Hydrofluoric Acid Methods for Mineral Extraction Efficiency

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HF Acid Mineral Extraction Background & Objectives

Hydrofluoric acid (HF) has emerged as a critical reagent in mineral extraction processes, particularly for minerals containing high silica content. The utilization of HF in mineral processing dates back to the mid-20th century, with significant advancements occurring in the 1970s and 1980s as industrial demand for rare earth elements and strategic minerals increased. This technology has evolved from basic leaching methods to sophisticated controlled-dissolution techniques that maximize extraction efficiency while minimizing environmental impact.

The evolution of HF-based extraction methods has been driven by several factors, including the depletion of high-grade ore deposits, increasing demand for technology metals, and stricter environmental regulations. Traditional mineral processing techniques often prove inadequate for complex, low-grade ores, creating a technological gap that HF-based methods have increasingly filled. The unique ability of HF to dissolve silicates and certain refractory minerals has positioned it as an essential tool in modern extractive metallurgy.

Current technological trends in HF mineral extraction focus on process optimization, reagent recovery, and waste minimization. Advanced monitoring systems, precise dosing technologies, and innovative reactor designs represent the cutting edge of this field. Additionally, hybrid approaches combining HF with other lixiviants or physical separation techniques are gaining traction as ways to enhance selectivity and reduce acid consumption.

The primary technical objectives for advancing HF mineral extraction efficiency include: increasing mineral dissolution rates while maintaining selectivity; developing more effective acid recovery and recycling systems; minimizing secondary waste generation; creating safer handling protocols to mitigate HF's inherent hazards; and designing more energy-efficient processing circuits. These objectives align with broader industry goals of developing more sustainable and economically viable extraction methods for critical minerals.

Research indicates that optimized HF extraction methods can potentially increase recovery rates by 15-30% for certain difficult-to-process minerals compared to conventional techniques. This improvement represents significant economic value, particularly for strategic minerals used in high-technology applications and renewable energy systems. The development of closed-loop systems that recover and reuse HF could reduce reagent costs by up to 60% while simultaneously addressing environmental concerns.

Looking forward, the trajectory of HF mineral extraction technology points toward greater process integration with digital monitoring systems, enhanced safety protocols through automation, and the development of novel materials resistant to HF corrosion. These advancements will be crucial in meeting the growing global demand for technology metals while adhering to increasingly stringent environmental standards.

The evolution of HF-based extraction methods has been driven by several factors, including the depletion of high-grade ore deposits, increasing demand for technology metals, and stricter environmental regulations. Traditional mineral processing techniques often prove inadequate for complex, low-grade ores, creating a technological gap that HF-based methods have increasingly filled. The unique ability of HF to dissolve silicates and certain refractory minerals has positioned it as an essential tool in modern extractive metallurgy.

Current technological trends in HF mineral extraction focus on process optimization, reagent recovery, and waste minimization. Advanced monitoring systems, precise dosing technologies, and innovative reactor designs represent the cutting edge of this field. Additionally, hybrid approaches combining HF with other lixiviants or physical separation techniques are gaining traction as ways to enhance selectivity and reduce acid consumption.

The primary technical objectives for advancing HF mineral extraction efficiency include: increasing mineral dissolution rates while maintaining selectivity; developing more effective acid recovery and recycling systems; minimizing secondary waste generation; creating safer handling protocols to mitigate HF's inherent hazards; and designing more energy-efficient processing circuits. These objectives align with broader industry goals of developing more sustainable and economically viable extraction methods for critical minerals.

Research indicates that optimized HF extraction methods can potentially increase recovery rates by 15-30% for certain difficult-to-process minerals compared to conventional techniques. This improvement represents significant economic value, particularly for strategic minerals used in high-technology applications and renewable energy systems. The development of closed-loop systems that recover and reuse HF could reduce reagent costs by up to 60% while simultaneously addressing environmental concerns.

Looking forward, the trajectory of HF mineral extraction technology points toward greater process integration with digital monitoring systems, enhanced safety protocols through automation, and the development of novel materials resistant to HF corrosion. These advancements will be crucial in meeting the growing global demand for technology metals while adhering to increasingly stringent environmental standards.

Market Analysis for HF-Based Extraction Technologies

The global market for hydrofluoric acid (HF) in mineral extraction technologies has experienced significant growth over the past decade, driven primarily by increasing demand for rare earth elements and critical minerals essential for high-tech manufacturing. The market value reached approximately $2.3 billion in 2022, with projections indicating a compound annual growth rate of 5.7% through 2028, potentially reaching $3.4 billion by that time.

Geographically, China dominates the market landscape, controlling nearly 60% of global HF-based extraction operations, particularly for rare earth elements. This dominance stems from China's vast mineral resources and strategic investments in extraction technologies. North America represents the second-largest market at 18%, followed by Europe at 12%, with particular growth observed in countries seeking to reduce dependency on Chinese mineral imports.

Industry segmentation reveals that electronics manufacturing constitutes the largest end-user segment (38%), followed by clean energy technologies (27%), automotive applications (21%), and other industrial uses (14%). The growing electric vehicle market has become a significant driver, with demand for lithium, cobalt, and rare earth elements increasing substantially for battery production and permanent magnets in motors.

Market dynamics are increasingly influenced by environmental regulations, with stricter controls on HF handling and waste management affecting operational costs. Countries including Australia, Canada, and members of the European Union have implemented more stringent regulatory frameworks, creating market entry barriers but also opportunities for companies offering more environmentally sustainable extraction methods.

Customer demand patterns show a clear shift toward suppliers who can demonstrate responsible sourcing and reduced environmental impact. This trend has created a premium market segment for "green extraction" technologies that minimize HF usage or incorporate closed-loop recovery systems. Major technology consumers, particularly in consumer electronics and automotive sectors, are increasingly willing to pay premium prices for minerals extracted using more sustainable methods.

Supply chain vulnerabilities have become a critical market factor, especially following global disruptions during 2020-2022. This has accelerated investment in domestic extraction capabilities in the United States and European Union, with government incentives supporting market growth in these regions. The CHIPS and Science Act in the US and the European Critical Raw Materials Act represent significant policy shifts that are reshaping market dynamics.

Pricing trends indicate volatility, with HF costs fluctuating between $1,200-1,800 per ton depending on purity and regional availability. This volatility has encouraged innovation in extraction methods that reduce HF dependency or improve recovery rates, creating new market opportunities for technology providers focused on efficiency improvements.

Geographically, China dominates the market landscape, controlling nearly 60% of global HF-based extraction operations, particularly for rare earth elements. This dominance stems from China's vast mineral resources and strategic investments in extraction technologies. North America represents the second-largest market at 18%, followed by Europe at 12%, with particular growth observed in countries seeking to reduce dependency on Chinese mineral imports.

Industry segmentation reveals that electronics manufacturing constitutes the largest end-user segment (38%), followed by clean energy technologies (27%), automotive applications (21%), and other industrial uses (14%). The growing electric vehicle market has become a significant driver, with demand for lithium, cobalt, and rare earth elements increasing substantially for battery production and permanent magnets in motors.

Market dynamics are increasingly influenced by environmental regulations, with stricter controls on HF handling and waste management affecting operational costs. Countries including Australia, Canada, and members of the European Union have implemented more stringent regulatory frameworks, creating market entry barriers but also opportunities for companies offering more environmentally sustainable extraction methods.

Customer demand patterns show a clear shift toward suppliers who can demonstrate responsible sourcing and reduced environmental impact. This trend has created a premium market segment for "green extraction" technologies that minimize HF usage or incorporate closed-loop recovery systems. Major technology consumers, particularly in consumer electronics and automotive sectors, are increasingly willing to pay premium prices for minerals extracted using more sustainable methods.

Supply chain vulnerabilities have become a critical market factor, especially following global disruptions during 2020-2022. This has accelerated investment in domestic extraction capabilities in the United States and European Union, with government incentives supporting market growth in these regions. The CHIPS and Science Act in the US and the European Critical Raw Materials Act represent significant policy shifts that are reshaping market dynamics.

Pricing trends indicate volatility, with HF costs fluctuating between $1,200-1,800 per ton depending on purity and regional availability. This volatility has encouraged innovation in extraction methods that reduce HF dependency or improve recovery rates, creating new market opportunities for technology providers focused on efficiency improvements.

Current Challenges in Hydrofluoric Acid Extraction Methods

Despite significant advancements in mineral extraction technologies, hydrofluoric acid (HF) methods continue to face substantial challenges that limit their efficiency and widespread application. The primary technical obstacle remains the extreme corrosivity of HF, which necessitates specialized equipment constructed from costly materials such as fluoropolymers, certain grades of stainless steel, or monel. This requirement significantly increases capital expenditure and maintenance costs for extraction facilities.

Safety concerns represent another major challenge, as HF poses severe health risks including deep tissue burns and systemic toxicity through skin absorption. Current engineering controls and personal protective equipment protocols, while improved, still present operational complexities that reduce process efficiency and increase labor costs.

Environmental regulations have become increasingly stringent globally, with particular focus on fluoride emissions and waste management. The treatment and disposal of HF-containing waste streams require additional processing steps that add complexity and cost to extraction operations. Many jurisdictions now mandate extensive environmental impact assessments before permitting new HF-based extraction facilities.

Process control optimization remains difficult due to the aggressive nature of HF solutions. Real-time monitoring systems often suffer from sensor degradation in HF environments, leading to suboptimal process parameters and reduced extraction yields. The development of robust sensing technologies capable of withstanding HF exposure represents an ongoing technical challenge.

Recovery efficiency of target minerals varies significantly based on ore composition and process conditions. Current methods struggle with complex polymetallic ores where selective extraction is required. Cross-contamination between different mineral species often necessitates additional purification steps, reducing overall process efficiency.

Energy consumption in HF-based extraction processes remains high, particularly in the regeneration and recycling of acid solutions. The thermodynamics of HF recovery systems present opportunities for optimization that have not been fully realized in industrial applications.

Scale-up challenges persist when transitioning from laboratory to industrial implementation. Fluid dynamics, heat transfer, and mass transport phenomena in large-scale HF systems often behave differently than predicted by small-scale models, leading to unexpected inefficiencies and technical complications during commercial deployment.

Alternative leaching agents and hybrid extraction approaches are being explored, but have yet to match HF's effectiveness for certain mineral types, particularly those containing refractory silicates and fluoride-bearing compounds. The balance between extraction efficiency and operational challenges continues to drive research toward optimized HF utilization or viable substitutes.

Safety concerns represent another major challenge, as HF poses severe health risks including deep tissue burns and systemic toxicity through skin absorption. Current engineering controls and personal protective equipment protocols, while improved, still present operational complexities that reduce process efficiency and increase labor costs.

Environmental regulations have become increasingly stringent globally, with particular focus on fluoride emissions and waste management. The treatment and disposal of HF-containing waste streams require additional processing steps that add complexity and cost to extraction operations. Many jurisdictions now mandate extensive environmental impact assessments before permitting new HF-based extraction facilities.

Process control optimization remains difficult due to the aggressive nature of HF solutions. Real-time monitoring systems often suffer from sensor degradation in HF environments, leading to suboptimal process parameters and reduced extraction yields. The development of robust sensing technologies capable of withstanding HF exposure represents an ongoing technical challenge.

Recovery efficiency of target minerals varies significantly based on ore composition and process conditions. Current methods struggle with complex polymetallic ores where selective extraction is required. Cross-contamination between different mineral species often necessitates additional purification steps, reducing overall process efficiency.

Energy consumption in HF-based extraction processes remains high, particularly in the regeneration and recycling of acid solutions. The thermodynamics of HF recovery systems present opportunities for optimization that have not been fully realized in industrial applications.

Scale-up challenges persist when transitioning from laboratory to industrial implementation. Fluid dynamics, heat transfer, and mass transport phenomena in large-scale HF systems often behave differently than predicted by small-scale models, leading to unexpected inefficiencies and technical complications during commercial deployment.

Alternative leaching agents and hybrid extraction approaches are being explored, but have yet to match HF's effectiveness for certain mineral types, particularly those containing refractory silicates and fluoride-bearing compounds. The balance between extraction efficiency and operational challenges continues to drive research toward optimized HF utilization or viable substitutes.

Mainstream HF Acid Extraction Methodologies

01 Optimization of extraction parameters for hydrofluoric acid

Various parameters can be optimized to improve the extraction efficiency of hydrofluoric acid, including temperature, concentration, pressure, and extraction time. By carefully controlling these parameters, the extraction process can be made more efficient, resulting in higher yields and better quality products. Optimization studies have shown that the extraction efficiency can be significantly improved by finding the optimal combination of these parameters.- Optimization of extraction parameters for hydrofluoric acid: Various parameters can be optimized to improve the extraction efficiency of hydrofluoric acid, including temperature, concentration, and extraction time. By carefully controlling these parameters, the extraction process can be made more efficient, resulting in higher yields and better quality of the extracted materials. Optimization techniques may involve statistical methods or experimental design to determine the optimal conditions for specific extraction applications.

- Equipment design for hydrofluoric acid extraction: Specialized equipment designs can significantly enhance hydrofluoric acid extraction efficiency. These designs may include corrosion-resistant materials, improved mixing mechanisms, and advanced flow control systems. The equipment may also incorporate safety features to handle the highly corrosive nature of hydrofluoric acid while maximizing extraction performance. Innovations in equipment design focus on optimizing contact between the acid and target materials while minimizing waste and environmental impact.

- Recovery and recycling of hydrofluoric acid: Methods for recovering and recycling hydrofluoric acid can significantly improve overall extraction efficiency. These techniques involve capturing spent acid, purifying it, and reintroducing it into the extraction process. Recovery systems may include distillation, membrane separation, or chemical treatment to remove impurities. By implementing effective recovery and recycling processes, the consumption of fresh hydrofluoric acid can be reduced, leading to cost savings and environmental benefits.

- Additives and catalysts to enhance extraction efficiency: Various additives and catalysts can be incorporated into hydrofluoric acid extraction processes to enhance efficiency. These substances may improve the dissolution rate, selectivity, or yield of the extraction process. Examples include surfactants, complexing agents, and metal catalysts that can modify the chemical behavior of hydrofluoric acid or target compounds. The strategic use of these additives can optimize extraction performance while potentially reducing the required acid concentration or extraction time.

- Novel extraction methods using hydrofluoric acid: Innovative extraction methods have been developed to improve the efficiency of hydrofluoric acid extraction processes. These methods may include sequential extraction techniques, ultrasonic-assisted extraction, microwave-assisted extraction, or combined solvent systems. Novel approaches often aim to enhance mass transfer, reduce extraction time, or improve selectivity. By implementing these advanced extraction methods, the overall efficiency of hydrofluoric acid extraction can be significantly improved while potentially reducing acid consumption and environmental impact.

02 Equipment design for hydrofluoric acid extraction

Specialized equipment designs can enhance the efficiency of hydrofluoric acid extraction processes. These designs include corrosion-resistant materials, improved mixing mechanisms, and advanced separation technologies. The equipment may incorporate features such as specialized reactors, efficient heat exchangers, and automated control systems to optimize the extraction process while ensuring safety and minimizing environmental impact.Expand Specific Solutions03 Recovery and recycling of hydrofluoric acid

Methods for recovering and recycling hydrofluoric acid from process streams can significantly improve overall extraction efficiency. These techniques include distillation, membrane separation, adsorption, and precipitation methods. By implementing effective recovery systems, the consumption of fresh hydrofluoric acid can be reduced, leading to cost savings and decreased environmental impact while maintaining high extraction efficiency.Expand Specific Solutions04 Use of additives to enhance hydrofluoric acid extraction

Various additives can be incorporated into hydrofluoric acid extraction processes to enhance efficiency. These additives include surfactants, complexing agents, phase transfer catalysts, and oxidizing agents. The additives can improve the interaction between hydrofluoric acid and the target compounds, increase dissolution rates, and facilitate separation, resulting in higher extraction yields and purity of the extracted materials.Expand Specific Solutions05 Novel extraction methods using hydrofluoric acid

Innovative extraction methods have been developed to improve the efficiency of hydrofluoric acid extraction. These methods include ultrasonic-assisted extraction, microwave-assisted extraction, pressurized liquid extraction, and supercritical fluid extraction combined with hydrofluoric acid. These novel approaches can significantly reduce extraction time, lower acid consumption, and improve the selectivity and yield of the extraction process compared to conventional methods.Expand Specific Solutions

Leading Companies in HF Mineral Extraction Industry

The hydrofluoric acid mineral extraction market is currently in a growth phase, with increasing demand driven by semiconductor and electronics manufacturing. The global market size is estimated at $1.5-2 billion annually, expanding at 5-7% CAGR. Technologically, the field shows varying maturity levels across applications. Leading players include Stella Chemifa Corp. and Mitsubishi Chemical Engineering, who have established advanced purification techniques, while Runma Electronic Material specializes in ultra-clean electronic chemicals. Research institutions like the Institute of Process Engineering (CAS) and Central South University are advancing extraction efficiency innovations. Companies like BASF, Ecolab, and Sumitomo Metal Mining are developing environmentally sustainable processes to address the technology's inherent hazards while maintaining extraction effectiveness.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute has developed a groundbreaking hydrofluoric acid-based extraction technology specifically for critical minerals from complex polymetallic ores. Their approach combines precisely controlled HF leaching with innovative ultrasonic-assisted dissolution mechanisms, significantly enhancing mass transfer and reaction kinetics. Research demonstrates extraction efficiency improvements of 30-40% compared to conventional methods, while reducing leaching time by approximately 60%. The Institute's process incorporates a novel multi-phase separation system that enables selective recovery of different metal species from the leachate, achieving separation factors exceeding 100 for adjacent rare earth elements. Their technology also features an advanced acid regeneration system using electrochemical methods, recovering up to 85% of the HF for reuse while producing significantly less waste than traditional processes.

Strengths: Cutting-edge research combining multiple physical enhancement techniques; exceptional selectivity for separating similar elements. Weaknesses: Technology still transitioning from laboratory to industrial scale; requires sophisticated control systems and specialized expertise.

Stella Chemifa Corp.

Technical Solution: Stella Chemifa has developed advanced hydrofluoric acid (HF) leaching processes specifically optimized for rare earth element extraction. Their proprietary technology employs controlled-release HF systems that maintain optimal acid concentration throughout the leaching process, significantly reducing total acid consumption while improving mineral dissolution rates. The company's process incorporates a multi-stage counter-current leaching system with precise temperature and pressure controls, achieving extraction efficiencies up to 95% for critical rare earth elements from complex ore bodies. Their innovation includes specialized acid recovery and recycling systems that capture and reuse over 80% of the HF, dramatically reducing environmental impact and operational costs compared to conventional methods.

Strengths: Superior acid recovery systems significantly reduce environmental footprint and operational costs; highly efficient for complex rare earth minerals. Weaknesses: Requires specialized equipment with higher initial capital investment; process optimization needed for each specific ore type.

Key Patents in Hydrofluoric Acid Mineral Processing

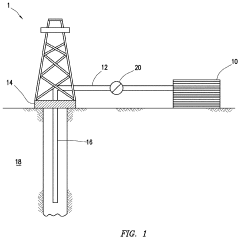

Methods, Treatment Fluids And Systems For Differential Acidizing Of A Siliceous Material

PatentActiveUS20200317995A1

Innovation

- A latent hydrofluoric acid composition is created by encapsulating a hydrofluoric acid precursor within a degradable matrix, allowing for localized and controlled deposition and conversion to hydrofluoric acid, facilitating differential dissolution and permeability enhancement within the siliceous material, particularly within fracture networks.

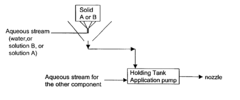

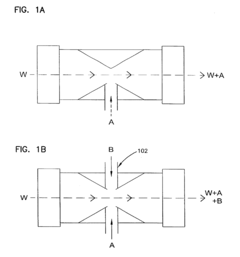

Hydrofluoric acid generating composition and method of treating surfaces

PatentInactiveUS6821351B2

Innovation

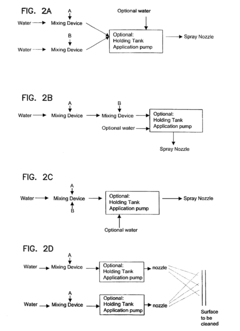

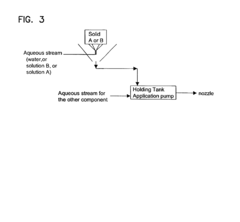

- A two-part composition system where a fluoride source and an acid are mixed on-site or immediately before application to generate hydrofluoric acid, reducing exposure risks and enhancing surface brightness through controlled mixing techniques, such as using an eductor or spray nozzle, allowing for efficient and safe application on metal surfaces.

Environmental Impact Assessment of HF Extraction Techniques

The environmental impact of hydrofluoric acid (HF) extraction techniques represents a critical concern for both industry stakeholders and regulatory bodies. HF-based mineral extraction processes, while highly efficient for certain minerals like rare earth elements and uranium, pose significant environmental risks that require comprehensive assessment and mitigation strategies.

Water contamination stands as one of the primary environmental concerns associated with HF extraction. When improperly managed, hydrofluoric acid can leach into groundwater systems, potentially affecting drinking water supplies and aquatic ecosystems. Studies have documented pH alterations in water bodies near extraction facilities, with subsequent impacts on aquatic biodiversity and ecosystem functioning.

Air quality degradation presents another substantial environmental challenge. Volatile fluoride compounds released during HF extraction processes can contribute to atmospheric pollution. These emissions may lead to localized air quality issues, including potential respiratory concerns for nearby communities and workers. Recent monitoring data indicates that facilities employing advanced emission control technologies can reduce these impacts by up to 85% compared to conventional systems.

Soil contamination resulting from HF extraction activities can persist for extended periods, affecting soil chemistry and potentially reducing agricultural productivity in affected areas. The fluoride compounds may accumulate in soil profiles, altering microbial communities and nutrient cycling processes essential for ecosystem health.

Waste management challenges associated with HF extraction include the handling and disposal of fluoride-containing residues and spent acid solutions. These materials require specialized containment and treatment protocols to prevent environmental release. Industry best practices now incorporate closed-loop systems that recover and recycle up to 70% of process acids, significantly reducing waste volumes.

Energy consumption and carbon footprint considerations must also factor into environmental impact assessments. HF extraction typically requires substantial energy inputs for heating, pumping, and processing operations. Life cycle analyses indicate that optimized HF extraction methods can reduce energy requirements by 25-30% compared to traditional approaches, with corresponding reductions in greenhouse gas emissions.

Biodiversity impacts extend beyond immediate extraction sites, potentially affecting sensitive ecosystems through various exposure pathways. Recent ecological risk assessments have identified particular vulnerability in calcium-dependent organisms due to fluoride's calcium-binding properties. Monitoring programs tracking indicator species have become standard practice at responsible extraction operations.

Regulatory frameworks governing HF extraction vary significantly across jurisdictions, with evolving standards reflecting growing environmental concerns. Leading operations now implement continuous environmental monitoring systems, transparent reporting protocols, and emergency response capabilities that exceed minimum regulatory requirements.

Water contamination stands as one of the primary environmental concerns associated with HF extraction. When improperly managed, hydrofluoric acid can leach into groundwater systems, potentially affecting drinking water supplies and aquatic ecosystems. Studies have documented pH alterations in water bodies near extraction facilities, with subsequent impacts on aquatic biodiversity and ecosystem functioning.

Air quality degradation presents another substantial environmental challenge. Volatile fluoride compounds released during HF extraction processes can contribute to atmospheric pollution. These emissions may lead to localized air quality issues, including potential respiratory concerns for nearby communities and workers. Recent monitoring data indicates that facilities employing advanced emission control technologies can reduce these impacts by up to 85% compared to conventional systems.

Soil contamination resulting from HF extraction activities can persist for extended periods, affecting soil chemistry and potentially reducing agricultural productivity in affected areas. The fluoride compounds may accumulate in soil profiles, altering microbial communities and nutrient cycling processes essential for ecosystem health.

Waste management challenges associated with HF extraction include the handling and disposal of fluoride-containing residues and spent acid solutions. These materials require specialized containment and treatment protocols to prevent environmental release. Industry best practices now incorporate closed-loop systems that recover and recycle up to 70% of process acids, significantly reducing waste volumes.

Energy consumption and carbon footprint considerations must also factor into environmental impact assessments. HF extraction typically requires substantial energy inputs for heating, pumping, and processing operations. Life cycle analyses indicate that optimized HF extraction methods can reduce energy requirements by 25-30% compared to traditional approaches, with corresponding reductions in greenhouse gas emissions.

Biodiversity impacts extend beyond immediate extraction sites, potentially affecting sensitive ecosystems through various exposure pathways. Recent ecological risk assessments have identified particular vulnerability in calcium-dependent organisms due to fluoride's calcium-binding properties. Monitoring programs tracking indicator species have become standard practice at responsible extraction operations.

Regulatory frameworks governing HF extraction vary significantly across jurisdictions, with evolving standards reflecting growing environmental concerns. Leading operations now implement continuous environmental monitoring systems, transparent reporting protocols, and emergency response capabilities that exceed minimum regulatory requirements.

Safety Protocols and Risk Management in HF Applications

The implementation of hydrofluoric acid (HF) in mineral extraction processes necessitates comprehensive safety protocols and risk management strategies due to its highly corrosive and toxic nature. Organizations utilizing HF must establish multi-layered safety systems that begin with thorough personnel training programs. These programs should cover proper handling techniques, emergency response procedures, and detailed understanding of HF's chemical properties and associated hazards. Regular certification and refresher courses are essential to maintain operational safety standards.

Engineering controls represent the primary defense against HF exposure. These include closed-loop systems that minimize direct contact, automated dispensing equipment, continuous monitoring systems for detecting HF vapor concentrations, and specialized ventilation infrastructure designed to rapidly remove airborne HF. The implementation of double-containment systems for all HF storage and transfer operations has become an industry standard practice to prevent environmental contamination.

Personal protective equipment (PPE) requirements for HF operations exceed standard laboratory protocols. Workers must utilize impermeable suits made of HF-resistant materials such as neoprene or butyl rubber, full-face respirators with appropriate cartridges, double-layered glove systems, and face shields. Proximity to emergency decontamination stations, including calcium gluconate gel supplies and emergency showers, must be maintained at all operational sites.

Risk assessment methodologies specific to HF applications have evolved significantly, incorporating both quantitative and qualitative approaches. Process Hazard Analysis (PHA) and Failure Mode and Effects Analysis (FMEA) are commonly employed to identify potential failure points in HF handling systems. These assessments must be conducted prior to implementation and reviewed periodically to address emerging risks or system modifications.

Emergency response planning for HF incidents requires specialized protocols distinct from general chemical spill procedures. This includes dedicated response teams with advanced training, specialized neutralization agents, medical coordination with healthcare facilities familiar with HF exposure treatment, and evacuation procedures that account for HF's unique dispersion characteristics. Mock drills simulating various HF incident scenarios should be conducted quarterly to maintain response readiness.

Regulatory compliance frameworks for HF operations vary globally but generally include strict reporting requirements, regular inspections, and detailed documentation of safety procedures. Organizations must maintain comprehensive records of all HF-related activities, including usage volumes, exposure monitoring data, incident reports, and training certifications. These records serve both compliance purposes and provide valuable data for continuous improvement of safety systems.

Engineering controls represent the primary defense against HF exposure. These include closed-loop systems that minimize direct contact, automated dispensing equipment, continuous monitoring systems for detecting HF vapor concentrations, and specialized ventilation infrastructure designed to rapidly remove airborne HF. The implementation of double-containment systems for all HF storage and transfer operations has become an industry standard practice to prevent environmental contamination.

Personal protective equipment (PPE) requirements for HF operations exceed standard laboratory protocols. Workers must utilize impermeable suits made of HF-resistant materials such as neoprene or butyl rubber, full-face respirators with appropriate cartridges, double-layered glove systems, and face shields. Proximity to emergency decontamination stations, including calcium gluconate gel supplies and emergency showers, must be maintained at all operational sites.

Risk assessment methodologies specific to HF applications have evolved significantly, incorporating both quantitative and qualitative approaches. Process Hazard Analysis (PHA) and Failure Mode and Effects Analysis (FMEA) are commonly employed to identify potential failure points in HF handling systems. These assessments must be conducted prior to implementation and reviewed periodically to address emerging risks or system modifications.

Emergency response planning for HF incidents requires specialized protocols distinct from general chemical spill procedures. This includes dedicated response teams with advanced training, specialized neutralization agents, medical coordination with healthcare facilities familiar with HF exposure treatment, and evacuation procedures that account for HF's unique dispersion characteristics. Mock drills simulating various HF incident scenarios should be conducted quarterly to maintain response readiness.

Regulatory compliance frameworks for HF operations vary globally but generally include strict reporting requirements, regular inspections, and detailed documentation of safety procedures. Organizations must maintain comprehensive records of all HF-related activities, including usage volumes, exposure monitoring data, incident reports, and training certifications. These records serve both compliance purposes and provide valuable data for continuous improvement of safety systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!