How to Conduct Tests with Hydrochloric Acid Accurately?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl Testing Background

Hydrochloric acid (HCl) testing has been a cornerstone of analytical chemistry for decades, playing a crucial role in various industries and scientific research. The accurate measurement and analysis of HCl concentrations are essential for quality control, environmental monitoring, and industrial processes. The history of HCl testing can be traced back to the early days of chemistry, with significant advancements occurring during the Industrial Revolution.

In the modern era, HCl testing has evolved to encompass a wide range of applications, from water treatment and food processing to pharmaceutical manufacturing and materials science. The importance of precise HCl testing cannot be overstated, as even small variations in acid concentration can have significant impacts on chemical reactions, product quality, and safety measures.

The development of HCl testing methods has been driven by the need for increased accuracy, efficiency, and safety. Traditional titration techniques, while still widely used, have been complemented by more advanced instrumental methods such as potentiometry, spectrophotometry, and ion chromatography. These modern techniques offer higher precision and the ability to analyze complex matrices with minimal sample preparation.

One of the key challenges in HCl testing is ensuring the stability and reliability of measurements across different environmental conditions. Factors such as temperature, pressure, and the presence of interfering substances can significantly affect the accuracy of results. As a result, standardization of testing procedures and the use of certified reference materials have become critical aspects of HCl analysis.

The global focus on environmental protection and workplace safety has further emphasized the importance of accurate HCl testing. Stringent regulations on emissions and exposure limits require precise monitoring of HCl levels in air, water, and industrial effluents. This has led to the development of specialized testing equipment and protocols designed for on-site and continuous monitoring applications.

In recent years, the integration of digital technologies and automation has revolutionized HCl testing practices. Advanced sensors, data logging systems, and artificial intelligence-driven analysis tools have enhanced the speed and reliability of measurements while reducing human error. These technological advancements have also facilitated remote monitoring and real-time data sharing, enabling more efficient process control and regulatory compliance.

As industries continue to evolve and new applications for HCl emerge, the field of HCl testing is expected to advance further. Research is ongoing to develop more sensitive and selective detection methods, miniaturize testing equipment for portable applications, and improve the sustainability of testing processes. The future of HCl testing lies in the convergence of chemical expertise, advanced materials science, and cutting-edge digital technologies.

In the modern era, HCl testing has evolved to encompass a wide range of applications, from water treatment and food processing to pharmaceutical manufacturing and materials science. The importance of precise HCl testing cannot be overstated, as even small variations in acid concentration can have significant impacts on chemical reactions, product quality, and safety measures.

The development of HCl testing methods has been driven by the need for increased accuracy, efficiency, and safety. Traditional titration techniques, while still widely used, have been complemented by more advanced instrumental methods such as potentiometry, spectrophotometry, and ion chromatography. These modern techniques offer higher precision and the ability to analyze complex matrices with minimal sample preparation.

One of the key challenges in HCl testing is ensuring the stability and reliability of measurements across different environmental conditions. Factors such as temperature, pressure, and the presence of interfering substances can significantly affect the accuracy of results. As a result, standardization of testing procedures and the use of certified reference materials have become critical aspects of HCl analysis.

The global focus on environmental protection and workplace safety has further emphasized the importance of accurate HCl testing. Stringent regulations on emissions and exposure limits require precise monitoring of HCl levels in air, water, and industrial effluents. This has led to the development of specialized testing equipment and protocols designed for on-site and continuous monitoring applications.

In recent years, the integration of digital technologies and automation has revolutionized HCl testing practices. Advanced sensors, data logging systems, and artificial intelligence-driven analysis tools have enhanced the speed and reliability of measurements while reducing human error. These technological advancements have also facilitated remote monitoring and real-time data sharing, enabling more efficient process control and regulatory compliance.

As industries continue to evolve and new applications for HCl emerge, the field of HCl testing is expected to advance further. Research is ongoing to develop more sensitive and selective detection methods, miniaturize testing equipment for portable applications, and improve the sustainability of testing processes. The future of HCl testing lies in the convergence of chemical expertise, advanced materials science, and cutting-edge digital technologies.

Market Demand Analysis

The market demand for accurate hydrochloric acid testing methods has been steadily increasing across various industries. In the chemical manufacturing sector, precise control of hydrochloric acid concentration is crucial for product quality and process efficiency. Environmental monitoring agencies require reliable testing techniques to assess water and soil contamination levels. The healthcare industry relies on accurate hydrochloric acid tests for diagnostic purposes and pharmaceutical production.

The global laboratory chemical reagents market, which includes hydrochloric acid testing supplies, is projected to grow significantly in the coming years. This growth is driven by the expanding research and development activities in life sciences, increasing demand for high-purity chemicals in various industries, and stringent quality control regulations.

In the industrial sector, the need for accurate hydrochloric acid testing is particularly pronounced in metal processing, where precise acid concentrations are essential for surface treatment and cleaning processes. The semiconductor industry also demands highly accurate testing methods to ensure the purity of hydrochloric acid used in chip manufacturing.

Environmental concerns have further fueled the demand for accurate hydrochloric acid testing. With stricter regulations on industrial emissions and wastewater treatment, companies are investing in advanced testing equipment and methodologies to comply with environmental standards and avoid penalties.

The healthcare sector's demand for precise hydrochloric acid testing is driven by its applications in clinical diagnostics, particularly in gastroenterology for assessing stomach acid levels. Additionally, the pharmaceutical industry requires accurate testing methods for quality control in drug manufacturing processes.

Research institutions and academic laboratories contribute significantly to the market demand, as they conduct extensive studies involving hydrochloric acid and require precise measurement techniques for reliable results.

The market trend indicates a shift towards automated and digital testing solutions that offer higher accuracy, repeatability, and efficiency. This trend is supported by the integration of advanced technologies such as spectrophotometry, potentiometry, and ion-selective electrodes in hydrochloric acid testing equipment.

As industries continue to prioritize quality control and regulatory compliance, the demand for training and certification programs in accurate hydrochloric acid testing methods is also on the rise. This has created a secondary market for educational services and specialized training courses.

The global laboratory chemical reagents market, which includes hydrochloric acid testing supplies, is projected to grow significantly in the coming years. This growth is driven by the expanding research and development activities in life sciences, increasing demand for high-purity chemicals in various industries, and stringent quality control regulations.

In the industrial sector, the need for accurate hydrochloric acid testing is particularly pronounced in metal processing, where precise acid concentrations are essential for surface treatment and cleaning processes. The semiconductor industry also demands highly accurate testing methods to ensure the purity of hydrochloric acid used in chip manufacturing.

Environmental concerns have further fueled the demand for accurate hydrochloric acid testing. With stricter regulations on industrial emissions and wastewater treatment, companies are investing in advanced testing equipment and methodologies to comply with environmental standards and avoid penalties.

The healthcare sector's demand for precise hydrochloric acid testing is driven by its applications in clinical diagnostics, particularly in gastroenterology for assessing stomach acid levels. Additionally, the pharmaceutical industry requires accurate testing methods for quality control in drug manufacturing processes.

Research institutions and academic laboratories contribute significantly to the market demand, as they conduct extensive studies involving hydrochloric acid and require precise measurement techniques for reliable results.

The market trend indicates a shift towards automated and digital testing solutions that offer higher accuracy, repeatability, and efficiency. This trend is supported by the integration of advanced technologies such as spectrophotometry, potentiometry, and ion-selective electrodes in hydrochloric acid testing equipment.

As industries continue to prioritize quality control and regulatory compliance, the demand for training and certification programs in accurate hydrochloric acid testing methods is also on the rise. This has created a secondary market for educational services and specialized training courses.

Current Challenges

Conducting accurate tests with hydrochloric acid presents several significant challenges that researchers and laboratory technicians must overcome. One of the primary difficulties lies in the highly corrosive nature of hydrochloric acid, which can pose serious safety risks and potentially damage equipment if not handled properly. This necessitates the use of specialized protective gear and acid-resistant materials, which can be costly and may limit the accessibility of certain testing procedures.

Another major challenge is maintaining the precise concentration of hydrochloric acid throughout the testing process. The acid's volatile nature means it can easily evaporate or absorb moisture from the air, leading to changes in concentration that can significantly impact test results. This requires careful storage, handling, and measurement techniques to ensure consistent acid strength across multiple experiments.

The reactivity of hydrochloric acid with various materials also presents challenges in selecting appropriate containers, instruments, and reaction vessels. Many common laboratory materials may be unsuitable for use with hydrochloric acid, necessitating the use of specialized equipment that can withstand its corrosive properties without contaminating the samples or affecting the test results.

Accurate pH measurement and control during hydrochloric acid tests can be particularly challenging due to the acid's strong dissociation properties. Standard pH meters may struggle to provide reliable readings in highly acidic solutions, requiring the use of specialized electrodes or alternative measurement techniques. This can introduce additional complexity and potential sources of error into the testing process.

The disposal of hydrochloric acid and its byproducts after testing also poses environmental and safety challenges. Proper neutralization and disposal procedures must be followed to prevent harm to the environment and comply with regulatory requirements. This adds an extra layer of complexity to the testing process and may require additional resources and expertise.

Furthermore, the potential for interference from other ions or compounds in the test samples can complicate the interpretation of results when using hydrochloric acid. This is particularly relevant in complex matrices such as environmental or biological samples, where multiple species may interact with the acid or affect its behavior in unpredictable ways.

Lastly, ensuring the reproducibility and comparability of test results across different laboratories or experimental setups remains a significant challenge. Variations in equipment, environmental conditions, and operator techniques can all contribute to discrepancies in results, necessitating the development and adherence to standardized protocols and quality control measures.

Another major challenge is maintaining the precise concentration of hydrochloric acid throughout the testing process. The acid's volatile nature means it can easily evaporate or absorb moisture from the air, leading to changes in concentration that can significantly impact test results. This requires careful storage, handling, and measurement techniques to ensure consistent acid strength across multiple experiments.

The reactivity of hydrochloric acid with various materials also presents challenges in selecting appropriate containers, instruments, and reaction vessels. Many common laboratory materials may be unsuitable for use with hydrochloric acid, necessitating the use of specialized equipment that can withstand its corrosive properties without contaminating the samples or affecting the test results.

Accurate pH measurement and control during hydrochloric acid tests can be particularly challenging due to the acid's strong dissociation properties. Standard pH meters may struggle to provide reliable readings in highly acidic solutions, requiring the use of specialized electrodes or alternative measurement techniques. This can introduce additional complexity and potential sources of error into the testing process.

The disposal of hydrochloric acid and its byproducts after testing also poses environmental and safety challenges. Proper neutralization and disposal procedures must be followed to prevent harm to the environment and comply with regulatory requirements. This adds an extra layer of complexity to the testing process and may require additional resources and expertise.

Furthermore, the potential for interference from other ions or compounds in the test samples can complicate the interpretation of results when using hydrochloric acid. This is particularly relevant in complex matrices such as environmental or biological samples, where multiple species may interact with the acid or affect its behavior in unpredictable ways.

Lastly, ensuring the reproducibility and comparability of test results across different laboratories or experimental setups remains a significant challenge. Variations in equipment, environmental conditions, and operator techniques can all contribute to discrepancies in results, necessitating the development and adherence to standardized protocols and quality control measures.

Existing HCl Test Methods

01 Improved measurement techniques for hydrochloric acid

Advanced measurement techniques have been developed to enhance the accuracy of hydrochloric acid concentration determination. These methods may include spectroscopic analysis, electrochemical sensors, or titration techniques with improved precision. Such advancements contribute to more reliable and precise measurements in various industrial and laboratory applications.- Improved measurement techniques for hydrochloric acid: Advanced methods for accurately measuring hydrochloric acid concentration, including spectroscopic analysis, titration techniques, and electrochemical sensors. These techniques enhance the precision of acid concentration determination in various industrial and laboratory applications.

- Purification and quality control of hydrochloric acid: Processes for purifying hydrochloric acid and maintaining its quality, involving distillation, membrane separation, and ion exchange methods. These techniques help to remove impurities and ensure consistent acid concentration, thereby improving overall accuracy in industrial processes.

- Automated systems for hydrochloric acid handling: Development of automated systems for dispensing, mixing, and monitoring hydrochloric acid. These systems incorporate advanced sensors, control algorithms, and feedback mechanisms to maintain precise acid concentrations and reduce human error in handling.

- Calibration methods for hydrochloric acid instruments: Techniques for calibrating instruments used in hydrochloric acid analysis, including standardization procedures, reference materials, and inter-laboratory comparisons. These methods ensure the accuracy and reliability of measurements across different devices and laboratories.

- Environmental and safety considerations in acid handling: Innovations in containment, neutralization, and disposal of hydrochloric acid to minimize environmental impact and improve worker safety. These developments include specialized storage containers, spill control systems, and personal protective equipment, all contributing to more accurate and safer acid handling practices.

02 Calibration methods for hydrochloric acid analysis

Calibration procedures play a crucial role in ensuring the accuracy of hydrochloric acid measurements. These methods may involve the use of standard solutions, reference materials, or automated calibration systems. Proper calibration helps to minimize systematic errors and improve the overall accuracy of acid concentration determinations.Expand Specific Solutions03 Specialized equipment for precise hydrochloric acid handling

Dedicated equipment and instruments have been designed to handle and measure hydrochloric acid with high accuracy. This may include corrosion-resistant materials, precise dispensing systems, or specialized containers that minimize contamination and evaporation. Such equipment contributes to maintaining the integrity of the acid and improving measurement accuracy.Expand Specific Solutions04 Quality control processes for hydrochloric acid production

Implementing rigorous quality control processes during hydrochloric acid production can significantly improve the accuracy of the final product. These processes may involve continuous monitoring, in-line analysis, or statistical process control techniques. By ensuring consistent production quality, the accuracy of the acid concentration can be maintained within tight tolerances.Expand Specific Solutions05 Environmental factors affecting hydrochloric acid accuracy

Various environmental factors can impact the accuracy of hydrochloric acid measurements. These may include temperature fluctuations, humidity levels, or the presence of interfering substances. Addressing these factors through controlled environments, compensation techniques, or specialized sample preparation methods can lead to improved accuracy in hydrochloric acid analysis.Expand Specific Solutions

Key Industry Players

The competitive landscape for conducting accurate tests with hydrochloric acid is characterized by a mature market with established players and ongoing technological advancements. The industry is in a growth phase, driven by increasing demand for precise chemical analysis across various sectors. Key players like Siemens Corp., Praxair Technology, Inc., and Xiamen Standao Scientific Instrument Co., Ltd. are at the forefront of developing advanced testing equipment and methodologies. The market size is substantial, with a global reach spanning industries such as pharmaceuticals, environmental monitoring, and industrial manufacturing. Technological maturity is high, with companies like Samsung Electronics Co., Ltd. and Panasonic Holdings Corp. contributing to the development of sophisticated analytical instruments and sensors for precise acid testing.

Siemens Corp.

Technical Solution: Siemens has developed advanced analytical instruments for precise hydrochloric acid testing. Their approach involves using ion-selective electrodes (ISE) combined with automated titration systems. This method allows for real-time monitoring of acid concentration with high accuracy. The system employs a sealed reference electrode to prevent contamination and ensure long-term stability[1]. Additionally, Siemens has integrated their acid testing technology with digital platforms for data logging and remote monitoring, enhancing the overall efficiency of the testing process[3].

Strengths: High precision, automation capabilities, and integration with digital systems. Weaknesses: Potentially high initial cost and need for specialized training.

Praxair Technology, Inc.

Technical Solution: Praxair has developed a novel approach to hydrochloric acid testing using spectroscopic techniques. Their method employs Raman spectroscopy to analyze the vibrational modes of HCl molecules, allowing for non-invasive and rapid determination of acid concentration. The system uses a fiber-optic probe that can be directly inserted into the acid solution, providing real-time measurements without the need for sample preparation[2]. Praxair has also implemented advanced algorithms for spectral analysis, enabling the detection of trace impurities in the acid[4].

Strengths: Non-invasive testing, rapid results, and ability to detect impurities. Weaknesses: May require expensive spectroscopic equipment and specialized expertise for data interpretation.

Innovative HCl Techniques

Reagents for detection of hypochlorous acid

PatentActiveEP2134724A1

Innovation

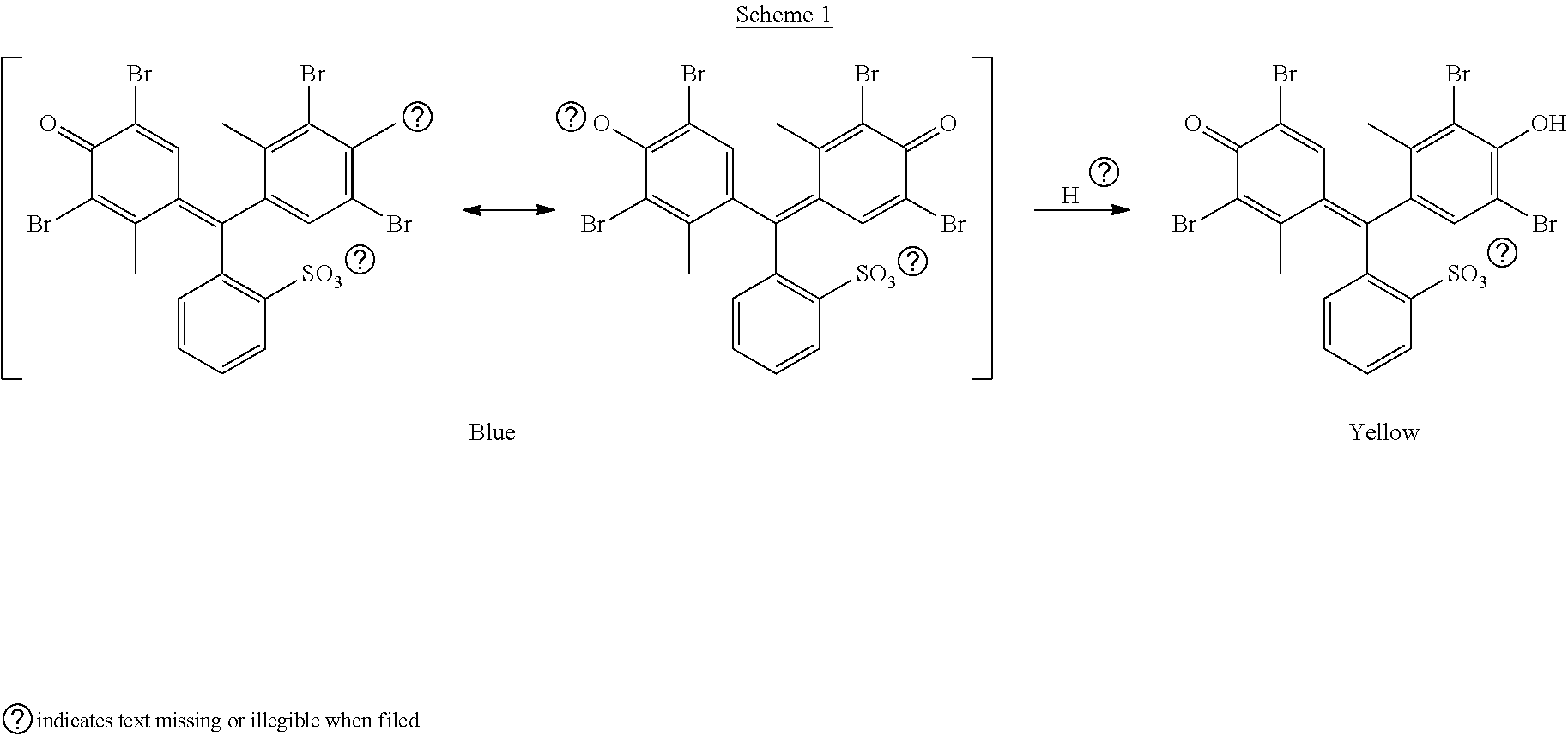

- Development of hypochlorous acid probes represented by specific chemical formulas that can selectively react with hypochlorous acid, even in the presence of other reactive oxygen and nitrogen species, forming fluorescent compounds whose fluorescence properties are used to quantify hypochlorous acid levels.

High throughput screening method of acid-producing microorganism

PatentInactiveUS20120329676A1

Innovation

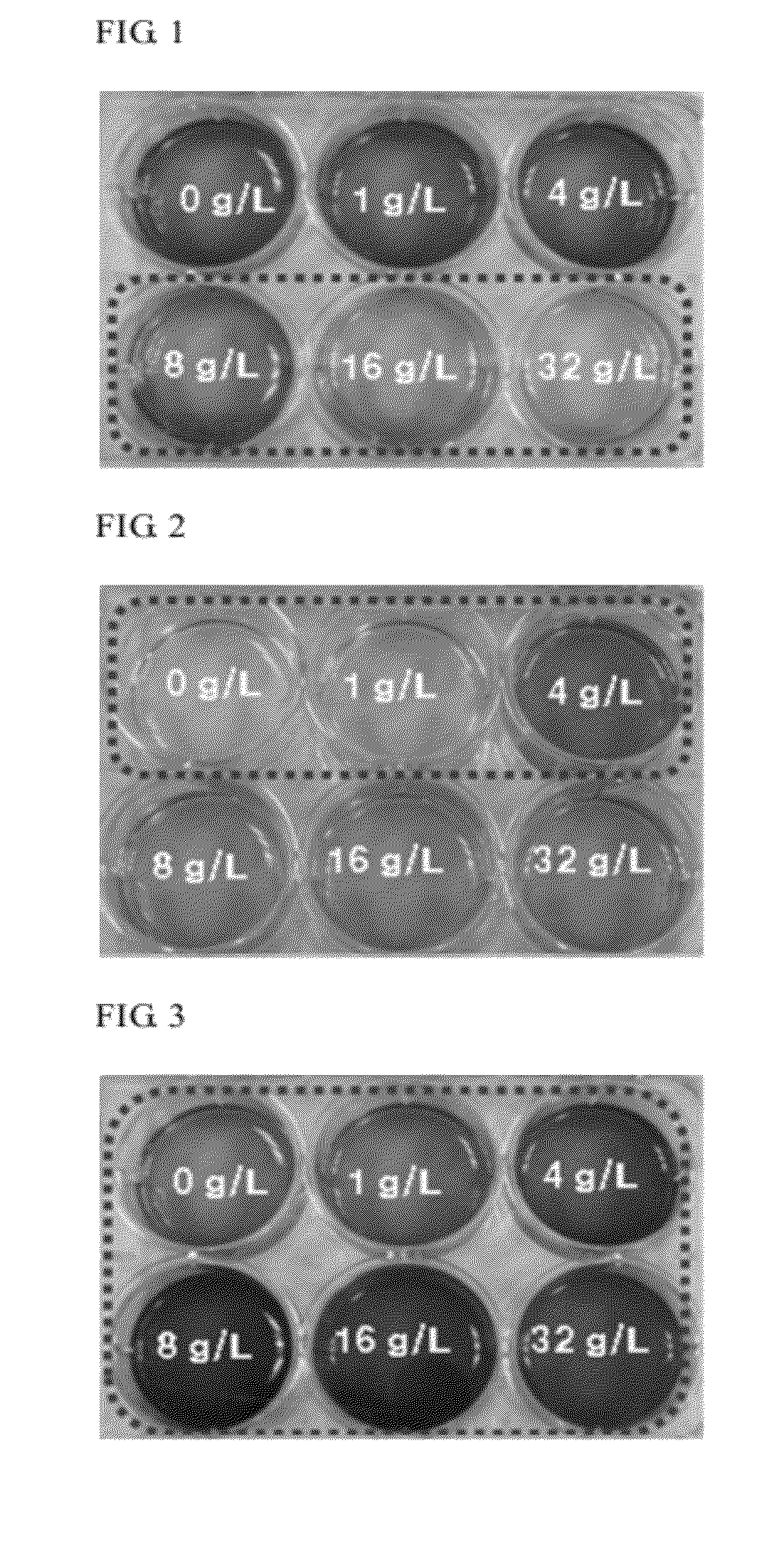

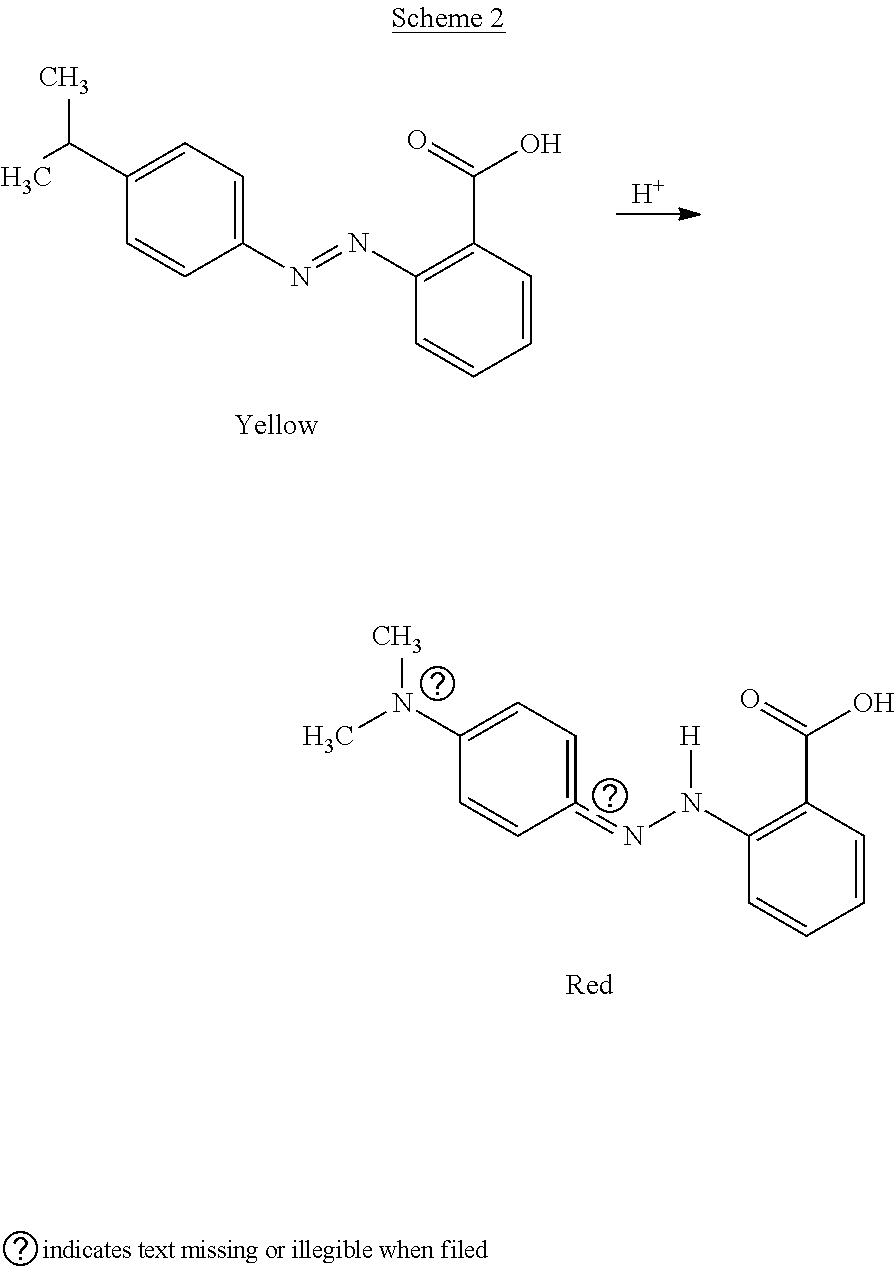

- A high throughput screening method using a mixture of at least two pH indicators, such as Bromocresol green and methyl red, added to a medium with an acid-producing microorganism, allowing for rapid and accurate measurement of acid production by observing color changes, which can be used to determine the acid production amount more effectively.

Safety Protocols

Safety protocols are paramount when conducting tests with hydrochloric acid due to its corrosive and hazardous nature. Proper personal protective equipment (PPE) is essential, including chemical-resistant gloves, safety goggles, a lab coat, and closed-toe shoes. A well-ventilated workspace, preferably a fume hood, should be used to minimize exposure to acid vapors. Before handling the acid, researchers must familiarize themselves with the Material Safety Data Sheet (MSDS) for hydrochloric acid and understand emergency procedures.

Proper storage and handling of hydrochloric acid are crucial. The acid should be stored in a cool, dry place away from direct sunlight and incompatible materials. When transferring or diluting the acid, always add acid to water slowly while stirring, never the reverse, to prevent splashing and excessive heat generation. Use appropriate containers made of acid-resistant materials such as glass or certain plastics.

Spill management protocols must be in place. Small spills can be neutralized with sodium bicarbonate or other suitable bases, followed by thorough rinsing with water. For larger spills, a spill kit should be readily available, and the area must be evacuated immediately. Proper disposal of acid waste is essential, adhering to local regulations and institutional guidelines.

Regular safety training and drills should be conducted to ensure all personnel are familiar with emergency procedures, including the locations of eyewash stations, safety showers, and fire extinguishers. A buddy system is recommended when working with hazardous chemicals, ensuring someone is always available to assist in case of an emergency.

Accurate labeling and documentation are vital for maintaining a safe laboratory environment. All containers must be clearly labeled with the chemical name, concentration, date of preparation, and any relevant hazard warnings. A chemical inventory system should be implemented to track the usage and storage of hydrochloric acid and other hazardous materials.

When conducting tests, it is important to use the minimum amount of acid necessary for the experiment to reduce risks. Dilutions should be prepared in advance and stored properly. Any equipment used with hydrochloric acid must be thoroughly cleaned and neutralized after use to prevent contamination and potential hazards in future experiments.

In case of accidental exposure, immediate action is crucial. For skin contact, the affected area should be flushed with copious amounts of water for at least 15 minutes. For eye exposure, eyes must be rinsed using an eyewash station for a minimum of 15 minutes. In case of ingestion, do not induce vomiting and seek medical attention immediately. All incidents, no matter how minor, should be reported and documented for future safety improvements.

Proper storage and handling of hydrochloric acid are crucial. The acid should be stored in a cool, dry place away from direct sunlight and incompatible materials. When transferring or diluting the acid, always add acid to water slowly while stirring, never the reverse, to prevent splashing and excessive heat generation. Use appropriate containers made of acid-resistant materials such as glass or certain plastics.

Spill management protocols must be in place. Small spills can be neutralized with sodium bicarbonate or other suitable bases, followed by thorough rinsing with water. For larger spills, a spill kit should be readily available, and the area must be evacuated immediately. Proper disposal of acid waste is essential, adhering to local regulations and institutional guidelines.

Regular safety training and drills should be conducted to ensure all personnel are familiar with emergency procedures, including the locations of eyewash stations, safety showers, and fire extinguishers. A buddy system is recommended when working with hazardous chemicals, ensuring someone is always available to assist in case of an emergency.

Accurate labeling and documentation are vital for maintaining a safe laboratory environment. All containers must be clearly labeled with the chemical name, concentration, date of preparation, and any relevant hazard warnings. A chemical inventory system should be implemented to track the usage and storage of hydrochloric acid and other hazardous materials.

When conducting tests, it is important to use the minimum amount of acid necessary for the experiment to reduce risks. Dilutions should be prepared in advance and stored properly. Any equipment used with hydrochloric acid must be thoroughly cleaned and neutralized after use to prevent contamination and potential hazards in future experiments.

In case of accidental exposure, immediate action is crucial. For skin contact, the affected area should be flushed with copious amounts of water for at least 15 minutes. For eye exposure, eyes must be rinsed using an eyewash station for a minimum of 15 minutes. In case of ingestion, do not induce vomiting and seek medical attention immediately. All incidents, no matter how minor, should be reported and documented for future safety improvements.

Environmental Impact

The environmental impact of conducting tests with hydrochloric acid is a critical consideration that requires careful attention. Hydrochloric acid, being a strong and corrosive substance, poses significant risks to both the environment and human health if not handled properly. When used in laboratory settings, even small amounts of hydrochloric acid can have detrimental effects on ecosystems if released into the environment.

One of the primary concerns is the potential for acid runoff. If hydrochloric acid is not properly neutralized or contained, it can contaminate soil and water systems. This contamination can lead to changes in soil pH, affecting plant growth and microbial communities. In aquatic environments, even small changes in pH can have far-reaching consequences for fish, amphibians, and other aquatic organisms.

Air pollution is another environmental risk associated with hydrochloric acid use. During testing procedures, fumes may be released, contributing to air quality degradation. These fumes can cause respiratory issues in humans and animals, and may also contribute to acid rain formation if released in significant quantities.

Proper disposal of hydrochloric acid and its byproducts is crucial to mitigate environmental impact. Neutralization processes must be carefully implemented to ensure that the acid is rendered harmless before disposal. Failure to do so can result in long-term environmental damage and potential legal consequences.

The production and transportation of hydrochloric acid also contribute to its environmental footprint. Manufacturing processes often involve energy-intensive methods and may result in emissions. Additionally, the risk of spills during transportation poses a threat to ecosystems along shipping routes.

To minimize environmental impact, laboratories and industries must adhere to strict protocols for handling, storage, and disposal of hydrochloric acid. This includes using appropriate personal protective equipment, implementing spill containment measures, and following regulated disposal procedures. Regular environmental assessments and monitoring of acid use and disposal practices are essential to ensure compliance with environmental regulations.

Developing alternative testing methods that reduce or eliminate the need for hydrochloric acid can significantly decrease environmental risks. Research into green chemistry alternatives and less hazardous substances is ongoing, with the aim of maintaining testing accuracy while reducing ecological impact.

One of the primary concerns is the potential for acid runoff. If hydrochloric acid is not properly neutralized or contained, it can contaminate soil and water systems. This contamination can lead to changes in soil pH, affecting plant growth and microbial communities. In aquatic environments, even small changes in pH can have far-reaching consequences for fish, amphibians, and other aquatic organisms.

Air pollution is another environmental risk associated with hydrochloric acid use. During testing procedures, fumes may be released, contributing to air quality degradation. These fumes can cause respiratory issues in humans and animals, and may also contribute to acid rain formation if released in significant quantities.

Proper disposal of hydrochloric acid and its byproducts is crucial to mitigate environmental impact. Neutralization processes must be carefully implemented to ensure that the acid is rendered harmless before disposal. Failure to do so can result in long-term environmental damage and potential legal consequences.

The production and transportation of hydrochloric acid also contribute to its environmental footprint. Manufacturing processes often involve energy-intensive methods and may result in emissions. Additionally, the risk of spills during transportation poses a threat to ecosystems along shipping routes.

To minimize environmental impact, laboratories and industries must adhere to strict protocols for handling, storage, and disposal of hydrochloric acid. This includes using appropriate personal protective equipment, implementing spill containment measures, and following regulated disposal procedures. Regular environmental assessments and monitoring of acid use and disposal practices are essential to ensure compliance with environmental regulations.

Developing alternative testing methods that reduce or eliminate the need for hydrochloric acid can significantly decrease environmental risks. Research into green chemistry alternatives and less hazardous substances is ongoing, with the aim of maintaining testing accuracy while reducing ecological impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!