How to Evaluate the Cost-Effectiveness of Hydrochloric Acid Usage?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl Usage Background and Objectives

Hydrochloric acid (HCl) has been a cornerstone in various industrial processes for decades, playing a crucial role in sectors such as chemical manufacturing, metal processing, and water treatment. The evaluation of its cost-effectiveness has become increasingly important as industries strive for operational efficiency and environmental sustainability. This technical pre-research report aims to provide a comprehensive overview of HCl usage, its historical context, and the objectives for assessing its cost-effectiveness.

The use of hydrochloric acid can be traced back to the alchemists of the Middle Ages, who referred to it as "spirit of salt." However, its large-scale industrial production and application began in the early 20th century with the development of the chlor-alkali process. Since then, HCl has become an indispensable chemical in numerous industrial applications, driving the need for continuous improvement in its production, handling, and utilization.

In recent years, the global HCl market has experienced significant fluctuations due to changes in supply and demand dynamics, environmental regulations, and technological advancements. These factors have heightened the importance of evaluating the cost-effectiveness of HCl usage across various industries. The primary objective of this evaluation is to optimize the use of HCl while minimizing costs and environmental impact.

To achieve this goal, it is essential to consider several key aspects of HCl usage. These include production methods, transportation and storage, application efficiency, waste management, and potential alternatives. By analyzing these factors, industries can identify areas for improvement and develop strategies to enhance the cost-effectiveness of their HCl-related processes.

Furthermore, the evaluation of HCl cost-effectiveness must take into account the evolving regulatory landscape. Stricter environmental regulations and safety standards have led to increased costs associated with HCl handling and disposal. This has prompted industries to seek innovative solutions for reducing HCl consumption and improving its overall efficiency.

Another critical objective of this evaluation is to explore emerging technologies and methodologies that can potentially revolutionize HCl usage. These may include advanced recycling techniques, novel application methods, or the development of alternative chemicals that can partially or fully replace HCl in certain processes. By staying at the forefront of these technological advancements, industries can maintain their competitive edge while improving their environmental performance.

In conclusion, the evaluation of HCl cost-effectiveness is a multifaceted challenge that requires a comprehensive understanding of its historical context, current market dynamics, and future trends. This technical pre-research report aims to provide a solid foundation for addressing this challenge, ultimately leading to more efficient and sustainable industrial processes across various sectors.

The use of hydrochloric acid can be traced back to the alchemists of the Middle Ages, who referred to it as "spirit of salt." However, its large-scale industrial production and application began in the early 20th century with the development of the chlor-alkali process. Since then, HCl has become an indispensable chemical in numerous industrial applications, driving the need for continuous improvement in its production, handling, and utilization.

In recent years, the global HCl market has experienced significant fluctuations due to changes in supply and demand dynamics, environmental regulations, and technological advancements. These factors have heightened the importance of evaluating the cost-effectiveness of HCl usage across various industries. The primary objective of this evaluation is to optimize the use of HCl while minimizing costs and environmental impact.

To achieve this goal, it is essential to consider several key aspects of HCl usage. These include production methods, transportation and storage, application efficiency, waste management, and potential alternatives. By analyzing these factors, industries can identify areas for improvement and develop strategies to enhance the cost-effectiveness of their HCl-related processes.

Furthermore, the evaluation of HCl cost-effectiveness must take into account the evolving regulatory landscape. Stricter environmental regulations and safety standards have led to increased costs associated with HCl handling and disposal. This has prompted industries to seek innovative solutions for reducing HCl consumption and improving its overall efficiency.

Another critical objective of this evaluation is to explore emerging technologies and methodologies that can potentially revolutionize HCl usage. These may include advanced recycling techniques, novel application methods, or the development of alternative chemicals that can partially or fully replace HCl in certain processes. By staying at the forefront of these technological advancements, industries can maintain their competitive edge while improving their environmental performance.

In conclusion, the evaluation of HCl cost-effectiveness is a multifaceted challenge that requires a comprehensive understanding of its historical context, current market dynamics, and future trends. This technical pre-research report aims to provide a solid foundation for addressing this challenge, ultimately leading to more efficient and sustainable industrial processes across various sectors.

Market Demand Analysis for HCl

The global market for hydrochloric acid (HCl) has shown steady growth in recent years, driven by its widespread applications across various industries. The demand for HCl is primarily fueled by its use in steel pickling, oil well acidizing, food processing, and chemical manufacturing. The steel industry, in particular, remains a significant consumer of HCl, using it for surface treatment and rust removal in steel production processes.

In the oil and gas sector, HCl plays a crucial role in well acidizing, where it is used to dissolve limestone, dolomite, and calcite scales in oil wells, enhancing production efficiency. This application has seen increased demand due to the expansion of hydraulic fracturing activities in shale gas extraction.

The chemical industry utilizes HCl as a key raw material in the production of various chemicals, including vinyl chloride for PVC manufacturing, and in the synthesis of pharmaceuticals and agrochemicals. The growing demand for these end-products has consequently boosted the market for HCl.

In the food processing industry, HCl finds applications in the production of food additives, gelatin, and as a pH regulator. The expanding food and beverage sector, particularly in developing economies, has contributed to the increased consumption of HCl in this segment.

Market analysis indicates that the Asia-Pacific region dominates the global HCl market, with China being the largest producer and consumer. The rapid industrialization and infrastructure development in countries like India, Indonesia, and Vietnam are expected to further drive the demand for HCl in this region.

Environmental regulations and sustainability concerns have begun to impact the HCl market. There is a growing trend towards recycling and recovering HCl from industrial processes, which may affect the overall demand for virgin HCl. However, this trend also presents opportunities for innovative technologies in HCl recovery and purification.

The market for high-purity HCl, used in the semiconductor and electronics industries, is experiencing significant growth due to the increasing demand for electronic devices and components. This niche segment offers higher profit margins and is expected to be a key focus area for market players.

Pricing trends for HCl have been volatile, influenced by factors such as raw material costs, energy prices, and supply-demand dynamics. The cost-effectiveness of HCl usage is therefore a critical consideration for end-users, driving the need for efficient utilization and process optimization.

In the oil and gas sector, HCl plays a crucial role in well acidizing, where it is used to dissolve limestone, dolomite, and calcite scales in oil wells, enhancing production efficiency. This application has seen increased demand due to the expansion of hydraulic fracturing activities in shale gas extraction.

The chemical industry utilizes HCl as a key raw material in the production of various chemicals, including vinyl chloride for PVC manufacturing, and in the synthesis of pharmaceuticals and agrochemicals. The growing demand for these end-products has consequently boosted the market for HCl.

In the food processing industry, HCl finds applications in the production of food additives, gelatin, and as a pH regulator. The expanding food and beverage sector, particularly in developing economies, has contributed to the increased consumption of HCl in this segment.

Market analysis indicates that the Asia-Pacific region dominates the global HCl market, with China being the largest producer and consumer. The rapid industrialization and infrastructure development in countries like India, Indonesia, and Vietnam are expected to further drive the demand for HCl in this region.

Environmental regulations and sustainability concerns have begun to impact the HCl market. There is a growing trend towards recycling and recovering HCl from industrial processes, which may affect the overall demand for virgin HCl. However, this trend also presents opportunities for innovative technologies in HCl recovery and purification.

The market for high-purity HCl, used in the semiconductor and electronics industries, is experiencing significant growth due to the increasing demand for electronic devices and components. This niche segment offers higher profit margins and is expected to be a key focus area for market players.

Pricing trends for HCl have been volatile, influenced by factors such as raw material costs, energy prices, and supply-demand dynamics. The cost-effectiveness of HCl usage is therefore a critical consideration for end-users, driving the need for efficient utilization and process optimization.

Current HCl Usage Challenges

The current challenges in hydrochloric acid (HCl) usage primarily revolve around cost management, environmental concerns, and process optimization. One of the most pressing issues is the fluctuating prices of HCl in the global market, which can significantly impact the operational costs of industries heavily reliant on this chemical. These price variations are often influenced by factors such as raw material availability, production capacity, and geopolitical tensions affecting supply chains.

Environmental regulations pose another significant challenge for HCl users. Stringent emission standards and waste disposal requirements have necessitated substantial investments in pollution control technologies and waste treatment facilities. Companies must continually adapt their processes to comply with evolving environmental regulations, which can be both costly and technically challenging.

The corrosive nature of HCl presents ongoing maintenance and safety concerns. Industrial equipment exposed to HCl requires frequent inspection, maintenance, and replacement, contributing to increased operational costs. Additionally, ensuring worker safety in environments where HCl is used demands rigorous safety protocols, specialized training, and personal protective equipment, all of which add to the overall expenses.

Optimizing HCl usage efficiency is a persistent challenge for many industries. Inefficient use not only increases costs but also exacerbates environmental impacts. Many companies struggle to find the right balance between using enough HCl to achieve desired results and minimizing excess consumption. This optimization process often requires sophisticated monitoring systems and process control technologies, which can be capital-intensive to implement.

The transportation and storage of HCl present logistical challenges that impact cost-effectiveness. Special handling requirements, including corrosion-resistant containers and strict safety measures during transit, add to the overall cost of HCl usage. Furthermore, on-site storage facilities must meet specific safety standards, often requiring significant investment in infrastructure.

Recycling and recovery of HCl from industrial processes remain technically challenging and economically uncertain for many users. While recycling can potentially reduce raw material costs and environmental impact, the processes involved are often complex and energy-intensive, requiring careful cost-benefit analysis to determine their viability.

Lastly, the variability in HCl concentration requirements across different applications poses challenges in standardization and bulk purchasing. Industries must often tailor their HCl procurement and handling processes to specific concentration needs, potentially missing out on economies of scale that could be achieved with more standardized usage.

Environmental regulations pose another significant challenge for HCl users. Stringent emission standards and waste disposal requirements have necessitated substantial investments in pollution control technologies and waste treatment facilities. Companies must continually adapt their processes to comply with evolving environmental regulations, which can be both costly and technically challenging.

The corrosive nature of HCl presents ongoing maintenance and safety concerns. Industrial equipment exposed to HCl requires frequent inspection, maintenance, and replacement, contributing to increased operational costs. Additionally, ensuring worker safety in environments where HCl is used demands rigorous safety protocols, specialized training, and personal protective equipment, all of which add to the overall expenses.

Optimizing HCl usage efficiency is a persistent challenge for many industries. Inefficient use not only increases costs but also exacerbates environmental impacts. Many companies struggle to find the right balance between using enough HCl to achieve desired results and minimizing excess consumption. This optimization process often requires sophisticated monitoring systems and process control technologies, which can be capital-intensive to implement.

The transportation and storage of HCl present logistical challenges that impact cost-effectiveness. Special handling requirements, including corrosion-resistant containers and strict safety measures during transit, add to the overall cost of HCl usage. Furthermore, on-site storage facilities must meet specific safety standards, often requiring significant investment in infrastructure.

Recycling and recovery of HCl from industrial processes remain technically challenging and economically uncertain for many users. While recycling can potentially reduce raw material costs and environmental impact, the processes involved are often complex and energy-intensive, requiring careful cost-benefit analysis to determine their viability.

Lastly, the variability in HCl concentration requirements across different applications poses challenges in standardization and bulk purchasing. Industries must often tailor their HCl procurement and handling processes to specific concentration needs, potentially missing out on economies of scale that could be achieved with more standardized usage.

Existing HCl Cost Evaluation Methods

01 Production process optimization

Improving the production process of hydrochloric acid can significantly enhance its cost-effectiveness. This includes optimizing reaction conditions, improving catalysts, and implementing more efficient separation and purification techniques. These advancements can lead to higher yields, reduced energy consumption, and lower production costs.- Production process optimization: Improving the production process of hydrochloric acid can significantly enhance its cost-effectiveness. This includes optimizing reaction conditions, improving catalysts, and implementing more efficient separation and purification techniques. These improvements can lead to higher yields, reduced energy consumption, and lower production costs.

- Recycling and recovery methods: Developing effective recycling and recovery methods for hydrochloric acid can greatly improve its cost-effectiveness. This involves implementing techniques to reclaim and reuse hydrochloric acid from industrial processes, reducing waste and lowering the overall cost of production. Advanced separation technologies and closed-loop systems can be employed to achieve this goal.

- By-product utilization: Maximizing the utilization of by-products generated during hydrochloric acid production can enhance overall cost-effectiveness. This includes finding valuable applications for secondary products or developing processes to convert them into useful materials. By turning waste streams into revenue streams, the economic efficiency of hydrochloric acid production can be improved.

- Energy efficiency improvements: Enhancing energy efficiency in hydrochloric acid production and handling processes can lead to significant cost savings. This may involve implementing heat recovery systems, optimizing reactor designs, and using more efficient equipment. By reducing energy consumption, the overall production costs can be lowered, improving the cost-effectiveness of hydrochloric acid.

- Supply chain and logistics optimization: Optimizing the supply chain and logistics for hydrochloric acid can contribute to its cost-effectiveness. This includes improving transportation methods, storage solutions, and distribution networks. By minimizing handling and transportation costs, as well as reducing losses during storage and transfer, the overall cost-effectiveness of hydrochloric acid can be enhanced.

02 Recycling and recovery methods

Developing effective recycling and recovery methods for hydrochloric acid can greatly improve its cost-effectiveness. This involves implementing techniques to reclaim and reuse hydrochloric acid from industrial processes, reducing waste and lowering the overall production costs. Advanced separation technologies and closed-loop systems can be employed to achieve this goal.Expand Specific Solutions03 By-product utilization

Maximizing the utilization of by-products generated during hydrochloric acid production can enhance its cost-effectiveness. This includes developing processes to convert or valorize by-products into useful chemicals or materials, thereby creating additional revenue streams and reducing waste disposal costs.Expand Specific Solutions04 Energy-efficient production methods

Implementing energy-efficient production methods can significantly reduce the overall cost of hydrochloric acid manufacturing. This involves using advanced heat recovery systems, optimizing reactor designs, and employing more efficient equipment to minimize energy consumption throughout the production process.Expand Specific Solutions05 Market analysis and supply chain optimization

Conducting thorough market analysis and optimizing the supply chain can improve the cost-effectiveness of hydrochloric acid. This includes forecasting demand, managing inventory efficiently, and streamlining transportation and distribution processes. Additionally, implementing advanced analytics and digital technologies can help in making data-driven decisions to reduce costs and improve overall efficiency.Expand Specific Solutions

Key HCl Industry Players

The market for evaluating the cost-effectiveness of hydrochloric acid usage is in a mature stage, with a significant global market size due to its widespread industrial applications. The technology for this evaluation is well-established, with several key players offering advanced solutions. Companies like Shin-Etsu Chemical Co., Ltd., LG Chem Ltd., and Evonik Operations GmbH are at the forefront, leveraging their extensive experience in chemical manufacturing to develop sophisticated cost-analysis tools. These firms, along with others like Fluid Energy Group Ltd. and Zhejiang University, are continuously refining their methodologies to improve accuracy and efficiency in hydrochloric acid cost assessment, reflecting the industry's commitment to innovation and sustainability.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed a sophisticated methodology for evaluating the cost-effectiveness of hydrochloric acid usage in their silicon and PVC production processes. Their approach combines detailed process engineering analysis with economic modeling to optimize acid consumption. The company utilizes advanced spectroscopic techniques for real-time monitoring of acid concentration and purity in various stages of production[4]. Shin-Etsu has also implemented a comprehensive waste reduction program that includes acid recovery and recycling systems, significantly improving overall cost-effectiveness. Their evaluation process incorporates a detailed analysis of energy consumption associated with acid handling and storage, as well as the impact on equipment longevity. Additionally, Shin-Etsu has developed proprietary software that integrates production data, market prices, and regulatory compliance costs to provide a holistic view of hydrochloric acid usage economics[6].

Strengths: Highly specialized for silicon and PVC production; Advanced spectroscopic monitoring; Comprehensive waste reduction program. Weaknesses: May be overly specialized for general application; Potentially high implementation costs for smaller operations.

Fluid Energy Group Ltd.

Technical Solution: Fluid Energy Group has developed an innovative approach to evaluate the cost-effectiveness of hydrochloric acid usage in the oil and gas industry, particularly for well stimulation and scale removal applications. Their method involves a comprehensive analysis of acid performance, including reaction kinetics, formation compatibility, and corrosion inhibition. The company utilizes advanced fluid dynamics modeling to optimize acid placement and coverage in reservoir conditions[7]. Fluid Energy Group has also developed eco-friendly acid formulations that reduce environmental impact and disposal costs, a key factor in their cost-effectiveness evaluation. Their approach includes real-time monitoring of acid concentration and spent acid recovery systems to maximize efficiency. Additionally, the company employs a risk-based assessment model that considers the long-term effects of acid usage on well productivity and equipment integrity, providing a more comprehensive view of cost-effectiveness beyond immediate material costs[8].

Strengths: Specialized for oil and gas applications; Advanced fluid dynamics modeling; Eco-friendly formulations. Weaknesses: Limited applicability outside the oil and gas sector; May require specialized expertise for implementation.

Key HCl Cost-Effectiveness Metrics

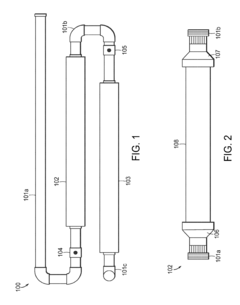

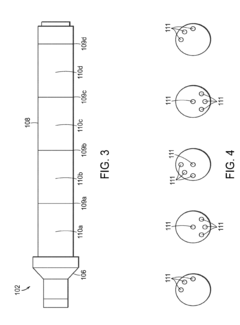

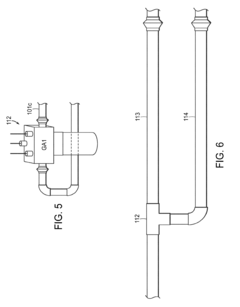

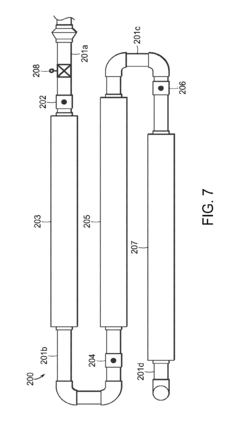

COMPOSITIONS OF HYPOCHLOROUS ACID(HOCl) AND METHODS OF MANUFACTURE THEREOF

PatentActiveUS20150150907A1

Innovation

- An air-free mixing method that combines a compound generating protons (H+) with one generating hypochlorite anions (OCl-) in water, without using chlorine gas or electrolysis, to produce a stable HOCl formulation with controlled pH, maintaining stability for several months to a year.

Mixing device

PatentWO2013121295A2

Innovation

- A mixing device that produces fluidic vortices within a chamber with strategically placed apertures to stabilize hypochlorous acid by controlling proton concentration and pH through the use of buffering agents like acetic acid, allowing for its production and storage for extended periods without the need for onsite generation.

Environmental Impact of HCl

The environmental impact of hydrochloric acid (HCl) usage is a critical consideration in evaluating its cost-effectiveness. HCl is widely used in various industries, including chemical manufacturing, metal processing, and water treatment. However, its corrosive nature and potential for harmful emissions necessitate careful assessment of its environmental footprint.

One of the primary environmental concerns associated with HCl is its potential for air pollution. When released into the atmosphere, HCl can contribute to the formation of acid rain, which can have detrimental effects on ecosystems, water bodies, and infrastructure. The acidification of soil and water resources can lead to the loss of biodiversity and damage to aquatic life. Additionally, HCl emissions can cause respiratory irritation in humans and animals, posing health risks to nearby communities.

Water pollution is another significant environmental impact of HCl usage. Improper disposal or accidental spills can contaminate water sources, altering pH levels and potentially harming aquatic ecosystems. The presence of HCl in water can also lead to the mobilization of heavy metals, further exacerbating environmental and health risks.

The production and transportation of HCl also contribute to its environmental footprint. The manufacturing process often involves energy-intensive operations and the use of fossil fuels, resulting in greenhouse gas emissions. Furthermore, the transportation of HCl requires specialized containers and safety measures, which can increase the carbon footprint associated with its distribution.

To mitigate these environmental impacts, industries are increasingly adopting cleaner production techniques and implementing stringent safety measures. This includes the use of closed-loop systems to minimize emissions, improved containment and handling procedures, and the development of more environmentally friendly alternatives where possible.

Regulatory frameworks play a crucial role in managing the environmental impact of HCl. Many countries have implemented strict regulations governing the production, use, and disposal of HCl, including emissions standards and waste management protocols. Compliance with these regulations is essential for industries using HCl, and the associated costs must be factored into any cost-effectiveness evaluation.

When assessing the cost-effectiveness of HCl usage, it is imperative to consider the long-term environmental costs alongside immediate economic benefits. This includes potential remediation expenses, regulatory compliance costs, and the impact on corporate sustainability goals. Companies are increasingly recognizing the importance of balancing economic considerations with environmental stewardship, leading to more comprehensive cost-benefit analyses that incorporate environmental factors.

In conclusion, the environmental impact of HCl usage is a multifaceted issue that significantly influences its overall cost-effectiveness. A thorough evaluation must consider not only the direct economic benefits but also the potential environmental risks and associated mitigation costs. As industries strive for more sustainable practices, the environmental impact of HCl will continue to be a critical factor in decision-making processes regarding its use and management.

One of the primary environmental concerns associated with HCl is its potential for air pollution. When released into the atmosphere, HCl can contribute to the formation of acid rain, which can have detrimental effects on ecosystems, water bodies, and infrastructure. The acidification of soil and water resources can lead to the loss of biodiversity and damage to aquatic life. Additionally, HCl emissions can cause respiratory irritation in humans and animals, posing health risks to nearby communities.

Water pollution is another significant environmental impact of HCl usage. Improper disposal or accidental spills can contaminate water sources, altering pH levels and potentially harming aquatic ecosystems. The presence of HCl in water can also lead to the mobilization of heavy metals, further exacerbating environmental and health risks.

The production and transportation of HCl also contribute to its environmental footprint. The manufacturing process often involves energy-intensive operations and the use of fossil fuels, resulting in greenhouse gas emissions. Furthermore, the transportation of HCl requires specialized containers and safety measures, which can increase the carbon footprint associated with its distribution.

To mitigate these environmental impacts, industries are increasingly adopting cleaner production techniques and implementing stringent safety measures. This includes the use of closed-loop systems to minimize emissions, improved containment and handling procedures, and the development of more environmentally friendly alternatives where possible.

Regulatory frameworks play a crucial role in managing the environmental impact of HCl. Many countries have implemented strict regulations governing the production, use, and disposal of HCl, including emissions standards and waste management protocols. Compliance with these regulations is essential for industries using HCl, and the associated costs must be factored into any cost-effectiveness evaluation.

When assessing the cost-effectiveness of HCl usage, it is imperative to consider the long-term environmental costs alongside immediate economic benefits. This includes potential remediation expenses, regulatory compliance costs, and the impact on corporate sustainability goals. Companies are increasingly recognizing the importance of balancing economic considerations with environmental stewardship, leading to more comprehensive cost-benefit analyses that incorporate environmental factors.

In conclusion, the environmental impact of HCl usage is a multifaceted issue that significantly influences its overall cost-effectiveness. A thorough evaluation must consider not only the direct economic benefits but also the potential environmental risks and associated mitigation costs. As industries strive for more sustainable practices, the environmental impact of HCl will continue to be a critical factor in decision-making processes regarding its use and management.

Safety Regulations for HCl Handling

Safety regulations for handling hydrochloric acid (HCl) are crucial for ensuring the cost-effectiveness of its usage while protecting workers and the environment. These regulations typically encompass several key areas, including storage, handling, personal protective equipment (PPE), and emergency procedures.

Storage requirements for HCl are stringent due to its corrosive nature. Facilities must use specialized containers made of acid-resistant materials such as high-density polyethylene or glass-lined steel. These containers should be stored in well-ventilated areas, away from incompatible substances like alkalis, metals, and oxidizing agents. Temperature control is essential, as extreme heat can cause pressure buildup in containers.

Handling procedures are designed to minimize exposure risks. Transfer of HCl should be conducted using closed systems whenever possible, with local exhaust ventilation to capture any vapors. Dilution of HCl requires careful attention, as the process generates heat and can cause splashing. The acid must always be added to water, never the reverse, to prevent violent reactions.

Personal protective equipment is mandatory when working with HCl. This includes chemical-resistant gloves, goggles or face shields, and acid-resistant aprons or suits. Respiratory protection may be necessary depending on concentration levels and exposure potential. Regular inspection and maintenance of PPE are essential to ensure its effectiveness.

Emergency response protocols are a critical component of safety regulations. Facilities must have readily accessible eyewash stations and safety showers in areas where HCl is used or stored. Spill control materials, such as neutralizing agents and absorbents, should be available, and personnel must be trained in their proper use. Emergency evacuation plans and clear communication systems are also required.

Worker training is a fundamental aspect of HCl safety regulations. Employees must receive comprehensive instruction on the hazards of HCl, proper handling techniques, PPE usage, and emergency procedures. This training should be regularly updated and documented to ensure compliance with evolving regulations.

Environmental considerations are increasingly important in HCl handling regulations. Proper disposal methods must be employed to prevent environmental contamination. This may include neutralization processes or specialized waste treatment facilities. Monitoring and reporting of emissions and spills are often required by environmental protection agencies.

Compliance with these safety regulations is not only a legal requirement but also a key factor in evaluating the cost-effectiveness of HCl usage. While implementing these measures incurs costs, they significantly reduce the risks of accidents, injuries, and environmental damage, which can lead to substantial financial liabilities and operational disruptions. Therefore, adherence to safety regulations should be viewed as an investment that enhances overall cost-effectiveness in the long term.

Storage requirements for HCl are stringent due to its corrosive nature. Facilities must use specialized containers made of acid-resistant materials such as high-density polyethylene or glass-lined steel. These containers should be stored in well-ventilated areas, away from incompatible substances like alkalis, metals, and oxidizing agents. Temperature control is essential, as extreme heat can cause pressure buildup in containers.

Handling procedures are designed to minimize exposure risks. Transfer of HCl should be conducted using closed systems whenever possible, with local exhaust ventilation to capture any vapors. Dilution of HCl requires careful attention, as the process generates heat and can cause splashing. The acid must always be added to water, never the reverse, to prevent violent reactions.

Personal protective equipment is mandatory when working with HCl. This includes chemical-resistant gloves, goggles or face shields, and acid-resistant aprons or suits. Respiratory protection may be necessary depending on concentration levels and exposure potential. Regular inspection and maintenance of PPE are essential to ensure its effectiveness.

Emergency response protocols are a critical component of safety regulations. Facilities must have readily accessible eyewash stations and safety showers in areas where HCl is used or stored. Spill control materials, such as neutralizing agents and absorbents, should be available, and personnel must be trained in their proper use. Emergency evacuation plans and clear communication systems are also required.

Worker training is a fundamental aspect of HCl safety regulations. Employees must receive comprehensive instruction on the hazards of HCl, proper handling techniques, PPE usage, and emergency procedures. This training should be regularly updated and documented to ensure compliance with evolving regulations.

Environmental considerations are increasingly important in HCl handling regulations. Proper disposal methods must be employed to prevent environmental contamination. This may include neutralization processes or specialized waste treatment facilities. Monitoring and reporting of emissions and spills are often required by environmental protection agencies.

Compliance with these safety regulations is not only a legal requirement but also a key factor in evaluating the cost-effectiveness of HCl usage. While implementing these measures incurs costs, they significantly reduce the risks of accidents, injuries, and environmental damage, which can lead to substantial financial liabilities and operational disruptions. Therefore, adherence to safety regulations should be viewed as an investment that enhances overall cost-effectiveness in the long term.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!