Innovations in aerospace-grade PMSM materials

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Material Evolution

The evolution of Permanent Magnet Synchronous Motor (PMSM) materials in aerospace applications has been marked by significant advancements over the past decades. Initially, ferrite magnets were widely used due to their low cost and availability. However, their limited magnetic properties restricted their application in high-performance aerospace systems.

The 1970s saw a breakthrough with the development of samarium-cobalt (SmCo) magnets. These rare-earth magnets offered superior magnetic properties, including high coercivity and excellent temperature stability. SmCo magnets quickly became the preferred choice for aerospace-grade PMSMs, enabling the design of more compact and efficient motors.

In the 1980s, neodymium-iron-boron (NdFeB) magnets emerged as a game-changer. NdFeB magnets provided even higher magnetic energy products than SmCo, allowing for further miniaturization and performance improvements in aerospace PMSMs. Their lower cost compared to SmCo made them an attractive option for many applications.

The early 2000s brought renewed focus on high-temperature performance, crucial for aerospace applications. This led to the development of dysprosium-doped NdFeB magnets, which offered improved thermal stability and coercivity at elevated temperatures. Simultaneously, advancements in SmCo magnets, such as Sm2Co17 compositions, provided alternatives for extreme temperature environments.

Recent years have seen a shift towards reducing reliance on heavy rare-earth elements like dysprosium. Grain boundary diffusion techniques have been developed to enhance the coercivity of NdFeB magnets while minimizing dysprosium content. This approach has resulted in more cost-effective and environmentally friendly aerospace-grade PMSM materials.

Parallel to permanent magnet developments, soft magnetic materials used in PMSM stators have also evolved. Silicon steel, traditionally used in electrical machines, has been refined to reduce core losses. The introduction of amorphous and nanocrystalline soft magnetic materials has further improved motor efficiency, particularly at high frequencies.

Looking forward, research is focused on developing novel magnetic materials that can withstand even higher temperatures and offer improved reliability in aerospace environments. Efforts are underway to explore new rare-earth-free permanent magnets, such as iron nitride compounds, which could potentially revolutionize aerospace PMSM technology if successfully commercialized.

The 1970s saw a breakthrough with the development of samarium-cobalt (SmCo) magnets. These rare-earth magnets offered superior magnetic properties, including high coercivity and excellent temperature stability. SmCo magnets quickly became the preferred choice for aerospace-grade PMSMs, enabling the design of more compact and efficient motors.

In the 1980s, neodymium-iron-boron (NdFeB) magnets emerged as a game-changer. NdFeB magnets provided even higher magnetic energy products than SmCo, allowing for further miniaturization and performance improvements in aerospace PMSMs. Their lower cost compared to SmCo made them an attractive option for many applications.

The early 2000s brought renewed focus on high-temperature performance, crucial for aerospace applications. This led to the development of dysprosium-doped NdFeB magnets, which offered improved thermal stability and coercivity at elevated temperatures. Simultaneously, advancements in SmCo magnets, such as Sm2Co17 compositions, provided alternatives for extreme temperature environments.

Recent years have seen a shift towards reducing reliance on heavy rare-earth elements like dysprosium. Grain boundary diffusion techniques have been developed to enhance the coercivity of NdFeB magnets while minimizing dysprosium content. This approach has resulted in more cost-effective and environmentally friendly aerospace-grade PMSM materials.

Parallel to permanent magnet developments, soft magnetic materials used in PMSM stators have also evolved. Silicon steel, traditionally used in electrical machines, has been refined to reduce core losses. The introduction of amorphous and nanocrystalline soft magnetic materials has further improved motor efficiency, particularly at high frequencies.

Looking forward, research is focused on developing novel magnetic materials that can withstand even higher temperatures and offer improved reliability in aerospace environments. Efforts are underway to explore new rare-earth-free permanent magnets, such as iron nitride compounds, which could potentially revolutionize aerospace PMSM technology if successfully commercialized.

Aerospace Market Demand

The aerospace industry has witnessed a growing demand for advanced Permanent Magnet Synchronous Motors (PMSMs) due to their high efficiency, power density, and reliability. This demand is driven by the increasing electrification of aircraft systems, the development of more electric aircraft (MEA) concepts, and the emergence of electric vertical takeoff and landing (eVTOL) vehicles.

In commercial aviation, the trend towards MEA has led to a significant increase in the use of electrical systems for functions previously powered by hydraulic, pneumatic, or mechanical means. This shift has created a substantial market for aerospace-grade PMSMs in applications such as electric environmental control systems, electric actuation systems for flight controls, and electric fuel pumps. The global market for aircraft electrical systems is projected to grow at a compound annual growth rate (CAGR) of over 6% in the coming years, with PMSMs playing a crucial role in this expansion.

The military aerospace sector also presents a significant market opportunity for aerospace-grade PMSM materials. Advanced fighter jets and unmanned aerial vehicles (UAVs) require high-performance electric motors for various applications, including weapon systems, radar systems, and electronic warfare equipment. The increasing focus on stealth capabilities and reduced thermal signatures further drives the demand for efficient and compact PMSMs in military aircraft.

The emerging urban air mobility (UAM) market, particularly eVTOL vehicles, represents a rapidly growing segment for aerospace-grade PMSM materials. These vehicles rely heavily on electric propulsion systems, with PMSMs serving as the primary choice for their propulsion motors. Industry analysts predict that the global eVTOL market could reach tens of billions of dollars by 2030, creating a substantial demand for high-performance, lightweight PMSMs.

Space exploration and satellite technologies also contribute to the market demand for aerospace-grade PMSM materials. The increasing number of satellite launches and the development of reusable launch vehicles require advanced electric motors for various applications, including attitude control systems, solar array drives, and robotic manipulators. The growing commercial space industry, led by companies like SpaceX and Blue Origin, is expected to further boost the demand for high-reliability PMSMs in space applications.

The market demand for aerospace-grade PMSM materials is also influenced by the industry's push towards sustainability and reduced environmental impact. As airlines and aerospace manufacturers strive to meet stringent emissions regulations and improve fuel efficiency, the adoption of more electric systems powered by high-efficiency PMSMs becomes increasingly attractive. This trend is expected to accelerate in the coming years, driven by both regulatory pressures and consumer demand for greener air travel options.

In commercial aviation, the trend towards MEA has led to a significant increase in the use of electrical systems for functions previously powered by hydraulic, pneumatic, or mechanical means. This shift has created a substantial market for aerospace-grade PMSMs in applications such as electric environmental control systems, electric actuation systems for flight controls, and electric fuel pumps. The global market for aircraft electrical systems is projected to grow at a compound annual growth rate (CAGR) of over 6% in the coming years, with PMSMs playing a crucial role in this expansion.

The military aerospace sector also presents a significant market opportunity for aerospace-grade PMSM materials. Advanced fighter jets and unmanned aerial vehicles (UAVs) require high-performance electric motors for various applications, including weapon systems, radar systems, and electronic warfare equipment. The increasing focus on stealth capabilities and reduced thermal signatures further drives the demand for efficient and compact PMSMs in military aircraft.

The emerging urban air mobility (UAM) market, particularly eVTOL vehicles, represents a rapidly growing segment for aerospace-grade PMSM materials. These vehicles rely heavily on electric propulsion systems, with PMSMs serving as the primary choice for their propulsion motors. Industry analysts predict that the global eVTOL market could reach tens of billions of dollars by 2030, creating a substantial demand for high-performance, lightweight PMSMs.

Space exploration and satellite technologies also contribute to the market demand for aerospace-grade PMSM materials. The increasing number of satellite launches and the development of reusable launch vehicles require advanced electric motors for various applications, including attitude control systems, solar array drives, and robotic manipulators. The growing commercial space industry, led by companies like SpaceX and Blue Origin, is expected to further boost the demand for high-reliability PMSMs in space applications.

The market demand for aerospace-grade PMSM materials is also influenced by the industry's push towards sustainability and reduced environmental impact. As airlines and aerospace manufacturers strive to meet stringent emissions regulations and improve fuel efficiency, the adoption of more electric systems powered by high-efficiency PMSMs becomes increasingly attractive. This trend is expected to accelerate in the coming years, driven by both regulatory pressures and consumer demand for greener air travel options.

Current PMSM Challenges

Permanent Magnet Synchronous Motors (PMSMs) have become increasingly prevalent in aerospace applications due to their high power density, efficiency, and reliability. However, as the aerospace industry continues to push the boundaries of performance and sustainability, several challenges have emerged in the development and implementation of aerospace-grade PMSM materials.

One of the primary challenges is the need for materials that can withstand extreme operating conditions. Aerospace PMSMs are subjected to high temperatures, intense vibrations, and rapid acceleration, which can lead to material degradation and reduced performance over time. Current materials struggle to maintain their magnetic properties and structural integrity under these demanding conditions, limiting the overall efficiency and lifespan of the motors.

Another significant challenge is the quest for higher power density. As aircraft manufacturers strive to reduce weight and increase fuel efficiency, there is a growing demand for PMSMs that can deliver more power in smaller, lighter packages. This requires the development of materials with superior magnetic properties and thermal management capabilities, which is proving to be a complex task given the current limitations of available materials.

The issue of rare earth element dependency also poses a significant challenge. Many high-performance PMSMs rely on rare earth elements, particularly neodymium and dysprosium, for their magnetic properties. However, the limited global supply and geopolitical concerns surrounding these elements have led to price volatility and potential supply chain disruptions. This has sparked a need for alternative materials or more efficient use of existing rare earth resources.

Thermal management remains a critical challenge in aerospace-grade PMSMs. The high power density and compact design of these motors generate substantial heat, which can compromise performance and reliability if not effectively dissipated. Current materials and cooling systems struggle to maintain optimal operating temperatures, especially in the confined spaces typical of aerospace applications.

Manufacturability and cost-effectiveness present additional hurdles. The complex geometries and precise material properties required for aerospace-grade PMSMs often necessitate advanced manufacturing techniques, which can be expensive and time-consuming. Balancing the need for high-performance materials with cost-effective production methods is an ongoing challenge for the industry.

Lastly, the aerospace industry's increasing focus on sustainability and environmental impact has introduced new challenges in PMSM material development. There is a growing need for materials that are not only high-performing but also environmentally friendly in their production, use, and end-of-life disposal. This includes considerations for recyclability, reduced carbon footprint, and minimization of toxic substances in the manufacturing process.

One of the primary challenges is the need for materials that can withstand extreme operating conditions. Aerospace PMSMs are subjected to high temperatures, intense vibrations, and rapid acceleration, which can lead to material degradation and reduced performance over time. Current materials struggle to maintain their magnetic properties and structural integrity under these demanding conditions, limiting the overall efficiency and lifespan of the motors.

Another significant challenge is the quest for higher power density. As aircraft manufacturers strive to reduce weight and increase fuel efficiency, there is a growing demand for PMSMs that can deliver more power in smaller, lighter packages. This requires the development of materials with superior magnetic properties and thermal management capabilities, which is proving to be a complex task given the current limitations of available materials.

The issue of rare earth element dependency also poses a significant challenge. Many high-performance PMSMs rely on rare earth elements, particularly neodymium and dysprosium, for their magnetic properties. However, the limited global supply and geopolitical concerns surrounding these elements have led to price volatility and potential supply chain disruptions. This has sparked a need for alternative materials or more efficient use of existing rare earth resources.

Thermal management remains a critical challenge in aerospace-grade PMSMs. The high power density and compact design of these motors generate substantial heat, which can compromise performance and reliability if not effectively dissipated. Current materials and cooling systems struggle to maintain optimal operating temperatures, especially in the confined spaces typical of aerospace applications.

Manufacturability and cost-effectiveness present additional hurdles. The complex geometries and precise material properties required for aerospace-grade PMSMs often necessitate advanced manufacturing techniques, which can be expensive and time-consuming. Balancing the need for high-performance materials with cost-effective production methods is an ongoing challenge for the industry.

Lastly, the aerospace industry's increasing focus on sustainability and environmental impact has introduced new challenges in PMSM material development. There is a growing need for materials that are not only high-performing but also environmentally friendly in their production, use, and end-of-life disposal. This includes considerations for recyclability, reduced carbon footprint, and minimization of toxic substances in the manufacturing process.

Advanced PMSM Solutions

01 Permanent magnet materials for PMSM

Permanent magnet synchronous motors (PMSMs) utilize high-performance magnetic materials to generate strong magnetic fields. Common materials include neodymium-iron-boron (NdFeB) and samarium-cobalt (SmCo) alloys. These materials offer high magnetic strength, allowing for compact and efficient motor designs.- Stator core materials for PMSM: Permanent Magnet Synchronous Motors (PMSM) utilize specific materials for their stator cores to enhance performance. These materials are typically soft magnetic materials with high permeability and low core losses, such as silicon steel laminations or amorphous alloys. The choice of stator core material significantly impacts the motor's efficiency and power density.

- Permanent magnet materials in PMSM rotors: The rotor of a PMSM contains permanent magnets, which are crucial for its operation. Common materials used include rare earth magnets like neodymium-iron-boron (NdFeB) or samarium-cobalt (SmCo). These materials provide high magnetic flux density, contributing to the motor's high torque and power density. Advancements in magnet materials focus on improving temperature stability and reducing reliance on rare earth elements.

- Winding materials for PMSM stators: The stator windings in PMSMs are typically made of copper or aluminum. The choice of winding material affects the motor's efficiency, power density, and thermal performance. Innovations in this area include the use of advanced insulation materials and novel winding configurations to improve heat dissipation and increase current density.

- Thermal management materials in PMSM: Effective thermal management is crucial for PMSM performance and longevity. Materials used for this purpose include thermally conductive polymers, phase change materials, and advanced cooling fluids. These materials help in dissipating heat from the motor windings and magnets, thereby maintaining optimal operating temperatures and preventing performance degradation.

- Bearing materials for PMSM: The choice of bearing materials in PMSMs is critical for reducing friction and ensuring long-term reliability. Common materials include ceramic bearings, which offer low friction and high wear resistance, and polymer-based bearings for specific applications. Advanced bearing materials and designs contribute to improved motor efficiency and reduced maintenance requirements.

02 Stator core materials for PMSM

The stator core in PMSMs is typically made from laminated electrical steel sheets to reduce eddy current losses. Silicon steel is commonly used due to its high magnetic permeability and low core losses. Some designs incorporate amorphous or nanocrystalline materials for improved efficiency.Expand Specific Solutions03 Winding materials for PMSM stators

Copper is the primary material used for stator windings in PMSMs due to its excellent electrical conductivity. Some designs utilize aluminum windings to reduce weight and cost. Advanced insulation materials are employed to improve thermal performance and reliability of the windings.Expand Specific Solutions04 Rotor construction materials for PMSM

PMSM rotors are typically constructed using a combination of materials. The rotor core is often made of laminated electrical steel, while the shaft is usually made of high-strength steel. Some designs incorporate lightweight materials like aluminum or carbon fiber to reduce inertia and improve dynamic performance.Expand Specific Solutions05 Thermal management materials for PMSM

Effective thermal management is crucial for PMSM performance and longevity. Materials with high thermal conductivity, such as aluminum alloys, are used for motor housings and heat sinks. Thermally conductive epoxies and gap fillers are employed to improve heat transfer between components. Some designs incorporate phase-change materials for enhanced cooling.Expand Specific Solutions

Aerospace PMSM Players

The aerospace-grade PMSM materials market is in a growth phase, driven by increasing demand for high-performance electric motors in aerospace applications. The market size is expanding as more aircraft manufacturers adopt electric propulsion systems. Technologically, the field is advancing rapidly, with companies like Boeing, GE, and NASA leading research efforts. Universities such as Xi'an Jiaotong University and Shandong University are contributing to material innovations. The technology is maturing, but there's still room for significant improvements in efficiency, power density, and thermal management. Collaboration between industry leaders and research institutions is accelerating progress in this competitive and dynamic sector.

The Boeing Co.

Technical Solution: Boeing has made significant strides in aerospace-grade PMSM materials for commercial and military aircraft applications. They have focused on developing lightweight, high-strength materials for PMSM rotors and stators to improve overall aircraft efficiency. Boeing's research includes the use of advanced composite materials in PMSM construction, such as carbon fiber reinforced polymers (CFRP), which offer excellent strength-to-weight ratios[2]. They have also explored the integration of thermal management systems within PMSM designs to optimize performance under varying flight conditions[4]. Boeing's innovations extend to the development of fault-tolerant PMSM architectures, enhancing reliability in critical aerospace applications[6].

Strengths: Expertise in lightweight materials and integration with aircraft systems. Weaknesses: Potential challenges in scaling up production for large commercial fleets.

US Air Force

Technical Solution: The US Air Force has been actively researching aerospace-grade PMSM materials for military aircraft and unmanned aerial vehicles (UAVs). Their focus has been on developing high-power density PMSMs that can operate in extreme environments. The Air Force has invested in research on advanced magnetic materials with improved temperature stability and resistance to demagnetization[8]. They have also explored the use of novel cooling techniques, such as spray cooling and phase change materials, to manage thermal loads in high-performance PMSMs[10]. Additionally, the Air Force has been investigating the potential of wide bandgap semiconductors, like Silicon Carbide (SiC) and Gallium Nitride (GaN), in PMSM drive systems to improve overall efficiency and power density[12].

Strengths: Focus on rugged, high-performance designs for extreme military environments. Weaknesses: Potential limitations in technology transfer to civilian applications due to security considerations.

Key PMSM Innovations

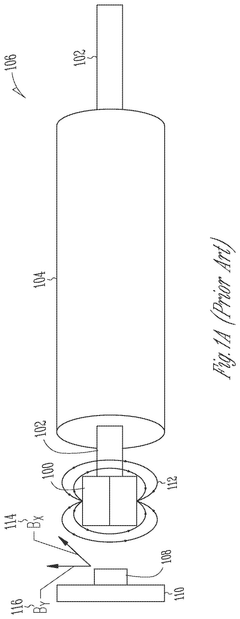

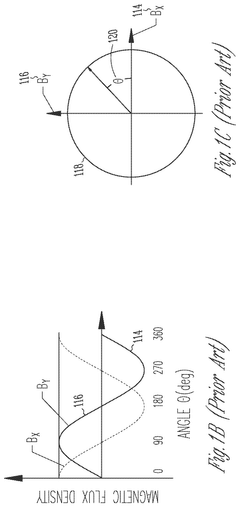

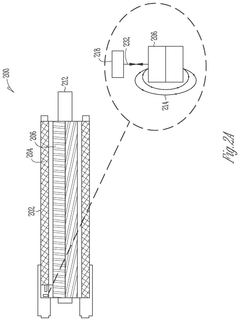

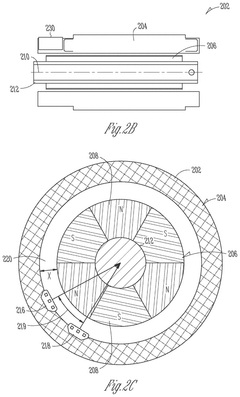

Permanent magnet synchronous motor (PMSM) integrated position sensing

PatentActiveUS12212257B2

Innovation

- The integration of analog magnetic flux sensors within the hollow cylindrical stator of the PMSM, arranged concentrically around the rotational axis at a constant mechanical angle relative to each other, allows for direct measurement of the magnetic flux from the rotor without external obstructions, enabling accurate rotor position sensing and reducing motor size and cost.

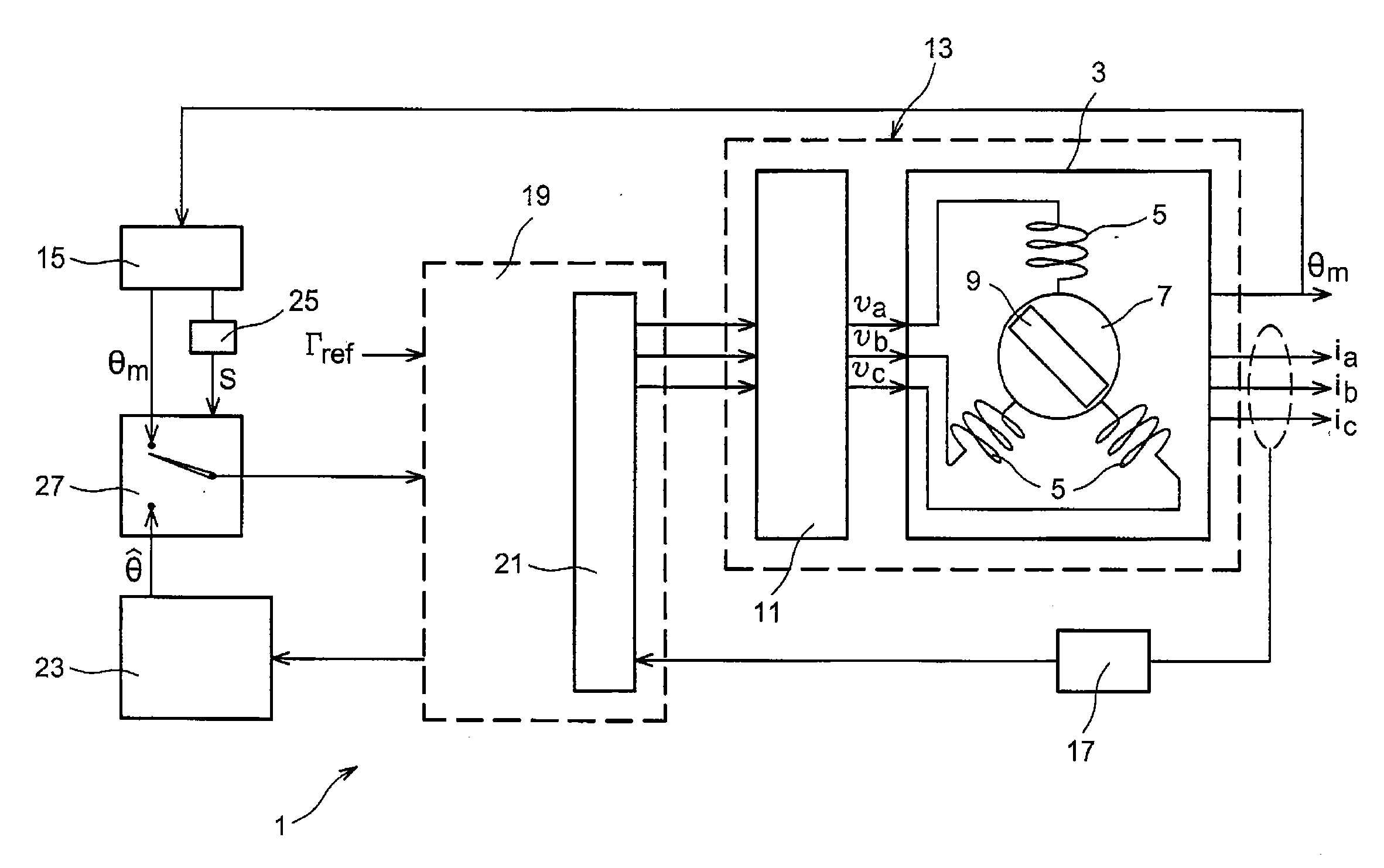

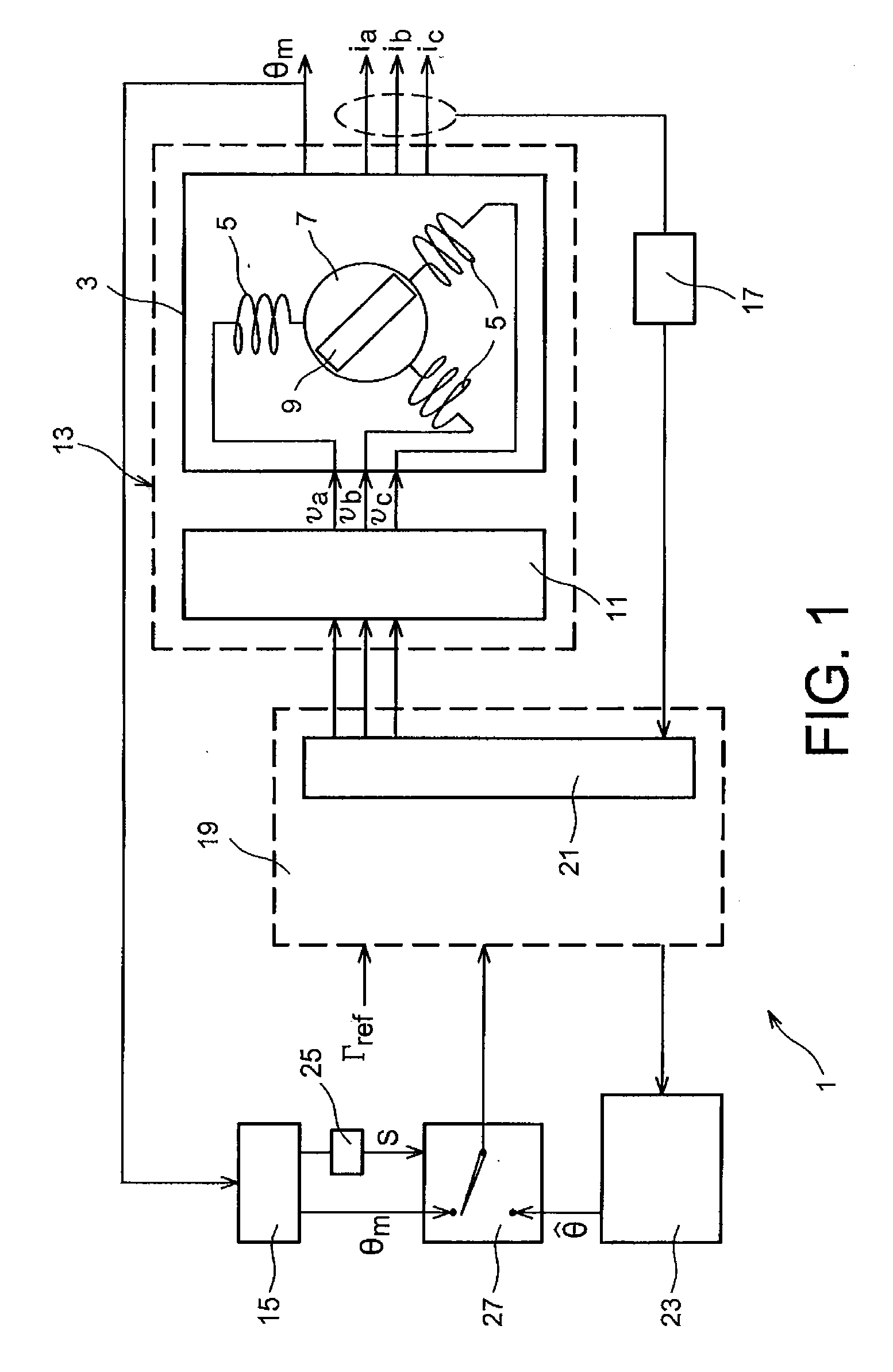

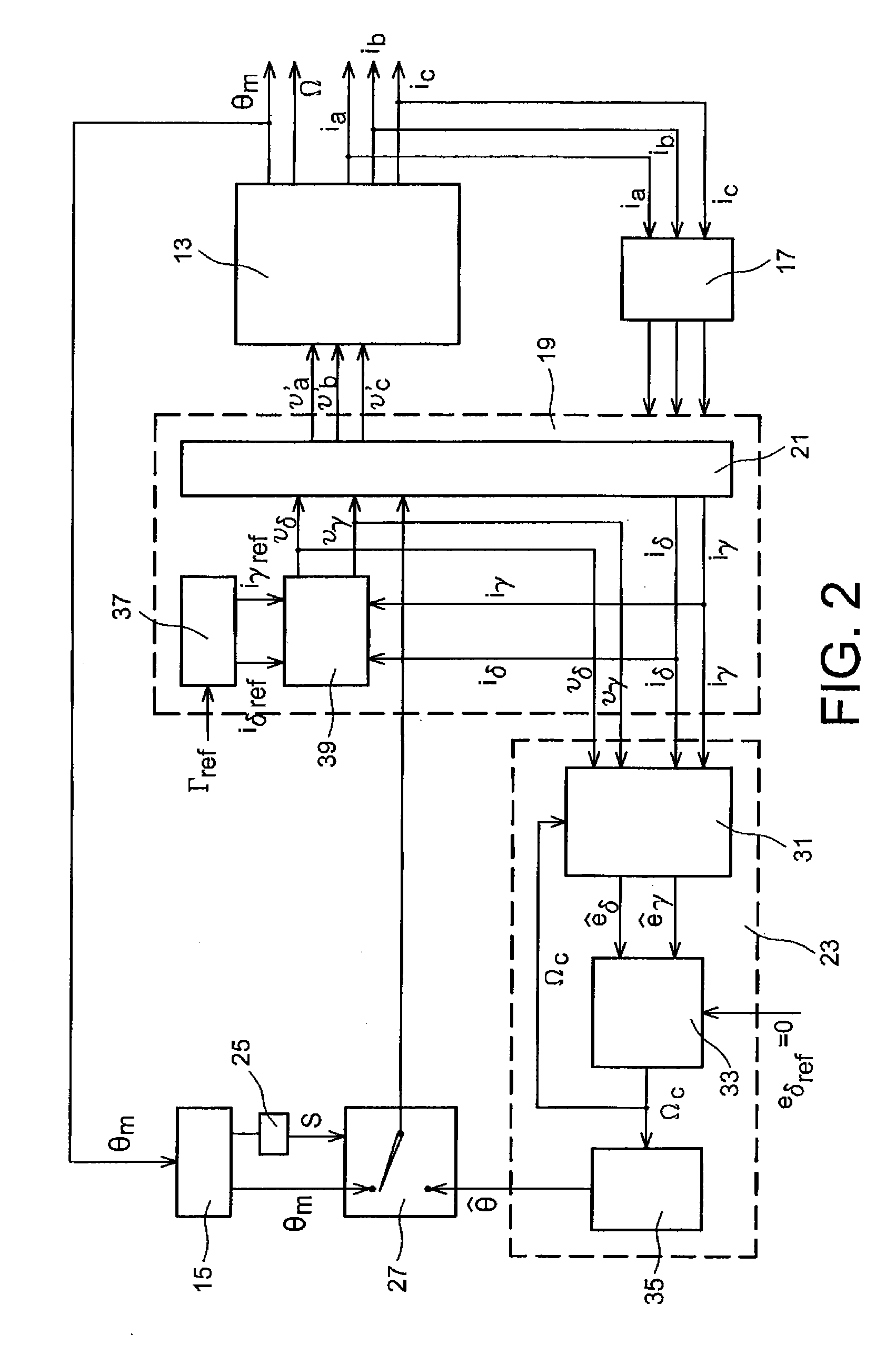

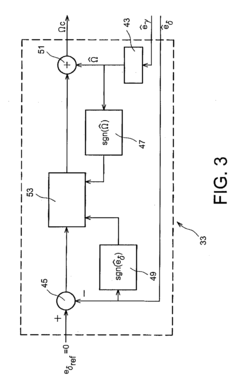

Device for control of a pmsm

PatentActiveUS20120280641A1

Innovation

- A control device that includes a sensor for measuring rotor position, estimation means to determine an estimated rotor position, a malfunction detector, and a switch to transition from sensor-based to sensorless control when a malfunction is detected, using an electromotive force estimator and non-linear corrector to ensure global convergence to the desired operating point.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of innovations in aerospace-grade Permanent Magnet Synchronous Motor (PMSM) materials. The aerospace industry is subject to stringent regulations and standards to ensure safety, reliability, and performance of aircraft components.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are the primary regulatory bodies overseeing aerospace materials and components. These agencies establish and enforce regulations that govern the design, manufacturing, and testing of aerospace-grade materials, including those used in PMSMs.

Compliance with standards such as DO-160 (Environmental Conditions and Test Procedures for Airborne Equipment) and DO-254 (Design Assurance Guidance for Airborne Electronic Hardware) is essential for aerospace-grade PMSM materials. These standards ensure that materials can withstand the harsh environmental conditions encountered during flight and meet the required performance criteria.

Material manufacturers must adhere to quality management systems like AS9100, which is specific to the aerospace industry. This standard ensures consistent quality and traceability throughout the supply chain, from raw material sourcing to final product delivery.

Innovations in aerospace-grade PMSM materials must also comply with regulations regarding electromagnetic compatibility (EMC) and electromagnetic interference (EMI). These regulations are critical for ensuring that the motors do not interfere with other aircraft systems or communication equipment.

Environmental regulations, such as the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) in the European Union, impact the development of new materials. Manufacturers must ensure that their innovations do not contain restricted substances or pose environmental risks.

Certification processes for new materials and components are rigorous and time-consuming. Manufacturers must provide extensive documentation, test results, and performance data to regulatory agencies for approval. This process can significantly impact the timeline for bringing new innovations to market.

As aerospace technology advances, regulatory bodies continually update their standards and requirements. Manufacturers must stay informed about these changes and adapt their innovation processes accordingly. This ongoing compliance effort ensures that new materials meet the latest safety and performance standards.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are the primary regulatory bodies overseeing aerospace materials and components. These agencies establish and enforce regulations that govern the design, manufacturing, and testing of aerospace-grade materials, including those used in PMSMs.

Compliance with standards such as DO-160 (Environmental Conditions and Test Procedures for Airborne Equipment) and DO-254 (Design Assurance Guidance for Airborne Electronic Hardware) is essential for aerospace-grade PMSM materials. These standards ensure that materials can withstand the harsh environmental conditions encountered during flight and meet the required performance criteria.

Material manufacturers must adhere to quality management systems like AS9100, which is specific to the aerospace industry. This standard ensures consistent quality and traceability throughout the supply chain, from raw material sourcing to final product delivery.

Innovations in aerospace-grade PMSM materials must also comply with regulations regarding electromagnetic compatibility (EMC) and electromagnetic interference (EMI). These regulations are critical for ensuring that the motors do not interfere with other aircraft systems or communication equipment.

Environmental regulations, such as the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) in the European Union, impact the development of new materials. Manufacturers must ensure that their innovations do not contain restricted substances or pose environmental risks.

Certification processes for new materials and components are rigorous and time-consuming. Manufacturers must provide extensive documentation, test results, and performance data to regulatory agencies for approval. This process can significantly impact the timeline for bringing new innovations to market.

As aerospace technology advances, regulatory bodies continually update their standards and requirements. Manufacturers must stay informed about these changes and adapt their innovation processes accordingly. This ongoing compliance effort ensures that new materials meet the latest safety and performance standards.

Environmental Impact

The environmental impact of innovations in aerospace-grade Permanent Magnet Synchronous Motor (PMSM) materials is a critical consideration in the development and implementation of these advanced technologies. As the aerospace industry strives for more efficient and sustainable solutions, the materials used in PMSMs play a significant role in determining the overall environmental footprint of aircraft and spacecraft.

One of the primary environmental benefits of advanced PMSM materials is their potential to improve energy efficiency. By enhancing the performance of electric motors, these materials can contribute to reduced fuel consumption and lower greenhouse gas emissions. This is particularly important in the context of the aviation industry's efforts to meet increasingly stringent environmental regulations and reduce its carbon footprint.

However, the production and disposal of aerospace-grade PMSM materials also present environmental challenges. Many of these materials, such as rare earth elements used in high-performance magnets, require energy-intensive mining and processing operations. The extraction of these elements can lead to soil degradation, water pollution, and habitat destruction if not managed responsibly. Additionally, the refining processes often involve the use of chemicals that can have negative environmental impacts if not properly controlled.

The lifecycle of PMSM materials is another crucial aspect to consider. While these materials can contribute to improved efficiency during operation, their long-term environmental impact depends on factors such as durability, recyclability, and end-of-life management. Innovations in material design that focus on extending the lifespan of PMSMs and facilitating easier recycling can significantly reduce the overall environmental burden.

Advancements in manufacturing techniques for aerospace-grade PMSM materials also have environmental implications. Emerging technologies such as additive manufacturing and precision forming can potentially reduce material waste and energy consumption during production. These innovations not only contribute to more sustainable manufacturing processes but also align with the aerospace industry's goals of lightweighting and improved fuel efficiency.

The development of alternative materials for PMSMs is an area of research with significant environmental potential. Efforts to reduce or eliminate the use of rare earth elements in favor of more abundant and less environmentally impactful materials could lead to substantial improvements in the sustainability of aerospace electric propulsion systems. This includes research into novel magnetic compounds and composite materials that offer comparable performance with reduced environmental costs.

In conclusion, while innovations in aerospace-grade PMSM materials offer promising environmental benefits through improved efficiency and performance, careful consideration must be given to the entire lifecycle of these materials. Balancing the positive impacts of enhanced motor efficiency against the environmental costs of production and disposal is crucial for ensuring that these technological advancements contribute to a more sustainable aerospace industry.

One of the primary environmental benefits of advanced PMSM materials is their potential to improve energy efficiency. By enhancing the performance of electric motors, these materials can contribute to reduced fuel consumption and lower greenhouse gas emissions. This is particularly important in the context of the aviation industry's efforts to meet increasingly stringent environmental regulations and reduce its carbon footprint.

However, the production and disposal of aerospace-grade PMSM materials also present environmental challenges. Many of these materials, such as rare earth elements used in high-performance magnets, require energy-intensive mining and processing operations. The extraction of these elements can lead to soil degradation, water pollution, and habitat destruction if not managed responsibly. Additionally, the refining processes often involve the use of chemicals that can have negative environmental impacts if not properly controlled.

The lifecycle of PMSM materials is another crucial aspect to consider. While these materials can contribute to improved efficiency during operation, their long-term environmental impact depends on factors such as durability, recyclability, and end-of-life management. Innovations in material design that focus on extending the lifespan of PMSMs and facilitating easier recycling can significantly reduce the overall environmental burden.

Advancements in manufacturing techniques for aerospace-grade PMSM materials also have environmental implications. Emerging technologies such as additive manufacturing and precision forming can potentially reduce material waste and energy consumption during production. These innovations not only contribute to more sustainable manufacturing processes but also align with the aerospace industry's goals of lightweighting and improved fuel efficiency.

The development of alternative materials for PMSMs is an area of research with significant environmental potential. Efforts to reduce or eliminate the use of rare earth elements in favor of more abundant and less environmentally impactful materials could lead to substantial improvements in the sustainability of aerospace electric propulsion systems. This includes research into novel magnetic compounds and composite materials that offer comparable performance with reduced environmental costs.

In conclusion, while innovations in aerospace-grade PMSM materials offer promising environmental benefits through improved efficiency and performance, careful consideration must be given to the entire lifecycle of these materials. Balancing the positive impacts of enhanced motor efficiency against the environmental costs of production and disposal is crucial for ensuring that these technological advancements contribute to a more sustainable aerospace industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!