Innovations in Electrolytic Cell Design for Sustainable Batteries and Energy Storage

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolytic Cell Evolution and Objectives

Electrolytic cells have been at the forefront of energy storage technology since their inception in the early 19th century. The evolution of these cells has been driven by the increasing demand for more efficient, sustainable, and high-capacity energy storage solutions. From the rudimentary designs of Alessandro Volta to the sophisticated lithium-ion batteries of today, the journey of electrolytic cell development has been marked by continuous innovation and scientific breakthroughs.

The primary objective in the field of electrolytic cell design for sustainable batteries and energy storage is to create systems that can meet the growing energy demands of our modern world while minimizing environmental impact. This involves improving energy density, enhancing cycle life, reducing costs, and utilizing more abundant and environmentally friendly materials. Researchers and engineers are focusing on developing cells that can store more energy in smaller volumes, charge faster, and maintain their performance over a greater number of charge-discharge cycles.

One of the key trends in electrolytic cell evolution is the shift towards solid-state electrolytes. These materials promise to overcome many of the limitations associated with liquid electrolytes, such as flammability and dendrite formation. The goal is to create safer, more stable batteries with higher energy densities. Another significant objective is the development of sustainable cathode and anode materials that can replace the current reliance on rare and expensive elements like cobalt and lithium.

The push for sustainability has also led to increased research into flow batteries and other large-scale energy storage solutions. These systems aim to provide grid-level storage capabilities, essential for integrating renewable energy sources like solar and wind into our power infrastructure. The objective here is to create scalable, long-duration storage systems that can efficiently manage the intermittent nature of renewable energy generation.

Nanotechnology is playing an increasingly important role in electrolytic cell design. By manipulating materials at the nanoscale, researchers aim to create electrode structures with vastly increased surface areas, leading to improved energy and power densities. This approach also opens up possibilities for novel electrode materials and architectures that were previously unfeasible.

As we look to the future, the objectives for electrolytic cell design are becoming more ambitious. There is a growing focus on developing bio-inspired and self-healing battery systems that can autonomously repair damage and maintain performance over extended periods. Additionally, researchers are exploring the potential of artificial intelligence and machine learning to optimize battery design and predict performance, potentially revolutionizing the way we approach energy storage solutions.

The primary objective in the field of electrolytic cell design for sustainable batteries and energy storage is to create systems that can meet the growing energy demands of our modern world while minimizing environmental impact. This involves improving energy density, enhancing cycle life, reducing costs, and utilizing more abundant and environmentally friendly materials. Researchers and engineers are focusing on developing cells that can store more energy in smaller volumes, charge faster, and maintain their performance over a greater number of charge-discharge cycles.

One of the key trends in electrolytic cell evolution is the shift towards solid-state electrolytes. These materials promise to overcome many of the limitations associated with liquid electrolytes, such as flammability and dendrite formation. The goal is to create safer, more stable batteries with higher energy densities. Another significant objective is the development of sustainable cathode and anode materials that can replace the current reliance on rare and expensive elements like cobalt and lithium.

The push for sustainability has also led to increased research into flow batteries and other large-scale energy storage solutions. These systems aim to provide grid-level storage capabilities, essential for integrating renewable energy sources like solar and wind into our power infrastructure. The objective here is to create scalable, long-duration storage systems that can efficiently manage the intermittent nature of renewable energy generation.

Nanotechnology is playing an increasingly important role in electrolytic cell design. By manipulating materials at the nanoscale, researchers aim to create electrode structures with vastly increased surface areas, leading to improved energy and power densities. This approach also opens up possibilities for novel electrode materials and architectures that were previously unfeasible.

As we look to the future, the objectives for electrolytic cell design are becoming more ambitious. There is a growing focus on developing bio-inspired and self-healing battery systems that can autonomously repair damage and maintain performance over extended periods. Additionally, researchers are exploring the potential of artificial intelligence and machine learning to optimize battery design and predict performance, potentially revolutionizing the way we approach energy storage solutions.

Market Demand for Sustainable Energy Storage

The market demand for sustainable energy storage solutions has been experiencing exponential growth in recent years, driven by the global shift towards renewable energy sources and the increasing need for grid stability. As intermittent renewable energy sources like solar and wind power become more prevalent, the demand for efficient and sustainable energy storage systems has skyrocketed.

The electric vehicle (EV) industry has emerged as a significant driver of this demand. With major automotive manufacturers committing to electrification of their fleets, the need for high-performance, long-lasting, and environmentally friendly batteries has become paramount. This trend is expected to continue, with the global EV battery market projected to grow at a compound annual growth rate (CAGR) of over 25% in the coming years.

Grid-scale energy storage represents another crucial segment of the market. As power grids integrate more renewable energy sources, the need for large-scale storage solutions to balance supply and demand has intensified. Utility companies and grid operators are increasingly investing in battery storage systems to enhance grid reliability and reduce reliance on fossil fuel-based peaker plants.

The residential and commercial sectors are also contributing to the growing demand for sustainable energy storage. With the rise of distributed energy resources and the concept of prosumers (producers and consumers of energy), there is a growing market for home and business energy storage systems. These systems allow for greater energy independence, reduced electricity costs, and improved resilience during power outages.

Industrial applications present another significant market opportunity for sustainable energy storage. Manufacturing facilities, data centers, and other energy-intensive industries are exploring ways to reduce their carbon footprint and energy costs through the implementation of advanced storage technologies.

The push for sustainability has also led to increased interest in second-life battery applications. As EV batteries reach the end of their useful life in vehicles, there is growing demand for repurposing these batteries for stationary storage applications, creating a circular economy approach to battery usage.

Geographically, the demand for sustainable energy storage is global, with particularly strong growth in regions with ambitious renewable energy targets and supportive policy frameworks. Countries like China, the United States, and several European nations are leading the charge, investing heavily in research, development, and deployment of advanced energy storage technologies.

The electric vehicle (EV) industry has emerged as a significant driver of this demand. With major automotive manufacturers committing to electrification of their fleets, the need for high-performance, long-lasting, and environmentally friendly batteries has become paramount. This trend is expected to continue, with the global EV battery market projected to grow at a compound annual growth rate (CAGR) of over 25% in the coming years.

Grid-scale energy storage represents another crucial segment of the market. As power grids integrate more renewable energy sources, the need for large-scale storage solutions to balance supply and demand has intensified. Utility companies and grid operators are increasingly investing in battery storage systems to enhance grid reliability and reduce reliance on fossil fuel-based peaker plants.

The residential and commercial sectors are also contributing to the growing demand for sustainable energy storage. With the rise of distributed energy resources and the concept of prosumers (producers and consumers of energy), there is a growing market for home and business energy storage systems. These systems allow for greater energy independence, reduced electricity costs, and improved resilience during power outages.

Industrial applications present another significant market opportunity for sustainable energy storage. Manufacturing facilities, data centers, and other energy-intensive industries are exploring ways to reduce their carbon footprint and energy costs through the implementation of advanced storage technologies.

The push for sustainability has also led to increased interest in second-life battery applications. As EV batteries reach the end of their useful life in vehicles, there is growing demand for repurposing these batteries for stationary storage applications, creating a circular economy approach to battery usage.

Geographically, the demand for sustainable energy storage is global, with particularly strong growth in regions with ambitious renewable energy targets and supportive policy frameworks. Countries like China, the United States, and several European nations are leading the charge, investing heavily in research, development, and deployment of advanced energy storage technologies.

Current Challenges in Electrolytic Cell Technology

Electrolytic cell technology, while promising for sustainable batteries and energy storage, faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary issues is the degradation of electrode materials over time, which leads to reduced efficiency and shortened lifespan of the cells. This degradation is often caused by side reactions, such as the formation of solid electrolyte interphase (SEI) layers on electrodes, particularly in lithium-ion batteries.

Another critical challenge is the limited energy density of current electrolytic cell designs. Despite ongoing research, the energy storage capacity of these cells still falls short of the demands for many applications, especially in electric vehicles and grid-scale energy storage. This limitation is partly due to the constraints of existing electrode materials and electrolyte compositions.

Thermal management presents a significant hurdle in electrolytic cell technology. During charging and discharging cycles, cells generate heat, which can lead to safety issues and reduced performance if not properly managed. Developing effective cooling systems that do not compromise the cell's energy density or increase costs substantially remains a complex engineering challenge.

The stability and safety of electrolytes pose another major concern. Many high-performance electrolytes are flammable or prone to decomposition under certain conditions, raising safety risks and limiting the operating temperature range of the cells. Finding electrolytes that offer both high performance and enhanced safety is an ongoing area of research.

Scaling up production while maintaining consistency and quality is a substantial challenge for the industry. As demand for electrolytic cells grows, manufacturers must develop processes that can produce large quantities of cells with uniform properties and performance. This scaling issue is particularly pronounced for newer, more advanced cell designs.

Cost remains a significant barrier to widespread adoption of advanced electrolytic cell technologies. While prices have decreased over time, further reductions are necessary to compete with traditional energy storage solutions and fossil fuel technologies. This challenge extends to the entire supply chain, from raw material sourcing to manufacturing processes.

Lastly, the environmental impact of electrolytic cell production and disposal is a growing concern. Developing sustainable manufacturing processes and effective recycling methods for spent cells is crucial for the long-term viability of this technology. Addressing these environmental challenges is essential for truly sustainable energy storage solutions.

Another critical challenge is the limited energy density of current electrolytic cell designs. Despite ongoing research, the energy storage capacity of these cells still falls short of the demands for many applications, especially in electric vehicles and grid-scale energy storage. This limitation is partly due to the constraints of existing electrode materials and electrolyte compositions.

Thermal management presents a significant hurdle in electrolytic cell technology. During charging and discharging cycles, cells generate heat, which can lead to safety issues and reduced performance if not properly managed. Developing effective cooling systems that do not compromise the cell's energy density or increase costs substantially remains a complex engineering challenge.

The stability and safety of electrolytes pose another major concern. Many high-performance electrolytes are flammable or prone to decomposition under certain conditions, raising safety risks and limiting the operating temperature range of the cells. Finding electrolytes that offer both high performance and enhanced safety is an ongoing area of research.

Scaling up production while maintaining consistency and quality is a substantial challenge for the industry. As demand for electrolytic cells grows, manufacturers must develop processes that can produce large quantities of cells with uniform properties and performance. This scaling issue is particularly pronounced for newer, more advanced cell designs.

Cost remains a significant barrier to widespread adoption of advanced electrolytic cell technologies. While prices have decreased over time, further reductions are necessary to compete with traditional energy storage solutions and fossil fuel technologies. This challenge extends to the entire supply chain, from raw material sourcing to manufacturing processes.

Lastly, the environmental impact of electrolytic cell production and disposal is a growing concern. Developing sustainable manufacturing processes and effective recycling methods for spent cells is crucial for the long-term viability of this technology. Addressing these environmental challenges is essential for truly sustainable energy storage solutions.

Existing Electrolytic Cell Innovations

01 Sustainable electrode materials

Development of sustainable electrode materials for electrolytic cells, focusing on renewable and environmentally friendly options. This includes the use of carbon-based materials, recycled metals, and novel composites that reduce the environmental impact of electrolytic processes while maintaining or improving efficiency.- Sustainable electrode materials: Development of sustainable electrode materials for electrolytic cells, focusing on environmentally friendly and recyclable options. This includes the use of novel materials that reduce environmental impact and improve the overall sustainability of electrolytic processes.

- Energy-efficient electrolytic cell designs: Innovations in electrolytic cell designs to enhance energy efficiency and reduce power consumption. These designs incorporate advanced technologies and optimized configurations to improve the sustainability of electrolytic processes by minimizing energy waste.

- Renewable energy integration: Integration of renewable energy sources with electrolytic cells to reduce reliance on fossil fuels and decrease carbon footprint. This approach combines sustainable power generation with electrolytic processes to create more environmentally friendly production methods.

- Waste reduction and recycling in electrolytic processes: Implementation of waste reduction strategies and recycling techniques in electrolytic cell operations. This includes the development of closed-loop systems and the recovery of valuable byproducts to minimize environmental impact and improve resource efficiency.

- Smart monitoring and control systems: Utilization of advanced monitoring and control systems to optimize electrolytic cell performance and sustainability. These smart systems employ sensors, data analytics, and automation to enhance efficiency, reduce waste, and prolong the lifespan of electrolytic cells.

02 Energy-efficient electrolytic processes

Implementation of energy-efficient electrolytic processes to reduce power consumption and improve sustainability. This involves optimizing cell design, enhancing electrolyte composition, and developing advanced control systems to minimize energy losses and maximize output, contributing to overall process sustainability.Expand Specific Solutions03 Waste reduction and recycling in electrolytic systems

Innovative approaches to reduce waste generation and promote recycling in electrolytic cell operations. This includes closed-loop systems for electrolyte recovery, byproduct utilization, and the integration of waste-to-energy technologies to minimize environmental impact and improve resource efficiency.Expand Specific Solutions04 Renewable energy integration in electrolytic processes

Integration of renewable energy sources to power electrolytic cells, enhancing the sustainability of the overall process. This involves developing smart grid connections, energy storage solutions, and adaptive control systems to efficiently utilize intermittent renewable energy sources like solar and wind power.Expand Specific Solutions05 Sustainable electrolyte formulations

Development of sustainable electrolyte formulations using environmentally friendly and biodegradable components. This includes research into bio-based electrolytes, ionic liquids, and water-based systems that reduce the environmental impact of electrolytic processes while maintaining or improving performance characteristics.Expand Specific Solutions

Key Players in Sustainable Battery Industry

The electrolytic cell design for sustainable batteries and energy storage is in a dynamic phase of development, with significant market potential driven by the growing demand for clean energy solutions. The industry is transitioning from early-stage research to commercial applications, with a market size expected to expand rapidly in the coming years. Technological maturity varies across different aspects of electrolytic cell design, with companies like Contemporary Amperex Technology Co., Ltd. and LG Energy Solution Ltd. leading in battery technology, while firms such as Power To Hydrogen LLC and C2CNT LLC focus on innovative electrolysis solutions. Research institutions like Xi'an Jiaotong University and Massachusetts Institute of Technology contribute to advancing fundamental understanding, fostering a competitive landscape that spans both academic and industrial sectors.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed innovative electrolytic cell designs for sustainable batteries, focusing on their CTP (cell-to-pack) technology. This approach integrates cells directly into the battery pack, eliminating the need for modules. Their latest iteration, CTP 3.0, achieves an energy density of up to 255 Wh/kg, significantly improving the range of electric vehicles[1]. CATL has also introduced sodium-ion batteries, which use abundant and low-cost materials, potentially offering a more sustainable alternative to lithium-ion batteries[2]. Their electrolytic cell design incorporates a unique hard carbon anode material and a redesigned cathode structure to optimize sodium ion storage and transport[3].

Strengths: High energy density, improved sustainability, cost-effective. Weaknesses: Sodium-ion technology still in early stages, potential challenges in scaling up production.

BASF Corp.

Technical Solution: BASF has made significant strides in electrolytic cell design for sustainable batteries, particularly in the development of high-nickel cathode active materials (CAM). Their innovative Nickel-Cobalt-Manganese (NCM) cathode materials have achieved energy densities exceeding 750 Wh/L at cell level[4]. BASF's electrolytic cell designs incorporate advanced coating technologies and particle engineering to enhance the stability and performance of these high-nickel cathodes. They have also developed novel electrolyte formulations that improve the interface between the cathode and the electrolyte, leading to enhanced cycle life and safety[5]. Additionally, BASF is exploring silicon-dominant anode materials, which could potentially increase the energy density of batteries by up to 20% compared to conventional graphite anodes[6].

Strengths: High energy density, improved safety, potential for significant performance gains. Weaknesses: High-nickel cathodes can be more expensive, potential supply chain challenges for some materials.

Breakthrough Electrolyte Materials and Designs

Electret Energy Storage System

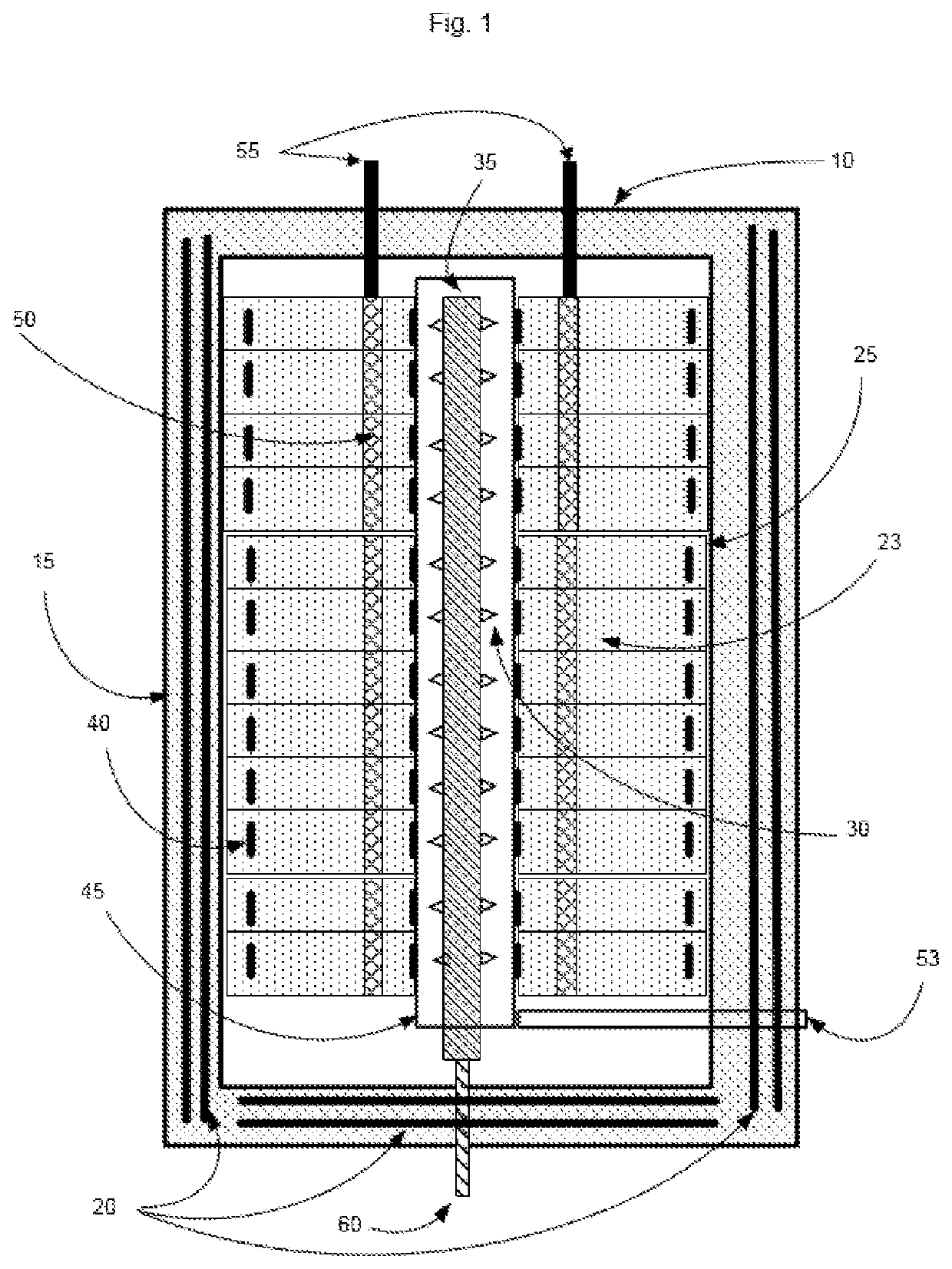

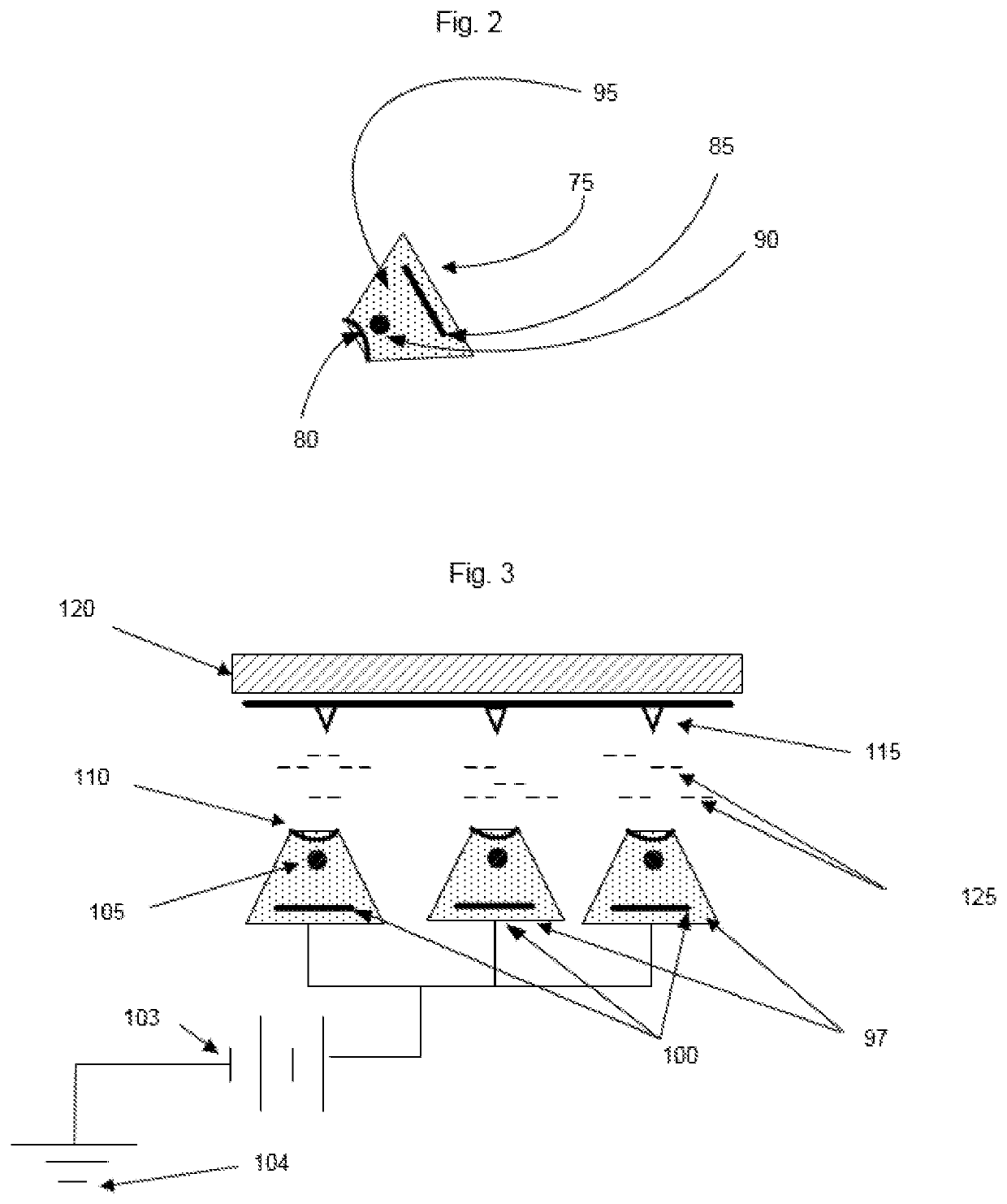

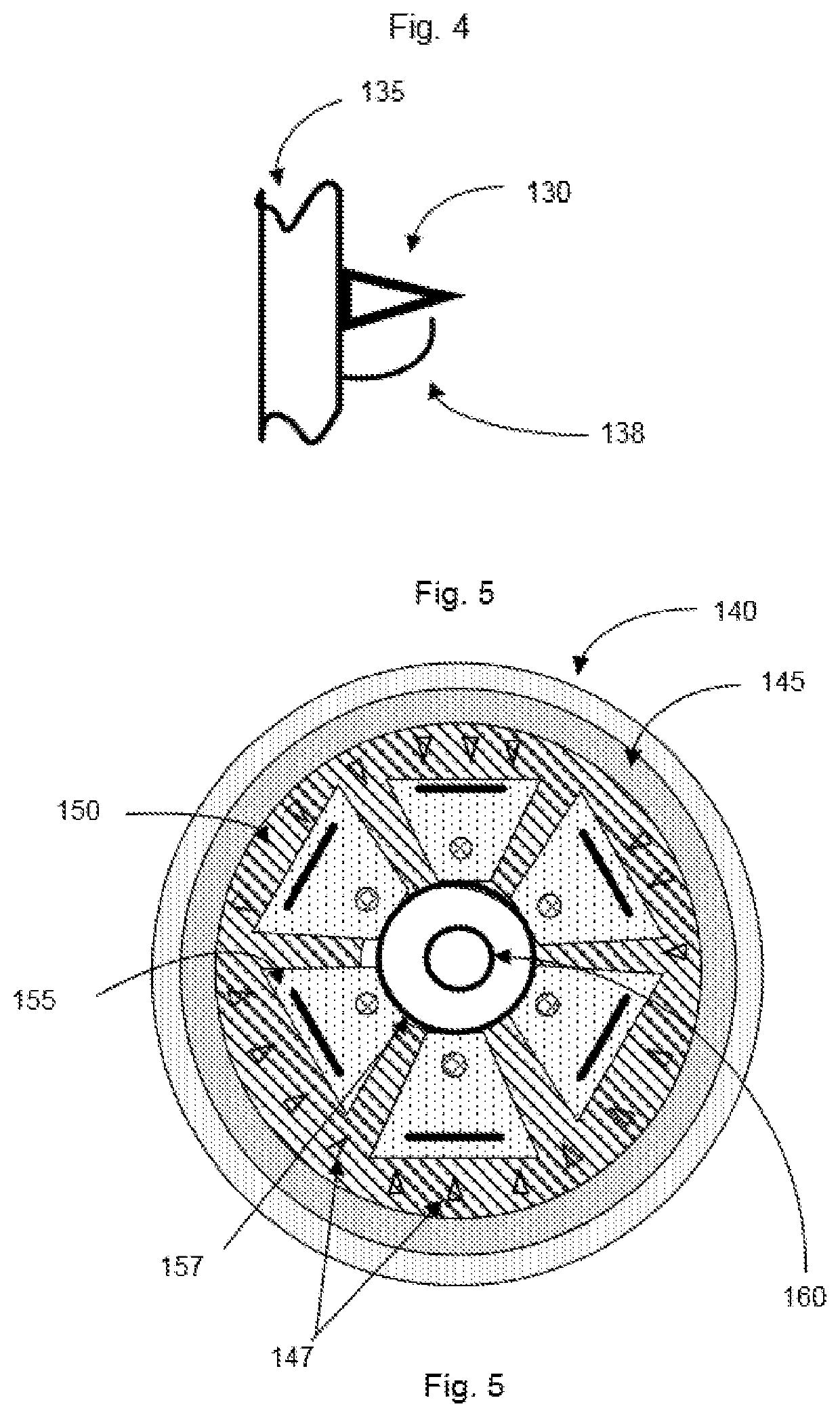

PatentActiveUS20200098525A1

Innovation

- The Electret Energy Storage System (EESS) integrates high voltage electret materials with traditional battery storage, utilizing energetic bremsstrahlung photons to create deep space charge electric fields for high energy density storage and employing magnetic fields, controlled humidity, and vacuum pressures to enhance energy retention and extraction efficiency.

Energy storage cell and production method

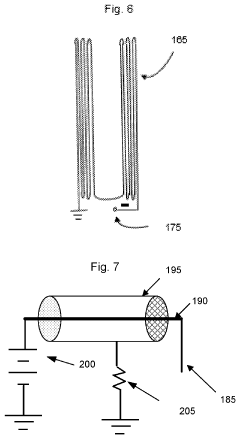

PatentWO2022034156A1

Innovation

- The energy storage cell design features a cylindrical coil configuration with strip-shaped electrodes and separators, a metallic tubular housing, and a contact element with a circular edge that functions as both a contact and a housing part, reducing internal resistance and enhancing heat dissipation through direct contact with the housing.

Environmental Impact Assessment

The environmental impact assessment of innovations in electrolytic cell design for sustainable batteries and energy storage is crucial for evaluating the long-term sustainability of these technologies. This assessment encompasses various aspects of the production, use, and disposal of electrolytic cells and their components.

One of the primary environmental considerations is the sourcing of raw materials for electrolytic cell production. The extraction of metals such as lithium, cobalt, and nickel can have significant ecological consequences, including habitat destruction, water pollution, and greenhouse gas emissions. Innovations in cell design that reduce the reliance on these materials or enable the use of more abundant, less environmentally impactful alternatives can greatly mitigate these concerns.

The manufacturing process of electrolytic cells also contributes to their environmental footprint. Energy-intensive production methods and the use of toxic chemicals in traditional cell fabrication can lead to air and water pollution. Advanced manufacturing techniques, such as additive manufacturing or green chemistry approaches, have the potential to reduce energy consumption and minimize harmful emissions during production.

During the operational phase, the environmental impact of electrolytic cells is closely tied to their efficiency and longevity. Innovations that improve energy conversion efficiency and extend the lifespan of cells can significantly reduce the overall environmental burden by decreasing the frequency of replacement and the associated resource consumption.

End-of-life considerations are equally important in the environmental assessment. The recyclability of cell components and the potential for second-life applications are critical factors. Innovations in cell design that facilitate easy disassembly and material recovery can promote a circular economy approach, reducing waste and the need for virgin material extraction.

The potential for unintended environmental consequences must also be evaluated. For instance, the increased use of certain materials in novel cell designs may lead to new environmental challenges, such as the accumulation of previously uncommon elements in ecosystems. Comprehensive life cycle assessments are essential to identify and address these potential issues.

Lastly, the broader environmental benefits of improved electrolytic cell designs should be considered. By enabling more efficient and widespread energy storage, these innovations can accelerate the transition to renewable energy sources, potentially leading to significant reductions in greenhouse gas emissions and other pollutants associated with fossil fuel-based energy systems.

One of the primary environmental considerations is the sourcing of raw materials for electrolytic cell production. The extraction of metals such as lithium, cobalt, and nickel can have significant ecological consequences, including habitat destruction, water pollution, and greenhouse gas emissions. Innovations in cell design that reduce the reliance on these materials or enable the use of more abundant, less environmentally impactful alternatives can greatly mitigate these concerns.

The manufacturing process of electrolytic cells also contributes to their environmental footprint. Energy-intensive production methods and the use of toxic chemicals in traditional cell fabrication can lead to air and water pollution. Advanced manufacturing techniques, such as additive manufacturing or green chemistry approaches, have the potential to reduce energy consumption and minimize harmful emissions during production.

During the operational phase, the environmental impact of electrolytic cells is closely tied to their efficiency and longevity. Innovations that improve energy conversion efficiency and extend the lifespan of cells can significantly reduce the overall environmental burden by decreasing the frequency of replacement and the associated resource consumption.

End-of-life considerations are equally important in the environmental assessment. The recyclability of cell components and the potential for second-life applications are critical factors. Innovations in cell design that facilitate easy disassembly and material recovery can promote a circular economy approach, reducing waste and the need for virgin material extraction.

The potential for unintended environmental consequences must also be evaluated. For instance, the increased use of certain materials in novel cell designs may lead to new environmental challenges, such as the accumulation of previously uncommon elements in ecosystems. Comprehensive life cycle assessments are essential to identify and address these potential issues.

Lastly, the broader environmental benefits of improved electrolytic cell designs should be considered. By enabling more efficient and widespread energy storage, these innovations can accelerate the transition to renewable energy sources, potentially leading to significant reductions in greenhouse gas emissions and other pollutants associated with fossil fuel-based energy systems.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for innovations in electrolytic cell design for sustainable batteries and energy storage are crucial factors in determining the feasibility and commercial viability of new technologies. As the demand for sustainable energy storage solutions continues to grow, the ability to scale up production and implement cost-effective manufacturing processes becomes increasingly important.

One of the primary challenges in scaling up electrolytic cell production is maintaining consistent quality and performance across large-scale manufacturing. This requires careful control of materials, processes, and environmental conditions throughout the production line. Advanced automation and quality control systems are essential to ensure uniformity and reliability in cell production, particularly when dealing with novel materials or complex cell designs.

The selection of materials for electrolytic cells also plays a significant role in scalability and manufacturing considerations. Researchers and engineers must balance performance requirements with material availability, cost, and processability. Sustainable battery technologies often involve the use of abundant and environmentally friendly materials, which may require the development of new manufacturing techniques or the adaptation of existing processes.

Another critical aspect is the optimization of cell assembly processes. This includes the development of efficient electrode coating methods, electrolyte filling techniques, and sealing processes. Innovations in these areas can significantly impact production speed, yield, and overall manufacturing costs. For instance, advancements in roll-to-roll manufacturing techniques have shown promise in improving the scalability of certain battery technologies.

Energy consumption during manufacturing is an important consideration, especially for sustainable energy storage solutions. Developing energy-efficient production methods and integrating renewable energy sources into manufacturing processes can help reduce the overall environmental impact of battery production. This aligns with the broader goals of sustainable energy storage and can contribute to the marketability of the final product.

The ability to rapidly prototype and iterate on cell designs is crucial for accelerating innovation and scaling up production. Advanced modeling and simulation tools, coupled with flexible manufacturing systems, allow for faster design cycles and more efficient optimization of cell performance and manufacturability. This approach can significantly reduce the time and resources required to bring new electrolytic cell designs from concept to commercial production.

Lastly, considerations for end-of-life management and recyclability must be integrated into the manufacturing process from the outset. Designing cells and production processes with recycling in mind can improve the overall sustainability of the technology and potentially reduce long-term costs associated with material sourcing and waste management.

One of the primary challenges in scaling up electrolytic cell production is maintaining consistent quality and performance across large-scale manufacturing. This requires careful control of materials, processes, and environmental conditions throughout the production line. Advanced automation and quality control systems are essential to ensure uniformity and reliability in cell production, particularly when dealing with novel materials or complex cell designs.

The selection of materials for electrolytic cells also plays a significant role in scalability and manufacturing considerations. Researchers and engineers must balance performance requirements with material availability, cost, and processability. Sustainable battery technologies often involve the use of abundant and environmentally friendly materials, which may require the development of new manufacturing techniques or the adaptation of existing processes.

Another critical aspect is the optimization of cell assembly processes. This includes the development of efficient electrode coating methods, electrolyte filling techniques, and sealing processes. Innovations in these areas can significantly impact production speed, yield, and overall manufacturing costs. For instance, advancements in roll-to-roll manufacturing techniques have shown promise in improving the scalability of certain battery technologies.

Energy consumption during manufacturing is an important consideration, especially for sustainable energy storage solutions. Developing energy-efficient production methods and integrating renewable energy sources into manufacturing processes can help reduce the overall environmental impact of battery production. This aligns with the broader goals of sustainable energy storage and can contribute to the marketability of the final product.

The ability to rapidly prototype and iterate on cell designs is crucial for accelerating innovation and scaling up production. Advanced modeling and simulation tools, coupled with flexible manufacturing systems, allow for faster design cycles and more efficient optimization of cell performance and manufacturability. This approach can significantly reduce the time and resources required to bring new electrolytic cell designs from concept to commercial production.

Lastly, considerations for end-of-life management and recyclability must be integrated into the manufacturing process from the outset. Designing cells and production processes with recycling in mind can improve the overall sustainability of the technology and potentially reduce long-term costs associated with material sourcing and waste management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!