Innovations in PMSM rotor design techniques

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Rotor Evolution

The evolution of Permanent Magnet Synchronous Motor (PMSM) rotor design has been a critical factor in the advancement of electric motor technology. Initially, PMSM rotors featured simple surface-mounted permanent magnets, which provided basic performance but were limited in terms of efficiency and power density.

As demand for higher performance motors grew, engineers developed interior permanent magnet (IPM) designs. These configurations embedded magnets within the rotor structure, offering improved mechanical integrity and allowing for the exploitation of reluctance torque. This innovation marked a significant leap in PMSM capabilities, enabling higher torque production and better efficiency across a wider speed range.

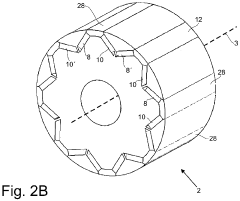

The next major evolution came with the introduction of multi-layer IPM designs. By strategically placing multiple layers of magnets within the rotor, designers could optimize the magnetic flux distribution and further enhance motor performance. This approach allowed for finer control over torque characteristics and improved the overall power density of PMSM systems.

Advancements in materials science played a crucial role in rotor evolution. The development of high-energy permanent magnets, particularly neodymium-iron-boron (NdFeB) magnets, revolutionized PMSM design. These materials enabled the creation of more compact and powerful rotors, significantly boosting the power-to-weight ratio of electric motors.

Computational modeling and simulation tools have been instrumental in pushing PMSM rotor design forward. Finite element analysis (FEA) and magnetic field simulation software have allowed engineers to optimize rotor geometries with unprecedented precision. This has led to the development of complex rotor structures that maximize torque production while minimizing losses.

Recent innovations have focused on addressing the challenges of high-speed operation and thermal management. Novel rotor designs incorporating advanced cooling techniques and mechanical reinforcement have emerged, enabling PMSMs to operate efficiently at higher speeds and under more demanding conditions.

The trend towards modular and scalable designs has also influenced rotor evolution. Manufacturers have developed standardized rotor architectures that can be easily adapted to different motor sizes and applications, streamlining production processes and reducing costs.

As environmental concerns grow, there has been a push towards more sustainable PMSM rotor designs. This has led to research into alternative magnet materials and rotor configurations that reduce reliance on rare earth elements while maintaining high performance standards.

As demand for higher performance motors grew, engineers developed interior permanent magnet (IPM) designs. These configurations embedded magnets within the rotor structure, offering improved mechanical integrity and allowing for the exploitation of reluctance torque. This innovation marked a significant leap in PMSM capabilities, enabling higher torque production and better efficiency across a wider speed range.

The next major evolution came with the introduction of multi-layer IPM designs. By strategically placing multiple layers of magnets within the rotor, designers could optimize the magnetic flux distribution and further enhance motor performance. This approach allowed for finer control over torque characteristics and improved the overall power density of PMSM systems.

Advancements in materials science played a crucial role in rotor evolution. The development of high-energy permanent magnets, particularly neodymium-iron-boron (NdFeB) magnets, revolutionized PMSM design. These materials enabled the creation of more compact and powerful rotors, significantly boosting the power-to-weight ratio of electric motors.

Computational modeling and simulation tools have been instrumental in pushing PMSM rotor design forward. Finite element analysis (FEA) and magnetic field simulation software have allowed engineers to optimize rotor geometries with unprecedented precision. This has led to the development of complex rotor structures that maximize torque production while minimizing losses.

Recent innovations have focused on addressing the challenges of high-speed operation and thermal management. Novel rotor designs incorporating advanced cooling techniques and mechanical reinforcement have emerged, enabling PMSMs to operate efficiently at higher speeds and under more demanding conditions.

The trend towards modular and scalable designs has also influenced rotor evolution. Manufacturers have developed standardized rotor architectures that can be easily adapted to different motor sizes and applications, streamlining production processes and reducing costs.

As environmental concerns grow, there has been a push towards more sustainable PMSM rotor designs. This has led to research into alternative magnet materials and rotor configurations that reduce reliance on rare earth elements while maintaining high performance standards.

Market Demand Analysis

The market demand for innovations in PMSM rotor design techniques has been steadily increasing in recent years, driven by the growing adoption of electric vehicles (EVs) and the push for more efficient industrial motors. As governments worldwide implement stricter emissions regulations and set ambitious targets for EV adoption, automakers are intensifying their focus on developing high-performance electric powertrains. This has created a significant demand for advanced PMSM technologies that can deliver improved efficiency, power density, and cost-effectiveness.

In the automotive sector, the global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years. This rapid expansion is directly translating into increased demand for PMSM motors, which are preferred for their high efficiency and power density. Innovations in rotor design techniques are crucial for meeting the automotive industry's requirements for longer driving ranges, faster acceleration, and reduced vehicle weight.

The industrial motor market is another key driver for PMSM rotor design innovations. With energy efficiency becoming a top priority for manufacturers, there is a growing trend towards replacing traditional induction motors with PMSMs in various applications such as pumps, fans, and compressors. The global industrial motor market is expected to reach a value of several billion dollars by 2025, with PMSMs capturing an increasing share due to their superior performance characteristics.

In the renewable energy sector, particularly wind power generation, there is a rising demand for large-scale PMSMs with advanced rotor designs. As wind turbines grow in size and capacity, the need for more efficient and reliable generators becomes paramount. This market segment presents significant opportunities for innovations in PMSM rotor design techniques that can enhance power output and reduce maintenance requirements.

The aerospace industry is also showing increased interest in PMSM technologies for electric propulsion systems. With the concept of electric aircraft gaining traction, there is a growing demand for lightweight, high-power-density motors that can meet the stringent requirements of aviation applications. This sector is expected to drive further innovations in PMSM rotor design, particularly in areas such as thermal management and high-speed operation.

From a geographical perspective, Asia-Pacific is emerging as a major market for PMSM technologies, driven by the rapid growth of EV production in countries like China and the strong presence of industrial manufacturing. North America and Europe are also significant markets, with a focus on high-end applications and advanced research and development activities.

Overall, the market demand for innovations in PMSM rotor design techniques is robust and diverse, spanning multiple industries and geographical regions. As technology continues to advance and new applications emerge, this demand is expected to further intensify, creating opportunities for companies and researchers to develop cutting-edge solutions in this field.

In the automotive sector, the global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years. This rapid expansion is directly translating into increased demand for PMSM motors, which are preferred for their high efficiency and power density. Innovations in rotor design techniques are crucial for meeting the automotive industry's requirements for longer driving ranges, faster acceleration, and reduced vehicle weight.

The industrial motor market is another key driver for PMSM rotor design innovations. With energy efficiency becoming a top priority for manufacturers, there is a growing trend towards replacing traditional induction motors with PMSMs in various applications such as pumps, fans, and compressors. The global industrial motor market is expected to reach a value of several billion dollars by 2025, with PMSMs capturing an increasing share due to their superior performance characteristics.

In the renewable energy sector, particularly wind power generation, there is a rising demand for large-scale PMSMs with advanced rotor designs. As wind turbines grow in size and capacity, the need for more efficient and reliable generators becomes paramount. This market segment presents significant opportunities for innovations in PMSM rotor design techniques that can enhance power output and reduce maintenance requirements.

The aerospace industry is also showing increased interest in PMSM technologies for electric propulsion systems. With the concept of electric aircraft gaining traction, there is a growing demand for lightweight, high-power-density motors that can meet the stringent requirements of aviation applications. This sector is expected to drive further innovations in PMSM rotor design, particularly in areas such as thermal management and high-speed operation.

From a geographical perspective, Asia-Pacific is emerging as a major market for PMSM technologies, driven by the rapid growth of EV production in countries like China and the strong presence of industrial manufacturing. North America and Europe are also significant markets, with a focus on high-end applications and advanced research and development activities.

Overall, the market demand for innovations in PMSM rotor design techniques is robust and diverse, spanning multiple industries and geographical regions. As technology continues to advance and new applications emerge, this demand is expected to further intensify, creating opportunities for companies and researchers to develop cutting-edge solutions in this field.

Technical Challenges

The development of Permanent Magnet Synchronous Motors (PMSM) has been a significant focus in the field of electric motors, with rotor design playing a crucial role in enhancing performance. However, several technical challenges persist in PMSM rotor design, hindering further advancements in this technology.

One of the primary challenges is the optimization of magnetic field distribution. The arrangement of permanent magnets on the rotor significantly impacts the motor's efficiency and torque characteristics. Achieving a uniform magnetic field distribution while minimizing cogging torque and torque ripple remains a complex task, requiring sophisticated design techniques and advanced simulation tools.

Thermal management presents another significant hurdle in PMSM rotor design. As motor power density increases, so does the heat generated within the rotor. Excessive heat can lead to demagnetization of the permanent magnets, reducing motor performance and lifespan. Developing effective cooling strategies and selecting materials with superior thermal properties are ongoing challenges for engineers.

The mechanical integrity of the rotor structure is a critical concern, especially in high-speed applications. Centrifugal forces can cause rotor deformation or even failure if not properly addressed. Balancing the need for a robust mechanical design with the requirements for optimal magnetic performance often involves complex trade-offs.

Material selection and optimization continue to pose challenges in PMSM rotor design. While rare-earth magnets offer excellent magnetic properties, their cost and supply chain vulnerabilities have led to a search for alternative materials. Developing rotors with reduced rare-earth content or utilizing novel magnetic materials without compromising performance is an active area of research.

Manufacturing complexities associated with PMSM rotors present additional technical hurdles. Precise magnet placement, magnetization processes, and rotor assembly techniques require advanced manufacturing capabilities. Improving production efficiency while maintaining tight tolerances and ensuring consistent quality across large-scale manufacturing remains challenging.

Lastly, the integration of sensors and control systems within the rotor design adds another layer of complexity. Accurate rotor position sensing is crucial for optimal motor control, but incorporating sensors without compromising the rotor's magnetic or mechanical properties is a delicate balance.

Addressing these technical challenges requires interdisciplinary approaches, combining expertise in electromagnetics, materials science, thermal engineering, and manufacturing processes. As researchers and engineers continue to innovate, overcoming these hurdles will pave the way for more efficient, reliable, and cost-effective PMSM designs in various applications.

One of the primary challenges is the optimization of magnetic field distribution. The arrangement of permanent magnets on the rotor significantly impacts the motor's efficiency and torque characteristics. Achieving a uniform magnetic field distribution while minimizing cogging torque and torque ripple remains a complex task, requiring sophisticated design techniques and advanced simulation tools.

Thermal management presents another significant hurdle in PMSM rotor design. As motor power density increases, so does the heat generated within the rotor. Excessive heat can lead to demagnetization of the permanent magnets, reducing motor performance and lifespan. Developing effective cooling strategies and selecting materials with superior thermal properties are ongoing challenges for engineers.

The mechanical integrity of the rotor structure is a critical concern, especially in high-speed applications. Centrifugal forces can cause rotor deformation or even failure if not properly addressed. Balancing the need for a robust mechanical design with the requirements for optimal magnetic performance often involves complex trade-offs.

Material selection and optimization continue to pose challenges in PMSM rotor design. While rare-earth magnets offer excellent magnetic properties, their cost and supply chain vulnerabilities have led to a search for alternative materials. Developing rotors with reduced rare-earth content or utilizing novel magnetic materials without compromising performance is an active area of research.

Manufacturing complexities associated with PMSM rotors present additional technical hurdles. Precise magnet placement, magnetization processes, and rotor assembly techniques require advanced manufacturing capabilities. Improving production efficiency while maintaining tight tolerances and ensuring consistent quality across large-scale manufacturing remains challenging.

Lastly, the integration of sensors and control systems within the rotor design adds another layer of complexity. Accurate rotor position sensing is crucial for optimal motor control, but incorporating sensors without compromising the rotor's magnetic or mechanical properties is a delicate balance.

Addressing these technical challenges requires interdisciplinary approaches, combining expertise in electromagnetics, materials science, thermal engineering, and manufacturing processes. As researchers and engineers continue to innovate, overcoming these hurdles will pave the way for more efficient, reliable, and cost-effective PMSM designs in various applications.

Current Design Solutions

01 Rotor design and construction

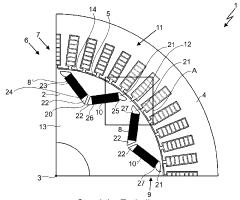

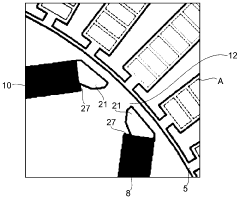

PMSM rotors are designed and constructed with specific configurations to optimize performance. This includes the arrangement of permanent magnets, the use of various materials for the rotor core, and the overall structure of the rotor to enhance efficiency and power output.- Rotor design and construction: PMSM rotors are designed with specific configurations to optimize performance. This includes the arrangement of permanent magnets, core materials, and overall structure to enhance efficiency and power output. Various design techniques are employed to reduce cogging torque and improve overall motor characteristics.

- Magnet arrangement and optimization: The arrangement of permanent magnets in PMSM rotors is crucial for performance. Different magnet configurations, such as surface-mounted, interior, or hybrid designs, are used to achieve desired characteristics. Optimization techniques are applied to determine the best magnet placement, shape, and material for specific applications.

- Thermal management and cooling: Effective thermal management is essential for PMSM rotors to maintain performance and longevity. Various cooling methods and heat dissipation techniques are employed to prevent overheating and maintain optimal operating temperatures. This includes the use of specialized materials and design features to enhance heat transfer.

- Manufacturing processes and materials: Advanced manufacturing processes and materials are used in PMSM rotor production to enhance performance and reliability. This includes the use of specialized alloys, composite materials, and precision manufacturing techniques to achieve desired magnetic properties and mechanical strength.

- Rotor balancing and vibration reduction: Techniques for balancing PMSM rotors and reducing vibration are crucial for smooth operation and longevity. This involves precise manufacturing, assembly methods, and the use of specialized balancing equipment to minimize mechanical stress and noise during operation.

02 Magnet arrangement and optimization

The arrangement of permanent magnets in PMSM rotors is crucial for performance. Various techniques are employed to optimize magnet placement, including buried magnet configurations, surface-mounted magnets, and hybrid designs. These arrangements aim to improve flux distribution and reduce cogging torque.Expand Specific Solutions03 Thermal management and cooling systems

Effective thermal management is essential for PMSM rotors to maintain performance and longevity. Cooling systems and heat dissipation methods are implemented to regulate temperature and prevent demagnetization of the permanent magnets during operation.Expand Specific Solutions04 Manufacturing processes and assembly techniques

Advanced manufacturing processes and assembly techniques are employed in the production of PMSM rotors. These may include precision machining, automated assembly, and specialized bonding methods to ensure high-quality construction and consistent performance.Expand Specific Solutions05 Rotor balancing and vibration reduction

Balancing techniques and vibration reduction methods are applied to PMSM rotors to enhance smooth operation and minimize wear. This includes dynamic balancing, structural optimization, and the use of damping materials to reduce noise and extend the motor's lifespan.Expand Specific Solutions

Key Industry Players

The market for innovations in PMSM rotor design techniques is in a growth phase, driven by increasing demand for high-efficiency electric motors across various industries. The global market size for PMSM is expanding rapidly, with key players like ABB Group, Rockwell Automation, and BYD Co., Ltd. leading the way. The technology is maturing, with companies such as Toyota Motor Corp. and Hyundai Motor Co., Ltd. investing heavily in research and development. Automotive giants like GM Global Technology Operations LLC and Volkswagen AG are also actively pursuing advancements in this field, indicating a competitive landscape with significant potential for further innovation and market expansion.

ABB Group

Technical Solution: ABB Group has developed innovative PMSM rotor designs focusing on high-efficiency and compact solutions. Their approach includes the use of advanced magnetic materials and optimized rotor geometries. ABB's SynRM² technology combines synchronous reluctance and permanent magnet motor principles, resulting in a hybrid design that offers improved efficiency and power density[1]. The company has also implemented segmented magnet arrangements to reduce eddy current losses and improve thermal management[2]. Additionally, ABB has explored the use of Halbach array configurations in PMSM rotors, which enhances the magnetic field distribution and reduces cogging torque[3].

Strengths: High efficiency, compact design, reduced losses. Weaknesses: Potentially higher manufacturing costs, complexity in assembly.

Rockwell Automation Technologies, Inc.

Technical Solution: Rockwell Automation has focused on PMSM rotor innovations for industrial applications. Their approach includes the development of modular rotor designs that allow for easier customization and maintenance. Rockwell has implemented advanced cooling techniques, such as oil spray cooling, to improve thermal management in high-power density motors[4]. They have also explored the use of composite materials in rotor construction to reduce weight and inertia. Rockwell's PMSM designs often incorporate skewed rotor configurations to minimize torque ripple and acoustic noise[5].

Strengths: Modular design, improved thermal management, reduced noise and vibration. Weaknesses: Potential increase in manufacturing complexity, higher initial costs.

Core Rotor Innovations

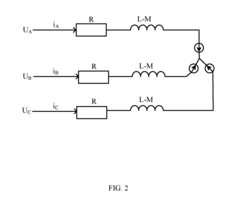

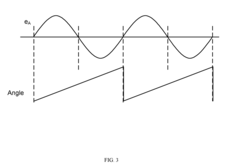

Driving circuit and driving method for permanent magnet synchronous motor

PatentActiveUS20170085196A1

Innovation

- A driving circuit and method that includes a current sampling circuit, back electromotive force (BEMF) circuit, and torque regulating circuit to estimate BEMF information and regulate the amplitude of a U-shaped modulation wave, allowing for maximum torque per ampere without a position sensor, using a sliding mode controller and PID regulator to synchronize rotor current with the modulation wave.

Permanent magnet synchronous motor

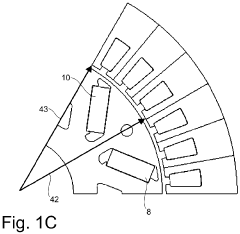

PatentPendingDE102021133591A1

Innovation

- Integration of a permanent magnet arrangement with two distinct magnet units into the rotor, enhancing magnetic field distribution and motor performance.

- Implementation of a non-magnetic solid material rotor bridge, connecting the magnets and rotor stack, improving structural integrity and reducing magnetic flux leakage.

- Non-positive connection between the rotor bridge, magnets, and rotor stack, potentially allowing for easier assembly and maintenance.

Material Advancements

Material advancements have played a crucial role in enhancing the performance and efficiency of Permanent Magnet Synchronous Motors (PMSMs), particularly in rotor design. Recent innovations in this field have focused on developing new magnetic materials and improving existing ones to achieve higher power density, better thermal stability, and increased reliability.

One of the most significant developments has been the introduction of rare-earth-based permanent magnets, such as Neodymium-Iron-Boron (NdFeB) and Samarium-Cobalt (SmCo). These materials offer superior magnetic properties, including high remanence and coercivity, which allow for more compact and powerful PMSM designs. NdFeB magnets, in particular, have become the preferred choice for many high-performance applications due to their exceptional magnetic strength-to-weight ratio.

To address the temperature sensitivity of NdFeB magnets, researchers have developed advanced compositions with added elements like Dysprosium (Dy) and Terbium (Tb). These additives improve the magnets' thermal stability and coercivity at elevated temperatures, expanding their usability in demanding environments such as automotive and aerospace applications.

Another area of material advancement is the development of nanocomposite magnetic materials. These materials combine the high remanence of soft magnetic phases with the high coercivity of hard magnetic phases at the nanoscale. This approach has the potential to create magnets with energy products exceeding those of conventional single-phase magnets, potentially revolutionizing PMSM rotor design.

Soft magnetic materials used in PMSM rotors have also seen significant improvements. Advanced silicon steel alloys with reduced core losses and improved magnetic permeability have been developed, enhancing the overall efficiency of the motor. Additionally, amorphous and nanocrystalline soft magnetic materials are being explored for their potential to further reduce core losses and improve high-frequency performance.

Researchers are also investigating the use of additive manufacturing techniques to create novel rotor structures with optimized magnetic circuits. This approach allows for the precise placement of magnetic materials and the creation of complex geometries that were previously difficult or impossible to manufacture using traditional methods.

Efforts to reduce the reliance on rare-earth elements have led to the development of alternative magnetic materials. Ferrite magnets, while less powerful than rare-earth magnets, are being improved and optimized for use in specific PMSM applications where cost and resource availability are critical factors. Additionally, research into manganese-based compounds and other non-rare-earth magnetic materials shows promise for future PMSM designs.

These material advancements are not only improving the performance of PMSMs but also addressing sustainability concerns by focusing on recyclability and reduced environmental impact. As research in this field continues, we can expect further innovations that will push the boundaries of PMSM rotor design and performance.

One of the most significant developments has been the introduction of rare-earth-based permanent magnets, such as Neodymium-Iron-Boron (NdFeB) and Samarium-Cobalt (SmCo). These materials offer superior magnetic properties, including high remanence and coercivity, which allow for more compact and powerful PMSM designs. NdFeB magnets, in particular, have become the preferred choice for many high-performance applications due to their exceptional magnetic strength-to-weight ratio.

To address the temperature sensitivity of NdFeB magnets, researchers have developed advanced compositions with added elements like Dysprosium (Dy) and Terbium (Tb). These additives improve the magnets' thermal stability and coercivity at elevated temperatures, expanding their usability in demanding environments such as automotive and aerospace applications.

Another area of material advancement is the development of nanocomposite magnetic materials. These materials combine the high remanence of soft magnetic phases with the high coercivity of hard magnetic phases at the nanoscale. This approach has the potential to create magnets with energy products exceeding those of conventional single-phase magnets, potentially revolutionizing PMSM rotor design.

Soft magnetic materials used in PMSM rotors have also seen significant improvements. Advanced silicon steel alloys with reduced core losses and improved magnetic permeability have been developed, enhancing the overall efficiency of the motor. Additionally, amorphous and nanocrystalline soft magnetic materials are being explored for their potential to further reduce core losses and improve high-frequency performance.

Researchers are also investigating the use of additive manufacturing techniques to create novel rotor structures with optimized magnetic circuits. This approach allows for the precise placement of magnetic materials and the creation of complex geometries that were previously difficult or impossible to manufacture using traditional methods.

Efforts to reduce the reliance on rare-earth elements have led to the development of alternative magnetic materials. Ferrite magnets, while less powerful than rare-earth magnets, are being improved and optimized for use in specific PMSM applications where cost and resource availability are critical factors. Additionally, research into manganese-based compounds and other non-rare-earth magnetic materials shows promise for future PMSM designs.

These material advancements are not only improving the performance of PMSMs but also addressing sustainability concerns by focusing on recyclability and reduced environmental impact. As research in this field continues, we can expect further innovations that will push the boundaries of PMSM rotor design and performance.

Efficiency Benchmarks

Efficiency benchmarks play a crucial role in evaluating the performance of Permanent Magnet Synchronous Motor (PMSM) rotor designs. These benchmarks provide a standardized framework for comparing different innovations and assessing their impact on overall motor efficiency.

One of the primary efficiency benchmarks for PMSM rotors is the power factor, which measures the ratio of real power to apparent power. Higher power factors indicate better utilization of the motor's capacity and reduced reactive power consumption. Advanced rotor designs aim to achieve power factors above 0.9, with some cutting-edge innovations pushing towards 0.95 or higher.

Another key benchmark is the torque density, expressed in Newton-meters per kilogram (Nm/kg). This metric quantifies the motor's ability to produce torque relative to its weight. State-of-the-art PMSM rotor designs have achieved torque densities exceeding 10 Nm/kg, with ongoing research targeting even higher values through innovative magnet arrangements and material selections.

Energy efficiency, typically measured as a percentage, is perhaps the most critical benchmark for PMSM rotors. Modern designs routinely achieve efficiencies above 90%, with premium efficiency motors reaching 95% or higher. The pursuit of higher efficiency drives much of the innovation in rotor design, as even small improvements can lead to significant energy savings over the motor's lifetime.

Thermal performance is another essential benchmark, often quantified by the maximum continuous operating temperature. Advanced rotor designs aim to maintain stable performance at temperatures exceeding 150°C, with some pushing the boundaries to 180°C or higher. This benchmark is particularly important for applications in harsh environments or those requiring high power density.

Speed range is a critical efficiency benchmark, especially for variable speed applications. The constant power speed range (CPSR) is often used to evaluate a motor's performance across different operating conditions. High-performance PMSM rotors can achieve CPSRs of 3:1 or greater, with some advanced designs reaching 5:1 or higher.

Cogging torque, measured in Newton-meters or as a percentage of rated torque, is an important benchmark for smooth operation, particularly at low speeds. Innovative rotor designs strive to minimize cogging torque, with some achieving values below 1% of rated torque through careful magnet shaping and skewing techniques.

These efficiency benchmarks serve as guideposts for researchers and engineers working on PMSM rotor innovations. They provide quantifiable targets for improvement and allow for objective comparisons between different design approaches. As the field continues to advance, these benchmarks are likely to evolve, driving further innovation and pushing the boundaries of what is possible in electric motor technology.

One of the primary efficiency benchmarks for PMSM rotors is the power factor, which measures the ratio of real power to apparent power. Higher power factors indicate better utilization of the motor's capacity and reduced reactive power consumption. Advanced rotor designs aim to achieve power factors above 0.9, with some cutting-edge innovations pushing towards 0.95 or higher.

Another key benchmark is the torque density, expressed in Newton-meters per kilogram (Nm/kg). This metric quantifies the motor's ability to produce torque relative to its weight. State-of-the-art PMSM rotor designs have achieved torque densities exceeding 10 Nm/kg, with ongoing research targeting even higher values through innovative magnet arrangements and material selections.

Energy efficiency, typically measured as a percentage, is perhaps the most critical benchmark for PMSM rotors. Modern designs routinely achieve efficiencies above 90%, with premium efficiency motors reaching 95% or higher. The pursuit of higher efficiency drives much of the innovation in rotor design, as even small improvements can lead to significant energy savings over the motor's lifetime.

Thermal performance is another essential benchmark, often quantified by the maximum continuous operating temperature. Advanced rotor designs aim to maintain stable performance at temperatures exceeding 150°C, with some pushing the boundaries to 180°C or higher. This benchmark is particularly important for applications in harsh environments or those requiring high power density.

Speed range is a critical efficiency benchmark, especially for variable speed applications. The constant power speed range (CPSR) is often used to evaluate a motor's performance across different operating conditions. High-performance PMSM rotors can achieve CPSRs of 3:1 or greater, with some advanced designs reaching 5:1 or higher.

Cogging torque, measured in Newton-meters or as a percentage of rated torque, is an important benchmark for smooth operation, particularly at low speeds. Innovative rotor designs strive to minimize cogging torque, with some achieving values below 1% of rated torque through careful magnet shaping and skewing techniques.

These efficiency benchmarks serve as guideposts for researchers and engineers working on PMSM rotor innovations. They provide quantifiable targets for improvement and allow for objective comparisons between different design approaches. As the field continues to advance, these benchmarks are likely to evolve, driving further innovation and pushing the boundaries of what is possible in electric motor technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!