How Advances in Electrolytic Cell Technology Affect Energy Policy

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Cell Tech Evolution and Objectives

Electrolytic cell technology has undergone significant evolution since its inception in the early 19th century. The fundamental principle of using electricity to drive chemical reactions has remained constant, but the efficiency, scale, and applications of this technology have expanded dramatically. Initially used for small-scale metal production and electroplating, electrolytic cells have become integral to various industrial processes, including large-scale metal refining, chlor-alkali production, and water treatment.

The development of more advanced electrode materials and cell designs has been a key driver in the progress of electrolytic cell technology. Early cells used simple carbon or metal electrodes, while modern cells employ sophisticated materials such as dimensionally stable anodes (DSA) and membrane electrode assemblies (MEA). These advancements have led to significant improvements in energy efficiency, reaction selectivity, and overall process economics.

In recent years, the focus of electrolytic cell technology has shifted towards addressing global energy and environmental challenges. The rise of renewable energy sources has created a need for efficient energy storage solutions, propelling research into electrolytic hydrogen production as a means of storing excess renewable energy. Additionally, the growing concern over carbon emissions has sparked interest in using electrolytic cells for carbon dioxide reduction, potentially offering a pathway to produce valuable chemicals and fuels from waste CO2.

The objectives of current electrolytic cell technology research are multifaceted. Primarily, there is a push to further improve energy efficiency, as electricity consumption remains a significant cost factor in many electrolytic processes. This involves developing new catalysts, optimizing cell geometries, and exploring novel electrolyte compositions. Another key objective is to enhance the durability and longevity of cell components, particularly in harsh operating conditions, to reduce maintenance costs and downtime.

Scalability is another critical goal, especially for emerging applications like green hydrogen production and CO2 electrolysis. Researchers are working on designs that can be easily scaled up from laboratory prototypes to industrial-scale operations without losing efficiency or increasing costs prohibitively. Furthermore, there is a growing emphasis on developing electrolytic technologies that can operate flexibly, adapting to the variable output of renewable energy sources.

As electrolytic cell technology continues to advance, its impact on energy policy becomes increasingly significant. The potential for large-scale energy storage through hydrogen production, coupled with the possibility of carbon-neutral fuel synthesis, positions this technology as a key enabler of the transition to a sustainable energy future. Consequently, research and development in this field are likely to play a crucial role in shaping energy policies worldwide, influencing decisions on infrastructure investment, renewable energy integration, and industrial decarbonization strategies.

The development of more advanced electrode materials and cell designs has been a key driver in the progress of electrolytic cell technology. Early cells used simple carbon or metal electrodes, while modern cells employ sophisticated materials such as dimensionally stable anodes (DSA) and membrane electrode assemblies (MEA). These advancements have led to significant improvements in energy efficiency, reaction selectivity, and overall process economics.

In recent years, the focus of electrolytic cell technology has shifted towards addressing global energy and environmental challenges. The rise of renewable energy sources has created a need for efficient energy storage solutions, propelling research into electrolytic hydrogen production as a means of storing excess renewable energy. Additionally, the growing concern over carbon emissions has sparked interest in using electrolytic cells for carbon dioxide reduction, potentially offering a pathway to produce valuable chemicals and fuels from waste CO2.

The objectives of current electrolytic cell technology research are multifaceted. Primarily, there is a push to further improve energy efficiency, as electricity consumption remains a significant cost factor in many electrolytic processes. This involves developing new catalysts, optimizing cell geometries, and exploring novel electrolyte compositions. Another key objective is to enhance the durability and longevity of cell components, particularly in harsh operating conditions, to reduce maintenance costs and downtime.

Scalability is another critical goal, especially for emerging applications like green hydrogen production and CO2 electrolysis. Researchers are working on designs that can be easily scaled up from laboratory prototypes to industrial-scale operations without losing efficiency or increasing costs prohibitively. Furthermore, there is a growing emphasis on developing electrolytic technologies that can operate flexibly, adapting to the variable output of renewable energy sources.

As electrolytic cell technology continues to advance, its impact on energy policy becomes increasingly significant. The potential for large-scale energy storage through hydrogen production, coupled with the possibility of carbon-neutral fuel synthesis, positions this technology as a key enabler of the transition to a sustainable energy future. Consequently, research and development in this field are likely to play a crucial role in shaping energy policies worldwide, influencing decisions on infrastructure investment, renewable energy integration, and industrial decarbonization strategies.

Energy Market Demand Analysis

The global energy market is experiencing a significant shift towards cleaner and more sustainable sources, driven by increasing environmental concerns and the need for energy security. Advances in electrolytic cell technology are playing a crucial role in this transition, particularly in the areas of hydrogen production and energy storage. The demand for these technologies is rapidly growing as countries and industries seek to decarbonize their energy systems and meet ambitious climate targets.

In the hydrogen sector, the market for electrolyzers is projected to expand dramatically in the coming years. Green hydrogen, produced through electrolysis powered by renewable energy, is seen as a key component in achieving net-zero emissions across various industries. Major economies, including the European Union, Japan, and South Korea, have announced substantial investments in hydrogen infrastructure, creating a robust market for advanced electrolytic cell technologies.

The energy storage market is another area where electrolytic cell technology is gaining traction. As the share of intermittent renewable energy sources in the power mix increases, there is a growing need for efficient and large-scale energy storage solutions. Flow batteries, which utilize electrolytic cells, are emerging as a promising option for grid-scale storage, complementing lithium-ion batteries in longer-duration applications.

Industrial sectors, particularly steel and chemical manufacturing, are also driving demand for electrolytic cell technology. These industries are exploring ways to reduce their carbon footprint by incorporating green hydrogen and electrolysis-based processes into their operations. This shift is creating new market opportunities for advanced electrolytic cell technologies that can operate at higher efficiencies and larger scales.

The transportation sector represents another significant market for electrolytic cell technology, especially in the context of fuel cell electric vehicles (FCEVs). While battery electric vehicles currently dominate the electric vehicle market, FCEVs are gaining attention for long-haul and heavy-duty applications where battery weight and charging times are limiting factors. The growth of the FCEV market is expected to drive demand for more efficient and cost-effective electrolysis technologies for hydrogen production.

As governments worldwide implement stricter emissions regulations and carbon pricing mechanisms, the economic case for electrolytic cell technologies is strengthening. This regulatory environment is creating a favorable market landscape for innovations in electrolysis, encouraging investment and accelerating the commercialization of advanced technologies. The market is responding with increased research and development efforts, aiming to improve the efficiency, durability, and cost-effectiveness of electrolytic cells.

In the hydrogen sector, the market for electrolyzers is projected to expand dramatically in the coming years. Green hydrogen, produced through electrolysis powered by renewable energy, is seen as a key component in achieving net-zero emissions across various industries. Major economies, including the European Union, Japan, and South Korea, have announced substantial investments in hydrogen infrastructure, creating a robust market for advanced electrolytic cell technologies.

The energy storage market is another area where electrolytic cell technology is gaining traction. As the share of intermittent renewable energy sources in the power mix increases, there is a growing need for efficient and large-scale energy storage solutions. Flow batteries, which utilize electrolytic cells, are emerging as a promising option for grid-scale storage, complementing lithium-ion batteries in longer-duration applications.

Industrial sectors, particularly steel and chemical manufacturing, are also driving demand for electrolytic cell technology. These industries are exploring ways to reduce their carbon footprint by incorporating green hydrogen and electrolysis-based processes into their operations. This shift is creating new market opportunities for advanced electrolytic cell technologies that can operate at higher efficiencies and larger scales.

The transportation sector represents another significant market for electrolytic cell technology, especially in the context of fuel cell electric vehicles (FCEVs). While battery electric vehicles currently dominate the electric vehicle market, FCEVs are gaining attention for long-haul and heavy-duty applications where battery weight and charging times are limiting factors. The growth of the FCEV market is expected to drive demand for more efficient and cost-effective electrolysis technologies for hydrogen production.

As governments worldwide implement stricter emissions regulations and carbon pricing mechanisms, the economic case for electrolytic cell technologies is strengthening. This regulatory environment is creating a favorable market landscape for innovations in electrolysis, encouraging investment and accelerating the commercialization of advanced technologies. The market is responding with increased research and development efforts, aiming to improve the efficiency, durability, and cost-effectiveness of electrolytic cells.

Current Electrolytic Cell Tech Challenges

Electrolytic cell technology, while promising significant advancements in energy production and storage, currently faces several critical challenges that impede its widespread adoption and efficiency. One of the primary obstacles is the high energy consumption required for the electrolysis process. This energy-intensive nature limits the overall efficiency and cost-effectiveness of electrolytic cells, particularly in large-scale applications.

Material degradation presents another significant hurdle. The harsh chemical environment within electrolytic cells leads to corrosion and wear of electrodes and other components, reducing their lifespan and increasing maintenance costs. This issue is particularly pronounced in high-temperature electrolysis systems, where material stability becomes even more critical.

The scalability of electrolytic cell technology also remains a challenge. While small-scale applications have shown promise, scaling up to industrial levels introduces complexities in system design, heat management, and overall efficiency. The integration of large-scale electrolytic systems into existing energy infrastructures poses both technical and logistical challenges.

Electrode design and optimization continue to be areas of intense research and development. Current electrode materials often struggle to balance efficiency, durability, and cost-effectiveness. The search for novel electrode materials that can withstand harsh conditions while maintaining high catalytic activity is ongoing.

Another significant challenge lies in the production and handling of hydrogen, especially in alkaline electrolysis. Safety concerns related to hydrogen storage and transportation need to be addressed to enable widespread adoption of hydrogen as an energy carrier produced through electrolysis.

The intermittent nature of renewable energy sources poses challenges for electrolytic systems designed to work in conjunction with these power sources. Developing electrolytic cells that can operate efficiently under variable power inputs remains a technical hurdle.

Lastly, the economic viability of electrolytic cell technology in comparison to traditional energy sources and other emerging technologies is a persistent challenge. The high capital costs associated with electrolytic systems, coupled with operational expenses, currently limit their competitiveness in many energy markets.

Addressing these challenges requires a multidisciplinary approach, combining advancements in materials science, electrochemistry, and system engineering. As research progresses, overcoming these obstacles will be crucial in realizing the full potential of electrolytic cell technology and its impact on energy policies worldwide.

Material degradation presents another significant hurdle. The harsh chemical environment within electrolytic cells leads to corrosion and wear of electrodes and other components, reducing their lifespan and increasing maintenance costs. This issue is particularly pronounced in high-temperature electrolysis systems, where material stability becomes even more critical.

The scalability of electrolytic cell technology also remains a challenge. While small-scale applications have shown promise, scaling up to industrial levels introduces complexities in system design, heat management, and overall efficiency. The integration of large-scale electrolytic systems into existing energy infrastructures poses both technical and logistical challenges.

Electrode design and optimization continue to be areas of intense research and development. Current electrode materials often struggle to balance efficiency, durability, and cost-effectiveness. The search for novel electrode materials that can withstand harsh conditions while maintaining high catalytic activity is ongoing.

Another significant challenge lies in the production and handling of hydrogen, especially in alkaline electrolysis. Safety concerns related to hydrogen storage and transportation need to be addressed to enable widespread adoption of hydrogen as an energy carrier produced through electrolysis.

The intermittent nature of renewable energy sources poses challenges for electrolytic systems designed to work in conjunction with these power sources. Developing electrolytic cells that can operate efficiently under variable power inputs remains a technical hurdle.

Lastly, the economic viability of electrolytic cell technology in comparison to traditional energy sources and other emerging technologies is a persistent challenge. The high capital costs associated with electrolytic systems, coupled with operational expenses, currently limit their competitiveness in many energy markets.

Addressing these challenges requires a multidisciplinary approach, combining advancements in materials science, electrochemistry, and system engineering. As research progresses, overcoming these obstacles will be crucial in realizing the full potential of electrolytic cell technology and its impact on energy policies worldwide.

State-of-the-Art Electrolytic Cell Solutions

01 Electrode materials and configurations

Advanced electrode materials and configurations are crucial for improving the efficiency and performance of electrolytic cells. This includes the development of novel electrode compositions, structures, and coatings to enhance conductivity, durability, and catalytic activity. Optimized electrode designs can significantly impact the overall cell performance and energy consumption.- Electrode materials and configurations: Advanced electrode materials and configurations are crucial for improving the efficiency and performance of electrolytic cells. This includes the development of novel electrode materials, coatings, and structures that enhance conductivity, durability, and catalytic activity. Optimized electrode designs can significantly impact the overall efficiency of electrolysis processes.

- Membrane technology: Innovative membrane technologies play a vital role in electrolytic cell performance. These membranes are designed to selectively allow the passage of specific ions while preventing the mixing of products. Advancements in membrane materials and structures can lead to improved efficiency, reduced energy consumption, and enhanced product purity in various electrolytic processes.

- Electrolyte composition and management: The composition and management of electrolytes are critical factors in electrolytic cell technology. This includes developing and optimizing electrolyte formulations, maintaining proper electrolyte concentrations, and managing temperature and pH levels. Effective electrolyte management can lead to improved cell performance, longer operational lifetimes, and reduced maintenance requirements.

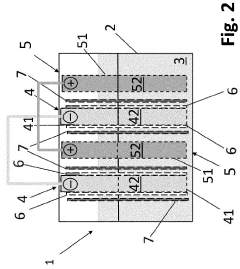

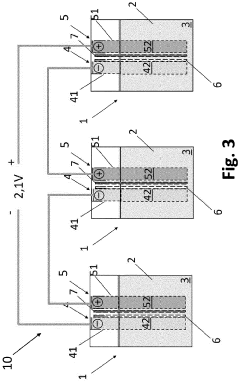

- Cell design and scaling: Advancements in electrolytic cell design and scaling techniques are essential for industrial applications. This involves optimizing cell geometry, flow patterns, and heat management to enhance efficiency and productivity. Innovative approaches to cell design and scaling can lead to improved performance in large-scale electrolysis operations across various industries.

- Process control and monitoring systems: Sophisticated process control and monitoring systems are crucial for optimizing electrolytic cell performance. These systems involve advanced sensors, data analytics, and automation technologies to maintain optimal operating conditions, detect anomalies, and adjust parameters in real-time. Implementing such systems can lead to improved efficiency, product quality, and operational safety in electrolytic processes.

02 Membrane technology

Innovative membrane technologies play a vital role in electrolytic cell performance. This involves the development of ion-selective membranes, composite membranes, and membrane electrode assemblies. Advanced membranes can improve ion transport, reduce resistance, and enhance the overall efficiency of electrolytic processes.Expand Specific Solutions03 Electrolyte composition and management

Optimizing electrolyte composition and management is essential for electrolytic cell technology. This includes developing novel electrolyte formulations, additives, and circulation systems to enhance conductivity, stability, and reaction kinetics. Proper electrolyte management can significantly impact cell performance and longevity.Expand Specific Solutions04 Cell design and scaling

Advancements in cell design and scaling are crucial for industrial applications of electrolytic technology. This involves optimizing cell geometry, flow patterns, and heat management to improve efficiency and productivity. Innovative approaches to cell stacking and modular designs enable better scalability for large-scale operations.Expand Specific Solutions05 Process control and monitoring

Implementing advanced process control and monitoring systems is essential for optimizing electrolytic cell performance. This includes the development of sensors, real-time data analysis, and intelligent control algorithms to maintain optimal operating conditions. Improved monitoring and control can lead to enhanced efficiency, product quality, and operational safety.Expand Specific Solutions

Key Players in Electrolytic Cell Industry

The electrolytic cell technology market is in a growth phase, driven by increasing demand for clean energy solutions and hydrogen production. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, advancements are occurring at a rapid pace, with companies like Umicore SA, Siemens Energy, and Mitsubishi Power leading innovation. These firms are developing more efficient and cost-effective electrolytic cell technologies, focusing on improving catalysts, membranes, and overall system design. Academic institutions such as Xi'an Jiaotong University and École Polytechnique Fédérale de Lausanne are also contributing to technological progress through research collaborations with industry partners.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed advanced electrolytic cell technology for green hydrogen production. Their Silyzer 300 system uses proton exchange membrane (PEM) electrolysis to achieve high efficiency and dynamic operation[1]. The system can produce up to 2,000 kg of hydrogen per day with an electrical efficiency of up to 75%[2]. Siemens Energy is also working on integrating electrolyzers with renewable energy sources to create a more sustainable energy ecosystem. Their technology allows for rapid response times, enabling the balancing of fluctuating power supply from wind and solar sources[3].

Strengths: High efficiency, scalability, and integration with renewable energy. Weaknesses: High initial investment costs and dependence on the availability of low-cost renewable electricity.

Ludao Hydrogen Energy (Xiamen) Technology Co., Ltd.

Technical Solution: Ludao Hydrogen Energy focuses on developing and manufacturing alkaline electrolyzers for hydrogen production. Their technology utilizes a zero-gap electrode structure and advanced catalysts to improve efficiency and reduce energy consumption[4]. The company's electrolyzers can achieve a hydrogen production efficiency of over 75% with a power consumption of less than 4.3 kWh/Nm³ H₂[5]. Ludao's systems are designed for scalability, ranging from small-scale applications to large industrial plants capable of producing several tons of hydrogen per day.

Strengths: Cost-effective alkaline technology, high efficiency, and scalability. Weaknesses: Lower purity of hydrogen compared to PEM technology and slower response times to load changes.

Breakthrough Electrolytic Cell Patents

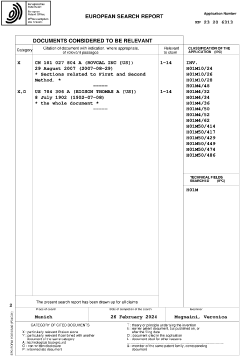

Electrolysis system and method with a high electrical energy transformation rate

PatentWO2018032120A1

Innovation

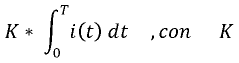

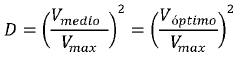

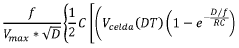

- An improved electrolysis system and method that utilizes a pulsating current with optimized amplitude, frequency, and duration to maximize electrical efficiency by modeling the electrolytic cell as a capacitive, inductive, and resistive system, operating in transient regimes to reduce energy consumption and enhance the separation of hydrogen and oxygen production.

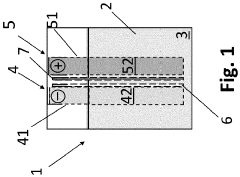

Improved electrolytic cell

PatentInactiveEP4362165A1

Innovation

- An electrolytic cell design featuring a copper oxide or metallic copper negative electrode, a nickel hydroxide-based positive electrode, and a semi-permeable polymer membrane that allows OH- and H+ ions to pass through, preventing copper hydroxide leakage and using a stable alkaline electrolyte solution with additives like lithium hydroxide and borate to enhance performance.

Energy Policy Implications

Advancements in electrolytic cell technology have significant implications for energy policy, influencing the direction and implementation of sustainable energy strategies worldwide. These technological improvements are reshaping the landscape of energy production, storage, and distribution, necessitating a reevaluation of existing policies and the development of new frameworks to support emerging technologies.

The increased efficiency and reduced costs associated with modern electrolytic cells are driving a shift towards hydrogen as a clean energy carrier. This trend is prompting policymakers to consider hydrogen-centric energy policies, including incentives for green hydrogen production and infrastructure development. As electrolysis becomes more economically viable, governments are exploring ways to integrate hydrogen into their renewable energy portfolios and decarbonization plans.

Energy storage policies are also being influenced by electrolytic cell advancements. The ability to convert excess renewable energy into hydrogen through electrolysis is encouraging the development of policies that support large-scale energy storage solutions. This includes regulatory frameworks for power-to-gas technologies and the repurposing of existing natural gas infrastructure for hydrogen transport and storage.

The potential for decentralized energy production through small-scale electrolyzers is prompting a reconsideration of grid management policies. Policymakers are exploring regulations that allow for greater flexibility in energy distribution and peer-to-peer energy trading, potentially leading to more resilient and adaptable energy systems.

Environmental policies are being updated to reflect the reduced carbon footprint of advanced electrolytic processes. This includes revisions to carbon pricing mechanisms and emissions trading schemes to account for the lower environmental impact of hydrogen produced through clean electrolysis. Additionally, policies are being developed to ensure the sustainable sourcing of materials used in electrolytic cell manufacturing.

International cooperation in energy policy is being influenced by the global nature of hydrogen markets. Countries are forming alliances and developing joint strategies to establish hydrogen supply chains, harmonize standards, and create a global market for clean hydrogen. This is leading to new trade agreements and cross-border energy policies focused on hydrogen as a commodity.

As electrolytic cell technology continues to advance, energy policies are evolving to create a supportive ecosystem for innovation. This includes increased funding for research and development, policies to facilitate technology transfer, and educational initiatives to build the workforce needed for a hydrogen-based economy. The dynamic nature of these technological advancements requires flexible and adaptive policy frameworks that can keep pace with rapid changes in the field.

The increased efficiency and reduced costs associated with modern electrolytic cells are driving a shift towards hydrogen as a clean energy carrier. This trend is prompting policymakers to consider hydrogen-centric energy policies, including incentives for green hydrogen production and infrastructure development. As electrolysis becomes more economically viable, governments are exploring ways to integrate hydrogen into their renewable energy portfolios and decarbonization plans.

Energy storage policies are also being influenced by electrolytic cell advancements. The ability to convert excess renewable energy into hydrogen through electrolysis is encouraging the development of policies that support large-scale energy storage solutions. This includes regulatory frameworks for power-to-gas technologies and the repurposing of existing natural gas infrastructure for hydrogen transport and storage.

The potential for decentralized energy production through small-scale electrolyzers is prompting a reconsideration of grid management policies. Policymakers are exploring regulations that allow for greater flexibility in energy distribution and peer-to-peer energy trading, potentially leading to more resilient and adaptable energy systems.

Environmental policies are being updated to reflect the reduced carbon footprint of advanced electrolytic processes. This includes revisions to carbon pricing mechanisms and emissions trading schemes to account for the lower environmental impact of hydrogen produced through clean electrolysis. Additionally, policies are being developed to ensure the sustainable sourcing of materials used in electrolytic cell manufacturing.

International cooperation in energy policy is being influenced by the global nature of hydrogen markets. Countries are forming alliances and developing joint strategies to establish hydrogen supply chains, harmonize standards, and create a global market for clean hydrogen. This is leading to new trade agreements and cross-border energy policies focused on hydrogen as a commodity.

As electrolytic cell technology continues to advance, energy policies are evolving to create a supportive ecosystem for innovation. This includes increased funding for research and development, policies to facilitate technology transfer, and educational initiatives to build the workforce needed for a hydrogen-based economy. The dynamic nature of these technological advancements requires flexible and adaptive policy frameworks that can keep pace with rapid changes in the field.

Environmental Impact Assessment

The environmental impact of advances in electrolytic cell technology is a critical consideration in shaping energy policies. As these technologies evolve, they offer potential benefits in terms of energy efficiency and reduced emissions, but also pose challenges that must be carefully assessed.

Electrolytic cells are increasingly being used in various industrial processes, including the production of hydrogen, which is seen as a promising clean energy carrier. The improved efficiency of these cells can lead to reduced energy consumption and lower greenhouse gas emissions compared to traditional fossil fuel-based processes. This aligns with global efforts to mitigate climate change and transition towards cleaner energy sources.

However, the widespread adoption of electrolytic cell technology also raises concerns about resource consumption. The production of electrodes and other components often requires rare earth elements and precious metals, which can lead to increased mining activities and associated environmental degradation. Policymakers must consider the full lifecycle impact of these technologies, including the extraction of raw materials and end-of-life disposal or recycling.

Water usage is another significant environmental factor. While some electrolytic processes can be designed to recycle water, others may require substantial freshwater inputs. In regions facing water scarcity, this could exacerbate existing environmental stresses and compete with other essential water needs.

The disposal of spent electrolytes and byproducts from electrolytic processes also presents environmental challenges. Some of these substances can be hazardous and require specialized treatment or disposal methods. Energy policies must address the management of these waste streams to prevent soil and water contamination.

On the positive side, advancements in electrolytic cell technology could contribute to grid stability and the integration of renewable energy sources. By enabling efficient energy storage through hydrogen production or other means, these technologies can help balance the intermittent nature of wind and solar power, potentially reducing the need for fossil fuel-based backup generation.

As policymakers consider the role of electrolytic cell technology in future energy systems, they must weigh these environmental impacts against the potential benefits. Comprehensive life cycle assessments and environmental impact studies should inform policy decisions, ensuring that the pursuit of cleaner energy does not come at the cost of other environmental objectives. Policies may need to incentivize research into more sustainable materials and processes for electrolytic cells, as well as promote best practices for their deployment and operation to minimize negative environmental impacts.

Electrolytic cells are increasingly being used in various industrial processes, including the production of hydrogen, which is seen as a promising clean energy carrier. The improved efficiency of these cells can lead to reduced energy consumption and lower greenhouse gas emissions compared to traditional fossil fuel-based processes. This aligns with global efforts to mitigate climate change and transition towards cleaner energy sources.

However, the widespread adoption of electrolytic cell technology also raises concerns about resource consumption. The production of electrodes and other components often requires rare earth elements and precious metals, which can lead to increased mining activities and associated environmental degradation. Policymakers must consider the full lifecycle impact of these technologies, including the extraction of raw materials and end-of-life disposal or recycling.

Water usage is another significant environmental factor. While some electrolytic processes can be designed to recycle water, others may require substantial freshwater inputs. In regions facing water scarcity, this could exacerbate existing environmental stresses and compete with other essential water needs.

The disposal of spent electrolytes and byproducts from electrolytic processes also presents environmental challenges. Some of these substances can be hazardous and require specialized treatment or disposal methods. Energy policies must address the management of these waste streams to prevent soil and water contamination.

On the positive side, advancements in electrolytic cell technology could contribute to grid stability and the integration of renewable energy sources. By enabling efficient energy storage through hydrogen production or other means, these technologies can help balance the intermittent nature of wind and solar power, potentially reducing the need for fossil fuel-based backup generation.

As policymakers consider the role of electrolytic cell technology in future energy systems, they must weigh these environmental impacts against the potential benefits. Comprehensive life cycle assessments and environmental impact studies should inform policy decisions, ensuring that the pursuit of cleaner energy does not come at the cost of other environmental objectives. Policies may need to incentivize research into more sustainable materials and processes for electrolytic cells, as well as promote best practices for their deployment and operation to minimize negative environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!