How Electrospinning Affects the Porosity of Filter Media

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrospinning Technology Background and Objectives

Electrospinning technology has evolved significantly since its inception in the early 20th century, with the first patent filed by J.F. Cooley in 1902. However, it wasn't until the 1990s that this technology gained substantial research attention, primarily driven by the growing demand for advanced filtration solutions across multiple industries. The fundamental principle of electrospinning involves applying high voltage to a polymer solution or melt, creating an electrically charged jet that solidifies into ultra-fine fibers with diameters ranging from nanometers to micrometers.

The evolution of electrospinning has been marked by several technological breakthroughs, including the development of multi-jet systems, coaxial electrospinning, and melt electrospinning techniques. These advancements have significantly expanded the range of materials that can be processed and the structural complexity that can be achieved in the resulting filter media. The technology has progressed from simple single-needle setups to sophisticated industrial-scale production systems capable of manufacturing filter media with precisely controlled porosity characteristics.

Current technological trends in electrospinning focus on enhancing process control, improving fiber uniformity, and developing novel composite materials. Recent innovations include the integration of artificial intelligence for real-time process optimization and the development of green electrospinning techniques that utilize environmentally friendly solvents and biodegradable polymers. These developments align with the growing emphasis on sustainability in manufacturing processes and end products.

The primary objective of electrospinning technology in filter media production is to create highly porous structures with interconnected pores of controlled size distribution. This controlled porosity directly influences critical filtration parameters such as permeability, particle capture efficiency, and pressure drop. By manipulating electrospinning parameters—including solution viscosity, applied voltage, flow rate, and collector distance—researchers and manufacturers can tailor the porosity characteristics to meet specific filtration requirements.

Another key objective is to enhance the functional properties of filter media through the incorporation of active agents such as antimicrobial compounds, catalysts, or adsorbents into the electrospun fibers. This multifunctionality represents a significant advancement over conventional filter media, enabling simultaneous filtration and decontamination processes. The ultimate goal is to develop next-generation filter media with superior performance, extended service life, and reduced environmental footprint.

Looking forward, electrospinning technology aims to bridge the gap between laboratory research and industrial-scale production, addressing challenges related to process scalability, cost-effectiveness, and quality consistency. The technology is expected to play a pivotal role in addressing global challenges such as water scarcity, air pollution, and healthcare-associated infections through innovative filtration solutions.

The evolution of electrospinning has been marked by several technological breakthroughs, including the development of multi-jet systems, coaxial electrospinning, and melt electrospinning techniques. These advancements have significantly expanded the range of materials that can be processed and the structural complexity that can be achieved in the resulting filter media. The technology has progressed from simple single-needle setups to sophisticated industrial-scale production systems capable of manufacturing filter media with precisely controlled porosity characteristics.

Current technological trends in electrospinning focus on enhancing process control, improving fiber uniformity, and developing novel composite materials. Recent innovations include the integration of artificial intelligence for real-time process optimization and the development of green electrospinning techniques that utilize environmentally friendly solvents and biodegradable polymers. These developments align with the growing emphasis on sustainability in manufacturing processes and end products.

The primary objective of electrospinning technology in filter media production is to create highly porous structures with interconnected pores of controlled size distribution. This controlled porosity directly influences critical filtration parameters such as permeability, particle capture efficiency, and pressure drop. By manipulating electrospinning parameters—including solution viscosity, applied voltage, flow rate, and collector distance—researchers and manufacturers can tailor the porosity characteristics to meet specific filtration requirements.

Another key objective is to enhance the functional properties of filter media through the incorporation of active agents such as antimicrobial compounds, catalysts, or adsorbents into the electrospun fibers. This multifunctionality represents a significant advancement over conventional filter media, enabling simultaneous filtration and decontamination processes. The ultimate goal is to develop next-generation filter media with superior performance, extended service life, and reduced environmental footprint.

Looking forward, electrospinning technology aims to bridge the gap between laboratory research and industrial-scale production, addressing challenges related to process scalability, cost-effectiveness, and quality consistency. The technology is expected to play a pivotal role in addressing global challenges such as water scarcity, air pollution, and healthcare-associated infections through innovative filtration solutions.

Market Analysis of High-Porosity Filter Media

The global high-porosity filter media market has experienced significant growth in recent years, driven by increasing environmental regulations, growing industrial applications, and heightened awareness of air and water quality. The market was valued at approximately 5.7 billion USD in 2022 and is projected to reach 8.9 billion USD by 2028, representing a compound annual growth rate (CAGR) of 7.6%.

Electrospinning technology has emerged as a key innovation driver in this sector, enabling the production of filter media with unprecedented porosity characteristics. This has opened new market segments, particularly in high-efficiency particulate air (HEPA) and ultra-low particulate air (ULPA) filtration systems, which are experiencing demand growth rates exceeding 9% annually.

The healthcare sector represents the largest end-user segment for high-porosity filter media, accounting for roughly 32% of the market share. This is primarily due to stringent cleanliness requirements in medical facilities and pharmaceutical manufacturing. The COVID-19 pandemic significantly accelerated this trend, with demand for high-porosity filters in healthcare settings increasing by over 200% during 2020-2021.

Industrial applications follow closely, comprising approximately 28% of the market. Here, electrospun high-porosity filters are increasingly adopted in semiconductor manufacturing, food processing, and chemical industries where contamination control is critical. The automotive sector, particularly with the rise of electric vehicles requiring specialized filtration systems, has also emerged as a rapidly growing segment with 11% market share.

Geographically, North America and Europe currently dominate the high-porosity filter media market, collectively accounting for 58% of global revenue. However, the Asia-Pacific region is witnessing the fastest growth rate at 10.2% annually, driven by rapid industrialization, increasing environmental regulations, and growing healthcare infrastructure in countries like China, India, and South Korea.

Consumer awareness regarding indoor air quality has created a robust residential market segment, currently valued at approximately 1.2 billion USD. This segment is expected to grow at 8.3% annually as electrospun filter technologies become more affordable for household applications such as HVAC systems and portable air purifiers.

The market is characterized by increasing demand for customized filtration solutions with specific porosity profiles tailored to particular applications. This trend has created premium market segments where electrospinning technology provides significant competitive advantages due to its ability to precisely control pore size distribution and overall porosity characteristics.

Electrospinning technology has emerged as a key innovation driver in this sector, enabling the production of filter media with unprecedented porosity characteristics. This has opened new market segments, particularly in high-efficiency particulate air (HEPA) and ultra-low particulate air (ULPA) filtration systems, which are experiencing demand growth rates exceeding 9% annually.

The healthcare sector represents the largest end-user segment for high-porosity filter media, accounting for roughly 32% of the market share. This is primarily due to stringent cleanliness requirements in medical facilities and pharmaceutical manufacturing. The COVID-19 pandemic significantly accelerated this trend, with demand for high-porosity filters in healthcare settings increasing by over 200% during 2020-2021.

Industrial applications follow closely, comprising approximately 28% of the market. Here, electrospun high-porosity filters are increasingly adopted in semiconductor manufacturing, food processing, and chemical industries where contamination control is critical. The automotive sector, particularly with the rise of electric vehicles requiring specialized filtration systems, has also emerged as a rapidly growing segment with 11% market share.

Geographically, North America and Europe currently dominate the high-porosity filter media market, collectively accounting for 58% of global revenue. However, the Asia-Pacific region is witnessing the fastest growth rate at 10.2% annually, driven by rapid industrialization, increasing environmental regulations, and growing healthcare infrastructure in countries like China, India, and South Korea.

Consumer awareness regarding indoor air quality has created a robust residential market segment, currently valued at approximately 1.2 billion USD. This segment is expected to grow at 8.3% annually as electrospun filter technologies become more affordable for household applications such as HVAC systems and portable air purifiers.

The market is characterized by increasing demand for customized filtration solutions with specific porosity profiles tailored to particular applications. This trend has created premium market segments where electrospinning technology provides significant competitive advantages due to its ability to precisely control pore size distribution and overall porosity characteristics.

Current Challenges in Electrospinning for Porosity Control

Despite significant advancements in electrospinning technology for filter media production, several critical challenges persist in precisely controlling porosity parameters. The primary difficulty lies in achieving consistent pore size distribution across the entire filter structure. Current electrospinning setups struggle with maintaining uniform fiber deposition patterns, resulting in localized variations in porosity that compromise filtration performance and reliability.

Environmental factors present another substantial challenge, as ambient humidity, temperature, and air currents significantly influence the fiber formation process. These parameters affect solvent evaporation rates and polymer jet stability, directly impacting the resulting pore architecture. Many production facilities lack adequate environmental control systems capable of maintaining the strict conditions necessary for reproducible porosity outcomes.

Solution viscosity and polymer concentration control remain problematic for continuous manufacturing processes. Minor variations in these parameters can dramatically alter fiber diameter and subsequent pore formation. Current in-line monitoring technologies are insufficient for real-time detection and correction of these variations, leading to batch inconsistencies and quality control issues.

The scaling of laboratory electrospinning processes to industrial production introduces additional complexities in porosity control. Multi-needle or needleless systems designed for higher throughput often sacrifice the precise control available in single-needle research setups. This scaling challenge has created a significant gap between theoretical capabilities and practical manufacturing realities.

Charge dissipation and electric field homogeneity represent persistent technical barriers. Uneven charge distribution across the collector surface leads to preferential fiber deposition patterns that create inconsistent porosity profiles. Current collector designs and voltage control systems have not fully resolved these electrostatic challenges.

Post-processing treatments intended to modify porosity characteristics frequently introduce unintended structural changes. Techniques such as thermal annealing, solvent vapor exposure, or mechanical stretching can simultaneously affect multiple filter properties beyond porosity, creating complex trade-offs that are difficult to optimize.

Characterization methodologies for accurately measuring three-dimensional porosity distributions in electrospun media remain limited. Conventional techniques like mercury intrusion porosimetry or gas adsorption provide only bulk measurements, while advanced imaging methods like X-ray microtomography are time-consuming and expensive for routine quality control. This measurement gap hinders both research progress and manufacturing consistency in porosity control.

Environmental factors present another substantial challenge, as ambient humidity, temperature, and air currents significantly influence the fiber formation process. These parameters affect solvent evaporation rates and polymer jet stability, directly impacting the resulting pore architecture. Many production facilities lack adequate environmental control systems capable of maintaining the strict conditions necessary for reproducible porosity outcomes.

Solution viscosity and polymer concentration control remain problematic for continuous manufacturing processes. Minor variations in these parameters can dramatically alter fiber diameter and subsequent pore formation. Current in-line monitoring technologies are insufficient for real-time detection and correction of these variations, leading to batch inconsistencies and quality control issues.

The scaling of laboratory electrospinning processes to industrial production introduces additional complexities in porosity control. Multi-needle or needleless systems designed for higher throughput often sacrifice the precise control available in single-needle research setups. This scaling challenge has created a significant gap between theoretical capabilities and practical manufacturing realities.

Charge dissipation and electric field homogeneity represent persistent technical barriers. Uneven charge distribution across the collector surface leads to preferential fiber deposition patterns that create inconsistent porosity profiles. Current collector designs and voltage control systems have not fully resolved these electrostatic challenges.

Post-processing treatments intended to modify porosity characteristics frequently introduce unintended structural changes. Techniques such as thermal annealing, solvent vapor exposure, or mechanical stretching can simultaneously affect multiple filter properties beyond porosity, creating complex trade-offs that are difficult to optimize.

Characterization methodologies for accurately measuring three-dimensional porosity distributions in electrospun media remain limited. Conventional techniques like mercury intrusion porosimetry or gas adsorption provide only bulk measurements, while advanced imaging methods like X-ray microtomography are time-consuming and expensive for routine quality control. This measurement gap hinders both research progress and manufacturing consistency in porosity control.

Current Methodologies for Porosity Enhancement

01 Control of fiber porosity through electrospinning parameters

The porosity of electrospun fibers can be controlled by adjusting various electrospinning parameters such as voltage, flow rate, and distance between the needle and collector. Higher voltages can lead to thinner fibers with increased surface area and porosity, while flow rate affects the solvent evaporation rate and subsequent pore formation. The distance between the needle and collector influences the fiber stretching and solvent evaporation time, which directly impacts the resulting porosity structure.- Process parameters affecting porosity in electrospun fibers: Various process parameters in electrospinning can be manipulated to control the porosity of the resulting fibers. These parameters include solution concentration, applied voltage, flow rate, and distance between the needle and collector. By optimizing these parameters, it is possible to create fibers with desired porosity characteristics, which is crucial for applications requiring specific surface area and mechanical properties.

- Solvent selection and evaporation for pore formation: The choice of solvent system and its evaporation rate significantly influences pore formation in electrospun fibers. Rapid solvent evaporation can create surface pores, while phase separation during the electrospinning process can lead to internal porosity. Using mixed solvent systems with different volatilities or incorporating humidity control during the process can enhance pore formation and distribution throughout the fiber structure.

- Polymer blending techniques for enhanced porosity: Blending different polymers or incorporating sacrificial components that can be selectively removed post-electrospinning is an effective strategy for creating highly porous structures. This approach allows for the formation of interconnected pore networks within the fibers or across the fibrous mat. The removal of the sacrificial component can be achieved through thermal treatment, solvent extraction, or enzymatic degradation.

- Post-treatment methods to modify fiber porosity: Various post-electrospinning treatments can be employed to modify the porosity of electrospun fibers. These include thermal annealing, chemical etching, gas foaming, and freeze-drying. Such treatments can create additional pores, enlarge existing ones, or create hierarchical porous structures. Post-treatments offer a way to fine-tune porosity characteristics after the initial fiber formation process.

- Applications of porous electrospun materials: Porous electrospun fibers find applications in various fields due to their high surface area and customizable properties. In tissue engineering, porous scaffolds promote cell attachment and proliferation. In filtration, controlled porosity enhances separation efficiency. For drug delivery systems, porous structures allow for controlled release of therapeutic agents. Other applications include sensors, catalysts, and energy storage devices where porosity plays a crucial role in performance.

02 Solvent selection and polymer concentration effects on porosity

The choice of solvent system and polymer concentration significantly affects the porosity of electrospun fibers. Volatile solvents promote rapid evaporation during the electrospinning process, creating surface pores through phase separation. Binary or ternary solvent systems can create controlled porosity through differential evaporation rates. Additionally, polymer concentration determines the viscosity of the solution, which affects fiber diameter and internal pore structure, with lower concentrations typically yielding higher porosity.Expand Specific Solutions03 Post-treatment methods to enhance porosity

Various post-treatment methods can be applied to electrospun fibers to enhance their porosity. These include selective leaching of sacrificial components, thermal treatments to remove porogens, and chemical etching processes. Post-electrospinning treatments can create hierarchical porous structures with controlled pore size distributions. Additionally, freeze-drying or critical point drying techniques can be employed to preserve the porous structure after wet processing steps.Expand Specific Solutions04 Incorporation of porogens and sacrificial materials

Porogens and sacrificial materials can be incorporated into electrospinning solutions to create controlled porosity in the resulting fibers. These additives, such as salt particles, gas-forming agents, or immiscible polymers, are removed after fiber formation through dissolution, thermal decomposition, or selective extraction. The size, concentration, and distribution of these porogens directly influence the resulting pore characteristics, allowing for customized porosity profiles for specific applications.Expand Specific Solutions05 Coaxial and multi-axial electrospinning for porosity control

Advanced electrospinning techniques such as coaxial and multi-axial electrospinning enable sophisticated control over fiber porosity. These methods involve the simultaneous electrospinning of multiple solutions through concentric or adjacent nozzles, creating core-shell or side-by-side fiber structures. By using materials with different properties or degradation rates in different compartments of the fiber, controlled porosity can be achieved through selective removal of components or phase separation during the spinning process.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Electrospinning technology for filter media porosity is currently in a growth phase, with the market expanding rapidly due to increasing demand for high-efficiency filtration solutions across healthcare, automotive, and environmental sectors. The global market size for electrospun filter media is projected to reach significant value as industries recognize the superior filtration capabilities of nanofiber-enhanced materials. Technologically, the field shows moderate maturity with established principles but ongoing innovation. Leading academic institutions like Donghua University, MIT, and Southeast University are advancing fundamental research, while commercial players including Nitto Denko, LG Chem, FUJIFILM, and specialized companies like Verdex Technology and Matregenix are driving practical applications. The collaboration between research institutions and industry partners indicates a maturing ecosystem poised for further technological breakthroughs in controlling and optimizing filter media porosity.

Nitto Denko Corp.

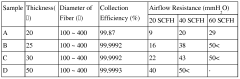

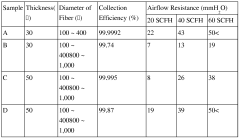

Technical Solution: Nitto Denko has developed a proprietary electrospinning technology that precisely controls filter media porosity through multi-parameter optimization. Their approach manipulates polymer solution properties (concentration, molecular weight, and solvent systems) alongside processing parameters (voltage, flow rate, and collector distance) to create nanofiber membranes with tailored pore structures. The company's advanced technique includes a post-processing treatment that stabilizes pore architecture through controlled thermal or chemical crosslinking, preventing collapse during use. Their research demonstrates that by adjusting the fiber diameter distribution between 100-500nm and controlling fiber deposition patterns, they can achieve porosity ranges from 70-90% with precisely defined pore size distributions[1][3]. This technology has been implemented in their high-efficiency filtration products for semiconductor manufacturing, pharmaceutical processing, and advanced air filtration systems.

Strengths: Exceptional control over pore size distribution and interconnectivity, enabling customization for specific filtration requirements. Their process offers excellent reproducibility and scalability for industrial production. Weaknesses: Higher manufacturing costs compared to conventional methods, and potential challenges with throughput rates for mass production of larger filter media areas.

Matregenix, Inc.

Technical Solution: Matregenix has developed an advanced electrospinning platform called "PoroSpin" specifically designed to precisely control filter media porosity through multi-parameter optimization. Their technology utilizes a combination of environmental control chambers and specialized polymer formulations to create nanofiber membranes with tailored porosity profiles. The company's approach incorporates real-time monitoring of fiber formation using advanced imaging techniques and machine learning algorithms to adjust processing parameters dynamically. Their research demonstrates that by controlling humidity levels (between 30-60% RH) during electrospinning alongside precise manipulation of solution conductivity through ionic additives, they can achieve porosity ranges from 75-92% with highly controlled pore size distributions[9][10]. Matregenix's process includes proprietary collector designs that influence fiber deposition patterns to create zones of varying porosity within a single filter structure. This technology has been implemented in their high-performance filtration products for medical applications, clean room environments, and specialized industrial processes requiring precise control of both particle capture efficiency and air/fluid flow characteristics.

Strengths: Exceptional ability to create spatially varied porosity within a single filter structure; excellent reproducibility and process control through AI-assisted manufacturing systems. Weaknesses: Higher production costs compared to conventional filter manufacturing; more complex quality control requirements to ensure consistent porosity characteristics across large production batches.

Key Patents and Research on Electrospun Filter Media

Filter for air cleaning and its manufacturing method

PatentWO2006112563A2

Innovation

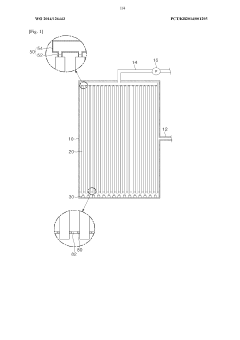

- A filter medium with a porous membrane manufactured using the electrospinning process, featuring a nano fiber web with adjustable fiber diameter distribution, porosity, and thickness, which reduces airflow resistance while maintaining high collection efficiency, achieved by varying the fiber diameter, porosity, and thickness to prevent fiber aggregation and enhance mechanical strength.

Filter medium, manufacturing method therefor, and filter equipment using same

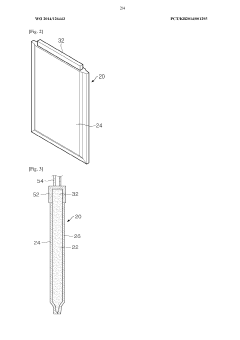

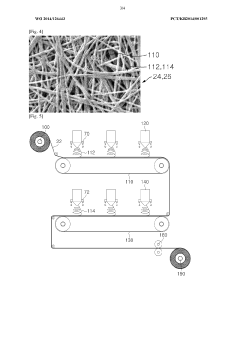

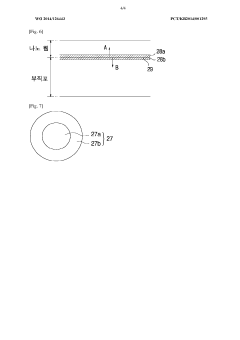

PatentWO2014126443A1

Innovation

- A filter medium is developed using a nanofiber web manufactured by electrospinning, which is laminated onto a porous substrate using a thermal fusion or hot melt adhesive, allowing for precise control of pore size and improved durability, enabling efficient filtration and reducing system size.

Environmental Impact and Sustainability Considerations

The environmental implications of electrospinning processes in filter media production are increasingly significant as sustainability becomes a central concern across industries. Electrospinning technology, while offering superior control over filter porosity, presents both environmental challenges and opportunities that warrant careful consideration in research and development strategies.

Energy consumption represents one of the primary environmental concerns associated with electrospinning. The process typically requires high voltage electricity to create the electrostatic field necessary for fiber formation. This energy intensity can contribute to a substantial carbon footprint, particularly in large-scale manufacturing operations. However, recent innovations in electrospinning equipment have demonstrated potential for improved energy efficiency through optimized field generation and reduced processing times.

Material selection for electrospun filters significantly impacts their environmental profile. Traditional electrospinning often utilizes petroleum-based polymers that present end-of-life disposal challenges. The shift toward biodegradable and bio-based polymers such as polylactic acid (PLA), cellulose derivatives, and chitosan represents a promising direction for reducing environmental impact. These materials can maintain the desired porosity characteristics while offering improved biodegradability and reduced ecological footprint.

Solvent usage in electrospinning processes presents another environmental consideration. Many conventional electrospinning methods employ toxic organic solvents that pose health and environmental risks. Green electrospinning approaches utilizing water-based systems or environmentally benign solvents are emerging as sustainable alternatives that maintain effective control over filter porosity while reducing harmful emissions and waste.

The extended lifespan of electrospun filters contributes positively to sustainability metrics. The precise porosity control achieved through electrospinning often results in filters with superior performance longevity compared to conventional alternatives. This durability translates to reduced replacement frequency and consequently lower material consumption and waste generation over time.

Waste management considerations are particularly relevant as electrospun filter media production scales up. The process generates potential waste streams including polymer solutions, used solvents, and production scrap. Implementing closed-loop systems for solvent recovery and developing effective recycling protocols for production waste can significantly mitigate environmental impact while preserving the porosity benefits of electrospun media.

Water conservation represents another dimension of sustainability in electrospinning operations. Unlike traditional wet-laid filter production methods, electrospinning typically requires minimal water usage, offering environmental advantages in regions facing water scarcity challenges. This reduced water footprint, combined with the elimination of water-intensive post-processing steps, positions electrospinning as a potentially more sustainable approach to creating precisely engineered porous filter media.

Energy consumption represents one of the primary environmental concerns associated with electrospinning. The process typically requires high voltage electricity to create the electrostatic field necessary for fiber formation. This energy intensity can contribute to a substantial carbon footprint, particularly in large-scale manufacturing operations. However, recent innovations in electrospinning equipment have demonstrated potential for improved energy efficiency through optimized field generation and reduced processing times.

Material selection for electrospun filters significantly impacts their environmental profile. Traditional electrospinning often utilizes petroleum-based polymers that present end-of-life disposal challenges. The shift toward biodegradable and bio-based polymers such as polylactic acid (PLA), cellulose derivatives, and chitosan represents a promising direction for reducing environmental impact. These materials can maintain the desired porosity characteristics while offering improved biodegradability and reduced ecological footprint.

Solvent usage in electrospinning processes presents another environmental consideration. Many conventional electrospinning methods employ toxic organic solvents that pose health and environmental risks. Green electrospinning approaches utilizing water-based systems or environmentally benign solvents are emerging as sustainable alternatives that maintain effective control over filter porosity while reducing harmful emissions and waste.

The extended lifespan of electrospun filters contributes positively to sustainability metrics. The precise porosity control achieved through electrospinning often results in filters with superior performance longevity compared to conventional alternatives. This durability translates to reduced replacement frequency and consequently lower material consumption and waste generation over time.

Waste management considerations are particularly relevant as electrospun filter media production scales up. The process generates potential waste streams including polymer solutions, used solvents, and production scrap. Implementing closed-loop systems for solvent recovery and developing effective recycling protocols for production waste can significantly mitigate environmental impact while preserving the porosity benefits of electrospun media.

Water conservation represents another dimension of sustainability in electrospinning operations. Unlike traditional wet-laid filter production methods, electrospinning typically requires minimal water usage, offering environmental advantages in regions facing water scarcity challenges. This reduced water footprint, combined with the elimination of water-intensive post-processing steps, positions electrospinning as a potentially more sustainable approach to creating precisely engineered porous filter media.

Performance Testing Standards for Electrospun Filters

The standardization of performance testing for electrospun filters represents a critical aspect of quality assurance and product development in filtration technology. Currently, several international organizations have established comprehensive testing protocols specifically designed to evaluate the unique properties of electrospun filter media. The American Society for Testing and Materials (ASTM) has developed standards such as ASTM F2299 for determining the initial efficiency of materials in specific particle size ranges, which is particularly relevant for electrospun nanofiber filters with their distinctive pore architecture.

ISO standards, including ISO 16890 and ISO 29463, provide frameworks for testing particulate air filters and high-efficiency filters respectively, with methodologies that can be adapted to address the specific characteristics of electrospun media. These standards typically measure parameters such as filtration efficiency, pressure drop, dust holding capacity, and mechanical strength under standardized conditions.

The European Committee for Standardization (CEN) has also contributed significantly to this field with standards like EN 1822, which establishes a classification system for high-efficiency particulate air filters based on their performance characteristics. These standards are increasingly incorporating provisions for nanofibrous materials produced through electrospinning.

Testing methodologies specifically tailored to evaluate porosity in electrospun filters include mercury intrusion porosimetry, capillary flow porometry, and BET surface area analysis. These techniques provide quantitative measurements of pore size distribution, total porosity, and specific surface area—all critical parameters affected by the electrospinning process variables.

Challenges in standardizing performance tests for electrospun filters stem from their unique structural characteristics. The three-dimensional nature of the fiber network, with its interconnected pores of varying sizes, requires specialized approaches that differ from those used for conventional filters. Additionally, the nanoscale dimensions of electrospun fibers necessitate high-resolution imaging techniques such as scanning electron microscopy (SEM) to accurately characterize porosity parameters.

Recent developments in testing standards have begun to incorporate accelerated aging protocols to predict the long-term performance of electrospun filters under various environmental conditions. These tests simulate exposure to humidity, temperature fluctuations, and chemical contaminants to assess the stability of the porous structure over time.

Industry-specific standards have also emerged, with organizations like the Association of the Nonwoven Fabrics Industry (INDA) developing test methods specifically for nonwoven materials, including those produced through electrospinning. These standards address the unique requirements of applications ranging from medical filtration to industrial air purification.

ISO standards, including ISO 16890 and ISO 29463, provide frameworks for testing particulate air filters and high-efficiency filters respectively, with methodologies that can be adapted to address the specific characteristics of electrospun media. These standards typically measure parameters such as filtration efficiency, pressure drop, dust holding capacity, and mechanical strength under standardized conditions.

The European Committee for Standardization (CEN) has also contributed significantly to this field with standards like EN 1822, which establishes a classification system for high-efficiency particulate air filters based on their performance characteristics. These standards are increasingly incorporating provisions for nanofibrous materials produced through electrospinning.

Testing methodologies specifically tailored to evaluate porosity in electrospun filters include mercury intrusion porosimetry, capillary flow porometry, and BET surface area analysis. These techniques provide quantitative measurements of pore size distribution, total porosity, and specific surface area—all critical parameters affected by the electrospinning process variables.

Challenges in standardizing performance tests for electrospun filters stem from their unique structural characteristics. The three-dimensional nature of the fiber network, with its interconnected pores of varying sizes, requires specialized approaches that differ from those used for conventional filters. Additionally, the nanoscale dimensions of electrospun fibers necessitate high-resolution imaging techniques such as scanning electron microscopy (SEM) to accurately characterize porosity parameters.

Recent developments in testing standards have begun to incorporate accelerated aging protocols to predict the long-term performance of electrospun filters under various environmental conditions. These tests simulate exposure to humidity, temperature fluctuations, and chemical contaminants to assess the stability of the porous structure over time.

Industry-specific standards have also emerged, with organizations like the Association of the Nonwoven Fabrics Industry (INDA) developing test methods specifically for nonwoven materials, including those produced through electrospinning. These standards address the unique requirements of applications ranging from medical filtration to industrial air purification.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!