Hydrofluoric Acid Efficiency in Surface Cleaning Technologies

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HF Acid Evolution and Cleaning Objectives

Hydrofluoric acid (HF) has been a cornerstone in surface cleaning technologies since its industrial application began in the early 20th century. Initially utilized primarily in glass etching processes, HF acid has evolved significantly over the decades to become an essential component in semiconductor manufacturing, metal surface preparation, and various high-precision cleaning applications. The evolution trajectory of HF-based cleaning technologies has been characterized by continuous refinement in concentration management, application methodologies, and safety protocols.

The 1970s marked a pivotal shift in HF acid utilization with the emergence of the semiconductor industry, which demanded unprecedented levels of surface cleanliness. This period saw the development of standardized cleaning sequences such as the RCA clean, where HF played a crucial role in native oxide removal. By the 1990s, as device geometries continued to shrink, the precision requirements for HF cleaning increased exponentially, leading to innovations in dilution techniques and application methods.

Recent technological advancements have focused on enhancing HF efficiency while minimizing environmental impact and safety risks. These include the development of buffered HF solutions, vapor-phase HF cleaning systems, and remote plasma-assisted HF cleaning technologies. Each iteration has aimed to optimize the balance between cleaning effectiveness and process control, particularly for nanoscale applications where surface integrity is paramount.

The primary objectives of modern HF cleaning technologies center around four key dimensions: efficiency, selectivity, safety, and sustainability. Efficiency objectives focus on maximizing contaminant removal rates while minimizing process time and chemical consumption. Selectivity goals involve developing formulations that target specific contaminants or oxides without affecting underlying or adjacent materials, which is particularly critical in complex multi-material structures.

Safety objectives have become increasingly prominent, driving innovations in exposure reduction, automated handling systems, and less hazardous alternative formulations. These include the development of HF-free cleaning solutions and processes that can achieve comparable results through different chemical mechanisms. Simultaneously, sustainability objectives address the environmental footprint of HF processes, including waste reduction, recycling possibilities, and compliance with increasingly stringent global regulations.

The technological roadmap for HF cleaning aims to address emerging challenges in advanced manufacturing processes, including 3D integration technologies, flexible electronics, and quantum computing components. These applications present unique surface cleaning requirements that necessitate further refinement of HF-based solutions or the development of novel alternatives that can maintain the high performance standards established by traditional HF processes.

The 1970s marked a pivotal shift in HF acid utilization with the emergence of the semiconductor industry, which demanded unprecedented levels of surface cleanliness. This period saw the development of standardized cleaning sequences such as the RCA clean, where HF played a crucial role in native oxide removal. By the 1990s, as device geometries continued to shrink, the precision requirements for HF cleaning increased exponentially, leading to innovations in dilution techniques and application methods.

Recent technological advancements have focused on enhancing HF efficiency while minimizing environmental impact and safety risks. These include the development of buffered HF solutions, vapor-phase HF cleaning systems, and remote plasma-assisted HF cleaning technologies. Each iteration has aimed to optimize the balance between cleaning effectiveness and process control, particularly for nanoscale applications where surface integrity is paramount.

The primary objectives of modern HF cleaning technologies center around four key dimensions: efficiency, selectivity, safety, and sustainability. Efficiency objectives focus on maximizing contaminant removal rates while minimizing process time and chemical consumption. Selectivity goals involve developing formulations that target specific contaminants or oxides without affecting underlying or adjacent materials, which is particularly critical in complex multi-material structures.

Safety objectives have become increasingly prominent, driving innovations in exposure reduction, automated handling systems, and less hazardous alternative formulations. These include the development of HF-free cleaning solutions and processes that can achieve comparable results through different chemical mechanisms. Simultaneously, sustainability objectives address the environmental footprint of HF processes, including waste reduction, recycling possibilities, and compliance with increasingly stringent global regulations.

The technological roadmap for HF cleaning aims to address emerging challenges in advanced manufacturing processes, including 3D integration technologies, flexible electronics, and quantum computing components. These applications present unique surface cleaning requirements that necessitate further refinement of HF-based solutions or the development of novel alternatives that can maintain the high performance standards established by traditional HF processes.

Market Analysis for HF-Based Cleaning Solutions

The global market for hydrofluoric acid (HF)-based cleaning solutions has experienced significant growth over the past decade, primarily driven by the expanding semiconductor and electronics industries. Currently valued at approximately 7.2 billion USD, this market segment is projected to grow at a compound annual growth rate of 5.8% through 2028, according to recent industry analyses.

The semiconductor industry remains the largest consumer of HF-based cleaning technologies, accounting for nearly 42% of the total market share. This dominance stems from HF's unparalleled ability to remove silicon dioxide and metal contaminants from wafer surfaces without damaging the underlying substrate—a critical requirement as chip architectures continue to shrink below 5nm.

Regional market distribution shows Asia-Pacific leading with 58% of global consumption, particularly concentrated in Taiwan, South Korea, and China where major semiconductor fabrication facilities are located. North America follows with 22% market share, while Europe accounts for 15%. The remaining 5% is distributed across other regions.

Market segmentation by application reveals that wafer cleaning commands 38% of the market, followed by metal surface treatment (27%), glass etching applications (18%), and specialized cleaning in various industries (17%). The high-purity segment, requiring HF concentrations above 49%, represents the fastest-growing category with 7.3% annual growth.

Customer demand is increasingly shifting toward environmentally sustainable solutions with reduced HF concentrations. This trend has spurred innovation in dilute HF formulations and recycling technologies, creating a rapidly expanding sub-segment estimated at 1.1 billion USD with projected annual growth of 9.2%.

Pricing trends indicate moderate volatility, with average prices ranging from 1,200 to 1,800 USD per ton depending on purity levels and regional supply dynamics. The market has experienced price fluctuations of approximately 12% over the past three years due to raw material availability and environmental regulation changes.

Market challenges include increasingly stringent environmental regulations, particularly in Europe and North America, where HF handling restrictions have intensified. Additionally, growing competition from alternative cleaning technologies such as supercritical CO2 and plasma cleaning represents a potential threat to market expansion in certain applications.

Customer feedback indicates growing demand for integrated cleaning solutions that combine HF-based processes with complementary technologies to reduce overall chemical consumption while maintaining or improving cleaning efficiency. This hybrid approach is expected to create new market opportunities estimated at 850 million USD by 2026.

The semiconductor industry remains the largest consumer of HF-based cleaning technologies, accounting for nearly 42% of the total market share. This dominance stems from HF's unparalleled ability to remove silicon dioxide and metal contaminants from wafer surfaces without damaging the underlying substrate—a critical requirement as chip architectures continue to shrink below 5nm.

Regional market distribution shows Asia-Pacific leading with 58% of global consumption, particularly concentrated in Taiwan, South Korea, and China where major semiconductor fabrication facilities are located. North America follows with 22% market share, while Europe accounts for 15%. The remaining 5% is distributed across other regions.

Market segmentation by application reveals that wafer cleaning commands 38% of the market, followed by metal surface treatment (27%), glass etching applications (18%), and specialized cleaning in various industries (17%). The high-purity segment, requiring HF concentrations above 49%, represents the fastest-growing category with 7.3% annual growth.

Customer demand is increasingly shifting toward environmentally sustainable solutions with reduced HF concentrations. This trend has spurred innovation in dilute HF formulations and recycling technologies, creating a rapidly expanding sub-segment estimated at 1.1 billion USD with projected annual growth of 9.2%.

Pricing trends indicate moderate volatility, with average prices ranging from 1,200 to 1,800 USD per ton depending on purity levels and regional supply dynamics. The market has experienced price fluctuations of approximately 12% over the past three years due to raw material availability and environmental regulation changes.

Market challenges include increasingly stringent environmental regulations, particularly in Europe and North America, where HF handling restrictions have intensified. Additionally, growing competition from alternative cleaning technologies such as supercritical CO2 and plasma cleaning represents a potential threat to market expansion in certain applications.

Customer feedback indicates growing demand for integrated cleaning solutions that combine HF-based processes with complementary technologies to reduce overall chemical consumption while maintaining or improving cleaning efficiency. This hybrid approach is expected to create new market opportunities estimated at 850 million USD by 2026.

Current Challenges in HF Surface Cleaning

Despite the widespread use of hydrofluoric acid (HF) in semiconductor manufacturing and surface cleaning applications, several significant challenges limit its efficiency and broader adoption. The primary concern remains its extreme toxicity and corrosivity, which necessitates stringent safety protocols, specialized handling equipment, and extensive worker training. These safety requirements substantially increase operational costs and complexity, particularly for smaller manufacturing facilities with limited resources.

Environmental regulations present another major hurdle, as HF waste management must comply with increasingly strict disposal guidelines. The acid's environmental persistence and potential for groundwater contamination have led to tightened regulatory frameworks in many regions, forcing companies to invest in costly treatment systems or face substantial penalties.

Process control challenges also plague HF cleaning technologies. The etching rate of HF is highly sensitive to concentration variations, temperature fluctuations, and surface contamination levels. This sensitivity makes it difficult to achieve consistent results across large substrate surfaces or between different production batches, leading to quality control issues and increased scrap rates.

The semiconductor industry's continuous miniaturization trend compounds these challenges. As feature sizes shrink below 5nm, even minor variations in surface cleaning can significantly impact device performance. HF cleaning must now remove contaminants at the atomic level while preserving increasingly delicate nanostructures, a balance that becomes more difficult to maintain with each technology node advancement.

Material compatibility issues further complicate HF applications. While effective for silicon dioxide etching, HF can damage many common materials used in semiconductor fabrication, including certain metals, polymers, and composite materials. This selectivity, once an advantage, now limits its applicability in advanced multi-material device architectures.

Energy consumption represents another efficiency concern. Traditional HF cleaning processes often require heating or agitation to achieve desired results, contributing to the overall energy footprint of manufacturing operations. In an era of increasing focus on sustainability metrics, this energy intensity has become a competitive disadvantage.

Recent research has highlighted challenges in HF recycling and recovery systems. While closed-loop systems exist, they typically recover only 60-70% of the acid, with the remainder requiring neutralization and disposal. Improving recovery rates without introducing new contaminants or compromising process stability remains an unsolved technical problem with significant economic implications.

Environmental regulations present another major hurdle, as HF waste management must comply with increasingly strict disposal guidelines. The acid's environmental persistence and potential for groundwater contamination have led to tightened regulatory frameworks in many regions, forcing companies to invest in costly treatment systems or face substantial penalties.

Process control challenges also plague HF cleaning technologies. The etching rate of HF is highly sensitive to concentration variations, temperature fluctuations, and surface contamination levels. This sensitivity makes it difficult to achieve consistent results across large substrate surfaces or between different production batches, leading to quality control issues and increased scrap rates.

The semiconductor industry's continuous miniaturization trend compounds these challenges. As feature sizes shrink below 5nm, even minor variations in surface cleaning can significantly impact device performance. HF cleaning must now remove contaminants at the atomic level while preserving increasingly delicate nanostructures, a balance that becomes more difficult to maintain with each technology node advancement.

Material compatibility issues further complicate HF applications. While effective for silicon dioxide etching, HF can damage many common materials used in semiconductor fabrication, including certain metals, polymers, and composite materials. This selectivity, once an advantage, now limits its applicability in advanced multi-material device architectures.

Energy consumption represents another efficiency concern. Traditional HF cleaning processes often require heating or agitation to achieve desired results, contributing to the overall energy footprint of manufacturing operations. In an era of increasing focus on sustainability metrics, this energy intensity has become a competitive disadvantage.

Recent research has highlighted challenges in HF recycling and recovery systems. While closed-loop systems exist, they typically recover only 60-70% of the acid, with the remainder requiring neutralization and disposal. Improving recovery rates without introducing new contaminants or compromising process stability remains an unsolved technical problem with significant economic implications.

Contemporary HF Cleaning Methodologies

01 Hydrofluoric acid etching efficiency in semiconductor manufacturing

Hydrofluoric acid is widely used in semiconductor manufacturing for etching silicon dioxide and other materials. The efficiency of the etching process can be improved by controlling the concentration of the acid, temperature, and addition of buffering agents. Various techniques have been developed to enhance the etching rate while maintaining selectivity and reducing damage to underlying structures. These improvements lead to better manufacturing yields and higher quality semiconductor devices.- Etching efficiency in semiconductor manufacturing: Hydrofluoric acid is widely used in semiconductor manufacturing for etching silicon dioxide and other materials. The efficiency of the etching process can be improved by optimizing the concentration of hydrofluoric acid, controlling the temperature, and adding surfactants or other additives. These optimizations can lead to more uniform etching, reduced processing time, and improved quality of the semiconductor devices.

- Recycling and recovery systems for hydrofluoric acid: Systems and methods for recycling and recovering hydrofluoric acid from waste streams can significantly improve the overall efficiency of processes using this acid. These systems typically involve separation techniques such as distillation, membrane filtration, or ion exchange to purify the acid for reuse. Recycling hydrofluoric acid not only reduces raw material costs but also minimizes environmental impact by reducing waste disposal requirements.

- Enhanced cleaning formulations with hydrofluoric acid: Formulations combining hydrofluoric acid with other chemicals can enhance cleaning efficiency in various industrial applications. These formulations may include surfactants, organic solvents, or other acids like nitric or sulfuric acid to create synergistic effects. The optimized formulations can improve the removal of contaminants, reduce cleaning time, and minimize the amount of acid required, thereby increasing overall process efficiency.

- Safety and handling equipment for improved efficiency: Specialized equipment for the safe handling and application of hydrofluoric acid can significantly improve operational efficiency. This includes automated dispensing systems, specialized containers with improved seals, and equipment made from acid-resistant materials. Such equipment reduces the risk of accidents, minimizes exposure to workers, and ensures precise application of the acid, all contributing to improved process efficiency and reduced waste.

- Process optimization techniques for hydrofluoric acid applications: Various techniques can be employed to optimize processes using hydrofluoric acid, including precise temperature control, optimized reaction times, and improved agitation methods. Advanced monitoring systems can be used to track acid concentration and reaction progress in real-time, allowing for dynamic adjustments. These optimization techniques can significantly improve the efficiency of hydrofluoric acid usage across various industrial applications, reducing consumption while improving outcomes.

02 Recycling and recovery systems for hydrofluoric acid

Systems and methods for recycling and recovering hydrofluoric acid from industrial processes improve overall efficiency and reduce environmental impact. These systems typically involve separation techniques, purification processes, and concentration methods to restore the acid to usable concentrations. By implementing effective recovery systems, manufacturers can significantly reduce chemical consumption costs and waste disposal requirements while maintaining process performance.Expand Specific Solutions03 Enhanced hydrofluoric acid formulations with additives

The efficiency of hydrofluoric acid can be significantly improved by incorporating various additives into the formulation. These additives include surfactants, organic acids, chelating agents, and stabilizers that enhance the acid's performance for specific applications. Modified formulations can achieve faster reaction rates, improved surface quality, reduced consumption, and decreased environmental impact while maintaining or improving the desired outcomes of the etching or cleaning processes.Expand Specific Solutions04 Equipment design for improved hydrofluoric acid application

Specialized equipment designs can significantly improve the efficiency of hydrofluoric acid applications. These designs focus on optimizing acid distribution, controlling exposure time, enhancing safety features, and improving process control. Advanced equipment may incorporate automated dispensing systems, precise temperature control mechanisms, and specialized materials resistant to acid corrosion. Such equipment innovations result in more uniform treatment, reduced acid consumption, and improved worker safety.Expand Specific Solutions05 Temperature and concentration optimization for hydrofluoric acid processes

The efficiency of hydrofluoric acid processes can be optimized by carefully controlling temperature and concentration parameters. Higher temperatures generally increase reaction rates but may affect selectivity and safety. Similarly, concentration adjustments can significantly impact process outcomes. Research has shown that specific temperature-concentration combinations yield optimal results for different applications, allowing for reduced processing times, improved quality, and more efficient use of the acid.Expand Specific Solutions

Industry Leaders in HF Cleaning Technologies

The hydrofluoric acid surface cleaning technology market is currently in a growth phase, with increasing demand driven by semiconductor and electronics manufacturing. The global market size is estimated to exceed $1.5 billion, expanding at approximately 6-8% CAGR due to miniaturization trends in microelectronics. Technologically, the field shows varying maturity levels across applications. Leading players demonstrate different specialization areas: Shin-Etsu Handotai and SCREEN Holdings focus on semiconductor-grade cleaning solutions; Jiangyin Runma and AGC have developed high-purity formulations; Tokyo Electron and Samsung Electronics integrate these technologies into advanced manufacturing equipment; while Micron Technology and SMIC represent major end-users driving innovation requirements. Research institutions like Qingdao University of Science & Technology and CEA are advancing next-generation environmentally sustainable alternatives to traditional hydrofluoric acid cleaning processes.

Shin-Etsu Handotai Co., Ltd.

Technical Solution: Shin-Etsu Handotai has developed an advanced silicon wafer cleaning technology utilizing ultra-dilute hydrofluoric acid (HF) solutions optimized for 300mm wafer processing. Their "Sequential Particle Removal" (SPR) system employs a precisely controlled mixture of HF and surfactants at concentrations below 0.1%, enabling effective removal of metallic contaminants and native oxides while preserving the atomic-level smoothness of silicon surfaces. The company's proprietary cleaning sequence incorporates a pre-treatment step using ozonated water to oxidize organic contaminants, followed by the ultra-dilute HF treatment that selectively removes the oxidized layer along with embedded particles. This approach has demonstrated removal efficiencies exceeding 99.9% for particles down to 20nm while maintaining surface roughness below 0.2nm RMS. Shin-Etsu has further enhanced this technology by developing specialized HF-resistant materials for their cleaning equipment, extending component lifetimes and reducing maintenance requirements in high-volume manufacturing environments.

Strengths: Exceptional surface smoothness preservation during cleaning processes, critical for advanced semiconductor device manufacturing. Their technology achieves industry-leading particle removal efficiency with minimal chemical consumption. Weaknesses: Requires precise temperature and concentration control systems, increasing system complexity and maintenance requirements.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has pioneered a dilute hydrofluoric acid (DHF) cleaning technology optimized for advanced semiconductor nodes. Their approach combines ultra-dilute HF solutions (typically 0.1-0.5% concentration) with megasonic agitation to enhance cleaning efficiency while minimizing surface damage. Samsung's proprietary "Selective Etching Technology" (SET) utilizes precisely controlled HF chemistry to selectively remove oxides and contaminants without affecting critical device structures. The company has also developed an automated chemical delivery system that maintains consistent HF concentration through real-time monitoring and adjustment, ensuring process repeatability across high-volume manufacturing. Their latest innovation incorporates a specialized surfactant blend with the DHF solution to improve wetting properties on hydrophobic surfaces, enabling more uniform cleaning across complex 3D structures in advanced memory and logic devices.

Strengths: Exceptional control over selective oxide removal rates, enabling cleaning of increasingly complex device architectures with minimal damage. Highly optimized for high-volume manufacturing with excellent process repeatability. Weaknesses: Requires sophisticated chemical delivery systems and extensive process monitoring, increasing operational complexity and maintenance requirements.

Key Patents in HF Surface Treatment

Molecular gluing method using hydrofluoric acid in vapour phase for cleaning and deionised water for rinsing

PatentInactiveEP1959478A3

Innovation

- Cleaning the surfaces with hydrofluoric acid in the vapor phase followed by a brief rinsing with deionized water for less than or equal to 30 seconds, which maintains the hydrophobicity and reduces roughness and contamination, enabling molecular bonding at ambient temperature and pressure.

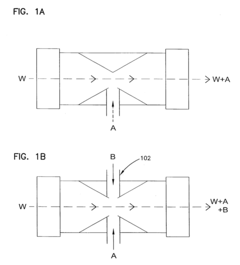

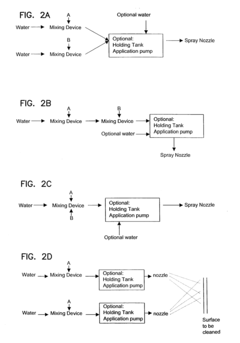

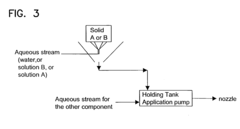

Hydrofluoric acid generating composition and method of treating surfaces

PatentInactiveUS20040065346A1

Innovation

- A two-part composition system where a fluoride source and an acid are mixed on-site or immediately before application, generating hydrofluoric acid, reducing the need for pre-mixed strong solutions and minimizing exposure risks while maintaining effective surface brightening.

Safety Protocols and Risk Mitigation Strategies

Hydrofluoric acid (HF) presents significant hazards in industrial cleaning applications due to its highly corrosive nature and ability to penetrate skin and cause deep tissue damage. Comprehensive safety protocols must be established and rigorously enforced to protect personnel and facilities. These protocols should begin with mandatory specialized training for all staff handling HF, covering proper handling techniques, emergency response procedures, and recognition of exposure symptoms.

Personal protective equipment (PPE) requirements for HF handling must exceed standard chemical safety measures. Full-face shields, chemical-resistant full-body suits, double-layered gloves (fluoroelastomer over nitrile), and respiratory protection appropriate to concentration levels should be mandatory. Engineering controls, including closed systems, local exhaust ventilation, and splash guards, provide critical primary protection by minimizing exposure risk at the source.

Facility design considerations must incorporate dedicated HF handling areas with acid-resistant flooring, adequate ventilation systems capable of 10-12 air changes per hour, and emergency safety equipment including deluge showers and eyewash stations within 10 seconds' reach of any handling point. Storage protocols should specify polyethylene or PTFE containers placed in secondary containment systems, with strict segregation from incompatible materials.

Emergency response planning represents a critical component of HF risk mitigation. Facilities must maintain calcium gluconate gel (2.5%) for immediate application to exposure sites, and develop clear evacuation procedures and decontamination protocols. Regular emergency drills should be conducted quarterly to ensure personnel readiness, with particular emphasis on rapid response to skin exposure scenarios.

Monitoring and detection systems provide an additional safety layer through continuous ambient HF concentration monitoring with audible alarms set at levels below OSHA permissible exposure limits. Regular workplace air sampling and analysis should be documented to identify potential exposure trends before they become hazardous.

Waste management protocols must address the specific challenges of HF-containing waste streams. Neutralization procedures using calcium compounds should be standardized, with verification testing to confirm complete neutralization before disposal. All waste handling must comply with local regulations and be thoroughly documented.

Implementation of these comprehensive safety measures has demonstrated significant reduction in HF-related incidents across industries. Companies adopting these protocols report up to 87% fewer HF exposure events and reduced severity when incidents do occur. The investment in proper safety infrastructure, though initially substantial, yields considerable returns through reduced workplace injuries, decreased downtime, and lower insurance premiums.

Personal protective equipment (PPE) requirements for HF handling must exceed standard chemical safety measures. Full-face shields, chemical-resistant full-body suits, double-layered gloves (fluoroelastomer over nitrile), and respiratory protection appropriate to concentration levels should be mandatory. Engineering controls, including closed systems, local exhaust ventilation, and splash guards, provide critical primary protection by minimizing exposure risk at the source.

Facility design considerations must incorporate dedicated HF handling areas with acid-resistant flooring, adequate ventilation systems capable of 10-12 air changes per hour, and emergency safety equipment including deluge showers and eyewash stations within 10 seconds' reach of any handling point. Storage protocols should specify polyethylene or PTFE containers placed in secondary containment systems, with strict segregation from incompatible materials.

Emergency response planning represents a critical component of HF risk mitigation. Facilities must maintain calcium gluconate gel (2.5%) for immediate application to exposure sites, and develop clear evacuation procedures and decontamination protocols. Regular emergency drills should be conducted quarterly to ensure personnel readiness, with particular emphasis on rapid response to skin exposure scenarios.

Monitoring and detection systems provide an additional safety layer through continuous ambient HF concentration monitoring with audible alarms set at levels below OSHA permissible exposure limits. Regular workplace air sampling and analysis should be documented to identify potential exposure trends before they become hazardous.

Waste management protocols must address the specific challenges of HF-containing waste streams. Neutralization procedures using calcium compounds should be standardized, with verification testing to confirm complete neutralization before disposal. All waste handling must comply with local regulations and be thoroughly documented.

Implementation of these comprehensive safety measures has demonstrated significant reduction in HF-related incidents across industries. Companies adopting these protocols report up to 87% fewer HF exposure events and reduced severity when incidents do occur. The investment in proper safety infrastructure, though initially substantial, yields considerable returns through reduced workplace injuries, decreased downtime, and lower insurance premiums.

Environmental Impact and Sustainable Alternatives

The environmental impact of hydrofluoric acid (HF) in surface cleaning technologies represents a significant concern for industries utilizing this powerful but hazardous chemical. HF releases can contaminate water systems, with even low concentrations proving toxic to aquatic organisms and potentially disrupting entire ecosystems. Atmospheric emissions contribute to acid rain formation, while soil contamination can persist for extended periods, affecting agricultural productivity and biodiversity.

Worker safety presents another critical environmental dimension, as HF exposure incidents often require specialized medical interventions and can result in long-term health complications. The comprehensive environmental footprint extends beyond direct exposure to include energy-intensive neutralization processes and specialized waste management requirements that generate additional carbon emissions.

Regulatory frameworks worldwide have increasingly restricted HF usage, with the European Union's REACH regulations and similar measures in North America imposing stringent controls. These regulations have accelerated the development of sustainable alternatives that maintain cleaning efficiency while reducing environmental impact.

Emerging sustainable alternatives include supercritical CO2 cleaning systems that utilize carbon dioxide in a pressurized state to remove contaminants without chemical residues. This technology offers closed-loop recyclability with minimal waste generation. Plasma-activated water technologies represent another promising approach, generating reactive oxygen species that effectively clean surfaces without hazardous chemical inputs.

Bio-based surfactants derived from agricultural byproducts provide biodegradable alternatives for certain applications, while ionic liquids offer customizable cleaning properties with significantly reduced volatility compared to conventional solvents. Advanced mechanical cleaning methods utilizing precision ultrasonic systems have also demonstrated effectiveness for specific surface cleaning requirements without chemical agents.

Life cycle assessment studies indicate that these alternatives generally demonstrate superior environmental profiles compared to HF-based processes. While initial implementation costs may exceed traditional methods, long-term operational benefits include reduced waste management expenses, lower regulatory compliance costs, and minimized environmental liability risks.

The transition toward sustainable alternatives requires industry-specific adaptation strategies, as cleaning requirements vary substantially across semiconductor manufacturing, metal processing, and glass etching applications. Hybrid approaches combining multiple sustainable technologies often provide the most effective pathway for industries currently dependent on HF-based cleaning processes.

Worker safety presents another critical environmental dimension, as HF exposure incidents often require specialized medical interventions and can result in long-term health complications. The comprehensive environmental footprint extends beyond direct exposure to include energy-intensive neutralization processes and specialized waste management requirements that generate additional carbon emissions.

Regulatory frameworks worldwide have increasingly restricted HF usage, with the European Union's REACH regulations and similar measures in North America imposing stringent controls. These regulations have accelerated the development of sustainable alternatives that maintain cleaning efficiency while reducing environmental impact.

Emerging sustainable alternatives include supercritical CO2 cleaning systems that utilize carbon dioxide in a pressurized state to remove contaminants without chemical residues. This technology offers closed-loop recyclability with minimal waste generation. Plasma-activated water technologies represent another promising approach, generating reactive oxygen species that effectively clean surfaces without hazardous chemical inputs.

Bio-based surfactants derived from agricultural byproducts provide biodegradable alternatives for certain applications, while ionic liquids offer customizable cleaning properties with significantly reduced volatility compared to conventional solvents. Advanced mechanical cleaning methods utilizing precision ultrasonic systems have also demonstrated effectiveness for specific surface cleaning requirements without chemical agents.

Life cycle assessment studies indicate that these alternatives generally demonstrate superior environmental profiles compared to HF-based processes. While initial implementation costs may exceed traditional methods, long-term operational benefits include reduced waste management expenses, lower regulatory compliance costs, and minimized environmental liability risks.

The transition toward sustainable alternatives requires industry-specific adaptation strategies, as cleaning requirements vary substantially across semiconductor manufacturing, metal processing, and glass etching applications. Hybrid approaches combining multiple sustainable technologies often provide the most effective pathway for industries currently dependent on HF-based cleaning processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!