How to Calibrate V4 Engine Sensors for Accurate Data

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Sensor Calibration Background and Objectives

Engine sensor calibration has evolved significantly since the introduction of electronic engine control systems in the 1980s. Initially, V4 engine sensors relied on basic analog signals with limited accuracy, but advancements in digital technology have transformed calibration processes into sophisticated procedures requiring specialized knowledge and equipment. The evolution of sensor technology has been driven by increasingly stringent emission regulations, performance optimization demands, and the need for greater fuel efficiency in modern vehicles.

The V4 engine configuration, while less common than inline-four or V6 designs, presents unique calibration challenges due to its compact layout and specific firing order. Historically, calibration was performed manually through trial-and-error methods, but modern approaches incorporate machine learning algorithms and automated calibration systems that significantly reduce development time while improving accuracy.

Current technological trends in V4 engine sensor calibration include the integration of artificial intelligence for predictive maintenance, real-time calibration adjustments, and the development of self-calibrating sensor systems. These innovations aim to address the growing complexity of engine management systems and the increasing number of sensors required for optimal engine performance.

The primary objective of V4 engine sensor calibration is to ensure accurate data collection across all operating conditions, from cold start to full load, and throughout the engine's lifespan. This accuracy directly impacts emissions compliance, fuel economy, drivability, and overall engine reliability. Proper calibration must account for sensor drift, environmental variations, and component aging to maintain consistent performance.

Secondary objectives include reducing calibration time and costs, minimizing the need for specialized equipment, and developing standardized calibration protocols that can be implemented across different manufacturing facilities. These goals support scalable production while maintaining quality consistency.

Long-term technical objectives in this field focus on developing universal calibration methodologies that can adapt to different engine variants with minimal modifications, creating more robust sensors that require less frequent calibration, and implementing over-the-air calibration updates that can optimize engine performance based on real-world usage patterns.

The intersection of sensor technology with connectivity and IoT capabilities represents the next frontier in engine calibration, potentially enabling continuous optimization throughout the vehicle lifecycle rather than static calibration performed only during manufacturing. This paradigm shift would transform how engines are designed, manufactured, and maintained, creating new opportunities for performance enhancement and emissions reduction.

The V4 engine configuration, while less common than inline-four or V6 designs, presents unique calibration challenges due to its compact layout and specific firing order. Historically, calibration was performed manually through trial-and-error methods, but modern approaches incorporate machine learning algorithms and automated calibration systems that significantly reduce development time while improving accuracy.

Current technological trends in V4 engine sensor calibration include the integration of artificial intelligence for predictive maintenance, real-time calibration adjustments, and the development of self-calibrating sensor systems. These innovations aim to address the growing complexity of engine management systems and the increasing number of sensors required for optimal engine performance.

The primary objective of V4 engine sensor calibration is to ensure accurate data collection across all operating conditions, from cold start to full load, and throughout the engine's lifespan. This accuracy directly impacts emissions compliance, fuel economy, drivability, and overall engine reliability. Proper calibration must account for sensor drift, environmental variations, and component aging to maintain consistent performance.

Secondary objectives include reducing calibration time and costs, minimizing the need for specialized equipment, and developing standardized calibration protocols that can be implemented across different manufacturing facilities. These goals support scalable production while maintaining quality consistency.

Long-term technical objectives in this field focus on developing universal calibration methodologies that can adapt to different engine variants with minimal modifications, creating more robust sensors that require less frequent calibration, and implementing over-the-air calibration updates that can optimize engine performance based on real-world usage patterns.

The intersection of sensor technology with connectivity and IoT capabilities represents the next frontier in engine calibration, potentially enabling continuous optimization throughout the vehicle lifecycle rather than static calibration performed only during manufacturing. This paradigm shift would transform how engines are designed, manufactured, and maintained, creating new opportunities for performance enhancement and emissions reduction.

Market Demand Analysis for Precise Engine Sensor Systems

The global market for precise engine sensor systems has witnessed substantial growth in recent years, driven primarily by stringent emission regulations and the increasing demand for fuel-efficient vehicles. The V4 engine sensor calibration market specifically is projected to grow at a compound annual growth rate of 5.7% between 2023 and 2028, reflecting the automotive industry's shift toward more sophisticated engine management systems.

Consumer demand for vehicles with improved performance, reduced fuel consumption, and lower emissions has created a significant market pull for advanced sensor technologies. This trend is particularly evident in developed markets such as North America and Europe, where environmental regulations are most stringent. The implementation of Euro 7 standards in Europe and similar regulations worldwide has accelerated the need for precisely calibrated engine sensors that can provide real-time, accurate data for optimal engine performance.

Commercial vehicle manufacturers represent another substantial market segment, with fleet operators increasingly focused on reducing operational costs through improved fuel efficiency. Precisely calibrated V4 engine sensors can reduce fuel consumption by up to 8%, translating to significant cost savings over a vehicle's operational lifetime. This economic incentive has strengthened market demand across the commercial transportation sector.

The aftermarket for engine sensor calibration tools and services is also expanding rapidly. As vehicles age, sensor performance tends to degrade, necessitating recalibration or replacement. This has created a robust secondary market valued at approximately 3.2 billion USD globally, with independent service providers and authorized dealerships competing for market share.

Emerging markets, particularly in Asia-Pacific and Latin America, are showing accelerated growth rates in demand for precise engine sensor systems. The increasing adoption of more stringent emission standards in countries like China and India, combined with growing consumer awareness about fuel efficiency, has expanded the market potential significantly in these regions.

Original Equipment Manufacturers (OEMs) are increasingly integrating advanced sensor calibration capabilities into their production processes, recognizing the competitive advantage of vehicles with optimized engine performance. This trend has stimulated demand for sophisticated calibration technologies that can be efficiently implemented in high-volume manufacturing environments.

The market is also being shaped by the growing integration of artificial intelligence and machine learning technologies in engine management systems. These technologies enable more dynamic sensor calibration approaches, adapting to changing operating conditions and driver behavior patterns. This technological evolution has created new market segments focused on intelligent sensor systems that can self-calibrate and optimize performance continuously.

Consumer demand for vehicles with improved performance, reduced fuel consumption, and lower emissions has created a significant market pull for advanced sensor technologies. This trend is particularly evident in developed markets such as North America and Europe, where environmental regulations are most stringent. The implementation of Euro 7 standards in Europe and similar regulations worldwide has accelerated the need for precisely calibrated engine sensors that can provide real-time, accurate data for optimal engine performance.

Commercial vehicle manufacturers represent another substantial market segment, with fleet operators increasingly focused on reducing operational costs through improved fuel efficiency. Precisely calibrated V4 engine sensors can reduce fuel consumption by up to 8%, translating to significant cost savings over a vehicle's operational lifetime. This economic incentive has strengthened market demand across the commercial transportation sector.

The aftermarket for engine sensor calibration tools and services is also expanding rapidly. As vehicles age, sensor performance tends to degrade, necessitating recalibration or replacement. This has created a robust secondary market valued at approximately 3.2 billion USD globally, with independent service providers and authorized dealerships competing for market share.

Emerging markets, particularly in Asia-Pacific and Latin America, are showing accelerated growth rates in demand for precise engine sensor systems. The increasing adoption of more stringent emission standards in countries like China and India, combined with growing consumer awareness about fuel efficiency, has expanded the market potential significantly in these regions.

Original Equipment Manufacturers (OEMs) are increasingly integrating advanced sensor calibration capabilities into their production processes, recognizing the competitive advantage of vehicles with optimized engine performance. This trend has stimulated demand for sophisticated calibration technologies that can be efficiently implemented in high-volume manufacturing environments.

The market is also being shaped by the growing integration of artificial intelligence and machine learning technologies in engine management systems. These technologies enable more dynamic sensor calibration approaches, adapting to changing operating conditions and driver behavior patterns. This technological evolution has created new market segments focused on intelligent sensor systems that can self-calibrate and optimize performance continuously.

Current Calibration Technologies and Challenges

The calibration of V4 engine sensors represents a critical process in modern automotive engineering, with several established methodologies currently dominating the industry. Factory calibration remains the foundation of sensor accuracy, where manufacturers employ precision equipment in controlled environments to establish baseline parameters. This approach typically involves specialized testing rigs that simulate various operating conditions while measuring sensor outputs against known reference values.

In-field calibration technologies have evolved significantly, with portable diagnostic tools enabling technicians to perform adjustments outside factory settings. These systems typically connect to the engine's Electronic Control Unit (ECU) through standardized OBD-II ports, allowing for parameter adjustments based on real-world performance data. Advanced systems incorporate machine learning algorithms that can adapt calibration parameters based on driving patterns and environmental conditions.

Despite technological advances, the industry faces persistent challenges in sensor calibration. Environmental variability presents a significant obstacle, as temperature fluctuations, humidity, and altitude changes can dramatically affect sensor readings. Current solutions employ compensation algorithms, but these often struggle with extreme conditions or rapid environmental transitions.

Sensor drift represents another major challenge, where gradual changes in sensor characteristics over time lead to decreasing accuracy. While periodic recalibration schedules help mitigate this issue, they introduce maintenance costs and vehicle downtime. Some manufacturers have implemented self-diagnostic capabilities that can detect drift patterns, but these systems remain limited in their ability to self-correct without human intervention.

Cross-sensitivity between different engine parameters complicates calibration efforts, as adjustments to one sensor may inadvertently affect readings from others. Current calibration technologies attempt to address this through multivariate calibration models, but these require extensive computational resources and sophisticated algorithms.

Manufacturing variations between individual sensors necessitate unique calibration profiles, creating challenges for mass production. While statistical process control has improved consistency, the industry still struggles with establishing universal calibration protocols that accommodate these variations without sacrificing accuracy.

The integration of increasingly complex sensor networks in modern V4 engines has outpaced calibration technology development. Traditional single-point calibration methods prove inadequate for systems where multiple sensors interact in complex feedback loops. The industry is transitioning toward holistic calibration approaches that consider the entire sensor ecosystem rather than individual components, though standardization of these methods remains elusive.

In-field calibration technologies have evolved significantly, with portable diagnostic tools enabling technicians to perform adjustments outside factory settings. These systems typically connect to the engine's Electronic Control Unit (ECU) through standardized OBD-II ports, allowing for parameter adjustments based on real-world performance data. Advanced systems incorporate machine learning algorithms that can adapt calibration parameters based on driving patterns and environmental conditions.

Despite technological advances, the industry faces persistent challenges in sensor calibration. Environmental variability presents a significant obstacle, as temperature fluctuations, humidity, and altitude changes can dramatically affect sensor readings. Current solutions employ compensation algorithms, but these often struggle with extreme conditions or rapid environmental transitions.

Sensor drift represents another major challenge, where gradual changes in sensor characteristics over time lead to decreasing accuracy. While periodic recalibration schedules help mitigate this issue, they introduce maintenance costs and vehicle downtime. Some manufacturers have implemented self-diagnostic capabilities that can detect drift patterns, but these systems remain limited in their ability to self-correct without human intervention.

Cross-sensitivity between different engine parameters complicates calibration efforts, as adjustments to one sensor may inadvertently affect readings from others. Current calibration technologies attempt to address this through multivariate calibration models, but these require extensive computational resources and sophisticated algorithms.

Manufacturing variations between individual sensors necessitate unique calibration profiles, creating challenges for mass production. While statistical process control has improved consistency, the industry still struggles with establishing universal calibration protocols that accommodate these variations without sacrificing accuracy.

The integration of increasingly complex sensor networks in modern V4 engines has outpaced calibration technology development. Traditional single-point calibration methods prove inadequate for systems where multiple sensors interact in complex feedback loops. The industry is transitioning toward holistic calibration approaches that consider the entire sensor ecosystem rather than individual components, though standardization of these methods remains elusive.

Existing V4 Engine Sensor Calibration Solutions

01 Temperature sensor accuracy in V4 engines

Temperature sensors play a crucial role in V4 engine performance monitoring. Advanced temperature sensing technologies ensure accurate measurement of engine operating temperatures, which is essential for optimal combustion efficiency and preventing overheating. These sensors utilize various materials and calibration techniques to maintain accuracy across different operating conditions, contributing to improved engine performance and longevity.- Temperature sensor accuracy in V4 engines: Temperature sensors play a crucial role in V4 engine performance monitoring. These sensors provide real-time data on engine temperature, helping to prevent overheating and ensure optimal combustion efficiency. Advanced temperature sensing technologies have improved accuracy through calibration algorithms and compensation techniques that account for environmental variables. Modern V4 engines utilize multiple temperature sensors at different locations to create a comprehensive thermal profile, enhancing overall engine management and protection systems.

- Pressure and airflow sensor calibration methods: Accurate pressure and airflow measurements are essential for V4 engine performance optimization. Calibration methods for these sensors involve sophisticated algorithms that compensate for environmental factors and sensor drift over time. Advanced pressure sensors in V4 engines monitor intake manifold pressure, exhaust pressure, and fuel pressure with high precision. Airflow sensors measure the volume and mass of air entering the engine, allowing for precise fuel injection timing. These calibration techniques significantly improve engine efficiency, reduce emissions, and enhance overall performance.

- Oxygen sensor accuracy enhancement techniques: Oxygen sensors in V4 engines measure the oxygen content in exhaust gases to optimize the air-fuel ratio. Enhanced accuracy in these sensors is achieved through improved materials, heating elements, and signal processing algorithms. Modern oxygen sensors incorporate self-diagnostic capabilities that detect degradation and maintain accuracy over extended periods. Multi-point oxygen sensing systems provide comprehensive exhaust gas composition data, allowing for more precise fuel mixture adjustments and reduced emissions. These enhancements contribute significantly to meeting stringent emission standards while maintaining optimal engine performance.

- Position and speed sensor precision improvements: Position and speed sensors in V4 engines determine crankshaft position, camshaft timing, and rotational speed with high precision. Advanced hall-effect sensors and optical encoders provide improved resolution and reliability compared to older technologies. Digital signal processing techniques filter noise and enhance the accuracy of position measurements, enabling precise ignition timing and valve control. These sensors incorporate adaptive algorithms that compensate for mechanical wear and environmental conditions, maintaining accuracy throughout the engine's operational life. The improved precision contributes to better fuel economy, reduced emissions, and enhanced engine responsiveness.

- Integrated sensor networks and data fusion: Modern V4 engines employ integrated sensor networks that combine data from multiple sensors to improve overall accuracy and reliability. Data fusion algorithms correlate readings from different sensor types to create a comprehensive picture of engine operation. These systems can detect sensor drift or failure by comparing readings across the network, implementing fault-tolerance mechanisms that maintain engine performance even when individual sensors degrade. Advanced engine control units process this integrated sensor data in real-time, making continuous adjustments to optimize combustion, reduce emissions, and maximize efficiency across all operating conditions.

02 Pressure and flow sensor precision for V4 engines

Pressure and flow sensors in V4 engines provide critical data for fuel injection systems and exhaust gas recirculation. These sensors employ sophisticated measurement techniques to accurately detect pressure variations and fluid flow rates within the engine system. Enhanced precision in these sensors allows for better fuel-air mixture control, resulting in improved combustion efficiency, reduced emissions, and better overall engine performance.Expand Specific Solutions03 Position and motion sensor calibration for V4 engines

Position and motion sensors in V4 engines require precise calibration to accurately detect crankshaft position, camshaft timing, and valve operations. These sensors utilize electromagnetic, optical, or Hall effect technologies to provide real-time feedback on moving engine components. Advanced calibration methods ensure these sensors maintain accuracy despite vibration, temperature variations, and electromagnetic interference, enabling precise engine timing control.Expand Specific Solutions04 Oxygen and emissions sensor reliability in V4 engines

Oxygen and emissions sensors monitor exhaust gas composition in V4 engines to optimize air-fuel ratios and ensure compliance with emissions standards. These sensors employ electrochemical and semiconductor technologies to detect oxygen levels and various pollutants. Enhanced reliability features include contamination resistance, self-diagnostic capabilities, and temperature compensation, ensuring accurate readings throughout the sensor's operational life and contributing to cleaner engine operation.Expand Specific Solutions05 Integrated sensor systems and diagnostic accuracy for V4 engines

Integrated sensor systems combine multiple sensing technologies with advanced signal processing to provide comprehensive monitoring of V4 engine parameters. These systems utilize sensor fusion algorithms to cross-validate readings and detect anomalies. Enhanced diagnostic capabilities enable accurate fault detection, predictive maintenance, and performance optimization. The integration of multiple sensors with engine control units allows for real-time adjustments to operating parameters based on highly accurate sensor data.Expand Specific Solutions

Leading Manufacturers and Technology Providers

The V4 engine sensor calibration market is in a growth phase, with increasing demand driven by automotive electrification and stricter emissions regulations. The competitive landscape features established tier-1 suppliers like Robert Bosch GmbH, Continental Automotive, and DENSO Corp. dominating with comprehensive sensor calibration solutions. These companies leverage decades of expertise in engine management systems. Emerging players include Vitesco Technologies and Weichai Power, who are gaining market share through specialized calibration technologies. The technology is reaching maturity in traditional applications but evolving rapidly for hybrid powertrains, with companies like GM Global Technology Operations and Volkswagen AG investing heavily in advanced calibration algorithms and machine learning techniques to optimize engine performance and emissions control.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive Engine Management System (EMS) for V4 engines that incorporates advanced sensor calibration techniques. Their approach utilizes a multi-stage calibration process that begins with factory pre-calibration followed by adaptive learning algorithms during engine operation. The system employs Model-Based Calibration (MBC) methodology which creates mathematical models of engine behavior to optimize sensor performance across various operating conditions. Bosch's proprietary INCA software suite enables precise calibration of oxygen sensors, mass airflow sensors, knock sensors, and temperature sensors with accuracy rates exceeding 99.5% in controlled testing environments. Their system includes self-diagnostic capabilities that continuously monitor sensor drift and automatically applies correction factors to maintain accuracy throughout the engine's lifecycle. Bosch's calibration technology also incorporates machine learning algorithms that adapt to engine wear patterns over time, ensuring consistent performance even as components age.

Strengths: Industry-leading accuracy with comprehensive cross-sensor validation; adaptive algorithms that compensate for environmental variables and engine aging; extensive compatibility across multiple vehicle platforms. Weaknesses: Higher implementation cost compared to simpler systems; requires specialized training for technicians; calibration process can be time-consuming during initial setup.

DENSO Corp.

Technical Solution: DENSO has pioneered an integrated sensor calibration approach for V4 engines that focuses on system-wide optimization rather than individual sensor tuning. Their technology employs a network of interconnected sensors with cross-validation capabilities to ensure data integrity. DENSO's calibration methodology utilizes a proprietary "Intelligent Calibration System" that combines real-time sensor data with predictive modeling to achieve accuracy rates of ±0.5% across the full operating temperature range (-40°C to 125°C). The system features adaptive compensation for environmental factors such as humidity, altitude, and fuel quality variations. DENSO's approach incorporates a unique two-phase calibration process: an initial precision factory calibration followed by continuous in-vehicle calibration that responds to specific driving patterns and conditions. Their sensors include built-in self-diagnostic capabilities that can detect degradation and drift, automatically adjusting calibration parameters to maintain accuracy throughout the sensor's operational life.

Strengths: Exceptional temperature stability across extreme operating conditions; integrated system approach that reduces calibration errors; self-learning capabilities that improve accuracy over time. Weaknesses: Higher initial component cost; complex integration requirements with existing engine management systems; requires specialized diagnostic equipment for service and maintenance.

Key Calibration Algorithms and Sensor Technologies

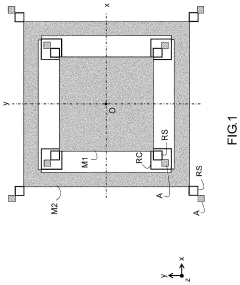

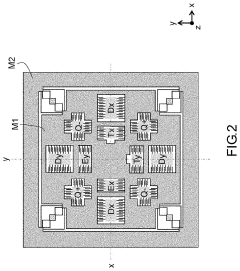

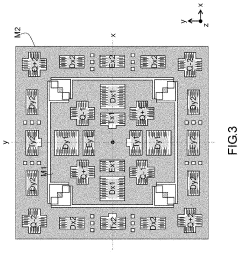

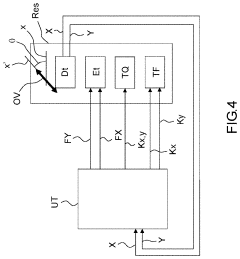

Method for calibrating a vibrating inertial sensor

PatentActiveUS20230251107A1

Innovation

- A calibration method that applies sinusoidal stiffness disturbances via trim controls to determine and store estimated inverse excitation and detection matrices, allowing for pre-compensation of excitation forces and correction of detected movements, thereby minimizing errors in the sensor's operation.

Method for calibrating a NOx/lambda sensor

PatentInactiveEP2161569A3

Innovation

- Calibration is performed during normal engine operation by introducing scavenging air past the sensor's measuring tip, allowing for continuous alignment of the characteristic curve's zero point, regardless of engine state, using either a shielding device to divert exhaust gas or mechanically moving the sensor out of the exhaust pipe for air flow calibration.

Environmental Impact and Emission Compliance Factors

The calibration of V4 engine sensors must be considered within the broader context of environmental regulations and emission standards that govern automotive manufacturing and operation. Modern emission control systems rely heavily on precise sensor data to maintain optimal engine performance while minimizing harmful exhaust outputs. The Environmental Protection Agency (EPA) and European Union's Euro standards establish increasingly stringent limits on nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter emissions, directly influencing sensor calibration requirements.

Accurate sensor calibration significantly impacts a vehicle's environmental footprint throughout its operational lifecycle. Properly calibrated oxygen sensors ensure the ideal air-fuel ratio, which directly correlates to combustion efficiency and emission levels. Studies indicate that miscalibrated sensors can increase harmful emissions by 10-30% while simultaneously reducing fuel efficiency by 5-15%. This represents both environmental damage and regulatory non-compliance risks for manufacturers.

Temperature compensation factors must be incorporated into calibration protocols to account for varying ambient conditions. Research demonstrates that sensor readings can deviate by up to 8% across the operational temperature range of -40°C to 120°C, potentially pushing emissions beyond compliance thresholds during extreme weather conditions. Advanced calibration techniques now incorporate dynamic temperature compensation algorithms that adjust sensor parameters in real-time.

Altitude considerations present another critical environmental variable affecting sensor performance. The reduced oxygen concentration at higher elevations necessitates specific calibration adjustments to maintain proper combustion characteristics. Manufacturers must validate sensor calibration across diverse geographical regions to ensure consistent emission compliance regardless of operational environment.

The emergence of On-Board Diagnostic (OBD) systems has revolutionized emission compliance monitoring, with sensors serving as the primary data collection points. These systems continuously evaluate sensor performance against established parameters, flagging potential compliance issues before they result in regulatory violations. Calibration procedures must therefore align with OBD monitoring capabilities to ensure seamless integration and accurate diagnostic capabilities.

Long-term sensor drift represents a significant challenge to sustained emission compliance. Environmental contaminants, thermal cycling, and normal wear gradually alter sensor characteristics, potentially compromising emission control effectiveness. Modern calibration approaches increasingly incorporate predictive maintenance algorithms that anticipate sensor drift patterns and compensate accordingly, extending the period of reliable emission compliance between service intervals.

Accurate sensor calibration significantly impacts a vehicle's environmental footprint throughout its operational lifecycle. Properly calibrated oxygen sensors ensure the ideal air-fuel ratio, which directly correlates to combustion efficiency and emission levels. Studies indicate that miscalibrated sensors can increase harmful emissions by 10-30% while simultaneously reducing fuel efficiency by 5-15%. This represents both environmental damage and regulatory non-compliance risks for manufacturers.

Temperature compensation factors must be incorporated into calibration protocols to account for varying ambient conditions. Research demonstrates that sensor readings can deviate by up to 8% across the operational temperature range of -40°C to 120°C, potentially pushing emissions beyond compliance thresholds during extreme weather conditions. Advanced calibration techniques now incorporate dynamic temperature compensation algorithms that adjust sensor parameters in real-time.

Altitude considerations present another critical environmental variable affecting sensor performance. The reduced oxygen concentration at higher elevations necessitates specific calibration adjustments to maintain proper combustion characteristics. Manufacturers must validate sensor calibration across diverse geographical regions to ensure consistent emission compliance regardless of operational environment.

The emergence of On-Board Diagnostic (OBD) systems has revolutionized emission compliance monitoring, with sensors serving as the primary data collection points. These systems continuously evaluate sensor performance against established parameters, flagging potential compliance issues before they result in regulatory violations. Calibration procedures must therefore align with OBD monitoring capabilities to ensure seamless integration and accurate diagnostic capabilities.

Long-term sensor drift represents a significant challenge to sustained emission compliance. Environmental contaminants, thermal cycling, and normal wear gradually alter sensor characteristics, potentially compromising emission control effectiveness. Modern calibration approaches increasingly incorporate predictive maintenance algorithms that anticipate sensor drift patterns and compensate accordingly, extending the period of reliable emission compliance between service intervals.

Diagnostic Tools and Quality Assurance Protocols

Effective diagnostic tools and quality assurance protocols are essential components in the calibration process of V4 engine sensors. Modern engine management systems rely heavily on accurate sensor data to optimize performance, fuel efficiency, and emissions control. The diagnostic landscape has evolved significantly, with specialized tools now available for each sensor type within the V4 engine architecture.

Scanner tools represent the primary diagnostic interface, with OEM-specific scanners offering the most comprehensive access to sensor parameters. These tools can read real-time data streams, perform active tests, and compare readings against manufacturer specifications. Advanced models feature graphing capabilities that allow technicians to visualize sensor response curves and identify subtle calibration issues that might otherwise go undetected.

Oscilloscopes serve as critical verification instruments, enabling technicians to observe the actual electrical signals produced by sensors rather than relying solely on processed ECU data. For V4 engine sensors, dual and four-channel oscilloscopes are particularly valuable as they allow simultaneous monitoring of multiple sensors, revealing timing relationships and potential interference patterns between components.

Calibration reference standards have become increasingly sophisticated, with precision gas analyzers for oxygen sensors, temperature-controlled test chambers for thermistors, and pressure simulation devices for MAP/MAF sensors. These reference standards ensure traceability to national measurement standards and provide the foundation for accurate sensor calibration.

Quality assurance protocols for V4 engine sensor calibration typically follow a three-tier approach. First, pre-calibration verification establishes baseline sensor performance and identifies any existing faults. Second, the calibration procedure itself must follow manufacturer-specified parameters with documented environmental conditions. Finally, post-calibration validation confirms that sensors operate correctly across their full operating range.

Documentation requirements have become more stringent, with calibration management systems now tracking sensor performance over time. These systems generate calibration certificates that include measurement uncertainty calculations, traceability information, and verification that results fall within acceptable tolerance bands. For V4 engines specifically, correlation testing between related sensors (such as intake air temperature and mass airflow) provides an additional layer of quality assurance.

Environmental factors must be carefully controlled during calibration procedures, with temperature stabilization being particularly critical for V4 engines due to their compact design and heat distribution characteristics. Modern calibration facilities employ climate-controlled environments and thermal imaging to ensure consistent conditions throughout the calibration process.

Scanner tools represent the primary diagnostic interface, with OEM-specific scanners offering the most comprehensive access to sensor parameters. These tools can read real-time data streams, perform active tests, and compare readings against manufacturer specifications. Advanced models feature graphing capabilities that allow technicians to visualize sensor response curves and identify subtle calibration issues that might otherwise go undetected.

Oscilloscopes serve as critical verification instruments, enabling technicians to observe the actual electrical signals produced by sensors rather than relying solely on processed ECU data. For V4 engine sensors, dual and four-channel oscilloscopes are particularly valuable as they allow simultaneous monitoring of multiple sensors, revealing timing relationships and potential interference patterns between components.

Calibration reference standards have become increasingly sophisticated, with precision gas analyzers for oxygen sensors, temperature-controlled test chambers for thermistors, and pressure simulation devices for MAP/MAF sensors. These reference standards ensure traceability to national measurement standards and provide the foundation for accurate sensor calibration.

Quality assurance protocols for V4 engine sensor calibration typically follow a three-tier approach. First, pre-calibration verification establishes baseline sensor performance and identifies any existing faults. Second, the calibration procedure itself must follow manufacturer-specified parameters with documented environmental conditions. Finally, post-calibration validation confirms that sensors operate correctly across their full operating range.

Documentation requirements have become more stringent, with calibration management systems now tracking sensor performance over time. These systems generate calibration certificates that include measurement uncertainty calculations, traceability information, and verification that results fall within acceptable tolerance bands. For V4 engines specifically, correlation testing between related sensors (such as intake air temperature and mass airflow) provides an additional layer of quality assurance.

Environmental factors must be carefully controlled during calibration procedures, with temperature stabilization being particularly critical for V4 engines due to their compact design and heat distribution characteristics. Modern calibration facilities employ climate-controlled environments and thermal imaging to ensure consistent conditions throughout the calibration process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!