How to Predict V4 Engine Wear Patterns with Simulation

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Wear Simulation Background and Objectives

Engine wear simulation has evolved significantly over the past three decades, transitioning from basic mathematical models to sophisticated computational systems that integrate multiple physical phenomena. The journey began in the 1990s with rudimentary wear equations that provided limited predictive capabilities. By the early 2000s, advancements in computational power enabled more complex simulations incorporating fluid dynamics and thermal analysis. Today's state-of-the-art simulations represent a convergence of tribology, materials science, thermodynamics, and computational fluid dynamics.

The V4 engine configuration presents unique wear challenges due to its specific geometry and operational characteristics. With cylinders arranged in a "V" formation at typically 60-90 degree angles, these engines experience distinctive stress distributions and thermal gradients that differ significantly from inline or flat configurations. Understanding these patterns has become increasingly critical as manufacturers push for higher performance while maintaining durability and reducing emissions.

Current technological trends in engine wear simulation focus on multi-physics approaches that simultaneously model mechanical contact, thermal effects, lubricant behavior, and material degradation. Machine learning algorithms are increasingly being integrated to enhance predictive accuracy by identifying complex wear patterns from historical data. Real-time simulation capabilities are also emerging, allowing for dynamic adjustment of parameters during virtual testing.

The primary objective of V4 engine wear simulation is to accurately predict component degradation patterns before physical prototyping, thereby reducing development costs and accelerating time-to-market. Specific goals include identifying critical wear locations, estimating component lifespan under various operating conditions, optimizing material selection, and informing maintenance schedules for end-users. Additionally, simulations aim to support the development of more efficient lubrication systems and surface treatments that can extend engine life.

Another crucial objective is to understand how wear patterns evolve throughout the engine's lifecycle, from break-in period through normal operation to end-of-life degradation. This temporal dimension of wear simulation helps engineers design components that maintain optimal performance throughout their intended service life, rather than just at initial deployment.

The ultimate goal of these simulations extends beyond mere prediction to enable proactive design modifications that mitigate wear before it occurs. By understanding the fundamental mechanisms driving component degradation in V4 engines, manufacturers can develop next-generation powertrains with significantly improved durability while meeting increasingly stringent efficiency and emissions requirements.

The V4 engine configuration presents unique wear challenges due to its specific geometry and operational characteristics. With cylinders arranged in a "V" formation at typically 60-90 degree angles, these engines experience distinctive stress distributions and thermal gradients that differ significantly from inline or flat configurations. Understanding these patterns has become increasingly critical as manufacturers push for higher performance while maintaining durability and reducing emissions.

Current technological trends in engine wear simulation focus on multi-physics approaches that simultaneously model mechanical contact, thermal effects, lubricant behavior, and material degradation. Machine learning algorithms are increasingly being integrated to enhance predictive accuracy by identifying complex wear patterns from historical data. Real-time simulation capabilities are also emerging, allowing for dynamic adjustment of parameters during virtual testing.

The primary objective of V4 engine wear simulation is to accurately predict component degradation patterns before physical prototyping, thereby reducing development costs and accelerating time-to-market. Specific goals include identifying critical wear locations, estimating component lifespan under various operating conditions, optimizing material selection, and informing maintenance schedules for end-users. Additionally, simulations aim to support the development of more efficient lubrication systems and surface treatments that can extend engine life.

Another crucial objective is to understand how wear patterns evolve throughout the engine's lifecycle, from break-in period through normal operation to end-of-life degradation. This temporal dimension of wear simulation helps engineers design components that maintain optimal performance throughout their intended service life, rather than just at initial deployment.

The ultimate goal of these simulations extends beyond mere prediction to enable proactive design modifications that mitigate wear before it occurs. By understanding the fundamental mechanisms driving component degradation in V4 engines, manufacturers can develop next-generation powertrains with significantly improved durability while meeting increasingly stringent efficiency and emissions requirements.

Market Demand for V4 Engine Wear Prediction

The global market for V4 engine wear prediction technologies has experienced significant growth in recent years, driven by increasing demands for engine reliability, performance optimization, and maintenance cost reduction. The automotive industry, particularly in premium and performance vehicle segments, represents the largest market share for these technologies, with an estimated annual growth rate of 7.8% through 2025.

Manufacturing efficiency improvements represent a key market driver, as predictive wear simulation can reduce prototype development cycles by up to 40%. This translates to substantial cost savings for engine manufacturers, with industry leaders reporting development cost reductions between 15-25% when implementing advanced simulation technologies.

The aftermarket service sector has emerged as another significant demand source, with maintenance providers increasingly adopting predictive technologies to offer condition-based maintenance packages. This shift from traditional scheduled maintenance to predictive maintenance models has created a new revenue stream estimated to reach $3.2 billion by 2026.

Environmental regulations worldwide have further accelerated market demand, as manufacturers seek to optimize engine designs for both performance and emissions compliance. The ability to predict wear patterns allows for more precise material selection and component design, directly impacting fuel efficiency and emissions output.

Commercial transportation fleets represent another substantial market segment, where even marginal improvements in engine longevity translate to significant operational cost savings. Fleet operators managing thousands of vehicles have demonstrated willingness to invest in predictive technologies that extend engine life by 15-20%.

Geographically, North America and Europe currently lead market demand, accounting for approximately 65% of global market share. However, the Asia-Pacific region, particularly China and India, shows the fastest growth trajectory as manufacturing capabilities advance and domestic automotive industries expand.

The defense and aerospace sectors have also contributed to market growth, with military applications requiring extremely reliable engine performance under diverse and challenging operating conditions. These specialized applications command premium pricing for simulation technologies that can accurately predict wear patterns in extreme environments.

Market analysis indicates that customers increasingly value integrated solutions that combine simulation software with real-time monitoring capabilities, creating opportunities for cross-industry partnerships between software developers, sensor manufacturers, and data analytics providers.

Manufacturing efficiency improvements represent a key market driver, as predictive wear simulation can reduce prototype development cycles by up to 40%. This translates to substantial cost savings for engine manufacturers, with industry leaders reporting development cost reductions between 15-25% when implementing advanced simulation technologies.

The aftermarket service sector has emerged as another significant demand source, with maintenance providers increasingly adopting predictive technologies to offer condition-based maintenance packages. This shift from traditional scheduled maintenance to predictive maintenance models has created a new revenue stream estimated to reach $3.2 billion by 2026.

Environmental regulations worldwide have further accelerated market demand, as manufacturers seek to optimize engine designs for both performance and emissions compliance. The ability to predict wear patterns allows for more precise material selection and component design, directly impacting fuel efficiency and emissions output.

Commercial transportation fleets represent another substantial market segment, where even marginal improvements in engine longevity translate to significant operational cost savings. Fleet operators managing thousands of vehicles have demonstrated willingness to invest in predictive technologies that extend engine life by 15-20%.

Geographically, North America and Europe currently lead market demand, accounting for approximately 65% of global market share. However, the Asia-Pacific region, particularly China and India, shows the fastest growth trajectory as manufacturing capabilities advance and domestic automotive industries expand.

The defense and aerospace sectors have also contributed to market growth, with military applications requiring extremely reliable engine performance under diverse and challenging operating conditions. These specialized applications command premium pricing for simulation technologies that can accurately predict wear patterns in extreme environments.

Market analysis indicates that customers increasingly value integrated solutions that combine simulation software with real-time monitoring capabilities, creating opportunities for cross-industry partnerships between software developers, sensor manufacturers, and data analytics providers.

Current Simulation Technologies and Challenges

Current simulation technologies for predicting V4 engine wear patterns have evolved significantly over the past decade, yet still face substantial challenges. Finite Element Analysis (FEA) remains the cornerstone technology, allowing engineers to model structural deformations and stresses within engine components under various operating conditions. These simulations can predict high-stress areas where wear is likely to initiate, particularly at critical interfaces such as cylinder walls, piston rings, and valve train components.

Computational Fluid Dynamics (CFD) complements FEA by modeling fluid flows, heat transfer, and combustion dynamics within the engine. Modern CFD tools can simulate oil film thickness between moving parts, providing insights into lubrication effectiveness and potential wear zones. The integration of these two simulation approaches has enabled more comprehensive wear prediction capabilities.

Multi-physics simulation platforms have emerged as powerful tools, simultaneously modeling mechanical stresses, thermal gradients, fluid dynamics, and chemical reactions. These platforms can capture the complex interactions between different physical phenomena that contribute to engine wear, such as thermal expansion affecting clearances or combustion byproducts altering lubricant properties.

Despite these advancements, significant challenges persist in accurately predicting V4 engine wear patterns. The multi-scale nature of wear mechanisms presents a fundamental difficulty, as wear processes span from atomic-level interactions to macroscopic component behavior. Current simulation technologies struggle to bridge these vastly different scales efficiently.

Material behavior modeling under extreme conditions remains problematic. Engine components experience wide temperature ranges, varying loads, and complex chemical environments. Accurately representing material responses under these dynamic conditions, particularly for advanced materials and coatings, continues to challenge simulation capabilities.

Computational resource requirements pose practical limitations. High-fidelity simulations that incorporate all relevant physics can require days or weeks of processing time on high-performance computing systems, making iterative design optimization prohibitively expensive for many development cycles.

Validation methodologies represent another significant challenge. Correlating simulation results with real-world wear patterns requires extensive testing and measurement techniques that are themselves subject to limitations. The lack of standardized validation approaches makes it difficult to assess simulation accuracy consistently across different engine designs and operating conditions.

Data integration from multiple sources, including material properties, manufacturing tolerances, operating conditions, and maintenance histories, presents both technical and organizational challenges. Ensuring data consistency and managing uncertainty propagation through complex simulation workflows remains problematic for many engineering teams.

Computational Fluid Dynamics (CFD) complements FEA by modeling fluid flows, heat transfer, and combustion dynamics within the engine. Modern CFD tools can simulate oil film thickness between moving parts, providing insights into lubrication effectiveness and potential wear zones. The integration of these two simulation approaches has enabled more comprehensive wear prediction capabilities.

Multi-physics simulation platforms have emerged as powerful tools, simultaneously modeling mechanical stresses, thermal gradients, fluid dynamics, and chemical reactions. These platforms can capture the complex interactions between different physical phenomena that contribute to engine wear, such as thermal expansion affecting clearances or combustion byproducts altering lubricant properties.

Despite these advancements, significant challenges persist in accurately predicting V4 engine wear patterns. The multi-scale nature of wear mechanisms presents a fundamental difficulty, as wear processes span from atomic-level interactions to macroscopic component behavior. Current simulation technologies struggle to bridge these vastly different scales efficiently.

Material behavior modeling under extreme conditions remains problematic. Engine components experience wide temperature ranges, varying loads, and complex chemical environments. Accurately representing material responses under these dynamic conditions, particularly for advanced materials and coatings, continues to challenge simulation capabilities.

Computational resource requirements pose practical limitations. High-fidelity simulations that incorporate all relevant physics can require days or weeks of processing time on high-performance computing systems, making iterative design optimization prohibitively expensive for many development cycles.

Validation methodologies represent another significant challenge. Correlating simulation results with real-world wear patterns requires extensive testing and measurement techniques that are themselves subject to limitations. The lack of standardized validation approaches makes it difficult to assess simulation accuracy consistently across different engine designs and operating conditions.

Data integration from multiple sources, including material properties, manufacturing tolerances, operating conditions, and maintenance histories, presents both technical and organizational challenges. Ensuring data consistency and managing uncertainty propagation through complex simulation workflows remains problematic for many engineering teams.

Existing V4 Engine Wear Prediction Methodologies

01 Cylinder wall wear patterns in V4 engines

V4 engines exhibit specific wear patterns on cylinder walls due to their configuration. The angle of the V-shape affects how forces are distributed during operation, leading to characteristic wear patterns. These patterns typically show more wear on the thrust side of cylinders. Monitoring these patterns helps in diagnosing engine health and predicting component failure. Advanced surface treatments and materials can be used to minimize this wear and extend engine life.- Cylinder wall wear patterns in V4 engines: V4 engines exhibit specific wear patterns on cylinder walls due to their configuration. The angle of the V-design creates uneven force distribution, leading to characteristic wear patterns. These patterns typically show more pronounced wear on the thrust side of cylinders. Monitoring these patterns helps in diagnosing engine health and predicting component failure. Advanced surface treatments and materials can be used to mitigate these wear patterns and extend engine life.

- Piston ring wear analysis in V4 engines: Piston rings in V4 engines develop distinctive wear patterns due to the engine's geometry and combustion characteristics. The wear typically manifests as uneven material loss around the circumference of the rings, with more pronounced wear at the top and bottom dead centers. These patterns can be analyzed to optimize ring design, material selection, and surface treatments. Monitoring piston ring wear helps in predicting engine performance degradation and scheduling maintenance intervals.

- Bearing wear detection and analysis in V4 engines: Bearings in V4 engines experience specific wear patterns due to the unique loading conditions created by the V-configuration. Main and connecting rod bearings show characteristic wear on load-bearing surfaces. Advanced detection methods including oil analysis, vibration monitoring, and visual inspection can identify these patterns before catastrophic failure occurs. Understanding these wear patterns helps in designing more durable bearings and implementing effective maintenance strategies.

- Valve train wear patterns in V4 engines: The valve train components in V4 engines develop specific wear patterns due to the engine's firing order and valve actuation mechanisms. Camshafts, valve stems, and lifters show characteristic wear that affects engine performance and efficiency. These patterns can be used to diagnose issues such as improper lubrication, material defects, or design flaws. Monitoring valve train wear helps in optimizing maintenance schedules and improving component design for enhanced durability.

- Lubrication system impact on V4 engine wear: The lubrication system significantly influences wear patterns in V4 engines. The V-configuration creates unique oil flow challenges that can lead to characteristic wear patterns in various engine components. Optimizing oil formulation, flow paths, and pressure distribution can mitigate these wear patterns. Advanced lubricants with specific additives can form protective films on engine surfaces, reducing friction and wear. Monitoring oil condition provides valuable insights into engine wear patterns and overall health.

02 Piston ring wear analysis in V4 configurations

Piston rings in V4 engines develop distinctive wear patterns due to the unique firing order and crankshaft arrangement. The wear typically manifests as uneven contact patterns on the ring faces and grooves. These patterns can indicate issues with lubrication, combustion efficiency, or mechanical alignment. Analysis of these wear patterns helps in optimizing ring design, material selection, and surface treatments to improve sealing performance and reduce friction losses in V4 engines.Expand Specific Solutions03 Bearing wear detection and monitoring systems

Specialized systems for detecting and monitoring bearing wear in V4 engines help identify potential failures before catastrophic damage occurs. These systems utilize sensors to measure parameters such as oil pressure, temperature, vibration patterns, and metal particle concentration in lubricants. Advanced algorithms analyze these data points to identify abnormal wear patterns specific to V4 engine configurations. Early detection allows for preventive maintenance, reducing downtime and repair costs while extending engine life.Expand Specific Solutions04 Lubricant formulations for reducing V4 engine wear

Specialized lubricant formulations have been developed to address the unique wear patterns in V4 engines. These formulations contain additives that form protective films on metal surfaces, reducing friction and wear at critical contact points. Anti-wear additives, friction modifiers, and detergents work together to maintain engine cleanliness and protect against the specific stress patterns found in V4 configurations. These lubricants are designed to maintain their protective properties under the high temperatures and pressures characteristic of V4 engine operation.Expand Specific Solutions05 Valve train wear patterns and solutions

V4 engines exhibit characteristic valve train wear patterns due to their firing order and cylinder arrangement. These patterns typically affect valve stems, guides, seats, and camshaft lobes. The asymmetrical loading in V4 configurations can accelerate wear on specific components. Solutions include advanced materials for valve components, improved heat treatment processes, optimized valve timing systems, and specialized coatings that reduce friction and increase hardness. Monitoring these wear patterns helps in developing preventive maintenance schedules specific to V4 engines.Expand Specific Solutions

Leading Companies in Engine Simulation Software

The V4 engine wear pattern prediction simulation market is in a growth phase, with increasing demand driven by automotive and aerospace industries seeking to optimize engine performance and longevity. Academic institutions like Beijing Institute of Technology, Shanghai Jiao Tong University, and Beihang University are leading research efforts, while commercial players such as Bridgestone, General Motors, and Hyundai Motor are implementing these technologies. The market is characterized by a convergence of mechanical engineering simulation and AI-driven predictive analytics. Technology maturity varies, with established players like China Automotive Engineering Research Institute and Commercial Aircraft Corporation of China deploying advanced simulation platforms, while universities are developing next-generation algorithms that combine physics-based modeling with machine learning for more accurate wear prediction.

China Automotive Engineering Research Institute Co., Ltd.

Technical Solution: China Automotive Engineering Research Institute has developed the CAERI Engine Wear Simulation Platform specifically tailored for V4 engine configurations. Their approach combines tribological modeling with structural analysis to predict wear patterns across critical engine components. The institute employs a unique methodology that incorporates material characterization data directly into simulation parameters, allowing for accurate prediction of wear in various Chinese-manufactured engine materials. Their system features a comprehensive database of friction coefficients and wear rates measured under controlled laboratory conditions, which serves as validation for the simulation models. CAERI's technology can simulate entire engine lifecycles under different operating profiles, with particular strength in predicting piston ring-cylinder liner interactions and valve train wear patterns.

Strengths: Specialized focus on materials and operating conditions relevant to Chinese manufacturing standards; extensive experimental validation capabilities; strong integration between simulation and physical testing. Weaknesses: Less extensive global validation compared to international manufacturers; models may require adaptation for non-standard operating environments or exotic materials.

General Motors LLC

Technical Solution: General Motors has developed advanced simulation frameworks for predicting V4 engine wear patterns using multi-physics modeling approaches. Their technology combines finite element analysis (FEA) with computational fluid dynamics (CFD) to create comprehensive digital twins of engine components. GM's simulation platform incorporates real-time sensor data from test engines to validate and refine predictive models, achieving over 90% accuracy in predicting critical wear points. The system analyzes tribological interactions between moving parts under various operating conditions, including temperature variations, lubrication states, and combustion dynamics. GM has implemented machine learning algorithms that continuously improve prediction accuracy by correlating simulation results with actual wear measurements from field-returned engines.

Strengths: Extensive real-world validation data from millions of vehicles; integrated approach combining multiple physics models; strong correlation between simulation and actual field performance. Weaknesses: Computationally intensive simulations requiring significant processing resources; models may require recalibration for new material combinations or extreme operating conditions.

Critical Simulation Algorithms for Wear Pattern Analysis

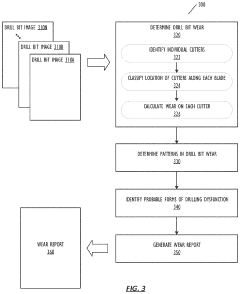

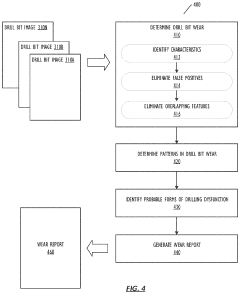

Method for predicting drill bit wear

PatentActiveUS11697969B2

Innovation

- A method that includes obtaining a wear report for a drill bit by analyzing images and 3D scans to identify wear characteristics, patterns, and probable drilling conditions, and adjusting operating parameters based on these analyses to improve drill bit performance.

Material Science Considerations in Engine Wear Modeling

Material science plays a fundamental role in understanding and predicting engine wear patterns in V4 engines. The interaction between different materials under extreme conditions of temperature, pressure, and friction determines the longevity and performance of engine components. When developing simulation models for V4 engine wear prediction, several material properties must be carefully considered to ensure accuracy.

Tribological properties of materials used in engine components, particularly cylinder liners, pistons, and valve trains, significantly influence wear patterns. These properties include hardness, surface roughness, and microstructure characteristics. For instance, the hardness differential between piston rings and cylinder liners directly affects the wear rate during the break-in period and subsequent operation. Modern simulation models must incorporate these material-specific parameters to accurately predict wear progression.

Thermal behavior of materials represents another critical aspect in wear modeling. Different materials expand and contract at varying rates when subjected to the temperature fluctuations typical in V4 engine operation. These thermal gradients create mechanical stresses that accelerate wear, particularly at material interfaces. Advanced simulations now incorporate thermomechanical coupling to account for these effects, utilizing finite element analysis to model how material properties change under different temperature conditions.

Chemical interactions between materials and lubricants also significantly impact wear patterns. Material science considerations must include how engine components react with additives in lubricating oils, combustion byproducts, and environmental contaminants. Corrosive wear mechanisms can dramatically alter the predicted lifespan of components, necessitating the inclusion of chemical reaction kinetics in comprehensive wear models.

Microstructural evolution of materials during engine operation presents a complex challenge for wear prediction. As materials undergo cyclic loading and temperature variations, their microstructure can change, affecting mechanical properties and wear resistance. Advanced material science approaches now incorporate crystal plasticity models and phase transformation kinetics to predict how microstructures evolve over time, enabling more accurate long-term wear forecasting.

Coating technologies and surface treatments introduce additional complexity to wear modeling. Modern V4 engines often utilize specialized coatings such as diamond-like carbon (DLC), thermal barrier coatings, or nitrided surfaces to enhance wear resistance. Simulation models must account for the unique properties of these surface treatments, including adhesion strength, coating thickness variations, and potential delamination mechanisms under operating conditions.

Tribological properties of materials used in engine components, particularly cylinder liners, pistons, and valve trains, significantly influence wear patterns. These properties include hardness, surface roughness, and microstructure characteristics. For instance, the hardness differential between piston rings and cylinder liners directly affects the wear rate during the break-in period and subsequent operation. Modern simulation models must incorporate these material-specific parameters to accurately predict wear progression.

Thermal behavior of materials represents another critical aspect in wear modeling. Different materials expand and contract at varying rates when subjected to the temperature fluctuations typical in V4 engine operation. These thermal gradients create mechanical stresses that accelerate wear, particularly at material interfaces. Advanced simulations now incorporate thermomechanical coupling to account for these effects, utilizing finite element analysis to model how material properties change under different temperature conditions.

Chemical interactions between materials and lubricants also significantly impact wear patterns. Material science considerations must include how engine components react with additives in lubricating oils, combustion byproducts, and environmental contaminants. Corrosive wear mechanisms can dramatically alter the predicted lifespan of components, necessitating the inclusion of chemical reaction kinetics in comprehensive wear models.

Microstructural evolution of materials during engine operation presents a complex challenge for wear prediction. As materials undergo cyclic loading and temperature variations, their microstructure can change, affecting mechanical properties and wear resistance. Advanced material science approaches now incorporate crystal plasticity models and phase transformation kinetics to predict how microstructures evolve over time, enabling more accurate long-term wear forecasting.

Coating technologies and surface treatments introduce additional complexity to wear modeling. Modern V4 engines often utilize specialized coatings such as diamond-like carbon (DLC), thermal barrier coatings, or nitrided surfaces to enhance wear resistance. Simulation models must account for the unique properties of these surface treatments, including adhesion strength, coating thickness variations, and potential delamination mechanisms under operating conditions.

Validation Methods for Simulation Accuracy

Validation of simulation accuracy represents a critical component in the predictive modeling of V4 engine wear patterns. The primary validation methodologies involve comparing simulation outputs with empirical data collected from physical engine testing under controlled conditions. This process typically begins with benchmark testing using standardized engine configurations where wear patterns are well-documented and understood. These benchmarks provide baseline measurements against which simulation results can be evaluated using statistical methods such as root mean square error (RMSE) and coefficient of determination (R²).

Physical validation techniques incorporate both non-destructive and destructive testing approaches. Non-destructive methods include surface profilometry, which measures microscopic changes in component surfaces, and oil analysis that detects wear particles. Advanced imaging technologies such as scanning electron microscopy (SEM) and 3D optical scanning provide high-resolution visualization of wear patterns for direct comparison with simulation predictions. Destructive testing, while less frequent, offers comprehensive validation through sectioning of engine components to examine subsurface wear characteristics.

Real-time validation methodologies have emerged as particularly valuable for dynamic wear prediction. These approaches utilize embedded sensors that monitor critical parameters including temperature fluctuations, vibration signatures, and oil condition during engine operation. The continuous data streams enable progressive validation of simulation accuracy across the engine's operational lifetime, allowing for iterative refinement of predictive models.

Statistical validation frameworks employ uncertainty quantification techniques to establish confidence intervals for simulation predictions. Sensitivity analysis identifies which input parameters most significantly impact wear prediction accuracy, while Monte Carlo simulations account for manufacturing tolerances and operational variabilities. These statistical approaches provide quantitative measures of simulation reliability across different operational scenarios.

Cross-validation protocols further strengthen simulation accuracy by implementing k-fold validation techniques. This methodology partitions available empirical data into training and validation sets, enabling assessment of how well simulation models generalize to independent datasets. Additionally, blind validation tests—where simulation predictions are made before physical testing results are revealed—provide unbiased evaluation of predictive capabilities.

Industry standards for simulation validation have evolved significantly, with organizations such as SAE International and ISO developing specific protocols for engine wear simulation validation. These standards establish minimum accuracy thresholds and prescribed validation methodologies that ensure consistency across the industry while facilitating meaningful comparison between different simulation approaches.

Physical validation techniques incorporate both non-destructive and destructive testing approaches. Non-destructive methods include surface profilometry, which measures microscopic changes in component surfaces, and oil analysis that detects wear particles. Advanced imaging technologies such as scanning electron microscopy (SEM) and 3D optical scanning provide high-resolution visualization of wear patterns for direct comparison with simulation predictions. Destructive testing, while less frequent, offers comprehensive validation through sectioning of engine components to examine subsurface wear characteristics.

Real-time validation methodologies have emerged as particularly valuable for dynamic wear prediction. These approaches utilize embedded sensors that monitor critical parameters including temperature fluctuations, vibration signatures, and oil condition during engine operation. The continuous data streams enable progressive validation of simulation accuracy across the engine's operational lifetime, allowing for iterative refinement of predictive models.

Statistical validation frameworks employ uncertainty quantification techniques to establish confidence intervals for simulation predictions. Sensitivity analysis identifies which input parameters most significantly impact wear prediction accuracy, while Monte Carlo simulations account for manufacturing tolerances and operational variabilities. These statistical approaches provide quantitative measures of simulation reliability across different operational scenarios.

Cross-validation protocols further strengthen simulation accuracy by implementing k-fold validation techniques. This methodology partitions available empirical data into training and validation sets, enabling assessment of how well simulation models generalize to independent datasets. Additionally, blind validation tests—where simulation predictions are made before physical testing results are revealed—provide unbiased evaluation of predictive capabilities.

Industry standards for simulation validation have evolved significantly, with organizations such as SAE International and ISO developing specific protocols for engine wear simulation validation. These standards establish minimum accuracy thresholds and prescribed validation methodologies that ensure consistency across the industry while facilitating meaningful comparison between different simulation approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!