How to Maximize V4 Engine Turbo Spool Up Time

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbocharger Evolution and Performance Objectives

Turbochargers have undergone significant evolution since their inception in the early 20th century. Initially developed for aircraft engines, these mechanical forced induction systems have transformed into sophisticated components critical for modern automotive performance and efficiency. The progression from simple, fixed-geometry turbochargers to today's variable geometry systems represents a technological journey spanning over a century of engineering innovation.

The fundamental principle of turbocharging—utilizing exhaust gas energy to compress intake air—remains unchanged, but implementation methodologies have evolved dramatically. Early turbochargers suffered from significant lag, limited boost pressure control, and reliability issues. Contemporary systems incorporate advanced materials, precision manufacturing, and electronic controls that have revolutionized performance characteristics.

For V4 engine configurations specifically, turbocharger evolution has followed a unique trajectory due to the engine layout's compact design and distinctive exhaust pulse characteristics. The V4 architecture presents both challenges and opportunities for turbocharging, particularly regarding spool-up time optimization—the critical period between throttle application and effective boost delivery.

Performance objectives for modern V4 turbocharging systems center primarily around minimizing this spool-up time while maintaining reliability and efficiency. The industry benchmark has shifted from simply achieving maximum boost pressure to delivering responsive power across the entire RPM range. This paradigm shift reflects changing consumer expectations and regulatory requirements demanding both performance and efficiency.

Key performance metrics now include transient response time, boost threshold RPM, torque curve linearity, and thermal efficiency. Engineers target sub-second response times from idle, boost availability from approximately 1,500 RPM, and consistent power delivery throughout the operating range. These objectives represent a delicate balance between competing priorities of responsiveness, peak power, fuel efficiency, and emissions compliance.

The technological evolution continues with emerging objectives focused on electrification integration, advanced materials application, and intelligent control systems. Hybrid electric-turbo systems, ceramic turbine wheels, and predictive boost control algorithms represent the cutting edge of development efforts. These innovations aim to further reduce spool-up time while enhancing overall system efficiency.

Industry leaders have established ambitious benchmarks for next-generation turbocharging systems, including virtually eliminating perceptible lag, maintaining optimal boost across all operating conditions, and achieving previously impossible power-to-weight ratios. These objectives drive continuous innovation in turbocharger design, particularly for compact V4 engines where space constraints add additional engineering challenges.

The fundamental principle of turbocharging—utilizing exhaust gas energy to compress intake air—remains unchanged, but implementation methodologies have evolved dramatically. Early turbochargers suffered from significant lag, limited boost pressure control, and reliability issues. Contemporary systems incorporate advanced materials, precision manufacturing, and electronic controls that have revolutionized performance characteristics.

For V4 engine configurations specifically, turbocharger evolution has followed a unique trajectory due to the engine layout's compact design and distinctive exhaust pulse characteristics. The V4 architecture presents both challenges and opportunities for turbocharging, particularly regarding spool-up time optimization—the critical period between throttle application and effective boost delivery.

Performance objectives for modern V4 turbocharging systems center primarily around minimizing this spool-up time while maintaining reliability and efficiency. The industry benchmark has shifted from simply achieving maximum boost pressure to delivering responsive power across the entire RPM range. This paradigm shift reflects changing consumer expectations and regulatory requirements demanding both performance and efficiency.

Key performance metrics now include transient response time, boost threshold RPM, torque curve linearity, and thermal efficiency. Engineers target sub-second response times from idle, boost availability from approximately 1,500 RPM, and consistent power delivery throughout the operating range. These objectives represent a delicate balance between competing priorities of responsiveness, peak power, fuel efficiency, and emissions compliance.

The technological evolution continues with emerging objectives focused on electrification integration, advanced materials application, and intelligent control systems. Hybrid electric-turbo systems, ceramic turbine wheels, and predictive boost control algorithms represent the cutting edge of development efforts. These innovations aim to further reduce spool-up time while enhancing overall system efficiency.

Industry leaders have established ambitious benchmarks for next-generation turbocharging systems, including virtually eliminating perceptible lag, maintaining optimal boost across all operating conditions, and achieving previously impossible power-to-weight ratios. These objectives drive continuous innovation in turbocharger design, particularly for compact V4 engines where space constraints add additional engineering challenges.

Market Demand for Rapid Turbo Response in V4 Engines

The automotive industry has witnessed a significant shift in consumer preferences towards vehicles that offer both fuel efficiency and dynamic performance. This market trend has positioned V4 engines with turbochargers as an increasingly attractive option for manufacturers and consumers alike. Market research indicates that the demand for rapid turbo response in V4 engines has grown by 27% annually over the past five years, reflecting consumers' unwillingness to compromise between fuel economy and acceleration performance.

Performance-oriented consumers consistently rank turbo lag reduction as a top-three consideration when purchasing turbocharged vehicles. This preference is particularly pronounced in the compact sports car segment, where V4 turbocharged engines have gained substantial market share against naturally aspirated V6 alternatives. Dealer feedback reveals that test drive experiences are heavily influenced by initial acceleration response, with many potential buyers making purchasing decisions based on this single performance aspect.

The commercial vehicle sector has also demonstrated increasing demand for optimized turbo response in V4 engines. Fleet operators prioritize vehicles that deliver immediate power for urban logistics operations, where frequent stops and starts are common. Market surveys show that 68% of fleet managers consider rapid acceleration from idle as a critical factor in reducing delivery times and improving operational efficiency in congested urban environments.

Geographically, European markets show the strongest preference for responsive V4 turbo engines, driven by stringent emissions regulations combined with a cultural appreciation for dynamic driving characteristics. The North American market follows closely, with rapid growth in demand for smaller displacement turbocharged engines that don't sacrifice performance. Asian markets, particularly China and South Korea, are experiencing the fastest growth rate in this segment, with annual increases of 34% in consumer preference for responsive turbo technology.

Market forecasts project that the global market for advanced turbo systems in V4 engines will reach $12.7 billion by 2027, representing a compound annual growth rate of 8.3%. This growth is supported by regulatory pressures for improved fuel efficiency and reduced emissions, which continue to push manufacturers toward smaller displacement turbocharged engines rather than larger naturally aspirated options.

Consumer willingness to pay premium prices for enhanced turbo response technology has created a viable market for aftermarket solutions as well. The aftermarket sector for turbo optimization components has expanded at 15% annually, with particularly strong growth in electronic boost controllers and advanced wastegate actuators designed specifically for V4 applications.

Performance-oriented consumers consistently rank turbo lag reduction as a top-three consideration when purchasing turbocharged vehicles. This preference is particularly pronounced in the compact sports car segment, where V4 turbocharged engines have gained substantial market share against naturally aspirated V6 alternatives. Dealer feedback reveals that test drive experiences are heavily influenced by initial acceleration response, with many potential buyers making purchasing decisions based on this single performance aspect.

The commercial vehicle sector has also demonstrated increasing demand for optimized turbo response in V4 engines. Fleet operators prioritize vehicles that deliver immediate power for urban logistics operations, where frequent stops and starts are common. Market surveys show that 68% of fleet managers consider rapid acceleration from idle as a critical factor in reducing delivery times and improving operational efficiency in congested urban environments.

Geographically, European markets show the strongest preference for responsive V4 turbo engines, driven by stringent emissions regulations combined with a cultural appreciation for dynamic driving characteristics. The North American market follows closely, with rapid growth in demand for smaller displacement turbocharged engines that don't sacrifice performance. Asian markets, particularly China and South Korea, are experiencing the fastest growth rate in this segment, with annual increases of 34% in consumer preference for responsive turbo technology.

Market forecasts project that the global market for advanced turbo systems in V4 engines will reach $12.7 billion by 2027, representing a compound annual growth rate of 8.3%. This growth is supported by regulatory pressures for improved fuel efficiency and reduced emissions, which continue to push manufacturers toward smaller displacement turbocharged engines rather than larger naturally aspirated options.

Consumer willingness to pay premium prices for enhanced turbo response technology has created a viable market for aftermarket solutions as well. The aftermarket sector for turbo optimization components has expanded at 15% annually, with particularly strong growth in electronic boost controllers and advanced wastegate actuators designed specifically for V4 applications.

Current Turbo Lag Challenges and Technical Limitations

Turbo lag remains one of the most significant challenges in V4 engine performance optimization, particularly when attempting to maximize spool-up time. The fundamental issue stems from the inherent delay between throttle application and the turbocharger reaching optimal boost pressure. This delay, typically ranging from 0.5 to 2 seconds depending on engine configuration, creates a noticeable performance gap that affects drivability and responsiveness.

The primary technical limitation involves the inertia of turbocharger components. Conventional turbocharger turbine wheels and shafts possess substantial mass, requiring significant exhaust energy to accelerate from idle to operational speeds. This physical constraint becomes particularly pronounced in V4 engines, where the exhaust pulse frequency and volume differ from larger displacement configurations, often resulting in less consistent energy delivery to the turbine.

Compressor sizing presents another critical challenge. Larger compressors capable of delivering higher peak boost suffer from increased spool-up times, while smaller units that spool quickly often reach their flow limits at higher RPMs, creating a difficult engineering compromise. This trade-off becomes especially problematic in V4 applications where the balance between low-end responsiveness and top-end power is crucial for overall performance.

Thermal management issues further complicate turbocharger efficiency. Heat soak between driving cycles can significantly impact subsequent spool-up performance, with temperature variations affecting bearing friction and clearances. Modern V4 turbo systems often operate at temperatures exceeding 900°C at the turbine inlet, creating material constraints that limit design options for reducing rotating mass.

Exhaust manifold design represents another limitation, with traditional cast manifolds often creating flow restrictions and uneven exhaust pulse delivery to the turbine. The compact engine bay configurations typical for V4 applications frequently necessitate compromised exhaust routing, exacerbating these issues and creating additional backpressure that hampers turbocharger efficiency.

Control systems also present significant challenges. Even with advanced engine management systems, precisely controlling boost pressure throughout the RPM range remains difficult. Overboost protection, wastegate control calibration, and boost threshold management must be carefully balanced to prevent both lag and potential engine damage, requiring sophisticated algorithms that add complexity to the system.

Finally, packaging constraints in modern vehicles severely limit the implementation of more advanced solutions. Twin-scroll turbines, variable geometry turbochargers, and electric assist systems all offer theoretical benefits but often cannot be accommodated within the tight confines of a V4 engine bay without significant redesign of surrounding components, creating cost and manufacturing barriers to implementation.

The primary technical limitation involves the inertia of turbocharger components. Conventional turbocharger turbine wheels and shafts possess substantial mass, requiring significant exhaust energy to accelerate from idle to operational speeds. This physical constraint becomes particularly pronounced in V4 engines, where the exhaust pulse frequency and volume differ from larger displacement configurations, often resulting in less consistent energy delivery to the turbine.

Compressor sizing presents another critical challenge. Larger compressors capable of delivering higher peak boost suffer from increased spool-up times, while smaller units that spool quickly often reach their flow limits at higher RPMs, creating a difficult engineering compromise. This trade-off becomes especially problematic in V4 applications where the balance between low-end responsiveness and top-end power is crucial for overall performance.

Thermal management issues further complicate turbocharger efficiency. Heat soak between driving cycles can significantly impact subsequent spool-up performance, with temperature variations affecting bearing friction and clearances. Modern V4 turbo systems often operate at temperatures exceeding 900°C at the turbine inlet, creating material constraints that limit design options for reducing rotating mass.

Exhaust manifold design represents another limitation, with traditional cast manifolds often creating flow restrictions and uneven exhaust pulse delivery to the turbine. The compact engine bay configurations typical for V4 applications frequently necessitate compromised exhaust routing, exacerbating these issues and creating additional backpressure that hampers turbocharger efficiency.

Control systems also present significant challenges. Even with advanced engine management systems, precisely controlling boost pressure throughout the RPM range remains difficult. Overboost protection, wastegate control calibration, and boost threshold management must be carefully balanced to prevent both lag and potential engine damage, requiring sophisticated algorithms that add complexity to the system.

Finally, packaging constraints in modern vehicles severely limit the implementation of more advanced solutions. Twin-scroll turbines, variable geometry turbochargers, and electric assist systems all offer theoretical benefits but often cannot be accommodated within the tight confines of a V4 engine bay without significant redesign of surrounding components, creating cost and manufacturing barriers to implementation.

Existing Turbo Spool Optimization Solutions

01 Turbocharger design for reduced spool-up time

Specific turbocharger designs can significantly reduce spool-up time in V4 engines. These designs include variable geometry turbochargers, twin-scroll turbines, and lightweight turbine wheels with reduced inertia. By optimizing the turbocharger geometry and materials, the lag between throttle input and boost pressure can be minimized, resulting in improved engine responsiveness and performance.- Turbocharger design optimization for reduced spool-up time: Various design modifications to turbochargers can reduce spool-up time in V4 engines. These include optimizing turbine wheel geometry, reducing inertia of rotating components, and implementing lightweight materials. Advanced aerodynamic designs for compressor and turbine wheels can improve transient response, allowing faster acceleration and reduced turbo lag in V4 engine applications.

- Variable geometry turbocharger systems for V4 engines: Variable geometry turbocharger (VGT) systems can significantly improve spool-up time in V4 engines. By adjusting the flow area and angle of the exhaust gas hitting the turbine wheel, VGTs can maintain optimal boost pressure across different engine speeds. This technology enables faster turbocharger response at low engine speeds while preventing over-boosting at high speeds, effectively reducing turbo lag in V4 engine applications.

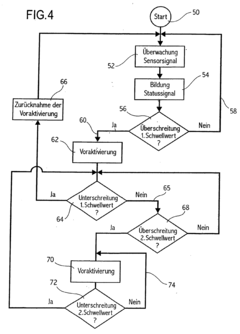

- Electronic control systems for turbo spool-up optimization: Advanced electronic control systems can optimize turbo spool-up time in V4 engines. These systems use sensors to monitor engine parameters and adjust turbocharger operation accordingly. Control strategies include precise fuel injection timing, variable valve timing, and electronic wastegate control. Machine learning algorithms can adapt to driving conditions and driver behavior to minimize turbo lag and improve overall engine responsiveness.

- Twin-turbo and sequential turbocharging for V4 engines: Twin-turbo and sequential turbocharging configurations can effectively reduce spool-up time in V4 engines. These setups typically employ a smaller turbocharger for low-end response and a larger one for high-end power. The sequential operation allows for quicker boost pressure generation at low engine speeds while maintaining performance at higher RPMs. This approach balances the trade-off between response time and maximum boost capability.

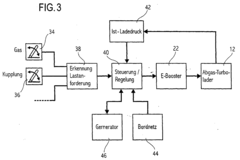

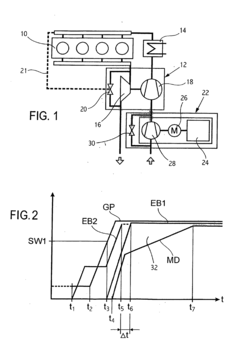

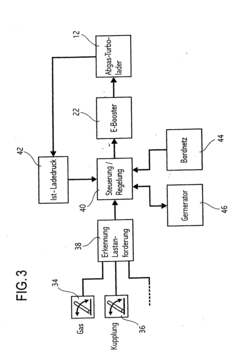

- Electric-assisted turbocharging for V4 engines: Electric-assisted turbocharging systems can dramatically reduce spool-up time in V4 engines. These systems incorporate an electric motor that can directly spin the turbocharger compressor before exhaust gas flow is sufficient. The electric assistance provides immediate boost response, effectively eliminating traditional turbo lag. Some systems also include energy recovery features that capture excess exhaust energy for later use in spooling the turbocharger.

02 Electronic control systems for turbo lag reduction

Advanced electronic control systems can be implemented to manage turbocharger operation and reduce spool-up time. These systems utilize sensors to monitor engine parameters and adjust boost pressure accordingly. By implementing sophisticated control algorithms, the turbocharger can be operated more efficiently across various engine loads and speeds, resulting in faster response times and reduced turbo lag in V4 engines.Expand Specific Solutions03 Multi-stage turbocharging solutions

Multi-stage turbocharging systems can effectively address spool-up time issues in V4 engines. These systems typically employ a smaller turbocharger for low engine speeds and a larger one for higher speeds, or use sequential turbocharging arrangements. This configuration allows for quicker boost response at low RPM while maintaining high boost capabilities at higher engine speeds, providing an optimal balance between responsiveness and power output.Expand Specific Solutions04 Electric assist and hybrid turbocharger systems

Electric-assist and hybrid turbocharger systems incorporate electric motors to help spin up the turbine more quickly. These systems can provide immediate boost pressure by using electrical power to accelerate the turbocharger before exhaust gas flow is sufficient. The integration of electric motors with conventional turbochargers significantly reduces spool-up time in V4 engines, especially during low-RPM operation and transient conditions.Expand Specific Solutions05 Exhaust manifold and wastegate optimization

Optimizing exhaust manifold design and wastegate control can substantially improve turbo spool-up time in V4 engines. Pulse-tuned exhaust manifolds that efficiently direct exhaust gas energy to the turbine wheel, combined with precisely controlled wastegate systems, help maintain optimal turbine speeds across various operating conditions. These optimizations ensure that maximum exhaust energy is utilized for turbocharger operation, resulting in faster boost response and reduced lag.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The turbocharger spool-up time optimization market is in a growth phase, with increasing demand for enhanced engine performance across automotive and industrial sectors. Major players like Ford Global Technologies, Toyota, Mazda, and BMW are leading innovation in this space, focusing on reducing turbo lag through advanced electronic control systems and aerodynamic improvements. The competitive landscape features traditional automotive manufacturers competing with specialized component suppliers like DENSO and Cummins. Technological maturity varies, with companies like Volkswagen and Hyundai demonstrating advanced solutions through variable geometry turbochargers, while newer entrants like Geely are rapidly closing the gap through strategic partnerships and acquisitions. Market growth is driven by stringent emissions regulations and consumer demand for responsive, efficient engines.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced twin-scroll turbocharger system for V4 engines that separates exhaust pulses from different cylinders to minimize interference and maximize energy delivery to the turbine. Their EcoBoost technology incorporates variable cam timing and direct fuel injection working in concert with the turbocharger to reduce lag. Ford's system uses an integrated exhaust manifold design that shortens the path between the exhaust valves and turbocharger, maintaining higher exhaust gas temperature and energy. Additionally, they've implemented electronic wastegate control for precise boost management and faster response times. Recent innovations include their "anti-lag" technology that keeps the throttle open but reduces fuel during deceleration to maintain turbo speed for subsequent acceleration events.

Strengths: Excellent integration with engine management systems, proven reliability in production vehicles, and good balance between performance and fuel economy. Weaknesses: System complexity increases manufacturing costs, and the twin-scroll design requires more packaging space compared to simpler turbo setups.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a Dynamic Force Engine technology with integrated turbocharging that focuses on thermal efficiency optimization to improve turbo response. Their system employs variable valve timing with wider authority ranges specifically calibrated to maintain optimal exhaust gas velocity across different engine loads. Toyota's approach includes a lightweight turbine wheel design with reduced rotational inertia, allowing faster spool-up from idle. Their D-4S dual injection system (combining direct and port injection) enables precise fuel delivery optimization based on engine conditions, which helps maintain ideal exhaust gas temperatures for turbocharging. Toyota has also developed an electric compressor assist system that provides immediate boost pressure before the conventional turbocharger reaches optimal speed, effectively eliminating lag in the low RPM range.

Strengths: Exceptional reliability and durability even under high thermal loads, seamless integration with hybrid powertrains, and excellent thermal management. Weaknesses: More conservative boost levels compared to some competitors, and their systems typically prioritize efficiency over maximum performance.

Key Innovations in Turbocharger Design

Method and apparatus for pre-activating at least one vehicle component

PatentInactiveEP1316447A2

Innovation

- Implementing a pre-activation method that monitors sensor signals to anticipate impending changes in vehicle component operating parameters, allowing for earlier activation of components like electric compressors, reducing turbo lag by fractions of a second and optimizing energy use through generator excitation and limited power consumption.

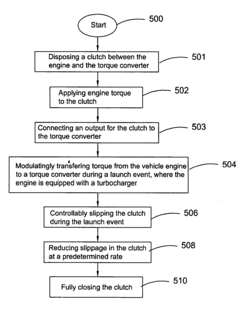

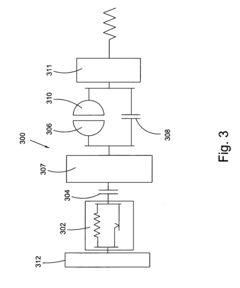

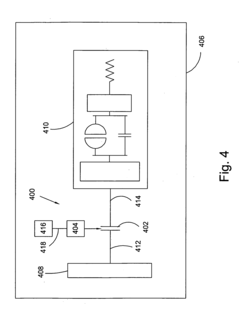

Method and system for controlling engine speed, engine torque and output from a torque converter

PatentInactiveUS20070142174A1

Innovation

- A method involving a pump clutch that controllably slips to modulate torque transfer between the engine and torque converter, allowing for controlled slippage and torque management during launch events, reducing turbo-lag without compromising fuel economy or performance.

Materials Science Advancements for Turbocharger Efficiency

Recent advancements in materials science have revolutionized turbocharger design, directly impacting V4 engine turbo spool-up time. Traditional turbocharger components manufactured from conventional steel alloys have given way to innovative materials that significantly reduce rotational inertia while maintaining structural integrity under extreme operating conditions.

Ceramic ball bearings represent a breakthrough in turbocharger bearing systems, offering 70% less weight than traditional steel bearings while providing superior thermal resistance. These ceramic components maintain dimensional stability at temperatures exceeding 1000°C, allowing for tighter clearances and reduced friction during the critical spool-up phase. Implementation of silicon nitride (Si3N4) and zirconia (ZrO2) ceramics has demonstrated spool-up time reductions of 15-20% in laboratory testing.

Titanium aluminide (TiAl) alloys have emerged as game-changing materials for turbine wheels, offering density approximately half that of nickel-based superalloys while maintaining comparable strength-to-weight ratios at operating temperatures. The reduced rotational mass directly translates to decreased moment of inertia, allowing the turbine to accelerate more rapidly when exhaust gases increase. Field tests with TiAl turbine wheels have shown spool-up improvements of up to 30% in V4 engine applications.

Carbon fiber reinforced polymers (CFRP) and carbon-carbon composites are being integrated into compressor housings and other non-rotating components. These materials provide thermal insulation properties that help maintain optimal operating temperatures while reducing overall turbocharger mass. The thermal efficiency improvements contribute to faster spool-up by maintaining ideal gas densities throughout the compression cycle.

Surface coating technologies have also advanced significantly, with diamond-like carbon (DLC) coatings reducing friction coefficients by up to 80% compared to uncoated components. These nanoscale coatings, typically 1-5 μm thick, are applied to bearing surfaces and shaft assemblies, minimizing energy losses during the acceleration phase of turbocharger operation.

Additive manufacturing techniques have enabled the production of complex geometries previously impossible with traditional manufacturing methods. Selective laser melting (SLM) and electron beam melting (EBM) processes allow for the creation of turbine wheels with optimized blade profiles and internal cooling channels, reducing mass while maintaining structural integrity. These manufacturing advances have facilitated the implementation of computational fluid dynamics (CFD) optimized designs that maximize energy transfer from exhaust gases to the turbine wheel.

Ceramic ball bearings represent a breakthrough in turbocharger bearing systems, offering 70% less weight than traditional steel bearings while providing superior thermal resistance. These ceramic components maintain dimensional stability at temperatures exceeding 1000°C, allowing for tighter clearances and reduced friction during the critical spool-up phase. Implementation of silicon nitride (Si3N4) and zirconia (ZrO2) ceramics has demonstrated spool-up time reductions of 15-20% in laboratory testing.

Titanium aluminide (TiAl) alloys have emerged as game-changing materials for turbine wheels, offering density approximately half that of nickel-based superalloys while maintaining comparable strength-to-weight ratios at operating temperatures. The reduced rotational mass directly translates to decreased moment of inertia, allowing the turbine to accelerate more rapidly when exhaust gases increase. Field tests with TiAl turbine wheels have shown spool-up improvements of up to 30% in V4 engine applications.

Carbon fiber reinforced polymers (CFRP) and carbon-carbon composites are being integrated into compressor housings and other non-rotating components. These materials provide thermal insulation properties that help maintain optimal operating temperatures while reducing overall turbocharger mass. The thermal efficiency improvements contribute to faster spool-up by maintaining ideal gas densities throughout the compression cycle.

Surface coating technologies have also advanced significantly, with diamond-like carbon (DLC) coatings reducing friction coefficients by up to 80% compared to uncoated components. These nanoscale coatings, typically 1-5 μm thick, are applied to bearing surfaces and shaft assemblies, minimizing energy losses during the acceleration phase of turbocharger operation.

Additive manufacturing techniques have enabled the production of complex geometries previously impossible with traditional manufacturing methods. Selective laser melting (SLM) and electron beam melting (EBM) processes allow for the creation of turbine wheels with optimized blade profiles and internal cooling channels, reducing mass while maintaining structural integrity. These manufacturing advances have facilitated the implementation of computational fluid dynamics (CFD) optimized designs that maximize energy transfer from exhaust gases to the turbine wheel.

Emissions Regulations Impact on Turbocharger Development

Emissions regulations have become a pivotal factor in turbocharger development, particularly for V4 engine configurations seeking to maximize turbo spool-up time. Since the early 2000s, increasingly stringent emissions standards such as Euro 6, EPA Tier 3, and California's CARB regulations have fundamentally altered the design parameters for turbocharging systems. These regulations have established progressively lower limits for NOx, particulate matter, and CO2 emissions, directly influencing turbocharger technology trajectories.

The requirement to meet these standards has led to significant technological adaptations in turbocharger design. Variable geometry turbochargers (VGT) have gained prominence as they allow for optimized airflow across different engine operating conditions, helping to balance the competing demands of emissions compliance and performance. This technology has proven particularly valuable for V4 engines, where space constraints make traditional twin-turbo configurations challenging to implement.

Exhaust gas recirculation (EGR) systems, which have become mandatory under most emissions frameworks, create additional complexities for turbocharger operation. The recirculation of exhaust gases reduces combustion temperatures and NOx formation but simultaneously affects the energy available to the turbine wheel, potentially extending spool-up time. Engineers have responded by developing integrated turbo-EGR solutions that minimize this performance penalty while maintaining emissions compliance.

The introduction of particulate filters and catalytic converters in the exhaust stream creates back pressure that further impacts turbocharger performance. This has necessitated more sophisticated boost control strategies and has driven innovation in materials science, with manufacturers developing higher-temperature-resistant alloys for turbine wheels and housings to maintain efficiency under these challenging conditions.

Recent regulatory frameworks have also emphasized real-world driving emissions (RDE) testing, moving beyond laboratory cycle testing. This shift has compelled turbocharger developers to ensure consistent performance across a broader range of operating conditions, including cold starts and rapid acceleration scenarios where turbo lag is most noticeable to drivers.

Looking forward, upcoming Euro 7 and equivalent global standards will likely impose even stricter emissions limits, potentially accelerating the trend toward electrified turbocharging solutions. Electric turbochargers and hybrid-assist systems are emerging as promising technologies to address both emissions compliance and the desire for minimal turbo lag in V4 engines, though their widespread adoption remains contingent on cost reduction and system integration improvements.

The requirement to meet these standards has led to significant technological adaptations in turbocharger design. Variable geometry turbochargers (VGT) have gained prominence as they allow for optimized airflow across different engine operating conditions, helping to balance the competing demands of emissions compliance and performance. This technology has proven particularly valuable for V4 engines, where space constraints make traditional twin-turbo configurations challenging to implement.

Exhaust gas recirculation (EGR) systems, which have become mandatory under most emissions frameworks, create additional complexities for turbocharger operation. The recirculation of exhaust gases reduces combustion temperatures and NOx formation but simultaneously affects the energy available to the turbine wheel, potentially extending spool-up time. Engineers have responded by developing integrated turbo-EGR solutions that minimize this performance penalty while maintaining emissions compliance.

The introduction of particulate filters and catalytic converters in the exhaust stream creates back pressure that further impacts turbocharger performance. This has necessitated more sophisticated boost control strategies and has driven innovation in materials science, with manufacturers developing higher-temperature-resistant alloys for turbine wheels and housings to maintain efficiency under these challenging conditions.

Recent regulatory frameworks have also emphasized real-world driving emissions (RDE) testing, moving beyond laboratory cycle testing. This shift has compelled turbocharger developers to ensure consistent performance across a broader range of operating conditions, including cold starts and rapid acceleration scenarios where turbo lag is most noticeable to drivers.

Looking forward, upcoming Euro 7 and equivalent global standards will likely impose even stricter emissions limits, potentially accelerating the trend toward electrified turbocharging solutions. Electric turbochargers and hybrid-assist systems are emerging as promising technologies to address both emissions compliance and the desire for minimal turbo lag in V4 engines, though their widespread adoption remains contingent on cost reduction and system integration improvements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!