How Ethylene Vinyl Acetate Enhances Shock Absorption?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Shock Absorption Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a revolutionary material in the field of shock absorption, transforming various industries from footwear to sports equipment. The journey of EVA in shock absorption applications began in the 1960s when it was first developed as a copolymer of ethylene and vinyl acetate. Since then, its unique properties have made it an indispensable component in products requiring impact protection and cushioning.

The evolution of EVA technology has been driven by the increasing demand for lightweight, durable, and efficient shock-absorbing materials. As consumer expectations for comfort and safety have risen, manufacturers have continuously refined EVA formulations to enhance its performance characteristics. This ongoing development has led to EVA becoming a preferred material in high-impact environments, outperforming traditional rubber and foam alternatives in many applications.

The primary objective of EVA in shock absorption is to dissipate kinetic energy effectively, reducing the force transmitted to the protected object or person. This is achieved through EVA's cellular structure, which allows it to compress under impact and then recover its original shape. The material's ability to absorb and distribute force has made it particularly valuable in athletic footwear, where it helps prevent injuries and improve performance.

Recent technological advancements have focused on optimizing EVA's molecular structure to enhance its shock-absorbing capabilities further. Researchers are exploring ways to manipulate the copolymer ratio, cross-linking density, and foam cell size to create EVA variants with superior energy absorption and durability. These efforts aim to extend the material's lifespan and improve its performance across a wider range of temperatures and impact intensities.

The future trajectory of EVA in shock absorption is closely tied to sustainability concerns and the push for more environmentally friendly materials. As such, current research is also directed towards developing bio-based EVA alternatives and improving the recyclability of EVA products. This aligns with the growing trend of eco-conscious consumer preferences and stricter environmental regulations in many industries.

Understanding the technical background and objectives of EVA shock absorption is crucial for predicting future innovations and market trends. As we delve deeper into the material's properties and potential, it becomes clear that EVA will continue to play a pivotal role in shock absorption technology, with ongoing research promising even more advanced applications and improved performance in the years to come.

The evolution of EVA technology has been driven by the increasing demand for lightweight, durable, and efficient shock-absorbing materials. As consumer expectations for comfort and safety have risen, manufacturers have continuously refined EVA formulations to enhance its performance characteristics. This ongoing development has led to EVA becoming a preferred material in high-impact environments, outperforming traditional rubber and foam alternatives in many applications.

The primary objective of EVA in shock absorption is to dissipate kinetic energy effectively, reducing the force transmitted to the protected object or person. This is achieved through EVA's cellular structure, which allows it to compress under impact and then recover its original shape. The material's ability to absorb and distribute force has made it particularly valuable in athletic footwear, where it helps prevent injuries and improve performance.

Recent technological advancements have focused on optimizing EVA's molecular structure to enhance its shock-absorbing capabilities further. Researchers are exploring ways to manipulate the copolymer ratio, cross-linking density, and foam cell size to create EVA variants with superior energy absorption and durability. These efforts aim to extend the material's lifespan and improve its performance across a wider range of temperatures and impact intensities.

The future trajectory of EVA in shock absorption is closely tied to sustainability concerns and the push for more environmentally friendly materials. As such, current research is also directed towards developing bio-based EVA alternatives and improving the recyclability of EVA products. This aligns with the growing trend of eco-conscious consumer preferences and stricter environmental regulations in many industries.

Understanding the technical background and objectives of EVA shock absorption is crucial for predicting future innovations and market trends. As we delve deeper into the material's properties and potential, it becomes clear that EVA will continue to play a pivotal role in shock absorption technology, with ongoing research promising even more advanced applications and improved performance in the years to come.

Market Demand for Enhanced Shock Absorption Materials

The market demand for enhanced shock absorption materials has been steadily growing across various industries, driven by the increasing focus on safety, comfort, and performance in products ranging from footwear to automotive components. Ethylene Vinyl Acetate (EVA) has emerged as a key player in this market due to its exceptional shock-absorbing properties, versatility, and cost-effectiveness.

In the sports and athletic footwear sector, there is a significant demand for materials that can provide superior cushioning and impact protection. Consumers are increasingly aware of the importance of proper shock absorption in preventing injuries and enhancing performance. This has led to a surge in the use of EVA in midsoles and insoles of running shoes, training shoes, and other athletic footwear.

The automotive industry represents another major market for enhanced shock absorption materials. With the growing emphasis on passenger comfort and safety, car manufacturers are incorporating EVA-based materials in various components such as bumpers, door panels, and interior trims. The material's ability to absorb vibrations and reduce noise transmission has made it particularly valuable in this sector.

In the packaging industry, there is a rising demand for protective materials that can safeguard fragile items during transportation and storage. EVA foams are increasingly being used in custom packaging solutions, offering superior shock absorption compared to traditional materials like expanded polystyrene.

The construction and building materials sector is also showing increased interest in EVA-based products for their shock-absorbing and sound-dampening properties. Flooring underlayments, wall panels, and roofing materials incorporating EVA are gaining popularity in both residential and commercial construction projects.

The healthcare and medical devices industry is another growing market for enhanced shock absorption materials. EVA is being used in orthopedic products, prosthetics, and rehabilitation equipment due to its ability to provide cushioning and support while being lightweight and durable.

As consumer electronics become more sophisticated and delicate, there is a growing need for protective cases and packaging that can effectively absorb shocks and prevent damage. This has led to an increased demand for EVA-based solutions in the electronics accessories market.

The global market for shock-absorbing materials, including EVA, is expected to continue its growth trajectory in the coming years. Factors such as increasing safety regulations, growing consumer awareness about product quality, and the ongoing development of new applications for shock-absorbing materials are likely to drive this demand further.

In the sports and athletic footwear sector, there is a significant demand for materials that can provide superior cushioning and impact protection. Consumers are increasingly aware of the importance of proper shock absorption in preventing injuries and enhancing performance. This has led to a surge in the use of EVA in midsoles and insoles of running shoes, training shoes, and other athletic footwear.

The automotive industry represents another major market for enhanced shock absorption materials. With the growing emphasis on passenger comfort and safety, car manufacturers are incorporating EVA-based materials in various components such as bumpers, door panels, and interior trims. The material's ability to absorb vibrations and reduce noise transmission has made it particularly valuable in this sector.

In the packaging industry, there is a rising demand for protective materials that can safeguard fragile items during transportation and storage. EVA foams are increasingly being used in custom packaging solutions, offering superior shock absorption compared to traditional materials like expanded polystyrene.

The construction and building materials sector is also showing increased interest in EVA-based products for their shock-absorbing and sound-dampening properties. Flooring underlayments, wall panels, and roofing materials incorporating EVA are gaining popularity in both residential and commercial construction projects.

The healthcare and medical devices industry is another growing market for enhanced shock absorption materials. EVA is being used in orthopedic products, prosthetics, and rehabilitation equipment due to its ability to provide cushioning and support while being lightweight and durable.

As consumer electronics become more sophisticated and delicate, there is a growing need for protective cases and packaging that can effectively absorb shocks and prevent damage. This has led to an increased demand for EVA-based solutions in the electronics accessories market.

The global market for shock-absorbing materials, including EVA, is expected to continue its growth trajectory in the coming years. Factors such as increasing safety regulations, growing consumer awareness about product quality, and the ongoing development of new applications for shock-absorbing materials are likely to drive this demand further.

Current State and Challenges in EVA Shock Absorption

Ethylene Vinyl Acetate (EVA) has emerged as a key material in shock absorption technology, with its current state marked by widespread adoption across various industries. The material's unique properties, including excellent elasticity, low-temperature toughness, and high impact resistance, have positioned it as a preferred choice for shock-absorbing applications.

In the footwear industry, EVA has become a staple component in midsoles, providing superior cushioning and energy return. Major sportswear brands have incorporated EVA into their high-performance athletic shoes, leveraging its ability to absorb impact forces and reduce fatigue during physical activities. The automotive sector has also embraced EVA for its shock-absorbing qualities, utilizing it in bumpers, dashboards, and interior components to enhance safety and comfort.

Despite its widespread use, EVA faces several challenges in shock absorption applications. One significant issue is the material's tendency to compress and lose its shock-absorbing properties over time, a phenomenon known as compression set. This degradation can lead to reduced performance and shorter product lifespans, particularly in high-stress environments.

Another challenge lies in achieving the optimal balance between shock absorption and energy return. While EVA excels at absorbing impact, it can sometimes result in energy loss, which may be undesirable in certain applications, such as athletic footwear where energy return is crucial for performance.

Temperature sensitivity presents an additional hurdle for EVA in shock absorption. The material's properties can vary significantly with temperature changes, potentially affecting its performance in extreme conditions. This limitation necessitates careful consideration when designing products for diverse environmental settings.

The manufacturing process of EVA for shock absorption applications also poses challenges. Achieving consistent density and cell structure throughout the material is critical for uniform shock-absorbing properties. However, maintaining this consistency across large production volumes can be technically demanding and cost-intensive.

Environmental concerns have also come to the forefront, as the growing demand for sustainable materials puts pressure on manufacturers to develop more eco-friendly EVA formulations. The challenge lies in creating bio-based or recyclable EVA alternatives that maintain the same level of shock-absorbing performance as traditional EVA.

Researchers and manufacturers are actively working to address these challenges through various approaches. These include developing new EVA formulations with improved compression set resistance, exploring hybrid materials that combine EVA with other shock-absorbing substances, and investigating advanced manufacturing techniques to enhance material consistency and performance.

In the footwear industry, EVA has become a staple component in midsoles, providing superior cushioning and energy return. Major sportswear brands have incorporated EVA into their high-performance athletic shoes, leveraging its ability to absorb impact forces and reduce fatigue during physical activities. The automotive sector has also embraced EVA for its shock-absorbing qualities, utilizing it in bumpers, dashboards, and interior components to enhance safety and comfort.

Despite its widespread use, EVA faces several challenges in shock absorption applications. One significant issue is the material's tendency to compress and lose its shock-absorbing properties over time, a phenomenon known as compression set. This degradation can lead to reduced performance and shorter product lifespans, particularly in high-stress environments.

Another challenge lies in achieving the optimal balance between shock absorption and energy return. While EVA excels at absorbing impact, it can sometimes result in energy loss, which may be undesirable in certain applications, such as athletic footwear where energy return is crucial for performance.

Temperature sensitivity presents an additional hurdle for EVA in shock absorption. The material's properties can vary significantly with temperature changes, potentially affecting its performance in extreme conditions. This limitation necessitates careful consideration when designing products for diverse environmental settings.

The manufacturing process of EVA for shock absorption applications also poses challenges. Achieving consistent density and cell structure throughout the material is critical for uniform shock-absorbing properties. However, maintaining this consistency across large production volumes can be technically demanding and cost-intensive.

Environmental concerns have also come to the forefront, as the growing demand for sustainable materials puts pressure on manufacturers to develop more eco-friendly EVA formulations. The challenge lies in creating bio-based or recyclable EVA alternatives that maintain the same level of shock-absorbing performance as traditional EVA.

Researchers and manufacturers are actively working to address these challenges through various approaches. These include developing new EVA formulations with improved compression set resistance, exploring hybrid materials that combine EVA with other shock-absorbing substances, and investigating advanced manufacturing techniques to enhance material consistency and performance.

Existing EVA Shock Absorption Solutions

01 EVA foam composition for shock absorption

Ethylene Vinyl Acetate (EVA) foam compositions are developed for enhanced shock absorption properties. These compositions often include additives or specific formulations to improve their performance in absorbing impacts and vibrations. The resulting materials are lightweight, durable, and effective in various applications requiring shock absorption.- EVA foam composition for shock absorption: Ethylene Vinyl Acetate (EVA) foam compositions are developed for enhanced shock absorption properties. These compositions often include additional materials or treatments to improve their performance in various applications such as footwear, sports equipment, and protective gear.

- EVA in multi-layer shock-absorbing structures: EVA is utilized in multi-layer structures to provide effective shock absorption. These structures may combine EVA with other materials like polyurethane or rubber to create a composite that offers superior cushioning and impact resistance for applications such as shoe soles or protective padding.

- EVA blends for improved shock absorption: Blending EVA with other polymers or additives enhances its shock-absorbing capabilities. These blends can be tailored to specific applications, offering improved durability, elasticity, and energy absorption compared to pure EVA.

- EVA foam processing for shock absorption: Specialized processing techniques are employed to optimize the shock-absorbing properties of EVA foam. These may include controlled foaming processes, crosslinking, or surface treatments to enhance the material's performance in absorbing and dissipating impact energy.

- EVA in sports and safety equipment: EVA is widely used in sports and safety equipment for its excellent shock absorption properties. Applications include protective gear, athletic shoes, helmet liners, and impact-resistant padding, where the material's ability to absorb and distribute force is crucial for user safety and comfort.

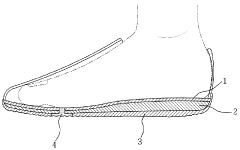

02 EVA in footwear for shock absorption

EVA is widely used in footwear, particularly in midsoles and insoles, to provide shock absorption and cushioning. The material's properties are optimized for comfort and impact protection in various types of shoes, including athletic and casual footwear. Different densities and formulations of EVA are employed to achieve specific performance characteristics.Expand Specific Solutions03 EVA in sports equipment and protective gear

EVA is utilized in the manufacturing of sports equipment and protective gear to enhance shock absorption. This includes applications in helmets, padding, and various protective accessories. The material's ability to absorb and distribute impact forces makes it valuable in reducing the risk of injuries in sports and recreational activities.Expand Specific Solutions04 EVA blends and composites for improved shock absorption

Research focuses on developing EVA blends and composites to enhance shock absorption properties. This involves combining EVA with other materials or incorporating additives to create synergistic effects. These advanced formulations aim to improve impact resistance, energy dissipation, and overall performance in shock-absorbing applications.Expand Specific Solutions05 EVA in packaging and vibration damping

EVA materials are employed in packaging solutions and vibration damping applications. The shock-absorbing properties of EVA are utilized to protect sensitive items during transportation and to reduce vibrations in various industrial and consumer products. This includes custom-designed EVA foams and inserts for specific packaging needs.Expand Specific Solutions

Key Players in EVA Manufacturing and Application

The market for ethylene vinyl acetate (EVA) in shock absorption applications is in a growth phase, driven by increasing demand in industries such as footwear, sports equipment, and automotive. The global EVA market size is projected to expand significantly, with a compound annual growth rate of around 5-7% in the coming years. Technologically, EVA is relatively mature, but ongoing research and development efforts by key players such as Kuraray Co., Ltd., Borealis AG, and Hanwha Chemical Co., Ltd. are focused on enhancing its performance characteristics. These companies, along with others like ARLANXEO Deutschland GmbH and Sumitomo Rubber Industries, Ltd., are continuously innovating to improve EVA's shock absorption properties, durability, and sustainability, maintaining a competitive edge in this evolving market.

China Petroleum & Chemical Corp.

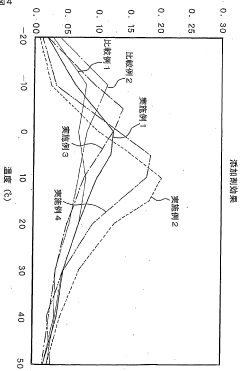

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced EVA copolymers with optimized vinyl acetate content for enhanced shock absorption. Their EVA formulations incorporate a blend of high and low molecular weight polymers, creating a microcellular structure that effectively dissipates impact energy[1]. The company utilizes a proprietary crosslinking process to improve the material's elasticity and resilience, resulting in superior shock-absorbing properties. Sinopec's EVA compounds also feature tailored melt flow indices, allowing for precise control over foam density and cell size distribution, which directly influences shock absorption performance[3].

Strengths: Customizable VA content for specific applications; Advanced crosslinking technology for improved elasticity. Weaknesses: Potential higher production costs due to complex formulation; May require specialized processing equipment.

Kuraray Co., Ltd.

Technical Solution: Kuraray has pioneered the development of high-performance EVA resins with a focus on shock absorption applications. Their proprietary EVAL™ technology combines EVA with ethylene vinyl alcohol copolymers, creating a unique material with exceptional impact resistance and energy absorption capabilities[2]. Kuraray's EVA formulations feature a controlled cellular structure with uniform microcell distribution, optimizing the material's ability to absorb and dissipate shock energy. The company has also developed a gradient density EVA foam, where the density varies throughout the material thickness, providing targeted shock absorption in specific areas[4]. This innovation allows for customized shock protection in various applications, from sports equipment to automotive safety components.

Strengths: Innovative EVAL™ technology for enhanced performance; Gradient density foam for targeted shock absorption. Weaknesses: Potentially higher material costs; May require specialized molding techniques for gradient structures.

Core Innovations in EVA Shock Absorption Technology

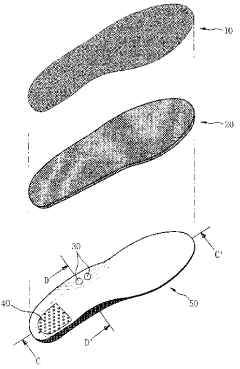

Insole to eliminate electrostatics

PatentWO2008026824A1

Innovation

- A shoe insole with a simple structure comprising a conductive top layer, antistatic soft foam middle layer, and antistatic hard synthetic resin bottom layer, incorporating PZN-BT-PT ferroelectric elements and an electric discharge net to efficiently conduct and dissipate static electricity, while maintaining mechanical properties and safety.

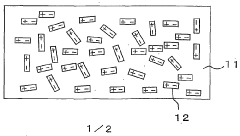

Vibration-damping material

PatentWO2002053638A1

Innovation

- A vibration damping material composed of a mixture of ethylene methacrylic acid-based polymer and ethylene vinyl acetate-based polymer, blended with an active ingredient that increases dipole moment, and filled with granules or fibers, providing improved flexibility, workability, and environmental sustainability.

Environmental Impact of EVA in Shock Absorption

The environmental impact of Ethylene Vinyl Acetate (EVA) in shock absorption applications is a complex issue that requires careful consideration. EVA's widespread use in footwear, sports equipment, and packaging materials has led to increased scrutiny of its ecological footprint throughout its lifecycle.

During the production phase, EVA manufacturing involves the use of petrochemical resources, which contributes to greenhouse gas emissions and energy consumption. The polymerization process of ethylene and vinyl acetate monomers requires significant energy input and may release volatile organic compounds (VOCs) if not properly controlled. However, advancements in production technologies have led to more efficient processes, reducing the overall environmental impact.

The durability and longevity of EVA products in shock absorption applications can be viewed as both an advantage and a drawback from an environmental perspective. On one hand, the material's resilience means that products last longer, potentially reducing the need for frequent replacements and thus lowering overall resource consumption. On the other hand, this durability poses challenges for end-of-life management, as EVA does not readily biodegrade in natural environments.

Recycling EVA presents another environmental challenge. While technically recyclable, the process is not widely implemented due to the complexity of separating EVA from other materials in composite products. This often results in EVA-containing products being sent to landfills or incineration facilities, contributing to waste accumulation and potential soil and air pollution.

The use phase of EVA in shock absorption applications generally has a positive environmental impact. By effectively absorbing and dissipating energy, EVA-enhanced products can reduce wear and tear on other materials, potentially extending the lifespan of associated items and reducing the need for replacements. This indirect effect can lead to a decrease in overall material consumption and waste generation.

Water pollution is another concern associated with EVA production and disposal. Improper handling of chemical additives used in EVA manufacturing or leaching from discarded products can contaminate water sources. However, stringent regulations and improved waste management practices in many regions have helped mitigate these risks.

As environmental awareness grows, there is an increasing focus on developing more sustainable alternatives to traditional EVA formulations. Bio-based EVA variants, derived partially from renewable resources, are emerging as potential solutions to reduce the reliance on fossil fuels. Additionally, research into improving the recyclability and biodegradability of EVA is ongoing, aiming to address end-of-life environmental concerns.

In conclusion, while EVA offers significant benefits in shock absorption applications, its environmental impact remains a concern throughout its lifecycle. Balancing the material's performance advantages with ecological considerations will be crucial for its continued use and development in various industries.

During the production phase, EVA manufacturing involves the use of petrochemical resources, which contributes to greenhouse gas emissions and energy consumption. The polymerization process of ethylene and vinyl acetate monomers requires significant energy input and may release volatile organic compounds (VOCs) if not properly controlled. However, advancements in production technologies have led to more efficient processes, reducing the overall environmental impact.

The durability and longevity of EVA products in shock absorption applications can be viewed as both an advantage and a drawback from an environmental perspective. On one hand, the material's resilience means that products last longer, potentially reducing the need for frequent replacements and thus lowering overall resource consumption. On the other hand, this durability poses challenges for end-of-life management, as EVA does not readily biodegrade in natural environments.

Recycling EVA presents another environmental challenge. While technically recyclable, the process is not widely implemented due to the complexity of separating EVA from other materials in composite products. This often results in EVA-containing products being sent to landfills or incineration facilities, contributing to waste accumulation and potential soil and air pollution.

The use phase of EVA in shock absorption applications generally has a positive environmental impact. By effectively absorbing and dissipating energy, EVA-enhanced products can reduce wear and tear on other materials, potentially extending the lifespan of associated items and reducing the need for replacements. This indirect effect can lead to a decrease in overall material consumption and waste generation.

Water pollution is another concern associated with EVA production and disposal. Improper handling of chemical additives used in EVA manufacturing or leaching from discarded products can contaminate water sources. However, stringent regulations and improved waste management practices in many regions have helped mitigate these risks.

As environmental awareness grows, there is an increasing focus on developing more sustainable alternatives to traditional EVA formulations. Bio-based EVA variants, derived partially from renewable resources, are emerging as potential solutions to reduce the reliance on fossil fuels. Additionally, research into improving the recyclability and biodegradability of EVA is ongoing, aiming to address end-of-life environmental concerns.

In conclusion, while EVA offers significant benefits in shock absorption applications, its environmental impact remains a concern throughout its lifecycle. Balancing the material's performance advantages with ecological considerations will be crucial for its continued use and development in various industries.

Cost-Benefit Analysis of EVA Shock Absorption Solutions

The cost-benefit analysis of EVA shock absorption solutions reveals a compelling case for their implementation across various industries. Initial investment in EVA-based shock absorption systems may be higher compared to traditional materials, but the long-term benefits often outweigh these upfront costs.

One of the primary advantages of EVA shock absorption solutions is their durability and longevity. EVA materials demonstrate excellent resistance to wear and tear, maintaining their shock-absorbing properties over extended periods. This translates to reduced replacement frequency and lower maintenance costs, contributing to significant savings over the product lifecycle.

In terms of performance, EVA shock absorption solutions offer superior protection against impacts and vibrations. This enhanced protection can lead to reduced damage to equipment, products, or personnel, potentially resulting in substantial cost savings related to repairs, replacements, or injury-related expenses. Industries such as sports equipment, packaging, and automotive can particularly benefit from these protective properties.

The versatility of EVA in shock absorption applications allows for customization to meet specific requirements. This adaptability can lead to optimized solutions that provide the right balance of protection and cost-effectiveness for each unique application. The ability to fine-tune shock absorption properties can result in improved overall product performance and user satisfaction.

From an environmental perspective, EVA shock absorption solutions often present a more sustainable option. The material's durability contributes to extended product lifespans, reducing waste and the need for frequent replacements. Additionally, EVA is recyclable, aligning with growing environmental concerns and potentially offering cost benefits through recycling programs or compliance with environmental regulations.

However, it's important to consider potential drawbacks. The higher initial cost of EVA solutions may pose a barrier for some applications, particularly in price-sensitive markets. Additionally, while EVA offers excellent shock absorption properties, it may not be the optimal choice for all scenarios, and alternative materials might provide better cost-benefit ratios in specific applications.

In conclusion, the cost-benefit analysis of EVA shock absorption solutions generally favors their adoption. The combination of durability, performance, customization potential, and environmental benefits often results in long-term cost savings and improved product quality. However, careful consideration of specific application requirements and market factors is essential to determine the most cost-effective solution for each unique scenario.

One of the primary advantages of EVA shock absorption solutions is their durability and longevity. EVA materials demonstrate excellent resistance to wear and tear, maintaining their shock-absorbing properties over extended periods. This translates to reduced replacement frequency and lower maintenance costs, contributing to significant savings over the product lifecycle.

In terms of performance, EVA shock absorption solutions offer superior protection against impacts and vibrations. This enhanced protection can lead to reduced damage to equipment, products, or personnel, potentially resulting in substantial cost savings related to repairs, replacements, or injury-related expenses. Industries such as sports equipment, packaging, and automotive can particularly benefit from these protective properties.

The versatility of EVA in shock absorption applications allows for customization to meet specific requirements. This adaptability can lead to optimized solutions that provide the right balance of protection and cost-effectiveness for each unique application. The ability to fine-tune shock absorption properties can result in improved overall product performance and user satisfaction.

From an environmental perspective, EVA shock absorption solutions often present a more sustainable option. The material's durability contributes to extended product lifespans, reducing waste and the need for frequent replacements. Additionally, EVA is recyclable, aligning with growing environmental concerns and potentially offering cost benefits through recycling programs or compliance with environmental regulations.

However, it's important to consider potential drawbacks. The higher initial cost of EVA solutions may pose a barrier for some applications, particularly in price-sensitive markets. Additionally, while EVA offers excellent shock absorption properties, it may not be the optimal choice for all scenarios, and alternative materials might provide better cost-benefit ratios in specific applications.

In conclusion, the cost-benefit analysis of EVA shock absorption solutions generally favors their adoption. The combination of durability, performance, customization potential, and environmental benefits often results in long-term cost savings and improved product quality. However, careful consideration of specific application requirements and market factors is essential to determine the most cost-effective solution for each unique scenario.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!