling exceptionally difficult.

Material compatibility issues present another major challenge. The vast compositional space of HEAs, while advantageous for property customization, creates complications in powder production with consistent quality. Current powder manufacturing techniques struggle to achieve homogeneous elemental distribution across particles, leading to compositional segregation during printing that compromises mechanical properties and reproducibility.

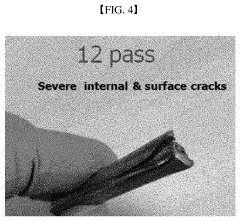

Thermal management during fabrication represents a critical technical hurdle. The multi-principal element composition of HEAs results in unique thermal conductivity profiles and melting ranges that differ significantly from conventional alloys. This creates challenges in parameter optimization, as laser power, scan speed, and layer thickness must be precisely calibrated for each specific HEA composition to prevent defects such as porosity, cracking, and undesired microstructural features.

Post-processing requirements further complicate HEA adoption in AM. Many printed HEA components require specialized heat treatments to achieve optimal microstructures and properties. However, the complex phase transformation behavior of HEAs makes developing standardized post-processing protocols difficult, often necessitating composition-specific approaches that increase production complexity and cost.

Quality control and certification present substantial barriers, particularly for high-consequence applications. The lack of standardized testing protocols specifically designed for additively manufactured HEAs hampers qualification efforts. Current non-destructive evaluation techniques have limited effectiveness in detecting subsurface defects in these complex alloy systems, creating uncertainty in component reliability.

Economic factors also constrain implementation. The high cost of high-purity elemental powders required for HEA production, combined with the need for specialized equipment and expertise, results in significantly higher production costs compared to conventional alloy systems. This cost differential currently limits HEA applications primarily to high-value, performance-critical components where the enhanced properties justify the premium.

Addressing these challenges requires coordinated efforts across materials science, manufacturing engineering, and computational modeling to develop robust process parameters, quality control methodologies, and cost-effective production techniques specifically tailored to HEA systems in additive manufacturing environments.

Material compatibility issues present another major challenge. The vast compositional space of HEAs, while advantageous for property customization, creates complications in powder production with consistent quality. Current powder manufacturing techniques struggle to achieve homogeneous elemental distribution across particles, leading to compositional segregation during printing that compromises mechanical properties and reproducibility.

Thermal management during fabrication represents a critical technical hurdle. The multi-principal element composition of HEAs results in unique thermal conductivity profiles and melting ranges that differ significantly from conventional alloys. This creates challenges in parameter optimization, as laser power, scan speed, and layer thickness must be precisely calibrated for each specific HEA composition to prevent defects such as porosity, cracking, and undesired microstructural features.

Post-processing requirements further complicate HEA adoption in AM. Many printed HEA components require specialized heat treatments to achieve optimal microstructures and properties. However, the complex phase transformation behavior of HEAs makes developing standardized post-processing protocols difficult, often necessitating composition-specific approaches that increase production complexity and cost.

Quality control and certification present substantial barriers, particularly for high-consequence applications. The lack of standardized testing protocols specifically designed for additively manufactured HEAs hampers qualification efforts. Current non-destructive evaluation techniques have limited effectiveness in detecting subsurface defects in these complex alloy systems, creating uncertainty in component reliability.

Economic factors also constrain implementation. The high cost of high-purity elemental powders required for HEA production, combined with the need for specialized equipment and expertise, results in significantly higher production costs compared to conventional alloy systems. This cost differential currently limits HEA applications primarily to high-value, performance-critical components where the enhanced properties justify the premium.

Addressing these challenges requires coordinated efforts across materials science, manufacturing engineering, and computational modeling to develop robust process parameters, quality control methodologies, and cost-effective production techniques specifically tailored to HEA systems in additive manufacturing environments.

Current HEA-AM Processing Techniques

01 Composition and structure of high-entropy alloys

High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, typically containing five or more elements. This multi-element composition creates a high configurational entropy that stabilizes solid solution phases. The unique atomic structure of HEAs contributes to their exceptional properties, including high strength, thermal stability, and resistance to wear and corrosion. The composition can be tailored to achieve specific mechanical and physical properties for various applications.- Composition and design of high-entropy alloys: High-entropy alloys (HEAs) are composed of multiple principal elements in near-equiatomic proportions, typically containing five or more elements. The design of these alloys focuses on achieving a single-phase solid solution with high configurational entropy. Various element combinations can be used to create HEAs with specific properties, including transition metals, refractory metals, and rare earth elements. The composition design often involves consideration of atomic size differences, mixing enthalpy, and valence electron concentration to predict phase stability.

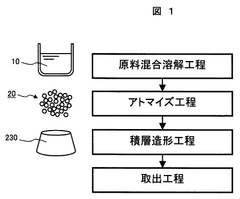

- Manufacturing methods for high-entropy alloys: Various manufacturing techniques are employed to produce high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. Each method offers different advantages in terms of microstructure control, scalability, and final properties. Arc melting is commonly used for laboratory-scale production, while powder metallurgy enables better control of grain size and porosity. Additive manufacturing techniques allow for complex geometries and compositional gradients in high-entropy alloys.

- Mechanical properties and structural applications: High-entropy alloys exhibit exceptional mechanical properties, including high strength, excellent ductility, superior fracture toughness, and good fatigue resistance. These properties make them suitable for structural applications in aerospace, automotive, and energy sectors. The unique combination of strength and ductility is attributed to their complex microstructure and multiple strengthening mechanisms. Some high-entropy alloys also demonstrate excellent performance at elevated temperatures, making them potential candidates for high-temperature structural applications.

- Functional properties and specialized applications: Beyond mechanical properties, high-entropy alloys exhibit various functional properties including corrosion resistance, radiation resistance, magnetic properties, and catalytic activity. These functional properties expand their application scope to include biomedical implants, nuclear reactor components, magnetic devices, and catalysts. Some high-entropy alloys show superparamagnetic behavior, while others demonstrate exceptional resistance to harsh environments. The multifunctionality of these alloys makes them versatile materials for advanced technological applications.

- Surface treatments and coatings of high-entropy alloys: Surface modification techniques and coating applications for high-entropy alloys enhance their performance in specific environments. These include the development of high-entropy alloy coatings using techniques such as physical vapor deposition, thermal spraying, and laser cladding. Such coatings provide improved wear resistance, oxidation resistance, and thermal barrier properties. High-entropy alloy films and coatings can be applied to conventional materials to impart superior surface properties while maintaining the bulk properties of the substrate material.

02 Manufacturing methods for high-entropy alloys

Various manufacturing techniques are employed to produce high-entropy alloys, including arc melting, mechanical alloying, powder metallurgy, and additive manufacturing. Each method offers distinct advantages in controlling the microstructure and properties of the resulting alloys. Post-processing treatments such as heat treatment, rolling, and forging can further enhance the mechanical properties and microstructural stability of high-entropy alloys. These manufacturing approaches enable the production of HEAs with tailored properties for specific applications.Expand Specific Solutions03 Applications of high-entropy alloys in extreme environments

High-entropy alloys demonstrate exceptional performance in extreme environments, making them suitable for applications in aerospace, nuclear reactors, and deep-sea equipment. Their superior high-temperature strength, oxidation resistance, and thermal stability enable use in turbine components and heat shields. Additionally, their excellent low-temperature toughness and cryogenic properties make them valuable for applications in superconducting magnets and space exploration. The combination of strength and ductility at extreme temperatures gives these alloys significant advantages over conventional materials.Expand Specific Solutions04 Functional properties and specialized applications of high-entropy alloys

Beyond mechanical properties, high-entropy alloys exhibit unique functional characteristics including magnetic, electrical, and catalytic properties. These alloys can be designed for specific applications such as hydrogen storage materials, magnetic refrigeration, and biomedical implants. Some HEAs demonstrate shape memory effects, superelasticity, and radiation resistance. The multifunctional nature of these alloys makes them promising candidates for next-generation electronic devices, energy conversion systems, and medical applications where conventional materials fall short.Expand Specific Solutions05 Computational design and property prediction of high-entropy alloys

Advanced computational methods are increasingly used to design and predict the properties of high-entropy alloys. Machine learning algorithms, density functional theory calculations, and CALPHAD (CALculation of PHAse Diagrams) approaches enable researchers to screen potential alloy compositions before experimental validation. These computational tools help identify promising compositions with desired properties, reducing the time and cost of alloy development. Integrated computational materials engineering frameworks facilitate the accelerated discovery of novel high-entropy alloys with optimized performance characteristics for specific applications.Expand Specific Solutions

Leading Companies and Research Institutions

High-Entropy Alloys (HEAs) in Additive Manufacturing (AM) are currently in an emerging growth phase, with the market expanding rapidly due to increasing applications in aerospace, automotive, and energy sectors. The global market size for HEAs in AM is projected to reach significant value by 2030, driven by their superior mechanical properties and performance in extreme conditions. Technologically, the field is in mid-maturity, with companies like LG Electronics, Hitachi, and Proterial leading commercial applications, while academic institutions such as Korea Advanced Institute of Science & Technology, Shanghai Jiao Tong University, and City University of Hong Kong are advancing fundamental research. InssTek and Nuovo Pignone Tecnologie are developing specialized AM processes for HEAs, while research collaborations between industry players and institutions like Korea Institute of Materials Science are accelerating technological readiness for widespread industrial adoption.

Hitachi Ltd.

Technical Solution: Hitachi has developed a comprehensive approach to high-entropy alloys (HEAs) in additive manufacturing, focusing on laser powder bed fusion (L-PBF) technology. Their process involves precise control of powder characteristics and laser parameters to achieve optimal microstructure development. Hitachi's method includes a proprietary post-processing heat treatment that enhances the mechanical properties of HEA components while maintaining dimensional accuracy. Their research has demonstrated that HEAs produced through their additive manufacturing process can achieve superior strength-to-weight ratios compared to conventional alloys, with tensile strengths exceeding 1200 MPa while maintaining good ductility[1]. Hitachi has particularly focused on CoCrFeMnNi-based HEAs, optimizing the composition to achieve balanced properties for industrial applications. Their process parameters have been fine-tuned to minimize defects such as porosity and cracking, which are common challenges in additive manufacturing of complex alloy systems.

Strengths: Superior control over microstructure development through optimized process parameters; excellent mechanical properties with high strength-to-weight ratio; proprietary post-processing techniques that enhance performance. Weaknesses: Higher production costs compared to conventional manufacturing; limited scalability for mass production; requires specialized equipment and expertise for implementation.

Huazhong University of Science & Technology

Technical Solution: Huazhong University of Science & Technology has developed a novel selective laser melting (SLM) approach specifically tailored for high-entropy alloys. Their technology features a customized laser scanning strategy that minimizes thermal gradients and residual stresses during the building process, addressing key challenges in HEA additive manufacturing. The university's research team has pioneered a pre-alloyed powder preparation method that ensures homogeneous element distribution and optimal particle morphology for the SLM process. Their approach incorporates a specialized building platform preheating system that can reach temperatures up to 800°C, significantly reducing crack formation in notoriously difficult-to-print refractory HEAs[8]. The university has successfully demonstrated the fabrication of TiZrNbHfTa and AlCoCrFeNi HEA components with exceptional mechanical properties, including compressive strengths exceeding 2000 MPa while maintaining good ductility. Their process parameters have been optimized through extensive computational modeling and experimental validation, resulting in near-full density parts (>99.8%) with controlled grain structures[9]. The university has also developed specialized post-processing protocols including hot isostatic pressing and heat treatment regimes that further enhance the performance of additively manufactured HEAs.

Strengths: Advanced high-temperature preheating capabilities enabling crack-free fabrication of refractory HEAs; sophisticated laser scanning strategies optimized for complex alloy systems; comprehensive process parameter database for various HEA compositions. Weaknesses: Technology primarily at research scale with limited industrial implementation; higher energy consumption due to extensive preheating requirements; longer processing times compared to conventional manufacturing.

Key Patents and Research Breakthroughs

High entropy alloy member, method for producing alloy member, and product using alloy member

PatentWO2017098848A1

Innovation

- A high-entropy alloy member composed of Co, Cr, Fe, Ni, and Ti, with Mo, processed using powder additive manufacturing, where needle-like crystals are dispersed in a three-dimensional lattice, and the chemical composition is optimized to achieve excellent homogeneity and shape controllability, enabling the production of complex shapes with high mechanical strength and corrosion resistance.

High-entropy alloy, and method for producing the same

PatentActiveUS20200392613A1

Innovation

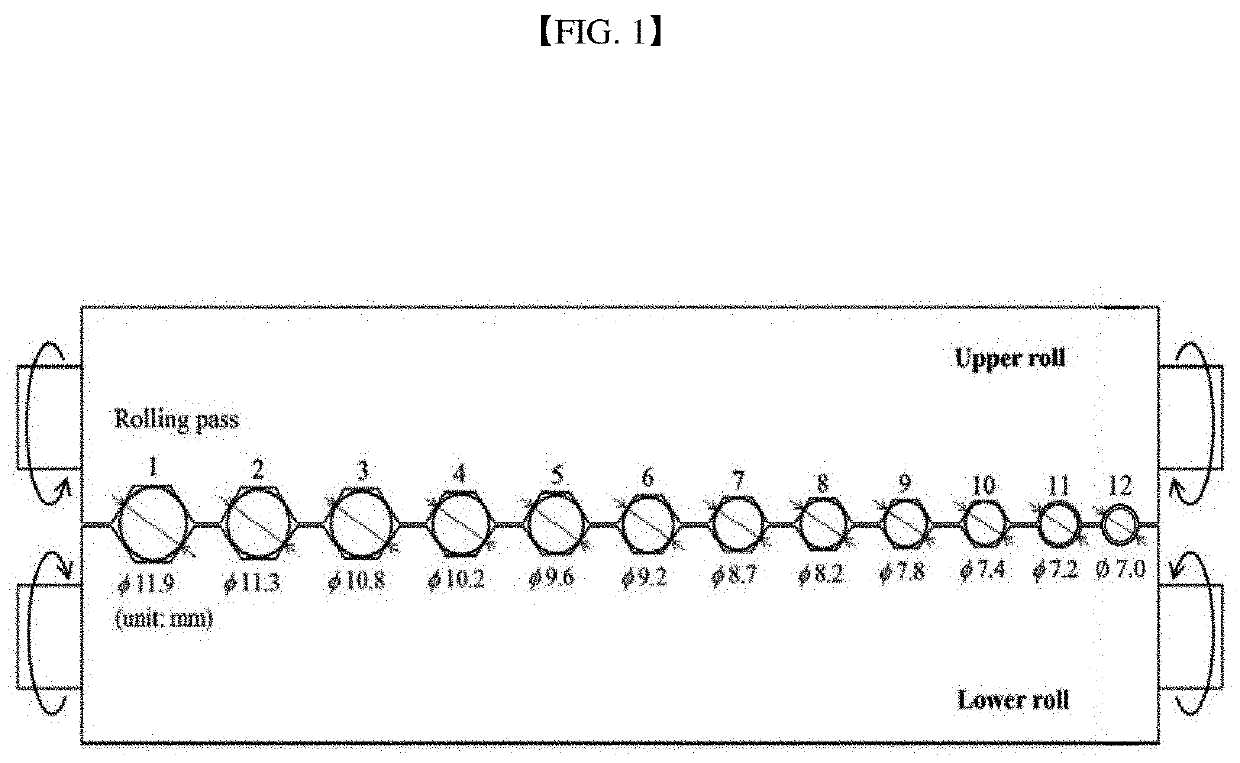

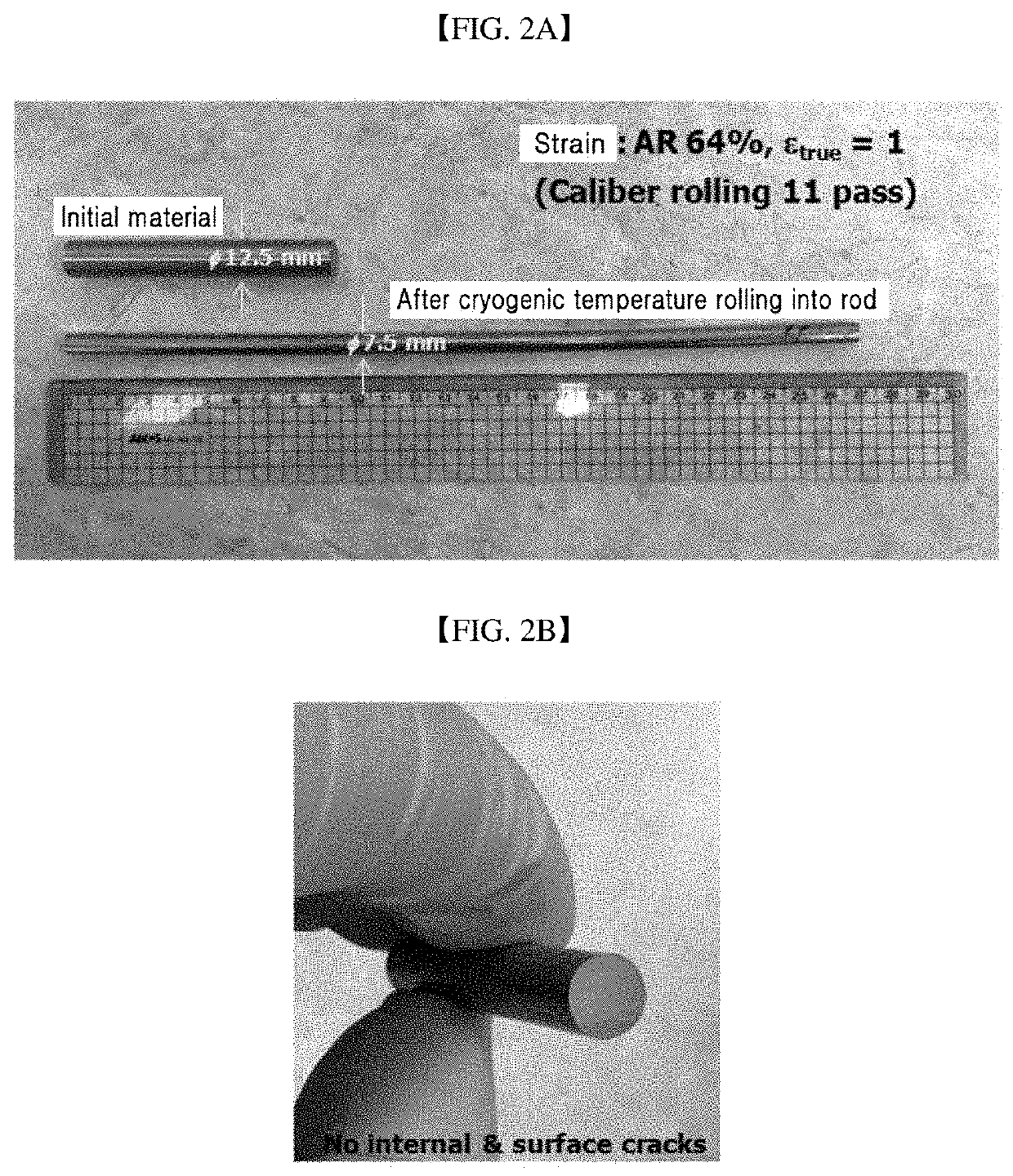

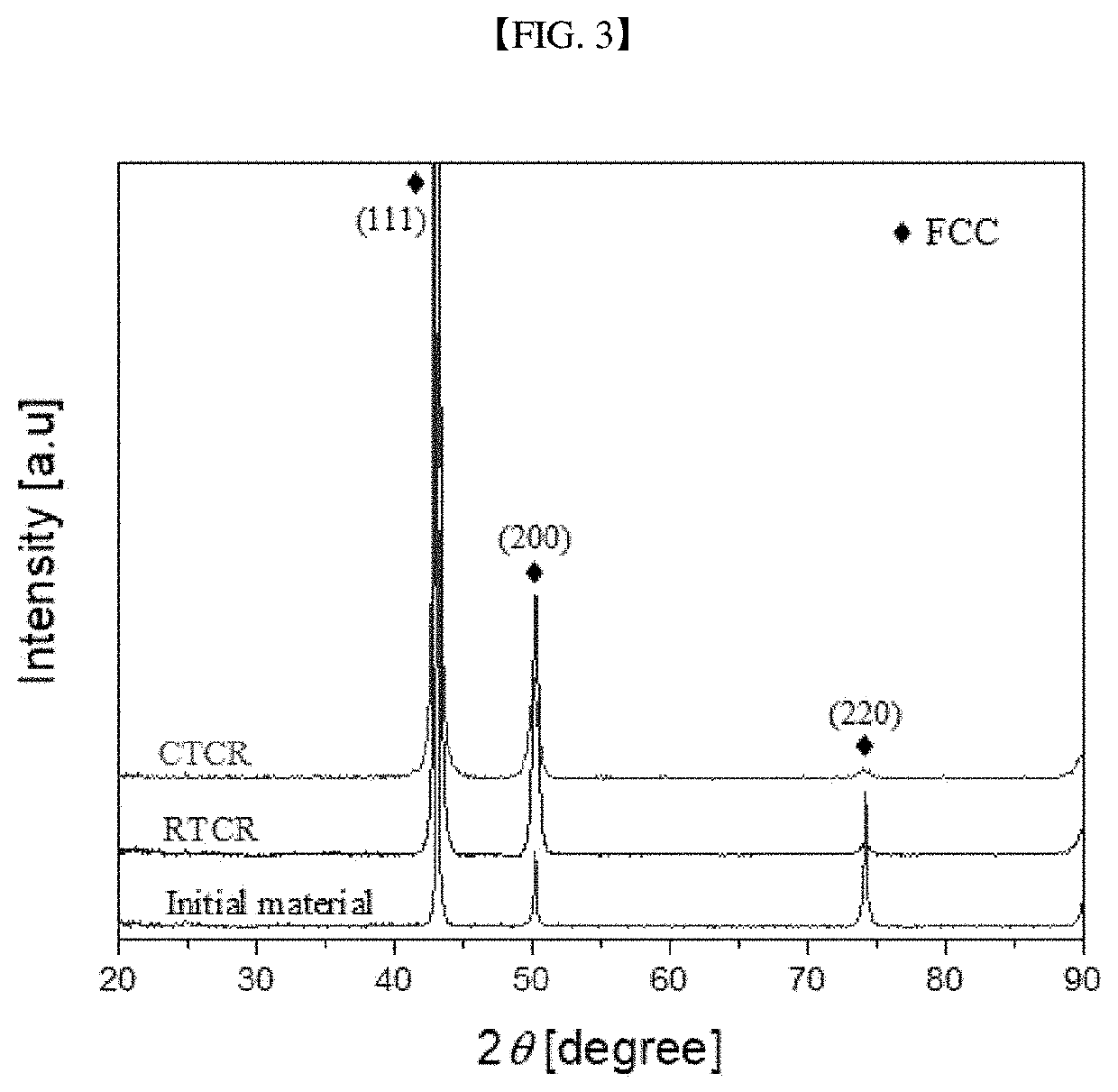

- A method involving annealing and homogenizing an initial alloy containing Co, Cr, Fe, Mn, and Ni, followed by cryogenic temperature rolling with a multi-pass caliber roller to form intersecting twins and secondary fine twins, enhancing grain refinement and hydrogen embrittlement resistance without severe plastic deformation.

Material Characterization Methods

Material characterization methods play a crucial role in understanding the complex microstructures and properties of High-Entropy Alloys (HEAs) in additive manufacturing (AM) processes. These methods enable researchers and engineers to analyze the unique phase formations, elemental distributions, and mechanical behaviors that distinguish HEAs from conventional alloys.

X-ray diffraction (XRD) serves as a fundamental technique for phase identification and crystallographic analysis of HEAs. This method reveals the characteristic multi-phase or single-phase solid solution structures that form during rapid solidification in AM processes. The peak broadening observed in XRD patterns provides valuable information about lattice distortion and residual stresses—phenomena particularly relevant to HEAs due to their severe lattice distortion from multiple principal elements.

Scanning Electron Microscopy (SEM) coupled with Energy Dispersive X-ray Spectroscopy (EDS) enables detailed microstructural examination and elemental mapping of AM-processed HEAs. These techniques are essential for visualizing the unique dendritic structures, segregation patterns, and compositional homogeneity that develop during layer-by-layer fabrication. The high cooling rates in AM processes often result in distinctive microstructures that require nanoscale characterization.

Transmission Electron Microscopy (TEM) provides atomic-level insights into the lattice structures and defects within HEAs. This technique is particularly valuable for identifying nanoprecipitates, dislocations, and stacking faults that contribute to the exceptional mechanical properties of these alloys. TEM analysis helps researchers understand the strengthening mechanisms unique to HEAs in AM processes.

Atom Probe Tomography (APT) offers three-dimensional atomic-scale compositional mapping, critical for analyzing elemental segregation and clustering in HEAs. This technique provides unprecedented insights into the atomic arrangements and local chemical environments that influence phase stability and mechanical behavior in these complex alloy systems.

Mechanical testing methodologies, including nanoindentation, tensile testing, and fatigue testing, are essential for evaluating the performance characteristics of AM-fabricated HEAs. These tests reveal the distinctive combinations of strength, ductility, and hardness that make HEAs promising for advanced applications. The layer-wise nature of AM processes introduces anisotropic properties that require comprehensive mechanical characterization.

Thermal analysis techniques, such as Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), help determine phase transformation temperatures, thermal stability, and oxidation resistance of HEAs. These properties are particularly important for high-temperature applications where HEAs show significant advantages over conventional alloys.

X-ray diffraction (XRD) serves as a fundamental technique for phase identification and crystallographic analysis of HEAs. This method reveals the characteristic multi-phase or single-phase solid solution structures that form during rapid solidification in AM processes. The peak broadening observed in XRD patterns provides valuable information about lattice distortion and residual stresses—phenomena particularly relevant to HEAs due to their severe lattice distortion from multiple principal elements.

Scanning Electron Microscopy (SEM) coupled with Energy Dispersive X-ray Spectroscopy (EDS) enables detailed microstructural examination and elemental mapping of AM-processed HEAs. These techniques are essential for visualizing the unique dendritic structures, segregation patterns, and compositional homogeneity that develop during layer-by-layer fabrication. The high cooling rates in AM processes often result in distinctive microstructures that require nanoscale characterization.

Transmission Electron Microscopy (TEM) provides atomic-level insights into the lattice structures and defects within HEAs. This technique is particularly valuable for identifying nanoprecipitates, dislocations, and stacking faults that contribute to the exceptional mechanical properties of these alloys. TEM analysis helps researchers understand the strengthening mechanisms unique to HEAs in AM processes.

Atom Probe Tomography (APT) offers three-dimensional atomic-scale compositional mapping, critical for analyzing elemental segregation and clustering in HEAs. This technique provides unprecedented insights into the atomic arrangements and local chemical environments that influence phase stability and mechanical behavior in these complex alloy systems.

Mechanical testing methodologies, including nanoindentation, tensile testing, and fatigue testing, are essential for evaluating the performance characteristics of AM-fabricated HEAs. These tests reveal the distinctive combinations of strength, ductility, and hardness that make HEAs promising for advanced applications. The layer-wise nature of AM processes introduces anisotropic properties that require comprehensive mechanical characterization.

Thermal analysis techniques, such as Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), help determine phase transformation temperatures, thermal stability, and oxidation resistance of HEAs. These properties are particularly important for high-temperature applications where HEAs show significant advantages over conventional alloys.

Sustainability Aspects of HEA Production

The sustainability of High-Entropy Alloy (HEA) production through additive manufacturing processes represents a critical consideration in their industrial adoption. When compared to conventional manufacturing methods, additive manufacturing of HEAs demonstrates significant environmental advantages through reduced material waste. The layer-by-layer construction inherent to additive processes typically achieves material utilization rates exceeding 95%, contrasting sharply with traditional subtractive manufacturing where material waste can reach 70-90% for complex components.

Energy consumption patterns in HEA production via additive manufacturing present a nuanced sustainability profile. While the energy intensity during the printing process remains high—particularly for laser and electron beam systems that require 0.3-0.6 kWh per cubic centimeter of material—the overall lifecycle energy footprint often proves favorable. This advantage stems from the elimination of multiple processing steps and transportation between facilities that characterize conventional manufacturing chains.

Carbon emissions associated with HEA production vary considerably depending on the specific manufacturing approach. Recent life cycle assessments indicate that powder bed fusion techniques for HEA components can reduce carbon emissions by 25-40% compared to traditional casting and machining processes, primarily due to localized production capabilities and optimized material usage.

Resource conservation extends beyond direct material savings. The ability to recycle and reuse unmelted metal powders in subsequent builds represents a significant sustainability advantage, with recovery rates typically reaching 95-98% for well-managed additive manufacturing operations. Furthermore, the extended service life of HEA components—owing to their superior mechanical properties and corrosion resistance—contributes to reduced replacement frequency and associated resource demands.

Water usage in HEA additive manufacturing processes remains substantially lower than conventional methods. While traditional metallurgical processes may require 50-200 liters of water per kilogram of finished product for cooling and cleaning operations, additive manufacturing systems typically consume less than 10 liters per kilogram, representing an 80-95% reduction in water footprint.

Supply chain sustainability benefits emerge through localized production capabilities, reducing transportation-related environmental impacts. The digital nature of additive manufacturing enables on-demand production closer to points of use, potentially eliminating extensive warehousing requirements and associated energy consumption for climate control and logistics.

Energy consumption patterns in HEA production via additive manufacturing present a nuanced sustainability profile. While the energy intensity during the printing process remains high—particularly for laser and electron beam systems that require 0.3-0.6 kWh per cubic centimeter of material—the overall lifecycle energy footprint often proves favorable. This advantage stems from the elimination of multiple processing steps and transportation between facilities that characterize conventional manufacturing chains.

Carbon emissions associated with HEA production vary considerably depending on the specific manufacturing approach. Recent life cycle assessments indicate that powder bed fusion techniques for HEA components can reduce carbon emissions by 25-40% compared to traditional casting and machining processes, primarily due to localized production capabilities and optimized material usage.

Resource conservation extends beyond direct material savings. The ability to recycle and reuse unmelted metal powders in subsequent builds represents a significant sustainability advantage, with recovery rates typically reaching 95-98% for well-managed additive manufacturing operations. Furthermore, the extended service life of HEA components—owing to their superior mechanical properties and corrosion resistance—contributes to reduced replacement frequency and associated resource demands.

Water usage in HEA additive manufacturing processes remains substantially lower than conventional methods. While traditional metallurgical processes may require 50-200 liters of water per kilogram of finished product for cooling and cleaning operations, additive manufacturing systems typically consume less than 10 liters per kilogram, representing an 80-95% reduction in water footprint.

Supply chain sustainability benefits emerge through localized production capabilities, reducing transportation-related environmental impacts. The digital nature of additive manufacturing enables on-demand production closer to points of use, potentially eliminating extensive warehousing requirements and associated energy consumption for climate control and logistics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!