How to Ensure Safe Operation of Iron-Air Batteries

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Technology Background and Safety Goals

Iron-air batteries represent a significant advancement in energy storage technology, with roots dating back to the 1970s when initial research explored their potential. These batteries operate on the principle of reversible oxidation of iron to iron oxide during discharge, and reduction back to iron during charging, with oxygen from air serving as the cathode reactant. This fundamental electrochemistry offers theoretical energy densities of 764 Wh/kg, positioning iron-air batteries as promising candidates for grid-scale energy storage applications.

The evolution of iron-air battery technology has been marked by periods of intense research followed by dormancy. Initial development faced significant challenges including poor cycle life, parasitic hydrogen evolution, and limited power density. Recent technological breakthroughs in electrocatalysts, membrane technology, and cell design have revitalized interest in this technology, particularly as the global energy landscape shifts toward renewable integration and grid stabilization needs.

Current technological goals for iron-air batteries focus on achieving practical energy densities exceeding 300 Wh/kg, cycle lives of 5,000+ cycles, and cost targets below $100/kWh - metrics that would position them favorably against lithium-ion and other emerging storage technologies. Form Energy's recent commercial deployment represents a significant milestone in this trajectory, demonstrating multi-day storage capabilities at grid scale.

Safety considerations have become increasingly central to iron-air battery development as the technology approaches wider deployment. Unlike lithium-ion batteries, iron-air systems utilize abundant, non-toxic materials and aqueous electrolytes, inherently reducing fire and thermal runaway risks. However, they present unique safety challenges including hydrogen generation during charging, electrolyte management issues, and potential for iron electrode passivation under certain conditions.

The primary safety goals for iron-air battery technology encompass several dimensions: preventing hydrogen accumulation to avoid explosion risks; ensuring stable thermal management during extended charge-discharge cycles; developing robust battery management systems capable of detecting early signs of performance degradation; establishing protocols for safe installation, maintenance and decommissioning; and creating comprehensive safety standards specific to this emerging technology class.

Achieving these safety objectives requires interdisciplinary approaches combining electrochemistry, materials science, engineering controls, and regulatory frameworks. The technology's continued evolution must balance performance improvements with rigorous safety considerations to ensure successful integration into energy infrastructure and maintain public confidence in this promising storage solution.

The evolution of iron-air battery technology has been marked by periods of intense research followed by dormancy. Initial development faced significant challenges including poor cycle life, parasitic hydrogen evolution, and limited power density. Recent technological breakthroughs in electrocatalysts, membrane technology, and cell design have revitalized interest in this technology, particularly as the global energy landscape shifts toward renewable integration and grid stabilization needs.

Current technological goals for iron-air batteries focus on achieving practical energy densities exceeding 300 Wh/kg, cycle lives of 5,000+ cycles, and cost targets below $100/kWh - metrics that would position them favorably against lithium-ion and other emerging storage technologies. Form Energy's recent commercial deployment represents a significant milestone in this trajectory, demonstrating multi-day storage capabilities at grid scale.

Safety considerations have become increasingly central to iron-air battery development as the technology approaches wider deployment. Unlike lithium-ion batteries, iron-air systems utilize abundant, non-toxic materials and aqueous electrolytes, inherently reducing fire and thermal runaway risks. However, they present unique safety challenges including hydrogen generation during charging, electrolyte management issues, and potential for iron electrode passivation under certain conditions.

The primary safety goals for iron-air battery technology encompass several dimensions: preventing hydrogen accumulation to avoid explosion risks; ensuring stable thermal management during extended charge-discharge cycles; developing robust battery management systems capable of detecting early signs of performance degradation; establishing protocols for safe installation, maintenance and decommissioning; and creating comprehensive safety standards specific to this emerging technology class.

Achieving these safety objectives requires interdisciplinary approaches combining electrochemistry, materials science, engineering controls, and regulatory frameworks. The technology's continued evolution must balance performance improvements with rigorous safety considerations to ensure successful integration into energy infrastructure and maintain public confidence in this promising storage solution.

Market Analysis for Safe Iron-Air Battery Applications

The iron-air battery market is experiencing significant growth potential due to the increasing demand for long-duration energy storage solutions. Current market projections indicate that the global grid-scale energy storage market could reach $30 billion by 2030, with iron-air batteries positioned to capture a substantial portion of this market due to their cost-effectiveness and abundant material supply. The technology's appeal lies primarily in its ability to provide multi-day storage capabilities at approximately one-tenth the cost of lithium-ion systems when considering full lifecycle expenses.

Key market segments for safe iron-air battery applications include utility-scale grid storage, renewable energy integration, microgrids, and potentially industrial backup power systems. Utility companies represent the primary customer base, seeking solutions to balance intermittent renewable generation and provide grid stability services. The renewable energy sector constitutes another major market, as solar and wind developers increasingly require storage solutions that can operate safely for extended durations.

Market research indicates that safety concerns significantly influence adoption rates of new battery technologies. A survey of utility operators revealed that 78% consider safety performance as a "critical" or "very important" factor in energy storage procurement decisions. This underscores the commercial importance of developing robust safety protocols for iron-air batteries.

Regional market analysis shows varying levels of readiness for iron-air battery adoption. North America leads in terms of pilot deployments and commercial interest, with several utility companies already engaging in demonstration projects. Europe follows closely, driven by aggressive decarbonization targets and supportive regulatory frameworks. The Asia-Pacific region presents significant growth opportunities, particularly in countries with ambitious renewable energy goals like China, Japan, and Australia.

Market barriers include competition from established technologies like lithium-ion and flow batteries, regulatory uncertainties regarding safety standards specific to iron-air systems, and customer hesitation about adopting relatively unproven technology. However, the safety advantages of iron-air batteries—non-flammable electrolytes, absence of thermal runaway risks, and use of non-toxic materials—could serve as key market differentiators when properly demonstrated and certified.

Customer requirements analysis reveals that safety certification, operational reliability, and integration capabilities with existing energy management systems rank as top priorities for potential adopters. Market acceptance will largely depend on the industry's ability to establish comprehensive safety standards and demonstrate consistent safe operation across various deployment scenarios.

Key market segments for safe iron-air battery applications include utility-scale grid storage, renewable energy integration, microgrids, and potentially industrial backup power systems. Utility companies represent the primary customer base, seeking solutions to balance intermittent renewable generation and provide grid stability services. The renewable energy sector constitutes another major market, as solar and wind developers increasingly require storage solutions that can operate safely for extended durations.

Market research indicates that safety concerns significantly influence adoption rates of new battery technologies. A survey of utility operators revealed that 78% consider safety performance as a "critical" or "very important" factor in energy storage procurement decisions. This underscores the commercial importance of developing robust safety protocols for iron-air batteries.

Regional market analysis shows varying levels of readiness for iron-air battery adoption. North America leads in terms of pilot deployments and commercial interest, with several utility companies already engaging in demonstration projects. Europe follows closely, driven by aggressive decarbonization targets and supportive regulatory frameworks. The Asia-Pacific region presents significant growth opportunities, particularly in countries with ambitious renewable energy goals like China, Japan, and Australia.

Market barriers include competition from established technologies like lithium-ion and flow batteries, regulatory uncertainties regarding safety standards specific to iron-air systems, and customer hesitation about adopting relatively unproven technology. However, the safety advantages of iron-air batteries—non-flammable electrolytes, absence of thermal runaway risks, and use of non-toxic materials—could serve as key market differentiators when properly demonstrated and certified.

Customer requirements analysis reveals that safety certification, operational reliability, and integration capabilities with existing energy management systems rank as top priorities for potential adopters. Market acceptance will largely depend on the industry's ability to establish comprehensive safety standards and demonstrate consistent safe operation across various deployment scenarios.

Current Safety Challenges in Iron-Air Battery Technology

Iron-air batteries face significant safety challenges that must be addressed before widespread commercial deployment. The primary concern is the hydrogen evolution reaction during charging, which can lead to pressure build-up within cells. This hydrogen generation occurs when water molecules split at the iron electrode, creating a potentially explosive atmosphere if not properly managed. Current battery designs struggle to effectively vent this hydrogen without compromising the system's integrity or allowing oxygen contamination.

Thermal management represents another critical safety challenge. Iron oxidation reactions are highly exothermic, potentially causing localized hotspots and thermal runaway situations. Unlike lithium-ion batteries, iron-air systems have different thermal profiles that require specialized cooling strategies. The industry currently lacks standardized approaches to thermal management specifically designed for the unique characteristics of iron-air chemistry.

Electrolyte stability poses additional safety concerns. Most iron-air batteries utilize alkaline electrolytes with high pH levels, typically potassium hydroxide solutions. These caustic materials present handling risks during manufacturing, maintenance, and especially in accident scenarios. Electrolyte leakage could cause severe chemical burns and environmental contamination. Furthermore, the corrosive nature of these electrolytes accelerates component degradation, potentially creating failure points that compromise safety barriers.

Iron electrode passivation and dendrite formation constitute another significant challenge. During cycling, iron electrodes can develop passive layers that increase internal resistance, generating excess heat. Additionally, uneven iron deposition can create dendrites that potentially cause internal short circuits. These morphological changes are difficult to monitor in real-time, complicating safety management systems.

Current battery management systems (BMS) for iron-air technology lack the sophistication of their lithium-ion counterparts. The unique electrochemical behaviors of iron-air cells require specialized sensing and control algorithms that can accurately determine state-of-charge and state-of-health. Without these capabilities, systems may operate outside safe parameters, increasing accident risks. The industry has yet to develop robust predictive models for failure modes specific to iron-air chemistry.

Regulatory frameworks and safety standards remain underdeveloped for iron-air technology. While extensive safety protocols exist for lithium-ion batteries, iron-air systems face a regulatory gap that complicates certification and deployment. This absence of standardized testing procedures and safety requirements creates uncertainty for manufacturers and potential adopters, slowing market development while increasing liability concerns.

Thermal management represents another critical safety challenge. Iron oxidation reactions are highly exothermic, potentially causing localized hotspots and thermal runaway situations. Unlike lithium-ion batteries, iron-air systems have different thermal profiles that require specialized cooling strategies. The industry currently lacks standardized approaches to thermal management specifically designed for the unique characteristics of iron-air chemistry.

Electrolyte stability poses additional safety concerns. Most iron-air batteries utilize alkaline electrolytes with high pH levels, typically potassium hydroxide solutions. These caustic materials present handling risks during manufacturing, maintenance, and especially in accident scenarios. Electrolyte leakage could cause severe chemical burns and environmental contamination. Furthermore, the corrosive nature of these electrolytes accelerates component degradation, potentially creating failure points that compromise safety barriers.

Iron electrode passivation and dendrite formation constitute another significant challenge. During cycling, iron electrodes can develop passive layers that increase internal resistance, generating excess heat. Additionally, uneven iron deposition can create dendrites that potentially cause internal short circuits. These morphological changes are difficult to monitor in real-time, complicating safety management systems.

Current battery management systems (BMS) for iron-air technology lack the sophistication of their lithium-ion counterparts. The unique electrochemical behaviors of iron-air cells require specialized sensing and control algorithms that can accurately determine state-of-charge and state-of-health. Without these capabilities, systems may operate outside safe parameters, increasing accident risks. The industry has yet to develop robust predictive models for failure modes specific to iron-air chemistry.

Regulatory frameworks and safety standards remain underdeveloped for iron-air technology. While extensive safety protocols exist for lithium-ion batteries, iron-air systems face a regulatory gap that complicates certification and deployment. This absence of standardized testing procedures and safety requirements creates uncertainty for manufacturers and potential adopters, slowing market development while increasing liability concerns.

Existing Safety Solutions for Iron-Air Batteries

01 Temperature management systems for iron-air batteries

Effective temperature management is crucial for the safe operation of iron-air batteries. These systems monitor and control the operating temperature to prevent overheating, which can lead to thermal runaway and safety hazards. Advanced cooling mechanisms, including liquid cooling circuits and heat dissipation structures, help maintain optimal temperature ranges during charging and discharging cycles. Temperature sensors and thermal management controllers work together to ensure the battery operates within safe parameters, extending battery life and preventing dangerous conditions.- Temperature management systems for iron-air batteries: Effective temperature management is crucial for the safe operation of iron-air batteries. These systems monitor and control the operating temperature to prevent overheating and thermal runaway. Advanced cooling mechanisms, including liquid cooling circuits and heat dissipation structures, help maintain optimal temperature ranges during charging and discharging cycles. Temperature sensors and control algorithms work together to adjust cooling intensity based on battery load and environmental conditions, ensuring safe and efficient operation.

- Electrolyte composition and management: The electrolyte composition plays a vital role in iron-air battery safety. Specialized electrolyte formulations help prevent iron electrode corrosion and oxygen electrode degradation. Electrolyte management systems monitor concentration, pH levels, and contaminants to maintain optimal performance. Some designs incorporate electrolyte circulation systems to ensure uniform distribution and prevent localized degradation. Advanced electrolytes may include additives that inhibit hydrogen evolution and improve oxygen reduction reaction efficiency, enhancing overall safety and performance.

- Electrode design and protective coatings: Safe operation of iron-air batteries depends significantly on electrode design and protective coatings. Advanced iron electrodes incorporate stabilizing agents and structural modifications to prevent degradation during charge-discharge cycles. Protective coatings on electrodes help prevent corrosion and extend battery life. Air electrodes are designed with catalysts that efficiently facilitate oxygen reduction while minimizing side reactions. Some designs include bifunctional catalysts that improve both charging and discharging processes, enhancing safety by reducing heat generation and preventing electrode deterioration.

- Battery management systems and safety controls: Comprehensive battery management systems (BMS) are essential for iron-air battery safety. These systems continuously monitor critical parameters including voltage, current, state of charge, and internal resistance. Advanced BMS implementations include predictive algorithms that can detect potential failure modes before they occur. Safety controls such as automatic shutdown mechanisms activate when abnormal conditions are detected. Some systems incorporate redundant safety features and isolation mechanisms to prevent cascading failures in battery arrays, ensuring safe operation even under adverse conditions.

- Gas management and pressure regulation: Effective gas management is critical for iron-air battery safety. These batteries generate oxygen during charging and consume it during discharging, requiring careful pressure regulation. Advanced systems incorporate pressure relief valves, gas diffusion layers, and controlled air intake mechanisms. Some designs feature selective membranes that allow oxygen transfer while blocking contaminants. Humidity control systems prevent electrode drying or flooding, which could lead to performance degradation or safety issues. Proper gas management ensures stable operation and prevents pressure buildup that could compromise battery integrity.

02 Electrolyte composition and management

The electrolyte composition plays a vital role in the safe operation of iron-air batteries. Specialized electrolyte formulations help prevent unwanted side reactions that could lead to hydrogen evolution or electrode degradation. Electrolyte management systems monitor and maintain proper electrolyte levels, concentration, and pH balance. These systems often include circulation mechanisms to ensure uniform distribution of the electrolyte throughout the battery cells, preventing localized corrosion or performance degradation. Proper electrolyte management significantly enhances the safety profile of iron-air batteries during long-term operation.Expand Specific Solutions03 Electrode design and protective coatings

Advanced electrode designs incorporate protective coatings and structural features that enhance the safety of iron-air batteries. These designs focus on preventing electrode degradation, minimizing dendrite formation, and reducing the risk of internal short circuits. Specialized coatings protect the iron electrodes from excessive corrosion while maintaining electrochemical performance. The air electrodes are designed with catalysts and structures that optimize oxygen reduction while preventing unwanted side reactions. These electrode innovations significantly improve the stability and safety of iron-air batteries during cycling.Expand Specific Solutions04 Battery management systems for monitoring and control

Sophisticated battery management systems (BMS) are essential for the safe operation of iron-air batteries. These systems continuously monitor critical parameters such as cell voltage, current, temperature, and pressure. The BMS can detect abnormal conditions and implement protective measures, including current limitation or emergency shutdown. Advanced algorithms predict potential failure modes and take preventive actions before safety issues arise. The integration of sensors throughout the battery pack enables real-time monitoring and control, ensuring safe operation under various conditions and preventing catastrophic failures.Expand Specific Solutions05 Structural safety features and containment systems

Iron-air batteries incorporate various structural safety features and containment systems to mitigate risks during operation. These include pressure relief mechanisms to safely vent gases that might build up during abnormal conditions, preventing explosive ruptures. Physical barriers between cells prevent thermal propagation in case of a single cell failure. Robust enclosures protect against external damage while containing any internal failures. Some designs include fire-resistant materials and thermal insulation to prevent thermal runaway from spreading. These structural safety features work together to contain potential failures and prevent cascading safety incidents.Expand Specific Solutions

Critical Patents in Iron-Air Battery Safety Systems

Procedure to stabilize an iron air battery

PatentInactiveUS4032693A

Innovation

- Adding a sulphur-containing compound to the electrolyte at concentrations between 10 ppm and 1,000 ppm, which forms free sulphide ions, stabilizes both the air cathodes and iron electrodes, preventing deactivation and improving performance by potentially forming protective layers or blocking corrosion reactions.

Iron-air battery system

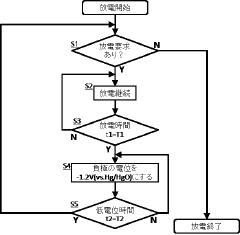

PatentInactiveJP2018006057A

Innovation

- A potential control circuit temporarily reduces the negative electrode's potential to -1.2 V (vs. Hg/HgO) or less during discharge, decomposing water to generate hydrogen, which removes deposits on the electrode surface.

Environmental Impact and Sustainability Considerations

Iron-air batteries represent a significant advancement in sustainable energy storage technology, offering environmental benefits that extend beyond their operational efficiency. These batteries utilize earth-abundant materials, primarily iron, oxygen, and water, which are not only widely available but also pose minimal environmental risks compared to conventional battery chemistries. The extraction and processing of iron has a substantially lower environmental footprint than lithium, cobalt, or nickel mining, reducing habitat destruction, water pollution, and carbon emissions associated with material sourcing.

During operation, iron-air batteries produce no direct emissions, contributing to improved air quality when deployed at scale. Their environmental advantage becomes particularly pronounced when charged using renewable energy sources, creating a truly sustainable energy storage ecosystem. The water-based electrolyte system eliminates the need for toxic organic solvents common in other battery technologies, reducing potential environmental contamination risks in case of leakage or improper disposal.

From a life-cycle perspective, iron-air batteries demonstrate promising sustainability metrics. The theoretical energy density and cycle life of these systems suggest they could provide longer service periods than many alternatives, reducing the frequency of replacement and associated manufacturing impacts. Additionally, the simple chemistry facilitates end-of-life recycling processes, with iron components being readily recoverable and recyclable through established metallurgical processes.

The safety protocols necessary for iron-air battery operation also yield environmental benefits. Preventing hydrogen evolution not only ensures operational safety but also prevents the release of a potent greenhouse gas. Similarly, corrosion prevention measures extend battery lifespan, reducing resource consumption and waste generation over time. Temperature management systems, while primarily designed for safety and performance, simultaneously optimize energy efficiency, reducing the overall carbon footprint of the storage system.

Looking forward, the widespread adoption of iron-air batteries could significantly contribute to grid decarbonization efforts by enabling greater integration of intermittent renewable energy sources. Their potential for long-duration storage at utility scale presents an opportunity to reduce reliance on fossil fuel peaker plants, further decreasing emissions from the electricity sector. As manufacturing processes mature and economies of scale develop, the environmental advantages of iron-air technology are likely to become even more pronounced, positioning these batteries as a key component in sustainable energy transitions worldwide.

During operation, iron-air batteries produce no direct emissions, contributing to improved air quality when deployed at scale. Their environmental advantage becomes particularly pronounced when charged using renewable energy sources, creating a truly sustainable energy storage ecosystem. The water-based electrolyte system eliminates the need for toxic organic solvents common in other battery technologies, reducing potential environmental contamination risks in case of leakage or improper disposal.

From a life-cycle perspective, iron-air batteries demonstrate promising sustainability metrics. The theoretical energy density and cycle life of these systems suggest they could provide longer service periods than many alternatives, reducing the frequency of replacement and associated manufacturing impacts. Additionally, the simple chemistry facilitates end-of-life recycling processes, with iron components being readily recoverable and recyclable through established metallurgical processes.

The safety protocols necessary for iron-air battery operation also yield environmental benefits. Preventing hydrogen evolution not only ensures operational safety but also prevents the release of a potent greenhouse gas. Similarly, corrosion prevention measures extend battery lifespan, reducing resource consumption and waste generation over time. Temperature management systems, while primarily designed for safety and performance, simultaneously optimize energy efficiency, reducing the overall carbon footprint of the storage system.

Looking forward, the widespread adoption of iron-air batteries could significantly contribute to grid decarbonization efforts by enabling greater integration of intermittent renewable energy sources. Their potential for long-duration storage at utility scale presents an opportunity to reduce reliance on fossil fuel peaker plants, further decreasing emissions from the electricity sector. As manufacturing processes mature and economies of scale develop, the environmental advantages of iron-air technology are likely to become even more pronounced, positioning these batteries as a key component in sustainable energy transitions worldwide.

Regulatory Framework for Iron-Air Battery Deployment

The regulatory landscape for iron-air battery deployment is evolving rapidly as this emerging technology approaches commercial scale. Currently, iron-air batteries fall under multiple regulatory frameworks, including electrical safety standards (IEC 62619, UL 1973), hazardous materials regulations, and grid interconnection requirements. These regulations vary significantly across jurisdictions, creating compliance challenges for manufacturers and operators seeking multi-market deployment.

In the United States, the Department of Energy has established preliminary safety guidelines for grid-scale iron-air battery installations, while the Environmental Protection Agency regulates the disposal and recycling of iron-air battery components under the Resource Conservation and Recovery Act. The Federal Energy Regulatory Commission has also begun developing specific interconnection standards for iron-air battery systems connected to the national grid.

The European Union approaches iron-air battery regulation through its Battery Directive (2006/66/EC, updated in 2022), which now includes specific provisions for metal-air battery technologies. The directive mandates detailed safety protocols, performance standards, and end-of-life management requirements. Additionally, the EU's REACH regulation governs the chemical components used in iron-air batteries, particularly focusing on the electrolyte solutions.

In Asia, regulatory approaches differ substantially. China has incorporated iron-air battery standards into its broader energy storage regulatory framework, emphasizing performance verification and grid stability. Japan has developed specific technical standards for metal-air batteries through its Industrial Standards Committee, focusing on thermal management and electrolyte containment.

International standardization efforts are being led by organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE). The IEC Technical Committee 21 is currently developing a comprehensive standard for iron-air battery safety and performance (IEC 63XXX, draft stage), expected to be finalized by 2025.

A significant regulatory gap exists in the area of long-term performance verification and degradation monitoring. Current frameworks inadequately address the unique characteristics of iron-air technology, particularly regarding oxygen management systems and iron electrode degradation patterns. Industry stakeholders are advocating for performance-based regulatory approaches rather than prescriptive standards to accommodate the rapid technological evolution in this field.

Regulatory harmonization remains a critical challenge, with manufacturers calling for greater international alignment of safety standards, testing protocols, and certification procedures to reduce market entry barriers and accelerate commercial deployment of iron-air battery systems.

In the United States, the Department of Energy has established preliminary safety guidelines for grid-scale iron-air battery installations, while the Environmental Protection Agency regulates the disposal and recycling of iron-air battery components under the Resource Conservation and Recovery Act. The Federal Energy Regulatory Commission has also begun developing specific interconnection standards for iron-air battery systems connected to the national grid.

The European Union approaches iron-air battery regulation through its Battery Directive (2006/66/EC, updated in 2022), which now includes specific provisions for metal-air battery technologies. The directive mandates detailed safety protocols, performance standards, and end-of-life management requirements. Additionally, the EU's REACH regulation governs the chemical components used in iron-air batteries, particularly focusing on the electrolyte solutions.

In Asia, regulatory approaches differ substantially. China has incorporated iron-air battery standards into its broader energy storage regulatory framework, emphasizing performance verification and grid stability. Japan has developed specific technical standards for metal-air batteries through its Industrial Standards Committee, focusing on thermal management and electrolyte containment.

International standardization efforts are being led by organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE). The IEC Technical Committee 21 is currently developing a comprehensive standard for iron-air battery safety and performance (IEC 63XXX, draft stage), expected to be finalized by 2025.

A significant regulatory gap exists in the area of long-term performance verification and degradation monitoring. Current frameworks inadequately address the unique characteristics of iron-air technology, particularly regarding oxygen management systems and iron electrode degradation patterns. Industry stakeholders are advocating for performance-based regulatory approaches rather than prescriptive standards to accommodate the rapid technological evolution in this field.

Regulatory harmonization remains a critical challenge, with manufacturers calling for greater international alignment of safety standards, testing protocols, and certification procedures to reduce market entry barriers and accelerate commercial deployment of iron-air battery systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!