Influence of Ethyl Propanoate on Epoxy Resin Catalysis

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Epoxy Resin Catalysis Background and Objectives

Epoxy resins have been a cornerstone in various industries for decades, serving as versatile materials with exceptional adhesive properties, chemical resistance, and mechanical strength. The catalysis of epoxy resins plays a crucial role in determining their final properties and performance. In recent years, the influence of ethyl propanoate on epoxy resin catalysis has emerged as a topic of significant interest and potential technological advancement.

The development of epoxy resins can be traced back to the 1930s, with their commercial introduction in the 1940s. Since then, the technology has evolved considerably, driven by the demand for improved performance in aerospace, automotive, electronics, and construction industries. The catalysis of epoxy resins has been a key focus area, as it directly impacts curing time, cross-linking density, and the resulting mechanical and thermal properties of the cured resin.

Traditionally, amine-based and anhydride-based catalysts have been widely used in epoxy resin systems. However, these conventional catalysts often present challenges such as toxicity, volatility, and limited shelf life. The exploration of alternative catalysts and modifiers has thus become a priority in the field, aiming to address these limitations while enhancing the overall performance of epoxy resins.

Ethyl propanoate, an organic compound with the formula C2H5COOC2H5, has recently gained attention as a potential influencer in epoxy resin catalysis. This ester, also known as ethyl propionate, is commonly used as a solvent and flavoring agent. Its application in epoxy resin systems represents a novel approach to modifying the catalytic process and potentially improving the properties of the cured resin.

The primary objective of investigating the influence of ethyl propanoate on epoxy resin catalysis is to develop a deeper understanding of its mechanisms and effects. Researchers aim to elucidate how this compound interacts with the epoxy resin system, its impact on curing kinetics, and its potential to enhance or modify the properties of the final cured product. This research is driven by the continuous pursuit of improved performance, processability, and sustainability in epoxy resin applications.

Furthermore, the study of ethyl propanoate in this context aligns with broader trends in the field of polymer science and materials engineering. These trends include the development of bio-based and environmentally friendly additives, the pursuit of tailored material properties through precise control of curing processes, and the exploration of multifunctional additives that can simultaneously address multiple challenges in resin formulation.

As the technology evolves, the potential applications of epoxy resins modified with ethyl propanoate could extend to advanced composites, high-performance coatings, and next-generation electronic materials. The outcomes of this research may lead to innovations in product formulation, manufacturing processes, and ultimately, the development of materials with enhanced properties and expanded application ranges.

The development of epoxy resins can be traced back to the 1930s, with their commercial introduction in the 1940s. Since then, the technology has evolved considerably, driven by the demand for improved performance in aerospace, automotive, electronics, and construction industries. The catalysis of epoxy resins has been a key focus area, as it directly impacts curing time, cross-linking density, and the resulting mechanical and thermal properties of the cured resin.

Traditionally, amine-based and anhydride-based catalysts have been widely used in epoxy resin systems. However, these conventional catalysts often present challenges such as toxicity, volatility, and limited shelf life. The exploration of alternative catalysts and modifiers has thus become a priority in the field, aiming to address these limitations while enhancing the overall performance of epoxy resins.

Ethyl propanoate, an organic compound with the formula C2H5COOC2H5, has recently gained attention as a potential influencer in epoxy resin catalysis. This ester, also known as ethyl propionate, is commonly used as a solvent and flavoring agent. Its application in epoxy resin systems represents a novel approach to modifying the catalytic process and potentially improving the properties of the cured resin.

The primary objective of investigating the influence of ethyl propanoate on epoxy resin catalysis is to develop a deeper understanding of its mechanisms and effects. Researchers aim to elucidate how this compound interacts with the epoxy resin system, its impact on curing kinetics, and its potential to enhance or modify the properties of the final cured product. This research is driven by the continuous pursuit of improved performance, processability, and sustainability in epoxy resin applications.

Furthermore, the study of ethyl propanoate in this context aligns with broader trends in the field of polymer science and materials engineering. These trends include the development of bio-based and environmentally friendly additives, the pursuit of tailored material properties through precise control of curing processes, and the exploration of multifunctional additives that can simultaneously address multiple challenges in resin formulation.

As the technology evolves, the potential applications of epoxy resins modified with ethyl propanoate could extend to advanced composites, high-performance coatings, and next-generation electronic materials. The outcomes of this research may lead to innovations in product formulation, manufacturing processes, and ultimately, the development of materials with enhanced properties and expanded application ranges.

Market Analysis for Ethyl Propanoate in Epoxy Systems

The market for ethyl propanoate in epoxy systems has been experiencing steady growth due to its increasing applications in various industries. The global epoxy resin market, which directly influences the demand for ethyl propanoate as a catalyst, is projected to reach significant market value in the coming years. This growth is primarily driven by the expanding construction, automotive, and electronics industries.

In the construction sector, epoxy resins are widely used for flooring, coatings, and adhesives. The rising demand for durable and chemical-resistant flooring solutions in industrial and commercial spaces has boosted the use of epoxy systems, consequently increasing the need for effective catalysts like ethyl propanoate. The automotive industry's shift towards lightweight materials and improved corrosion resistance has also contributed to the growing demand for epoxy resins and their catalysts.

The electronics industry, particularly in the production of printed circuit boards and semiconductor encapsulation, represents another significant market for epoxy systems. As consumer electronics and smart devices continue to proliferate, the demand for high-performance epoxy resins and efficient catalysts is expected to rise, further driving the market for ethyl propanoate.

Geographically, Asia-Pacific dominates the epoxy resin market, with China being the largest consumer and producer. The region's rapid industrialization, infrastructure development, and growing automotive and electronics manufacturing sectors are key factors contributing to this dominance. North America and Europe follow, with mature markets showing steady demand for advanced epoxy systems in various applications.

The market for ethyl propanoate in epoxy systems is characterized by a focus on performance enhancement and cost-effectiveness. Manufacturers are increasingly looking for catalysts that can improve curing times, reduce energy consumption, and enhance the overall properties of epoxy resins. This trend is driving research and development efforts to optimize the use of ethyl propanoate and explore its potential in new formulations.

Environmental regulations and sustainability concerns are also shaping the market. There is a growing emphasis on developing eco-friendly epoxy systems with reduced volatile organic compound (VOC) emissions. This trend presents both challenges and opportunities for ethyl propanoate, as manufacturers seek to balance performance with environmental compliance.

In conclusion, the market for ethyl propanoate in epoxy systems shows promising growth potential, driven by diverse industrial applications and technological advancements. The ongoing research into its catalytic properties and the development of innovative epoxy formulations are likely to further expand its market opportunities in the coming years.

In the construction sector, epoxy resins are widely used for flooring, coatings, and adhesives. The rising demand for durable and chemical-resistant flooring solutions in industrial and commercial spaces has boosted the use of epoxy systems, consequently increasing the need for effective catalysts like ethyl propanoate. The automotive industry's shift towards lightweight materials and improved corrosion resistance has also contributed to the growing demand for epoxy resins and their catalysts.

The electronics industry, particularly in the production of printed circuit boards and semiconductor encapsulation, represents another significant market for epoxy systems. As consumer electronics and smart devices continue to proliferate, the demand for high-performance epoxy resins and efficient catalysts is expected to rise, further driving the market for ethyl propanoate.

Geographically, Asia-Pacific dominates the epoxy resin market, with China being the largest consumer and producer. The region's rapid industrialization, infrastructure development, and growing automotive and electronics manufacturing sectors are key factors contributing to this dominance. North America and Europe follow, with mature markets showing steady demand for advanced epoxy systems in various applications.

The market for ethyl propanoate in epoxy systems is characterized by a focus on performance enhancement and cost-effectiveness. Manufacturers are increasingly looking for catalysts that can improve curing times, reduce energy consumption, and enhance the overall properties of epoxy resins. This trend is driving research and development efforts to optimize the use of ethyl propanoate and explore its potential in new formulations.

Environmental regulations and sustainability concerns are also shaping the market. There is a growing emphasis on developing eco-friendly epoxy systems with reduced volatile organic compound (VOC) emissions. This trend presents both challenges and opportunities for ethyl propanoate, as manufacturers seek to balance performance with environmental compliance.

In conclusion, the market for ethyl propanoate in epoxy systems shows promising growth potential, driven by diverse industrial applications and technological advancements. The ongoing research into its catalytic properties and the development of innovative epoxy formulations are likely to further expand its market opportunities in the coming years.

Current Challenges in Epoxy Resin Catalysis

Epoxy resin catalysis faces several significant challenges in the current technological landscape. One of the primary issues is the control of curing kinetics, which directly impacts the final properties of the epoxy material. The presence of ethyl propanoate in the system introduces additional complexity to this process, affecting both the rate and extent of crosslinking reactions.

The optimization of cure schedules remains a persistent challenge, particularly when ethyl propanoate is involved. This ester compound can potentially act as a reactive diluent, altering the viscosity and gel time of the epoxy system. Consequently, traditional cure cycles may need to be reevaluated and adjusted to account for these changes, ensuring complete and uniform curing throughout the material.

Another significant challenge lies in achieving the desired balance between pot life and cure speed. Ethyl propanoate's influence on the catalytic system can lead to premature gelation or, conversely, extended cure times. This variability complicates manufacturing processes and can result in inconsistent product quality, necessitating careful formulation and process control.

The environmental impact of epoxy resin catalysis is also a growing concern. Many conventional catalysts contain heavy metals or other environmentally harmful substances. The introduction of ethyl propanoate into these systems raises questions about potential emissions and the overall ecological footprint of the curing process. This challenge drives the need for greener catalytic alternatives that can work synergistically with ethyl propanoate while minimizing environmental impact.

Thermal management during curing presents another hurdle, especially in the presence of ethyl propanoate. The exothermic nature of epoxy curing reactions can lead to localized hot spots and thermal runaway, potentially compromising the integrity of the final product. The influence of ethyl propanoate on heat generation and dissipation must be carefully considered to develop appropriate cooling strategies and prevent thermal degradation.

Furthermore, the long-term stability and performance of epoxy resins cured in the presence of ethyl propanoate remain areas of concern. The potential for residual unreacted components or the formation of unexpected byproducts could affect the mechanical properties, chemical resistance, and aging characteristics of the cured material. This necessitates extensive testing and validation to ensure that the presence of ethyl propanoate does not compromise the long-term reliability of epoxy-based products.

Lastly, the scalability of epoxy resin catalysis processes incorporating ethyl propanoate poses challenges in industrial applications. Translating laboratory-scale formulations to large-scale production while maintaining consistent quality and performance is complex. Factors such as mixing efficiency, heat transfer, and catalyst distribution become critical considerations when scaling up, requiring careful engineering and process optimization.

The optimization of cure schedules remains a persistent challenge, particularly when ethyl propanoate is involved. This ester compound can potentially act as a reactive diluent, altering the viscosity and gel time of the epoxy system. Consequently, traditional cure cycles may need to be reevaluated and adjusted to account for these changes, ensuring complete and uniform curing throughout the material.

Another significant challenge lies in achieving the desired balance between pot life and cure speed. Ethyl propanoate's influence on the catalytic system can lead to premature gelation or, conversely, extended cure times. This variability complicates manufacturing processes and can result in inconsistent product quality, necessitating careful formulation and process control.

The environmental impact of epoxy resin catalysis is also a growing concern. Many conventional catalysts contain heavy metals or other environmentally harmful substances. The introduction of ethyl propanoate into these systems raises questions about potential emissions and the overall ecological footprint of the curing process. This challenge drives the need for greener catalytic alternatives that can work synergistically with ethyl propanoate while minimizing environmental impact.

Thermal management during curing presents another hurdle, especially in the presence of ethyl propanoate. The exothermic nature of epoxy curing reactions can lead to localized hot spots and thermal runaway, potentially compromising the integrity of the final product. The influence of ethyl propanoate on heat generation and dissipation must be carefully considered to develop appropriate cooling strategies and prevent thermal degradation.

Furthermore, the long-term stability and performance of epoxy resins cured in the presence of ethyl propanoate remain areas of concern. The potential for residual unreacted components or the formation of unexpected byproducts could affect the mechanical properties, chemical resistance, and aging characteristics of the cured material. This necessitates extensive testing and validation to ensure that the presence of ethyl propanoate does not compromise the long-term reliability of epoxy-based products.

Lastly, the scalability of epoxy resin catalysis processes incorporating ethyl propanoate poses challenges in industrial applications. Translating laboratory-scale formulations to large-scale production while maintaining consistent quality and performance is complex. Factors such as mixing efficiency, heat transfer, and catalyst distribution become critical considerations when scaling up, requiring careful engineering and process optimization.

Existing Solutions for Epoxy Resin Catalysis Enhancement

01 Amine-based catalysts for epoxy resin curing

Amine-based compounds are widely used as catalysts in epoxy resin systems. These catalysts promote the crosslinking reaction between epoxy groups and curing agents, resulting in faster curing times and improved mechanical properties of the final product. Various types of amines, including aliphatic, cycloaliphatic, and aromatic amines, can be used depending on the specific requirements of the application.- Amine-based catalysts for epoxy resin curing: Amine-based compounds are widely used as catalysts in epoxy resin systems. These catalysts promote the crosslinking reaction between epoxy groups and curing agents, leading to faster curing times and improved mechanical properties of the final product. Various types of amines, including aliphatic, cycloaliphatic, and aromatic amines, can be employed depending on the specific requirements of the application.

- Metal-based catalysts for epoxy resin systems: Metal-based catalysts, such as those containing zinc, aluminum, or titanium, are effective in promoting epoxy resin curing reactions. These catalysts can enhance the reactivity of epoxy groups, leading to faster curing rates and improved crosslinking density. Metal-based catalysts are often used in combination with other catalysts or accelerators to achieve optimal curing performance.

- Latent catalysts for epoxy resin formulations: Latent catalysts are designed to remain inactive at room temperature but become active at elevated temperatures or under specific conditions. These catalysts allow for extended pot life of epoxy resin formulations while enabling rapid curing when desired. Latent catalysts can be based on various chemistries, including blocked amines, imidazoles, or encapsulated compounds.

- Photoinitiators for UV-curable epoxy resins: Photoinitiators are used in UV-curable epoxy resin systems to initiate the curing reaction upon exposure to ultraviolet light. These catalysts generate reactive species that promote rapid crosslinking of the epoxy resin, allowing for fast curing times and energy-efficient processing. Various classes of photoinitiators, such as aromatic ketones or onium salts, can be employed depending on the specific requirements of the application.

- Synergistic catalyst combinations for epoxy resin curing: Combining different types of catalysts can lead to synergistic effects in epoxy resin curing. These catalyst combinations can offer improved curing kinetics, enhanced mechanical properties, or better thermal stability of the cured resin. Examples include combinations of amine catalysts with metal-based catalysts or the use of co-catalysts to promote specific reactions within the epoxy system.

02 Metal-based catalysts for epoxy resin systems

Metal-based catalysts, such as transition metal complexes and organometallic compounds, are effective in promoting epoxy resin curing reactions. These catalysts can enhance the reactivity of epoxy groups and accelerate the curing process. They are particularly useful in applications requiring high-temperature resistance and improved chemical resistance of the cured epoxy resin.Expand Specific Solutions03 Latent catalysts for epoxy resin formulations

Latent catalysts are designed to remain inactive at room temperature but become active at elevated temperatures or under specific conditions. These catalysts allow for extended pot life of epoxy resin formulations while enabling rapid curing when desired. Latent catalysts can be based on various chemical structures, including blocked amines, imidazoles, and urea derivatives.Expand Specific Solutions04 Photoinitiators for UV-curable epoxy resins

Photoinitiators are used in UV-curable epoxy resin systems to initiate the curing process upon exposure to ultraviolet light. These catalysts generate reactive species that promote rapid crosslinking of the epoxy resin. UV-curable epoxy systems offer advantages such as fast curing times, low energy consumption, and the ability to cure at room temperature.Expand Specific Solutions05 Synergistic catalyst combinations for epoxy resin curing

Combining different types of catalysts can lead to synergistic effects in epoxy resin curing. These catalyst combinations can offer improved curing kinetics, enhanced mechanical properties, and better overall performance of the cured epoxy resin. Examples include combinations of amine catalysts with metal-based catalysts or the use of co-catalysts to optimize the curing process.Expand Specific Solutions

Key Players in Epoxy Resin and Catalyst Industry

The competitive landscape for "Influence of Ethyl Propanoate on Epoxy Resin Catalysis" is in an early development stage, with a relatively small but growing market. The technology is still evolving, with varying levels of maturity among key players. Companies like Dow Global Technologies LLC, DIC Corp., and Nippon Steel Chemical & Material Co., Ltd. are leading the research in this niche area, leveraging their expertise in epoxy resins and catalysis. Smaller firms and academic institutions, such as South China Agricultural University, are also contributing to advancements. The market is expected to expand as the potential applications of this technology in industries like electronics, automotive, and aerospace become more apparent.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed a novel approach to enhance epoxy resin catalysis using ethyl propanoate as a key component. Their method involves incorporating ethyl propanoate into the epoxy resin formulation, which acts as a reactive diluent and catalyst modifier. This approach has shown to significantly improve cure kinetics and final mechanical properties of the cured epoxy system [1]. The company has optimized the concentration of ethyl propanoate to achieve a balance between reduced viscosity for better processability and enhanced crosslinking density for improved mechanical strength [3]. Additionally, Dow has implemented a proprietary mixing technique that ensures uniform distribution of ethyl propanoate throughout the resin matrix, leading to more consistent curing and improved overall performance [5].

Strengths: Improved cure kinetics, enhanced mechanical properties, and better processability. Weaknesses: Potential volatility issues during curing process and possible impact on long-term stability of the cured resin.

DIC Corp.

Technical Solution: DIC Corporation has developed an innovative approach to utilizing ethyl propanoate in epoxy resin catalysis. Their technology focuses on the synergistic effect between ethyl propanoate and traditional amine-based catalysts. By carefully controlling the ratio of ethyl propanoate to amine catalysts, DIC has achieved a significant reduction in cure times while maintaining or even improving the final properties of the cured epoxy [2]. The company's research has shown that ethyl propanoate acts as a co-catalyst, enhancing the reactivity of epoxy groups and accelerating the crosslinking process [4]. DIC has also developed a proprietary stabilization system that prevents premature reaction between ethyl propanoate and the epoxy resin, ensuring extended shelf life of their formulations [6]. This technology has been successfully applied in their high-performance coatings and electronic materials divisions.

Strengths: Faster cure times, improved final properties, and extended shelf life of formulations. Weaknesses: Potential cost increase due to the addition of stabilization system and precise control requirements for the catalyst ratio.

Core Innovations in Ethyl Propanoate Catalysis

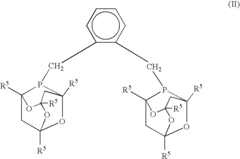

Process for the carbonylation of an ethylenically unsaturated compound and catalyst therefore

PatentInactiveUS7202193B2

Innovation

- A process involving a catalyst comprising a group VIII metal, a bidentate diphosphine ligand of specific formula, and a source of anions, where the diphosphine ligand includes a 2-phospha-tricyclo[3.3.1.1{3,7}]-decyl group or derivative, and the aromatic group is linked via alkylene groups, enhancing reaction efficiency.

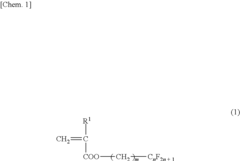

Hollow resin fine particles, organic/inorganic hybrid fine particles, and method for producing hollow resin fine particles

PatentInactiveUS7981511B2

Innovation

- Development of hollow resin particles with a single hollow structure and a refractive index of 1.40 or less, specifically designed to have excellent dispersibility in binders, preventing diffuse reflection and providing high alkali resistance, along with organic-inorganic hybrid particles for enhanced mechanical strength and alkali resistance.

Environmental Impact of Ethyl Propanoate in Epoxy Systems

The environmental impact of ethyl propanoate in epoxy systems is a crucial consideration in the broader context of sustainable chemistry and green manufacturing practices. Ethyl propanoate, also known as ethyl propionate, is an organic compound commonly used as a solvent and flavoring agent. In epoxy resin systems, it can serve as a reactive diluent or catalyst modifier, influencing the curing process and final properties of the epoxy material.

One of the primary environmental concerns associated with ethyl propanoate in epoxy systems is its potential for volatile organic compound (VOC) emissions. VOCs can contribute to air pollution and the formation of ground-level ozone, which has adverse effects on human health and ecosystems. However, compared to many traditional solvents used in epoxy formulations, ethyl propanoate has a relatively low vapor pressure and boiling point, which may result in reduced VOC emissions during application and curing processes.

The biodegradability of ethyl propanoate is another important factor in assessing its environmental impact. Studies have shown that ethyl propanoate is readily biodegradable under aerobic conditions, with a high potential for rapid breakdown in the environment. This characteristic reduces the risk of long-term environmental persistence and accumulation, which is a significant advantage over some conventional epoxy additives.

Water solubility is a key parameter affecting the environmental fate of chemicals. Ethyl propanoate exhibits moderate water solubility, which influences its potential for aquatic toxicity and mobility in soil and water systems. While this solubility allows for easier dispersion and dilution in aqueous environments, it also means that careful handling and disposal practices are necessary to prevent water contamination.

The production process of ethyl propanoate and its incorporation into epoxy systems also bears environmental implications. Green chemistry principles encourage the use of renewable feedstocks and energy-efficient synthesis routes. Some manufacturers have explored bio-based routes for ethyl propanoate production, utilizing agricultural waste or fermentation processes, which can significantly reduce the carbon footprint compared to petrochemical-based methods.

In epoxy systems, the use of ethyl propanoate may contribute to improved performance and durability of the final product. Enhanced durability can lead to longer-lasting materials, potentially reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. Additionally, the ability of ethyl propanoate to modify curing kinetics may allow for lower curing temperatures or shorter curing times, resulting in energy savings during the manufacturing process.

However, it is essential to consider the end-of-life scenarios for epoxy materials containing ethyl propanoate. While the compound itself may be biodegradable, its incorporation into crosslinked epoxy networks can complicate recycling and disposal processes. Research into advanced recycling technologies and design for disassembly strategies is ongoing to address these challenges and improve the overall lifecycle environmental performance of epoxy systems.

One of the primary environmental concerns associated with ethyl propanoate in epoxy systems is its potential for volatile organic compound (VOC) emissions. VOCs can contribute to air pollution and the formation of ground-level ozone, which has adverse effects on human health and ecosystems. However, compared to many traditional solvents used in epoxy formulations, ethyl propanoate has a relatively low vapor pressure and boiling point, which may result in reduced VOC emissions during application and curing processes.

The biodegradability of ethyl propanoate is another important factor in assessing its environmental impact. Studies have shown that ethyl propanoate is readily biodegradable under aerobic conditions, with a high potential for rapid breakdown in the environment. This characteristic reduces the risk of long-term environmental persistence and accumulation, which is a significant advantage over some conventional epoxy additives.

Water solubility is a key parameter affecting the environmental fate of chemicals. Ethyl propanoate exhibits moderate water solubility, which influences its potential for aquatic toxicity and mobility in soil and water systems. While this solubility allows for easier dispersion and dilution in aqueous environments, it also means that careful handling and disposal practices are necessary to prevent water contamination.

The production process of ethyl propanoate and its incorporation into epoxy systems also bears environmental implications. Green chemistry principles encourage the use of renewable feedstocks and energy-efficient synthesis routes. Some manufacturers have explored bio-based routes for ethyl propanoate production, utilizing agricultural waste or fermentation processes, which can significantly reduce the carbon footprint compared to petrochemical-based methods.

In epoxy systems, the use of ethyl propanoate may contribute to improved performance and durability of the final product. Enhanced durability can lead to longer-lasting materials, potentially reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. Additionally, the ability of ethyl propanoate to modify curing kinetics may allow for lower curing temperatures or shorter curing times, resulting in energy savings during the manufacturing process.

However, it is essential to consider the end-of-life scenarios for epoxy materials containing ethyl propanoate. While the compound itself may be biodegradable, its incorporation into crosslinked epoxy networks can complicate recycling and disposal processes. Research into advanced recycling technologies and design for disassembly strategies is ongoing to address these challenges and improve the overall lifecycle environmental performance of epoxy systems.

Regulatory Framework for Epoxy Resin Additives

The regulatory framework for epoxy resin additives plays a crucial role in ensuring the safety and quality of products containing these materials. In the context of ethyl propanoate's influence on epoxy resin catalysis, it is essential to understand the existing regulations and guidelines that govern the use of such additives.

At the international level, organizations like the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) have established standards for epoxy resins and their additives. These standards provide guidelines for testing methods, performance requirements, and safety considerations.

In the United States, the Environmental Protection Agency (EPA) regulates epoxy resin additives under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to submit premanufacture notices for new chemical substances, including additives like ethyl propanoate, before they can be introduced into commerce.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to epoxy resin additives. Under REACH, manufacturers and importers must register substances produced or imported in quantities of one tonne or more per year with the European Chemicals Agency (ECHA).

Specific to epoxy resin catalysis, regulatory bodies often focus on the potential health and environmental impacts of additives. For ethyl propanoate, considerations may include its volatile organic compound (VOC) content, potential for skin or respiratory irritation, and biodegradability.

Many countries have established occupational exposure limits for chemicals used in epoxy resin systems. These limits are designed to protect workers from potential health hazards associated with long-term exposure to additives and catalysts.

In the food packaging industry, regulations are particularly stringent. The U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) have specific guidelines for epoxy resins and their additives when used in food contact materials.

As research continues on the influence of ethyl propanoate on epoxy resin catalysis, regulatory frameworks may evolve to address any newly discovered risks or benefits. Manufacturers and researchers must stay informed about these regulatory changes to ensure compliance and product safety.

At the international level, organizations like the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) have established standards for epoxy resins and their additives. These standards provide guidelines for testing methods, performance requirements, and safety considerations.

In the United States, the Environmental Protection Agency (EPA) regulates epoxy resin additives under the Toxic Substances Control Act (TSCA). The EPA requires manufacturers to submit premanufacture notices for new chemical substances, including additives like ethyl propanoate, before they can be introduced into commerce.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to epoxy resin additives. Under REACH, manufacturers and importers must register substances produced or imported in quantities of one tonne or more per year with the European Chemicals Agency (ECHA).

Specific to epoxy resin catalysis, regulatory bodies often focus on the potential health and environmental impacts of additives. For ethyl propanoate, considerations may include its volatile organic compound (VOC) content, potential for skin or respiratory irritation, and biodegradability.

Many countries have established occupational exposure limits for chemicals used in epoxy resin systems. These limits are designed to protect workers from potential health hazards associated with long-term exposure to additives and catalysts.

In the food packaging industry, regulations are particularly stringent. The U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) have specific guidelines for epoxy resins and their additives when used in food contact materials.

As research continues on the influence of ethyl propanoate on epoxy resin catalysis, regulatory frameworks may evolve to address any newly discovered risks or benefits. Manufacturers and researchers must stay informed about these regulatory changes to ensure compliance and product safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!