In-Field Calibration Protocols For Long-Term Monitoring

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

In-Field Calibration Evolution and Objectives

In-field calibration has evolved significantly over the past decades, transitioning from manual, labor-intensive processes to sophisticated automated systems. Initially, calibration required removing sensors from their operational environment and transporting them to laboratory settings, resulting in significant downtime and potential data gaps. This approach proved particularly problematic for long-term environmental monitoring applications where continuous data collection is essential for trend analysis and early warning systems.

The evolution of in-field calibration technologies began in earnest during the 1990s with the development of portable calibration equipment that allowed technicians to perform basic calibration procedures on-site. By the early 2000s, remote calibration capabilities emerged, enabling partial automation of the calibration process through telemetry systems, though still requiring human intervention for many steps.

A paradigm shift occurred in the 2010s with the integration of smart sensor technologies featuring self-diagnostic capabilities and built-in calibration verification algorithms. These advancements laid the groundwork for today's sophisticated in-field calibration protocols that combine hardware innovations with advanced software solutions to maintain measurement accuracy over extended deployment periods.

The primary objective of modern in-field calibration protocols is to ensure measurement accuracy and reliability without disrupting the continuous monitoring process. This involves developing methodologies that can detect and correct sensor drift, compensate for environmental interferences, and validate measurement integrity in real-time or near-real-time conditions.

Secondary objectives include minimizing human intervention requirements, reducing operational costs associated with maintenance visits, and extending the functional lifespan of monitoring equipment. These goals are particularly relevant for remote or hazardous monitoring locations where physical access is limited or expensive.

Technical objectives focus on developing calibration algorithms that can distinguish between actual environmental changes and sensor drift, implementing robust validation procedures that can operate under varying field conditions, and creating standardized protocols that ensure consistency across different monitoring networks and sensor types.

The future trajectory of in-field calibration development aims toward fully autonomous calibration systems incorporating artificial intelligence for predictive maintenance, blockchain technologies for calibration verification and traceability, and integration with digital twin models to simulate and optimize sensor performance under various environmental conditions.

The evolution of in-field calibration technologies began in earnest during the 1990s with the development of portable calibration equipment that allowed technicians to perform basic calibration procedures on-site. By the early 2000s, remote calibration capabilities emerged, enabling partial automation of the calibration process through telemetry systems, though still requiring human intervention for many steps.

A paradigm shift occurred in the 2010s with the integration of smart sensor technologies featuring self-diagnostic capabilities and built-in calibration verification algorithms. These advancements laid the groundwork for today's sophisticated in-field calibration protocols that combine hardware innovations with advanced software solutions to maintain measurement accuracy over extended deployment periods.

The primary objective of modern in-field calibration protocols is to ensure measurement accuracy and reliability without disrupting the continuous monitoring process. This involves developing methodologies that can detect and correct sensor drift, compensate for environmental interferences, and validate measurement integrity in real-time or near-real-time conditions.

Secondary objectives include minimizing human intervention requirements, reducing operational costs associated with maintenance visits, and extending the functional lifespan of monitoring equipment. These goals are particularly relevant for remote or hazardous monitoring locations where physical access is limited or expensive.

Technical objectives focus on developing calibration algorithms that can distinguish between actual environmental changes and sensor drift, implementing robust validation procedures that can operate under varying field conditions, and creating standardized protocols that ensure consistency across different monitoring networks and sensor types.

The future trajectory of in-field calibration development aims toward fully autonomous calibration systems incorporating artificial intelligence for predictive maintenance, blockchain technologies for calibration verification and traceability, and integration with digital twin models to simulate and optimize sensor performance under various environmental conditions.

Market Demand for Long-Term Monitoring Solutions

The long-term monitoring solutions market has experienced substantial growth over the past decade, driven by increasing demands across multiple sectors including environmental management, industrial operations, infrastructure maintenance, and healthcare. This market is projected to reach $29.3 billion by 2027, with a compound annual growth rate of 8.7% from 2022 to 2027, according to recent industry analyses.

Environmental monitoring represents one of the largest segments, with governmental regulations worldwide mandating continuous monitoring of air quality, water resources, and soil conditions. The EPA and similar international bodies have strengthened requirements for continuous environmental data collection, creating sustained demand for reliable monitoring systems with accurate calibration protocols.

Industrial sectors, particularly manufacturing, oil and gas, and chemical processing, constitute another significant market segment. These industries require continuous monitoring of equipment performance, process parameters, and safety conditions. The financial implications of equipment failure or process deviations have made preventive monitoring systems essential, with calibration accuracy directly impacting operational efficiency and safety compliance.

Infrastructure monitoring has emerged as a rapidly growing segment, particularly for aging bridges, dams, tunnels, and buildings. The American Society of Civil Engineers estimates that the United States alone needs to invest $4.5 trillion by 2025 to upgrade its infrastructure, with monitoring systems being a critical component of these investments. Similar trends are observed globally, especially in developed economies with aging infrastructure.

Healthcare applications represent another expanding market, with remote patient monitoring systems requiring precise calibration to ensure accurate health data collection over extended periods. The COVID-19 pandemic accelerated this trend, with remote monitoring becoming essential for managing patients outside traditional healthcare settings.

A key market driver across all segments is the increasing demand for autonomous monitoring systems that can operate reliably in remote or harsh environments with minimal human intervention. This has intensified the need for sophisticated in-field calibration protocols that can maintain measurement accuracy over extended deployment periods.

End-users consistently identify several critical requirements: extended calibration intervals to reduce maintenance costs, automated calibration capabilities to minimize human error, remote calibration management to reduce field visits, and comprehensive calibration documentation for regulatory compliance. Market research indicates that solutions addressing these needs command premium pricing, with customers willing to pay 15-20% more for systems with advanced calibration capabilities.

Environmental monitoring represents one of the largest segments, with governmental regulations worldwide mandating continuous monitoring of air quality, water resources, and soil conditions. The EPA and similar international bodies have strengthened requirements for continuous environmental data collection, creating sustained demand for reliable monitoring systems with accurate calibration protocols.

Industrial sectors, particularly manufacturing, oil and gas, and chemical processing, constitute another significant market segment. These industries require continuous monitoring of equipment performance, process parameters, and safety conditions. The financial implications of equipment failure or process deviations have made preventive monitoring systems essential, with calibration accuracy directly impacting operational efficiency and safety compliance.

Infrastructure monitoring has emerged as a rapidly growing segment, particularly for aging bridges, dams, tunnels, and buildings. The American Society of Civil Engineers estimates that the United States alone needs to invest $4.5 trillion by 2025 to upgrade its infrastructure, with monitoring systems being a critical component of these investments. Similar trends are observed globally, especially in developed economies with aging infrastructure.

Healthcare applications represent another expanding market, with remote patient monitoring systems requiring precise calibration to ensure accurate health data collection over extended periods. The COVID-19 pandemic accelerated this trend, with remote monitoring becoming essential for managing patients outside traditional healthcare settings.

A key market driver across all segments is the increasing demand for autonomous monitoring systems that can operate reliably in remote or harsh environments with minimal human intervention. This has intensified the need for sophisticated in-field calibration protocols that can maintain measurement accuracy over extended deployment periods.

End-users consistently identify several critical requirements: extended calibration intervals to reduce maintenance costs, automated calibration capabilities to minimize human error, remote calibration management to reduce field visits, and comprehensive calibration documentation for regulatory compliance. Market research indicates that solutions addressing these needs command premium pricing, with customers willing to pay 15-20% more for systems with advanced calibration capabilities.

Current Calibration Challenges and Limitations

In-field calibration for long-term monitoring systems faces significant challenges that limit effectiveness and reliability. Traditional calibration methods often require removing sensors from their operational environment, creating discontinuities in data collection and potentially introducing errors during reinstallation. This approach becomes particularly problematic for remote or difficult-to-access deployment locations such as deep-sea environments, high-altitude installations, or hazardous industrial settings.

Environmental variability presents another major challenge, as field conditions rarely match controlled laboratory settings where initial calibrations occur. Temperature fluctuations, humidity changes, pressure variations, and exposure to contaminants can all affect sensor performance in unpredictable ways. These dynamic environmental factors necessitate calibration protocols that can account for real-world conditions rather than idealized laboratory parameters.

Sensor drift remains one of the most persistent technical limitations, occurring gradually over time as components age or react to environmental stressors. Without regular recalibration, this drift introduces systematic errors that compound over extended monitoring periods, potentially invalidating long-term trend analyses. The rate of drift varies significantly between sensor types and even between individual units of the same model, making standardized calibration intervals problematic.

Resource constraints further complicate calibration efforts, particularly for large-scale sensor networks. The time, expertise, and equipment required for comprehensive calibration often exceed available resources, leading to compromises in calibration frequency or thoroughness. For battery-powered or energy-harvesting systems, the energy budget for calibration routines must be carefully balanced against operational requirements.

Reference standard availability poses another significant limitation. In-field calibration requires reliable reference measurements against which sensor outputs can be compared. However, maintaining reference standards in field conditions presents its own challenges, creating a circular problem where the reference itself may require validation. This is especially problematic for parameters that lack stable, portable reference standards.

Data continuity requirements often conflict with calibration needs, as many monitoring applications cannot tolerate interruptions in data collection. This creates a fundamental tension between maintaining continuous operation and ensuring measurement accuracy through regular calibration. Techniques that allow for calibration without disrupting data collection are technically challenging to implement.

Interoperability issues arise when attempting to standardize calibration across heterogeneous sensor networks that incorporate devices from multiple manufacturers with different specifications, communication protocols, and calibration requirements. The lack of universal calibration standards across the industry further complicates efforts to develop consistent, widely applicable in-field calibration methodologies.

Environmental variability presents another major challenge, as field conditions rarely match controlled laboratory settings where initial calibrations occur. Temperature fluctuations, humidity changes, pressure variations, and exposure to contaminants can all affect sensor performance in unpredictable ways. These dynamic environmental factors necessitate calibration protocols that can account for real-world conditions rather than idealized laboratory parameters.

Sensor drift remains one of the most persistent technical limitations, occurring gradually over time as components age or react to environmental stressors. Without regular recalibration, this drift introduces systematic errors that compound over extended monitoring periods, potentially invalidating long-term trend analyses. The rate of drift varies significantly between sensor types and even between individual units of the same model, making standardized calibration intervals problematic.

Resource constraints further complicate calibration efforts, particularly for large-scale sensor networks. The time, expertise, and equipment required for comprehensive calibration often exceed available resources, leading to compromises in calibration frequency or thoroughness. For battery-powered or energy-harvesting systems, the energy budget for calibration routines must be carefully balanced against operational requirements.

Reference standard availability poses another significant limitation. In-field calibration requires reliable reference measurements against which sensor outputs can be compared. However, maintaining reference standards in field conditions presents its own challenges, creating a circular problem where the reference itself may require validation. This is especially problematic for parameters that lack stable, portable reference standards.

Data continuity requirements often conflict with calibration needs, as many monitoring applications cannot tolerate interruptions in data collection. This creates a fundamental tension between maintaining continuous operation and ensuring measurement accuracy through regular calibration. Techniques that allow for calibration without disrupting data collection are technically challenging to implement.

Interoperability issues arise when attempting to standardize calibration across heterogeneous sensor networks that incorporate devices from multiple manufacturers with different specifications, communication protocols, and calibration requirements. The lack of universal calibration standards across the industry further complicates efforts to develop consistent, widely applicable in-field calibration methodologies.

Existing In-Field Calibration Methodologies

01 Field-based sensor calibration methods

Various methods for calibrating sensors directly in the field without removing them from their operational environment. These approaches include automated calibration procedures that can be performed on-site, reducing downtime and maintaining measurement accuracy. The techniques often involve reference standards or comparison with known values to adjust sensor parameters for optimal performance in actual operating conditions.- Field-based sensor calibration methods: Various methods for calibrating sensors directly in the field without removing them from their operational environment. These approaches include automated calibration procedures that can be performed on-site, reducing downtime and maintaining measurement accuracy. The techniques often involve reference measurements, comparison with known standards, and algorithmic adjustments to ensure sensors maintain accuracy under actual operating conditions.

- Wireless and remote calibration systems: Systems that enable calibration of field instruments through wireless connections or remote access, eliminating the need for physical presence at the sensor location. These solutions incorporate communication protocols that allow technicians to perform calibration procedures from a distance, receive real-time feedback, and make necessary adjustments. The technology supports automated calibration sequences and can be integrated with central monitoring systems.

- Self-calibration technologies for field instruments: Advanced instruments with built-in self-calibration capabilities that can automatically detect drift and make necessary adjustments. These technologies incorporate internal reference standards or comparative measurement techniques to verify and correct calibration without external equipment. Self-calibration may be triggered by time intervals, environmental changes, or detected measurement anomalies, ensuring continuous accuracy in field operations.

- Environmental compensation in calibration protocols: Calibration methods that account for environmental factors such as temperature, humidity, and pressure that can affect sensor readings in field conditions. These protocols incorporate compensation algorithms and adjustment factors to maintain accuracy across varying environmental conditions. The approaches may include multi-point calibration under different environmental conditions or real-time adjustment based on environmental sensor inputs.

- Mobile calibration equipment and standards: Portable calibration equipment and reference standards designed specifically for in-field use, allowing technicians to perform accurate calibrations at the installation site. These solutions include compact, ruggedized calibration devices with high precision capabilities, transportable reference standards, and field-friendly interfaces. The equipment is designed to withstand environmental challenges while maintaining the precision required for proper calibration procedures.

02 Wireless and remote calibration systems

Systems that enable calibration of field equipment through wireless connections or remote access, eliminating the need for physical presence at the sensor location. These solutions incorporate communication protocols that allow technicians to perform calibration procedures from a distance, receive real-time feedback, and make necessary adjustments. The technology supports efficient maintenance of distributed sensor networks across large geographical areas.Expand Specific Solutions03 Automated calibration verification techniques

Advanced techniques for automatically verifying calibration status of instruments in the field. These methods incorporate self-diagnostic capabilities that continuously monitor sensor performance against expected parameters. When deviations are detected, the system can either automatically recalibrate or alert operators to the need for intervention, ensuring measurement integrity without manual inspection.Expand Specific Solutions04 Environmental compensation in calibration protocols

Calibration methods that account for environmental factors affecting sensor performance in field conditions. These protocols incorporate compensation algorithms that adjust for temperature, humidity, pressure, and other environmental variables that can influence measurement accuracy. By dynamically adapting calibration parameters based on ambient conditions, these systems maintain measurement precision across varying operational environments.Expand Specific Solutions05 Imaging and vision-based calibration systems

Calibration systems that utilize imaging technologies and computer vision to perform precise alignment and calibration of field equipment. These approaches use optical references, pattern recognition, and image processing algorithms to detect misalignments or calibration drift. The technology enables non-contact calibration of sensors and instruments, particularly beneficial for equipment in hazardous or difficult-to-access locations.Expand Specific Solutions

Leading Organizations in Calibration Technology

The in-field calibration protocols for long-term monitoring market is currently in a growth phase, with increasing demand driven by industrial automation and environmental compliance requirements. The market size is estimated to be expanding at 5-8% annually, reaching approximately $3.5 billion globally. From a technological maturity perspective, the field shows varying levels of development across sectors. Energy industry leaders like Halliburton Energy Services and Baker Hughes have established sophisticated calibration systems for oil and gas monitoring, while companies such as Endress+Hauser and Thales SA are advancing sensor calibration technologies for industrial applications. State Grid Corp. of China and Boeing are developing protocols for infrastructure and aerospace monitoring respectively, while tech giants like Microsoft and Qualcomm are integrating calibration capabilities into IoT and wireless monitoring solutions.

Thales SA

Technical Solution: Thales has pioneered remote calibration systems for long-term monitoring applications in defense and aerospace sectors. Their approach combines hardware redundancy with sophisticated software algorithms for continuous self-calibration. The company's SMART (Self-Monitoring Analysis and Reporting Technology) platform implements multiple reference points within sensor networks to enable cross-validation and automatic adjustment. For critical infrastructure monitoring, Thales employs a distributed architecture where sensors periodically calibrate against local reference standards, with results transmitted to a central system for analysis and adjustment commands. Their calibration protocols incorporate machine learning algorithms that can identify drift patterns and predict maintenance needs before measurement accuracy is compromised. The system supports both scheduled and event-triggered calibration procedures, with the latter activated when environmental conditions change significantly or when diagnostic tests indicate potential measurement drift[2]. For remote installations, Thales has developed energy-efficient calibration routines that minimize power consumption while maintaining measurement integrity.

Strengths: Military-grade reliability suitable for mission-critical applications; advanced predictive maintenance capabilities; highly secure data transmission protocols for sensitive monitoring applications. Weaknesses: Higher implementation costs compared to commercial alternatives; complex deployment requiring specialized expertise; calibration protocols may be overengineered for simpler industrial applications.

Ford Global Technologies LLC

Technical Solution: Ford has developed sophisticated in-field calibration protocols specifically designed for vehicle emissions monitoring systems and powertrain sensors that must maintain accuracy over the vehicle's lifetime. Their approach combines onboard diagnostics with periodic recalibration procedures that can be performed during routine maintenance. Ford's Intelligent Calibration System (ICS) utilizes reference sensors strategically placed throughout the vehicle to provide baseline measurements for continuous comparison. The system implements adaptive calibration algorithms that account for sensor aging and environmental factors, automatically adjusting parameters to maintain measurement accuracy. For long-term monitoring of battery systems in electric vehicles, Ford has pioneered a multi-point verification protocol that correlates data from temperature, voltage, and current sensors to detect drift in any individual component[3]. Their calibration management system maintains a comprehensive history of each sensor's performance, enabling predictive maintenance based on degradation trends rather than fixed schedules. Ford's approach also includes remote calibration capabilities that allow certain sensor adjustments to be performed via over-the-air updates, reducing service visits while ensuring monitoring systems remain accurate throughout the vehicle lifecycle.

Strengths: Seamless integration with vehicle maintenance schedules; sophisticated drift compensation algorithms specifically tuned for automotive applications; capability for over-the-air calibration updates. Weaknesses: Primarily optimized for automotive applications; requires dealer network infrastructure for some calibration procedures; limited transferability to non-automotive monitoring contexts.

Key Technical Innovations in Calibration Protocols

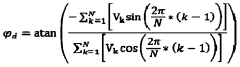

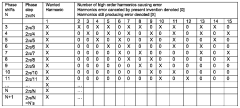

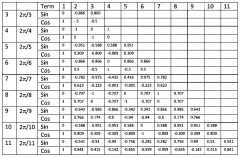

Method and system for multi-phase dynamic calibration of three-dimensional (3D) sensors in a time-of-flight system

PatentWO2012009170A1

Innovation

- Implementing a multi-phase dynamic calibration method using an odd number of phase shifts (e.g., 3, 5, 7) to reduce bias errors from high-order harmonics, while maintaining high modulation contrast, and optionally using look-up tables for finer corrections, thereby reducing storage requirements and enhancing calibration accuracy over time and temperature.

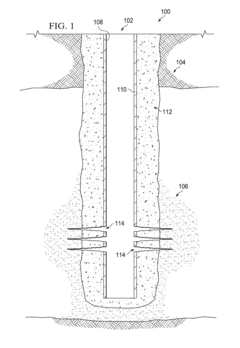

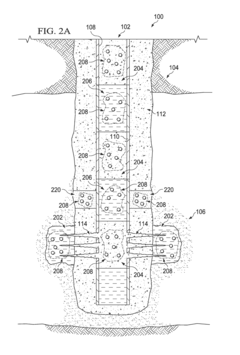

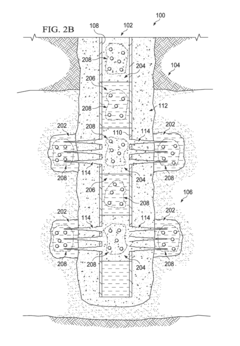

Methods and systems for long-term monitoring of a well system during abandonment

PatentInactiveUS20130299165A1

Innovation

- The implementation of a system that forms multiple barriers within the well formation and casing, including formation, casing, and annulus barriers, equipped with sensors to monitor conditions over time, powered by long-lasting or renewable energy sources, allowing for wireless or wired communication with monitoring systems to ensure the integrity of the well's sealing and detect any leaks.

Environmental Factors Affecting Calibration Stability

Environmental monitoring systems deployed in the field are subject to a wide range of environmental conditions that can significantly impact calibration stability over time. Temperature fluctuations represent one of the most critical factors affecting sensor performance, with most electronic sensors exhibiting temperature-dependent drift characteristics. Research indicates that for every 10°C change in ambient temperature, certain electrochemical sensors may experience up to 5% deviation in measurement accuracy. This temperature dependency necessitates compensation algorithms or regular recalibration protocols adjusted to seasonal variations.

Humidity and moisture exposure constitute another major challenge for long-term monitoring systems. High humidity environments can lead to condensation on sensing elements, creating short circuits or accelerating corrosion processes. Studies conducted across various climate zones demonstrate that relative humidity exceeding 85% for extended periods can reduce calibration stability by up to 40% in non-hermetically sealed instruments. Particularly vulnerable are optical sensors, where moisture can gradually alter optical properties of detection surfaces.

Atmospheric pressure variations, while often overlooked, significantly impact gas concentration measurements in particular. Barometric pressure changes affect gas solubility in liquids and can alter diffusion rates across semi-permeable membranes commonly used in gas sensors. Field data from mountainous regions shows calibration shifts of up to 2% per 10 hPa pressure change in non-compensated systems.

Solar radiation exposure presents dual challenges through both direct heating effects and photochemical degradation of sensor components. UV radiation can degrade polymer-based components, altering their physical and chemical properties over time. Long-term field studies indicate that sensors with direct sun exposure may require recalibration frequencies up to three times higher than identical shielded units.

Chemical contamination from airborne pollutants represents a particularly insidious threat to calibration stability. Industrial areas with high concentrations of volatile organic compounds, sulfur compounds, or particulate matter show accelerated sensor drift patterns. Cross-sensitivity issues emerge when target analytes must be detected in complex matrices containing interfering compounds. Research demonstrates that even low-level chemical contamination can gradually modify reference electrode potentials in electrochemical sensors.

Mechanical stress factors including vibration and physical impacts also contribute to calibration instability. Continuous vibration can gradually alter the physical configuration of precision components, while sudden impacts may cause immediate calibration shifts. Transportation-related vibrations during maintenance visits themselves can inadvertently affect calibration status, necessitating post-transport verification procedures.

Humidity and moisture exposure constitute another major challenge for long-term monitoring systems. High humidity environments can lead to condensation on sensing elements, creating short circuits or accelerating corrosion processes. Studies conducted across various climate zones demonstrate that relative humidity exceeding 85% for extended periods can reduce calibration stability by up to 40% in non-hermetically sealed instruments. Particularly vulnerable are optical sensors, where moisture can gradually alter optical properties of detection surfaces.

Atmospheric pressure variations, while often overlooked, significantly impact gas concentration measurements in particular. Barometric pressure changes affect gas solubility in liquids and can alter diffusion rates across semi-permeable membranes commonly used in gas sensors. Field data from mountainous regions shows calibration shifts of up to 2% per 10 hPa pressure change in non-compensated systems.

Solar radiation exposure presents dual challenges through both direct heating effects and photochemical degradation of sensor components. UV radiation can degrade polymer-based components, altering their physical and chemical properties over time. Long-term field studies indicate that sensors with direct sun exposure may require recalibration frequencies up to three times higher than identical shielded units.

Chemical contamination from airborne pollutants represents a particularly insidious threat to calibration stability. Industrial areas with high concentrations of volatile organic compounds, sulfur compounds, or particulate matter show accelerated sensor drift patterns. Cross-sensitivity issues emerge when target analytes must be detected in complex matrices containing interfering compounds. Research demonstrates that even low-level chemical contamination can gradually modify reference electrode potentials in electrochemical sensors.

Mechanical stress factors including vibration and physical impacts also contribute to calibration instability. Continuous vibration can gradually alter the physical configuration of precision components, while sudden impacts may cause immediate calibration shifts. Transportation-related vibrations during maintenance visits themselves can inadvertently affect calibration status, necessitating post-transport verification procedures.

Data Integrity and Validation Frameworks

Data integrity and validation frameworks are essential components of in-field calibration protocols for long-term monitoring systems. These frameworks establish systematic approaches to ensure the reliability, accuracy, and trustworthiness of collected data throughout the entire monitoring lifecycle. The implementation of robust validation mechanisms helps identify anomalies, errors, and drift patterns that might compromise data quality during extended deployment periods.

Effective data integrity frameworks typically incorporate multi-layered validation processes, beginning with automated real-time checks that flag outliers and inconsistencies immediately upon data collection. These systems employ statistical methods such as z-score analysis, moving averages, and regression models to establish acceptable data boundaries and identify potential calibration issues before they significantly impact monitoring results.

Cross-validation techniques represent another critical element within these frameworks, whereby measurements from multiple sensors or alternative measurement methodologies are compared to verify consistency. This redundancy approach provides an additional layer of confidence in data quality and helps isolate specific sensors requiring recalibration. For environmental monitoring applications, cross-referencing with nearby monitoring stations or satellite data has proven particularly valuable in maintaining data integrity across geographically distributed networks.

Metadata management constitutes a fundamental aspect of validation frameworks, documenting calibration events, environmental conditions, and system modifications throughout the monitoring period. This contextual information enables more sophisticated validation algorithms that can account for expected variations due to environmental factors versus those indicating actual calibration drift. Advanced frameworks incorporate machine learning techniques that continuously improve validation parameters based on historical patterns and calibration outcomes.

Traceability chains form the backbone of rigorous validation frameworks, establishing unbroken links between field measurements and recognized measurement standards. These chains document all intermediate comparisons and calibration transfers, allowing uncertainty quantification at each step. For long-term monitoring, maintaining these traceability relationships becomes increasingly challenging but remains essential for ensuring data comparability across extended timeframes.

Digital authentication mechanisms have emerged as critical safeguards against data tampering or corruption, employing cryptographic techniques to verify data provenance and integrity. These systems create tamper-evident records of calibration events and measurement data, particularly valuable in regulatory environments where data defensibility is paramount. Blockchain-based solutions are increasingly being explored to provide immutable calibration histories that enhance confidence in long-term monitoring data.

Effective data integrity frameworks typically incorporate multi-layered validation processes, beginning with automated real-time checks that flag outliers and inconsistencies immediately upon data collection. These systems employ statistical methods such as z-score analysis, moving averages, and regression models to establish acceptable data boundaries and identify potential calibration issues before they significantly impact monitoring results.

Cross-validation techniques represent another critical element within these frameworks, whereby measurements from multiple sensors or alternative measurement methodologies are compared to verify consistency. This redundancy approach provides an additional layer of confidence in data quality and helps isolate specific sensors requiring recalibration. For environmental monitoring applications, cross-referencing with nearby monitoring stations or satellite data has proven particularly valuable in maintaining data integrity across geographically distributed networks.

Metadata management constitutes a fundamental aspect of validation frameworks, documenting calibration events, environmental conditions, and system modifications throughout the monitoring period. This contextual information enables more sophisticated validation algorithms that can account for expected variations due to environmental factors versus those indicating actual calibration drift. Advanced frameworks incorporate machine learning techniques that continuously improve validation parameters based on historical patterns and calibration outcomes.

Traceability chains form the backbone of rigorous validation frameworks, establishing unbroken links between field measurements and recognized measurement standards. These chains document all intermediate comparisons and calibration transfers, allowing uncertainty quantification at each step. For long-term monitoring, maintaining these traceability relationships becomes increasingly challenging but remains essential for ensuring data comparability across extended timeframes.

Digital authentication mechanisms have emerged as critical safeguards against data tampering or corruption, employing cryptographic techniques to verify data provenance and integrity. These systems create tamper-evident records of calibration events and measurement data, particularly valuable in regulatory environments where data defensibility is paramount. Blockchain-based solutions are increasingly being explored to provide immutable calibration histories that enhance confidence in long-term monitoring data.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!