How to Address Logistics in Hydrochloric Acid Distribution?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl Distribution Background and Objectives

Hydrochloric acid (HCl) distribution has been a critical component of the chemical industry for decades, playing a vital role in various sectors such as manufacturing, water treatment, and food processing. The logistics of HCl distribution have evolved significantly over time, driven by advancements in technology, changing regulatory landscapes, and increasing demand for efficient and safe transportation methods.

The primary objective of addressing logistics in HCl distribution is to ensure the safe, efficient, and cost-effective movement of this corrosive substance from production facilities to end-users. This involves a comprehensive approach that encompasses transportation, storage, handling, and delivery systems. The goal is to minimize risks associated with the hazardous nature of HCl while maximizing operational efficiency and meeting the growing market demands.

Historically, HCl distribution faced numerous challenges due to the corrosive nature of the acid and its potential environmental impact. Early distribution methods often relied on glass or ceramic containers, which were fragile and limited in capacity. As industrial demand grew, larger-scale transportation solutions became necessary, leading to the development of specialized tanker trucks and rail cars equipped with corrosion-resistant linings.

The technological evolution in HCl distribution has been marked by significant milestones. The introduction of rubber-lined steel tanks in the mid-20th century revolutionized bulk transportation, allowing for safer and more efficient movement of larger quantities. Subsequently, the development of advanced polymer linings and composite materials further enhanced the durability and safety of storage and transportation vessels.

In recent years, the focus has shifted towards integrating smart technologies and automation into HCl distribution logistics. This includes the implementation of real-time monitoring systems, GPS tracking, and predictive maintenance algorithms to optimize route planning, reduce downtime, and enhance overall safety. Additionally, there has been a growing emphasis on developing more environmentally friendly distribution methods, such as exploring alternative packaging materials and optimizing transportation routes to reduce carbon footprints.

The current landscape of HCl distribution logistics is characterized by a complex interplay of technological innovation, regulatory compliance, and market dynamics. As global demand for HCl continues to rise, particularly in emerging economies, there is an increasing need for scalable and adaptable distribution solutions. This necessitates a forward-looking approach that anticipates future challenges and opportunities in the HCl supply chain.

The primary objective of addressing logistics in HCl distribution is to ensure the safe, efficient, and cost-effective movement of this corrosive substance from production facilities to end-users. This involves a comprehensive approach that encompasses transportation, storage, handling, and delivery systems. The goal is to minimize risks associated with the hazardous nature of HCl while maximizing operational efficiency and meeting the growing market demands.

Historically, HCl distribution faced numerous challenges due to the corrosive nature of the acid and its potential environmental impact. Early distribution methods often relied on glass or ceramic containers, which were fragile and limited in capacity. As industrial demand grew, larger-scale transportation solutions became necessary, leading to the development of specialized tanker trucks and rail cars equipped with corrosion-resistant linings.

The technological evolution in HCl distribution has been marked by significant milestones. The introduction of rubber-lined steel tanks in the mid-20th century revolutionized bulk transportation, allowing for safer and more efficient movement of larger quantities. Subsequently, the development of advanced polymer linings and composite materials further enhanced the durability and safety of storage and transportation vessels.

In recent years, the focus has shifted towards integrating smart technologies and automation into HCl distribution logistics. This includes the implementation of real-time monitoring systems, GPS tracking, and predictive maintenance algorithms to optimize route planning, reduce downtime, and enhance overall safety. Additionally, there has been a growing emphasis on developing more environmentally friendly distribution methods, such as exploring alternative packaging materials and optimizing transportation routes to reduce carbon footprints.

The current landscape of HCl distribution logistics is characterized by a complex interplay of technological innovation, regulatory compliance, and market dynamics. As global demand for HCl continues to rise, particularly in emerging economies, there is an increasing need for scalable and adaptable distribution solutions. This necessitates a forward-looking approach that anticipates future challenges and opportunities in the HCl supply chain.

Market Analysis for HCl Logistics

The global hydrochloric acid (HCl) market has been experiencing steady growth, driven by increasing demand from various industries such as steel pickling, oil well acidizing, and chemical manufacturing. The market size for HCl was valued at approximately $7.8 billion in 2020 and is projected to reach $10.1 billion by 2027, growing at a CAGR of 3.8% during the forecast period.

The logistics of HCl distribution play a crucial role in this market's dynamics. The corrosive nature of HCl presents unique challenges in transportation and storage, necessitating specialized equipment and safety measures. This has led to a growing demand for efficient and safe logistics solutions within the industry.

Key market trends in HCl logistics include the adoption of advanced corrosion-resistant materials for storage tanks and transportation vessels, implementation of real-time monitoring systems for leak detection, and the development of smart logistics solutions to optimize route planning and reduce transportation costs.

Geographically, Asia-Pacific dominates the HCl market, accounting for over 40% of global consumption. This region, particularly China and India, is expected to continue driving demand due to rapid industrialization and infrastructure development. North America and Europe follow, with significant consumption in the chemical and manufacturing sectors.

The HCl logistics market is characterized by a fragmented landscape, with numerous regional and global players. Major companies in this space include Brenntag AG, Univar Solutions Inc., and Helm AG, which have established strong distribution networks and specialized handling capabilities for hazardous chemicals.

Emerging trends in HCl logistics include the integration of blockchain technology for enhanced traceability and transparency in the supply chain, the use of IoT devices for real-time monitoring of shipments, and the adoption of eco-friendly packaging solutions to reduce environmental impact.

Challenges facing the HCl logistics market include stringent regulations regarding the transportation of hazardous materials, fluctuating raw material prices affecting overall logistics costs, and the need for continuous investment in safety measures and equipment upgrades.

Opportunities in the market lie in the development of innovative logistics solutions that can address the specific needs of HCl transportation, such as advanced leak detection systems, improved corrosion-resistant materials, and more efficient route optimization algorithms. Additionally, there is potential for growth in providing integrated logistics services that combine transportation, storage, and handling of HCl and related chemicals.

The logistics of HCl distribution play a crucial role in this market's dynamics. The corrosive nature of HCl presents unique challenges in transportation and storage, necessitating specialized equipment and safety measures. This has led to a growing demand for efficient and safe logistics solutions within the industry.

Key market trends in HCl logistics include the adoption of advanced corrosion-resistant materials for storage tanks and transportation vessels, implementation of real-time monitoring systems for leak detection, and the development of smart logistics solutions to optimize route planning and reduce transportation costs.

Geographically, Asia-Pacific dominates the HCl market, accounting for over 40% of global consumption. This region, particularly China and India, is expected to continue driving demand due to rapid industrialization and infrastructure development. North America and Europe follow, with significant consumption in the chemical and manufacturing sectors.

The HCl logistics market is characterized by a fragmented landscape, with numerous regional and global players. Major companies in this space include Brenntag AG, Univar Solutions Inc., and Helm AG, which have established strong distribution networks and specialized handling capabilities for hazardous chemicals.

Emerging trends in HCl logistics include the integration of blockchain technology for enhanced traceability and transparency in the supply chain, the use of IoT devices for real-time monitoring of shipments, and the adoption of eco-friendly packaging solutions to reduce environmental impact.

Challenges facing the HCl logistics market include stringent regulations regarding the transportation of hazardous materials, fluctuating raw material prices affecting overall logistics costs, and the need for continuous investment in safety measures and equipment upgrades.

Opportunities in the market lie in the development of innovative logistics solutions that can address the specific needs of HCl transportation, such as advanced leak detection systems, improved corrosion-resistant materials, and more efficient route optimization algorithms. Additionally, there is potential for growth in providing integrated logistics services that combine transportation, storage, and handling of HCl and related chemicals.

Current Challenges in HCl Transportation

The transportation of hydrochloric acid (HCl) presents significant challenges due to its corrosive nature and potential hazards. One of the primary issues is the selection of appropriate containment materials. HCl readily corrodes many metals, necessitating the use of specialized containers and transport vessels. These must be constructed from materials resistant to acid attack, such as high-grade stainless steel, rubber-lined carbon steel, or certain plastics like polyethylene or polypropylene.

Another major challenge is the risk of leaks or spills during transit. Even small releases of HCl can pose serious health and environmental risks. This requires robust containment systems, regular inspections, and stringent safety protocols. Transportation companies must invest in specialized equipment and training to handle HCl safely, which increases operational costs and complexity.

The volatile nature of HCl also presents challenges in temperature control during transportation. Extreme temperatures can cause pressure buildup in containers, potentially leading to ruptures or explosions. This necessitates careful monitoring and control of ambient conditions throughout the transportation process, often requiring specialized climate-controlled vehicles or additional insulation measures.

Regulatory compliance adds another layer of complexity to HCl transportation. Different countries and regions have varying regulations governing the transport of hazardous materials. Adhering to these diverse requirements can be challenging for companies operating across multiple jurisdictions, requiring extensive documentation, permits, and adherence to specific routing and handling procedures.

The potential for accidents during transportation poses significant risks to public safety and the environment. Emergency response planning is crucial, requiring coordination between transporters, local authorities, and specialized hazmat teams. This includes developing detailed contingency plans, providing appropriate personal protective equipment, and ensuring rapid response capabilities along transportation routes.

Lastly, the logistics of HCl transportation are complicated by the need for specialized loading and unloading facilities. These must be equipped to handle the corrosive nature of HCl safely, with proper ventilation, containment systems, and emergency response equipment. The limited availability of such facilities can restrict transportation options and increase costs.

Addressing these challenges requires a multifaceted approach, combining technological innovations in containment and monitoring systems, comprehensive safety protocols, and ongoing training for personnel involved in HCl transportation. As industries continue to rely on HCl for various applications, finding effective solutions to these transportation challenges remains a critical focus for logistics and chemical handling sectors.

Another major challenge is the risk of leaks or spills during transit. Even small releases of HCl can pose serious health and environmental risks. This requires robust containment systems, regular inspections, and stringent safety protocols. Transportation companies must invest in specialized equipment and training to handle HCl safely, which increases operational costs and complexity.

The volatile nature of HCl also presents challenges in temperature control during transportation. Extreme temperatures can cause pressure buildup in containers, potentially leading to ruptures or explosions. This necessitates careful monitoring and control of ambient conditions throughout the transportation process, often requiring specialized climate-controlled vehicles or additional insulation measures.

Regulatory compliance adds another layer of complexity to HCl transportation. Different countries and regions have varying regulations governing the transport of hazardous materials. Adhering to these diverse requirements can be challenging for companies operating across multiple jurisdictions, requiring extensive documentation, permits, and adherence to specific routing and handling procedures.

The potential for accidents during transportation poses significant risks to public safety and the environment. Emergency response planning is crucial, requiring coordination between transporters, local authorities, and specialized hazmat teams. This includes developing detailed contingency plans, providing appropriate personal protective equipment, and ensuring rapid response capabilities along transportation routes.

Lastly, the logistics of HCl transportation are complicated by the need for specialized loading and unloading facilities. These must be equipped to handle the corrosive nature of HCl safely, with proper ventilation, containment systems, and emergency response equipment. The limited availability of such facilities can restrict transportation options and increase costs.

Addressing these challenges requires a multifaceted approach, combining technological innovations in containment and monitoring systems, comprehensive safety protocols, and ongoing training for personnel involved in HCl transportation. As industries continue to rely on HCl for various applications, finding effective solutions to these transportation challenges remains a critical focus for logistics and chemical handling sectors.

Existing HCl Transportation Solutions

01 Production methods of hydrochloric acid

Various methods are employed for the production of hydrochloric acid, including chemical reactions and industrial processes. These methods may involve the use of specific catalysts, reactants, or equipment to efficiently produce hydrochloric acid at different concentrations and purities.- Production methods of hydrochloric acid: Various methods are employed for the production of hydrochloric acid, including direct synthesis from hydrogen and chlorine, as a byproduct in chlorination processes, and through the reaction of sulfuric acid with sodium chloride. These methods are optimized for efficiency and purity in industrial settings.

- Purification and concentration techniques: Techniques for purifying and concentrating hydrochloric acid involve distillation, membrane separation, and adsorption processes. These methods aim to remove impurities and adjust the concentration of the acid for specific industrial applications.

- Applications in chemical processing: Hydrochloric acid is widely used in various chemical processes, including metal treatment, pH regulation, and as a reagent in organic synthesis. Its strong acidic properties make it valuable in industries such as steel production, water treatment, and pharmaceuticals.

- Safety and handling considerations: Proper safety measures and handling procedures are crucial when working with hydrochloric acid due to its corrosive nature. This includes the use of specialized storage containers, personal protective equipment, and neutralization techniques for spills or disposal.

- Environmental impact and recycling: Efforts to mitigate the environmental impact of hydrochloric acid include developing recycling processes and finding alternative applications for waste acid. These approaches aim to reduce emissions and promote sustainable use of the chemical in industrial processes.

02 Applications in chemical processing

Hydrochloric acid is widely used in various chemical processing applications. It serves as a key reagent in industrial processes, such as metal treatment, pH adjustment, and as a catalyst in organic synthesis reactions. Its versatility makes it an essential component in many manufacturing sectors.Expand Specific Solutions03 Purification and treatment of hydrochloric acid

Techniques for purifying and treating hydrochloric acid are crucial for obtaining high-quality acid suitable for specific applications. These methods may include distillation, membrane separation, or chemical treatments to remove impurities and adjust the concentration of the acid.Expand Specific Solutions04 Storage and handling systems

Specialized storage and handling systems are designed for the safe management of hydrochloric acid. These systems may include corrosion-resistant materials, safety features, and specific designs to prevent leaks and ensure proper containment of the acid during storage and transportation.Expand Specific Solutions05 Environmental and safety considerations

Environmental and safety aspects are crucial when dealing with hydrochloric acid. This includes methods for neutralization, proper disposal, emission control, and protective measures to ensure worker safety and minimize environmental impact in industrial settings where hydrochloric acid is used or produced.Expand Specific Solutions

Key Players in HCl Logistics Industry

The hydrochloric acid distribution market is in a mature stage, with established players and well-defined logistics processes. The global market size for hydrochloric acid is substantial, driven by its widespread use in various industries. Technologically, the distribution process is well-developed, focusing on safety and efficiency. Companies like Covestro Deutschland AG, Mitsubishi Heavy Industries, and Industrie De Nora SpA are key players, leveraging their expertise in chemical handling and distribution. Innovation in this sector primarily revolves around improving safety measures, optimizing transportation methods, and enhancing storage solutions to meet stringent regulatory requirements and environmental standards.

Covestro Deutschland AG

Technical Solution: Covestro has developed an innovative approach to hydrochloric acid distribution using a closed-loop system. This system incorporates advanced corrosion-resistant materials and intelligent monitoring technologies to ensure safe and efficient transportation. The company utilizes specially designed tanker trucks with multi-layer protective coatings and integrated safety sensors[1]. These trucks are equipped with real-time tracking and remote monitoring capabilities, allowing for precise control of temperature, pressure, and pH levels during transit[3]. Covestro has also implemented a network of strategically located storage facilities with automated filling and unloading systems, minimizing human exposure and reducing the risk of spills[5].

Strengths: Enhanced safety features, reduced environmental impact, and improved logistics efficiency. Weaknesses: High initial investment costs and potential complexity in implementation across diverse geographic regions.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed a comprehensive hydrochloric acid distribution system that focuses on sustainability and efficiency. Their approach includes the use of advanced pipeline networks for bulk transportation, complemented by a fleet of specially designed rail cars and tanker trucks for last-mile delivery[2]. The company has implemented a proprietary digital platform that optimizes routing and scheduling, taking into account factors such as demand forecasting, inventory management, and real-time traffic conditions[4]. Shell's system also incorporates innovative packaging solutions, such as reusable intermediate bulk containers (IBCs) with built-in neutralization capabilities, reducing the environmental impact of acid transportation[6].

Strengths: Integrated multi-modal transportation system, advanced digital logistics management, and focus on sustainability. Weaknesses: High infrastructure requirements and potential challenges in adapting to rapidly changing market demands.

Innovative HCl Containment Technologies

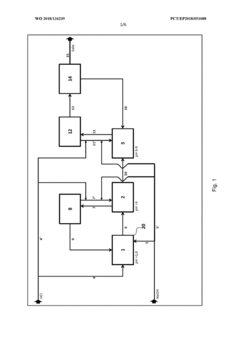

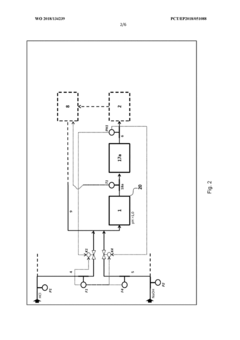

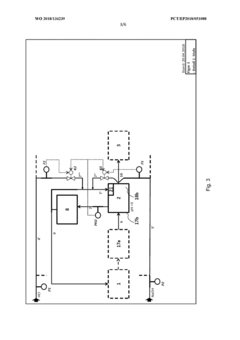

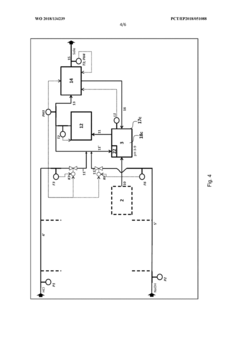

Method for flexibly controlling the use of hydrochloric acid from chemical production

PatentWO2018134239A1

Innovation

- A flexible control process for hydrochloric acid management involves neutralizing hydrochloric acid with concentrated alkali, specifically sodium hydroxide, in a multi-stage continuous process that adjusts pH values and compensates for flow and concentration variations, allowing for efficient handling and recycling of hydrochloric acid even when traditional acceptance points are unavailable.

Method for flexibly controlling the use of hydrochloric acid from chemical production

PatentInactiveEP3571157A1

Innovation

- A multi-stage neutralization process using concentrated alkali, specifically sodium hydroxide, to control the pH value of hydrochloric acid in a continuously automated mode, allowing for flexible handling and recycling of hydrochloric acid, even when traditional acceptance points are unavailable, by employing a three-stage neutralization system with cooled recirculated partial streams to manage reaction heat and maintain target pH values.

Safety Regulations for HCl Transport

The transportation of hydrochloric acid (HCl) is subject to stringent safety regulations due to its corrosive and hazardous nature. These regulations are designed to protect workers, the public, and the environment from potential risks associated with HCl distribution. In the United States, the Department of Transportation (DOT) oversees the transportation of hazardous materials, including HCl, through the Pipeline and Hazardous Materials Safety Administration (PHMSA).

HCl is classified as a Class 8 corrosive substance under the DOT's Hazardous Materials Regulations (HMR). This classification mandates specific packaging, labeling, and handling requirements. Containers used for HCl transport must be made of corrosion-resistant materials, such as polyethylene or specially lined steel tanks. These containers must undergo regular inspections and testing to ensure their integrity and compliance with safety standards.

Proper labeling is crucial for HCl transport. Vehicles carrying HCl must display appropriate placards indicating the presence of corrosive materials. Additionally, shipping papers must accompany the cargo, detailing the exact nature of the substance, its quantity, and emergency response information. This documentation is essential for first responders in case of accidents or spills.

Training is a critical component of HCl transport safety regulations. Drivers and handlers involved in HCl distribution must receive specialized training in hazardous materials handling, emergency procedures, and proper use of personal protective equipment (PPE). This training must be regularly updated to ensure compliance with the latest safety standards and best practices.

Emergency response planning is another key aspect of HCl transport regulations. Companies involved in HCl distribution must develop and maintain comprehensive emergency response plans. These plans should outline procedures for handling spills, leaks, and other potential incidents. They must also include provisions for immediate notification of local authorities and emergency services in case of accidents.

Route planning and risk assessment are integral to HCl transport safety. Carriers must carefully select routes that minimize potential hazards, avoiding densely populated areas and environmentally sensitive regions when possible. Regular risk assessments should be conducted to identify and mitigate potential dangers along transport routes.

Monitoring and tracking systems are increasingly becoming part of safety regulations for HCl transport. These systems allow real-time tracking of HCl shipments, enabling quick response to any deviations from planned routes or schedules. Some regulations now require the use of electronic logging devices (ELDs) to accurately record driving hours and ensure compliance with rest period requirements.

Compliance with international regulations is essential for cross-border HCl transport. The United Nations' Recommendations on the Transport of Dangerous Goods serve as a global framework, which many countries, including the United States, have incorporated into their national regulations. This harmonization facilitates safer international transport of HCl and other hazardous materials.

HCl is classified as a Class 8 corrosive substance under the DOT's Hazardous Materials Regulations (HMR). This classification mandates specific packaging, labeling, and handling requirements. Containers used for HCl transport must be made of corrosion-resistant materials, such as polyethylene or specially lined steel tanks. These containers must undergo regular inspections and testing to ensure their integrity and compliance with safety standards.

Proper labeling is crucial for HCl transport. Vehicles carrying HCl must display appropriate placards indicating the presence of corrosive materials. Additionally, shipping papers must accompany the cargo, detailing the exact nature of the substance, its quantity, and emergency response information. This documentation is essential for first responders in case of accidents or spills.

Training is a critical component of HCl transport safety regulations. Drivers and handlers involved in HCl distribution must receive specialized training in hazardous materials handling, emergency procedures, and proper use of personal protective equipment (PPE). This training must be regularly updated to ensure compliance with the latest safety standards and best practices.

Emergency response planning is another key aspect of HCl transport regulations. Companies involved in HCl distribution must develop and maintain comprehensive emergency response plans. These plans should outline procedures for handling spills, leaks, and other potential incidents. They must also include provisions for immediate notification of local authorities and emergency services in case of accidents.

Route planning and risk assessment are integral to HCl transport safety. Carriers must carefully select routes that minimize potential hazards, avoiding densely populated areas and environmentally sensitive regions when possible. Regular risk assessments should be conducted to identify and mitigate potential dangers along transport routes.

Monitoring and tracking systems are increasingly becoming part of safety regulations for HCl transport. These systems allow real-time tracking of HCl shipments, enabling quick response to any deviations from planned routes or schedules. Some regulations now require the use of electronic logging devices (ELDs) to accurately record driving hours and ensure compliance with rest period requirements.

Compliance with international regulations is essential for cross-border HCl transport. The United Nations' Recommendations on the Transport of Dangerous Goods serve as a global framework, which many countries, including the United States, have incorporated into their national regulations. This harmonization facilitates safer international transport of HCl and other hazardous materials.

Environmental Impact Assessment

The environmental impact assessment of hydrochloric acid distribution logistics is a critical aspect that requires thorough consideration. Hydrochloric acid, being a highly corrosive substance, poses significant risks to the environment if not handled and transported properly. The primary environmental concerns include potential soil and water contamination, air pollution, and harm to flora and fauna.

One of the major environmental risks in hydrochloric acid distribution is the possibility of spills during transportation. Such incidents can lead to severe soil acidification, affecting the local ecosystem and potentially contaminating groundwater sources. To mitigate this risk, stringent containment measures and spill response protocols must be implemented. This includes using corrosion-resistant containers, regular inspection of transport vehicles, and training personnel in proper handling and emergency procedures.

Air pollution is another significant concern, particularly in the event of a leak or during loading and unloading processes. Hydrochloric acid vapors can contribute to acid rain formation and pose respiratory risks to both humans and wildlife. To address this, distribution centers and transport vehicles should be equipped with advanced vapor recovery systems and air quality monitoring devices.

The carbon footprint of hydrochloric acid distribution is also an important consideration. Optimizing transportation routes, utilizing fuel-efficient vehicles, and exploring alternative transportation methods such as rail or waterways can significantly reduce greenhouse gas emissions associated with distribution logistics.

Waste management is a crucial aspect of environmental impact assessment in hydrochloric acid distribution. Proper disposal of contaminated materials, including packaging and cleaning residues, is essential to prevent environmental contamination. Implementing closed-loop systems and exploring recycling options for acid containers can help minimize waste generation.

To ensure comprehensive environmental protection, regular environmental audits and impact assessments should be conducted along the entire distribution chain. This includes evaluating the environmental performance of suppliers, distributors, and end-users. Implementing an environmental management system (EMS) that adheres to international standards such as ISO 14001 can provide a structured approach to managing environmental risks and continually improving performance.

Collaboration with local environmental agencies and stakeholders is vital for developing and implementing effective environmental protection strategies. This includes engaging in community outreach programs to educate the public about the measures taken to ensure safe and environmentally responsible hydrochloric acid distribution.

In conclusion, addressing the environmental impact of hydrochloric acid distribution logistics requires a multifaceted approach. By implementing robust safety measures, optimizing transportation methods, managing waste effectively, and fostering collaboration with stakeholders, the industry can significantly reduce its environmental footprint and ensure sustainable operations.

One of the major environmental risks in hydrochloric acid distribution is the possibility of spills during transportation. Such incidents can lead to severe soil acidification, affecting the local ecosystem and potentially contaminating groundwater sources. To mitigate this risk, stringent containment measures and spill response protocols must be implemented. This includes using corrosion-resistant containers, regular inspection of transport vehicles, and training personnel in proper handling and emergency procedures.

Air pollution is another significant concern, particularly in the event of a leak or during loading and unloading processes. Hydrochloric acid vapors can contribute to acid rain formation and pose respiratory risks to both humans and wildlife. To address this, distribution centers and transport vehicles should be equipped with advanced vapor recovery systems and air quality monitoring devices.

The carbon footprint of hydrochloric acid distribution is also an important consideration. Optimizing transportation routes, utilizing fuel-efficient vehicles, and exploring alternative transportation methods such as rail or waterways can significantly reduce greenhouse gas emissions associated with distribution logistics.

Waste management is a crucial aspect of environmental impact assessment in hydrochloric acid distribution. Proper disposal of contaminated materials, including packaging and cleaning residues, is essential to prevent environmental contamination. Implementing closed-loop systems and exploring recycling options for acid containers can help minimize waste generation.

To ensure comprehensive environmental protection, regular environmental audits and impact assessments should be conducted along the entire distribution chain. This includes evaluating the environmental performance of suppliers, distributors, and end-users. Implementing an environmental management system (EMS) that adheres to international standards such as ISO 14001 can provide a structured approach to managing environmental risks and continually improving performance.

Collaboration with local environmental agencies and stakeholders is vital for developing and implementing effective environmental protection strategies. This includes engaging in community outreach programs to educate the public about the measures taken to ensure safe and environmentally responsible hydrochloric acid distribution.

In conclusion, addressing the environmental impact of hydrochloric acid distribution logistics requires a multifaceted approach. By implementing robust safety measures, optimizing transportation methods, managing waste effectively, and fostering collaboration with stakeholders, the industry can significantly reduce its environmental footprint and ensure sustainable operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!