Integration of PMSM in offshore drilling operations

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM in Offshore Drilling: Background and Objectives

Permanent Magnet Synchronous Motors (PMSMs) have emerged as a promising technology in the offshore drilling industry, offering significant advantages over traditional motor systems. The integration of PMSMs in offshore drilling operations represents a critical advancement in improving efficiency, reliability, and environmental sustainability of drilling processes.

The evolution of motor technology in offshore drilling has been driven by the need for more powerful, compact, and energy-efficient solutions. Historically, the industry relied on conventional induction motors and hydraulic systems, which often struggled to meet the demanding requirements of deep-sea operations. PMSMs, with their high power density, precise control capabilities, and excellent efficiency, have become increasingly attractive for offshore applications.

The primary objective of integrating PMSMs in offshore drilling is to enhance overall system performance while reducing operational costs and environmental impact. These motors offer superior torque characteristics, allowing for more precise control of drilling equipment, which is crucial in challenging offshore environments. Additionally, their compact design helps to optimize space utilization on offshore platforms, where real estate is at a premium.

Another key goal is to improve energy efficiency in drilling operations. PMSMs are known for their high efficiency across a wide range of operating conditions, which can lead to significant reductions in power consumption. This not only reduces operational costs but also aligns with the industry's growing focus on sustainability and reducing carbon footprint.

The integration of PMSMs also aims to enhance the reliability and durability of drilling systems. Offshore environments are notoriously harsh, with extreme temperatures, high humidity, and corrosive conditions. PMSMs, with their simpler construction and fewer wear-prone components compared to traditional motors, offer improved reliability and reduced maintenance requirements, which is crucial for minimizing downtime in offshore operations.

Furthermore, the adoption of PMSMs in offshore drilling is part of a broader trend towards electrification and digitalization in the oil and gas industry. This transition seeks to leverage advanced control systems and data analytics to optimize drilling processes, improve safety, and increase overall operational efficiency.

As the offshore drilling industry continues to push into deeper waters and more challenging environments, the role of advanced motor technologies like PMSMs becomes increasingly critical. The successful integration of these motors is expected to play a pivotal role in enabling more efficient, reliable, and environmentally friendly drilling operations in the coming years.

The evolution of motor technology in offshore drilling has been driven by the need for more powerful, compact, and energy-efficient solutions. Historically, the industry relied on conventional induction motors and hydraulic systems, which often struggled to meet the demanding requirements of deep-sea operations. PMSMs, with their high power density, precise control capabilities, and excellent efficiency, have become increasingly attractive for offshore applications.

The primary objective of integrating PMSMs in offshore drilling is to enhance overall system performance while reducing operational costs and environmental impact. These motors offer superior torque characteristics, allowing for more precise control of drilling equipment, which is crucial in challenging offshore environments. Additionally, their compact design helps to optimize space utilization on offshore platforms, where real estate is at a premium.

Another key goal is to improve energy efficiency in drilling operations. PMSMs are known for their high efficiency across a wide range of operating conditions, which can lead to significant reductions in power consumption. This not only reduces operational costs but also aligns with the industry's growing focus on sustainability and reducing carbon footprint.

The integration of PMSMs also aims to enhance the reliability and durability of drilling systems. Offshore environments are notoriously harsh, with extreme temperatures, high humidity, and corrosive conditions. PMSMs, with their simpler construction and fewer wear-prone components compared to traditional motors, offer improved reliability and reduced maintenance requirements, which is crucial for minimizing downtime in offshore operations.

Furthermore, the adoption of PMSMs in offshore drilling is part of a broader trend towards electrification and digitalization in the oil and gas industry. This transition seeks to leverage advanced control systems and data analytics to optimize drilling processes, improve safety, and increase overall operational efficiency.

As the offshore drilling industry continues to push into deeper waters and more challenging environments, the role of advanced motor technologies like PMSMs becomes increasingly critical. The successful integration of these motors is expected to play a pivotal role in enabling more efficient, reliable, and environmentally friendly drilling operations in the coming years.

Market Analysis for PMSM in Offshore Applications

The market for Permanent Magnet Synchronous Motors (PMSM) in offshore applications, particularly in drilling operations, has been experiencing significant growth in recent years. This surge is primarily driven by the increasing demand for more efficient and reliable power systems in offshore environments. The offshore oil and gas industry, which forms a substantial part of this market, has been actively seeking advanced technologies to improve operational efficiency and reduce environmental impact.

The global offshore drilling market, valued at approximately $65 billion in 2020, is projected to grow at a CAGR of 3.5% from 2021 to 2026. Within this market, the demand for PMSM is expected to increase at an even higher rate due to its superior performance characteristics. The adoption of PMSM in offshore drilling operations is particularly strong in regions with extensive offshore activities, such as the Gulf of Mexico, the North Sea, and the Asia-Pacific.

Key factors driving the market growth include the need for higher energy efficiency, reduced maintenance requirements, and improved reliability in harsh offshore environments. PMSM offers significant advantages over traditional motor technologies, including higher power density, better speed control, and improved overall system efficiency. These benefits are crucial in offshore operations where space is limited, and operational costs are high.

The market for PMSM in offshore applications is also being influenced by stringent environmental regulations. As the offshore industry faces increasing pressure to reduce its carbon footprint, the adoption of more energy-efficient technologies like PMSM becomes imperative. This trend is expected to continue, further boosting the market growth for PMSM in offshore drilling operations.

Another significant market driver is the ongoing digitalization and automation trend in the offshore industry. PMSM, with its precise control capabilities, aligns well with the industry's move towards more automated drilling processes. This compatibility is likely to increase the integration of PMSM in next-generation offshore drilling systems.

However, the market also faces certain challenges. The high initial cost of PMSM compared to conventional motors can be a deterrent for some operators, especially in a cost-sensitive industry. Additionally, the complexity of integrating PMSM into existing offshore systems and the need for specialized maintenance skills pose challenges to widespread adoption.

Despite these challenges, the long-term outlook for PMSM in offshore applications remains positive. As technology advances and economies of scale are achieved, the cost-benefit ratio of PMSM is expected to improve further. The market is also likely to benefit from ongoing research and development efforts aimed at enhancing the performance and reliability of PMSM in extreme offshore conditions.

The global offshore drilling market, valued at approximately $65 billion in 2020, is projected to grow at a CAGR of 3.5% from 2021 to 2026. Within this market, the demand for PMSM is expected to increase at an even higher rate due to its superior performance characteristics. The adoption of PMSM in offshore drilling operations is particularly strong in regions with extensive offshore activities, such as the Gulf of Mexico, the North Sea, and the Asia-Pacific.

Key factors driving the market growth include the need for higher energy efficiency, reduced maintenance requirements, and improved reliability in harsh offshore environments. PMSM offers significant advantages over traditional motor technologies, including higher power density, better speed control, and improved overall system efficiency. These benefits are crucial in offshore operations where space is limited, and operational costs are high.

The market for PMSM in offshore applications is also being influenced by stringent environmental regulations. As the offshore industry faces increasing pressure to reduce its carbon footprint, the adoption of more energy-efficient technologies like PMSM becomes imperative. This trend is expected to continue, further boosting the market growth for PMSM in offshore drilling operations.

Another significant market driver is the ongoing digitalization and automation trend in the offshore industry. PMSM, with its precise control capabilities, aligns well with the industry's move towards more automated drilling processes. This compatibility is likely to increase the integration of PMSM in next-generation offshore drilling systems.

However, the market also faces certain challenges. The high initial cost of PMSM compared to conventional motors can be a deterrent for some operators, especially in a cost-sensitive industry. Additionally, the complexity of integrating PMSM into existing offshore systems and the need for specialized maintenance skills pose challenges to widespread adoption.

Despite these challenges, the long-term outlook for PMSM in offshore applications remains positive. As technology advances and economies of scale are achieved, the cost-benefit ratio of PMSM is expected to improve further. The market is also likely to benefit from ongoing research and development efforts aimed at enhancing the performance and reliability of PMSM in extreme offshore conditions.

Current PMSM Technology in Offshore Environments

Permanent Magnet Synchronous Motors (PMSMs) have gained significant traction in offshore drilling operations due to their high efficiency, compact size, and excellent control capabilities. In the harsh offshore environment, PMSMs offer several advantages over traditional motor technologies, making them increasingly popular for various applications in drilling systems.

The current PMSM technology in offshore environments is characterized by robust design and advanced control strategies. These motors are typically designed with enhanced protection against saltwater corrosion, utilizing specialized coatings and sealing techniques to ensure longevity in marine conditions. The use of rare-earth permanent magnets, such as neodymium-iron-boron (NdFeB), enables high power density and improved thermal management, crucial for the confined spaces on offshore platforms.

One of the key advancements in PMSM technology for offshore applications is the development of sensorless control systems. These systems eliminate the need for position sensors, which are often vulnerable to failure in harsh environments. By employing sophisticated algorithms and advanced estimation techniques, sensorless control enhances the reliability and reduces maintenance requirements of PMSM-driven equipment in offshore drilling operations.

Variable frequency drives (VFDs) play a crucial role in the integration of PMSMs in offshore drilling. Modern VFDs specifically designed for marine applications offer improved power quality, reduced harmonics, and enhanced efficiency. These drives often incorporate advanced features such as regenerative braking capabilities, which can recover energy during the lowering of drill strings, contributing to overall system efficiency.

The integration of PMSMs in offshore drilling has also led to the development of specialized cooling systems. Liquid cooling solutions, often using seawater or a closed-loop system with a heat exchanger, have been implemented to maintain optimal motor temperatures in the confined and high-temperature environments typical of offshore platforms. This approach not only enhances motor performance but also extends the operational life of the equipment.

Recent advancements in PMSM technology for offshore applications include the use of high-temperature superconducting (HTS) materials in motor windings. While still in the early stages of adoption, HTS PMSMs offer the potential for even higher power densities and efficiencies, which could revolutionize offshore drilling operations in the future.

The current state of PMSM technology in offshore environments also encompasses advanced condition monitoring and predictive maintenance systems. These systems utilize real-time data analytics and machine learning algorithms to detect potential issues before they lead to equipment failure, thereby minimizing downtime and improving overall operational efficiency in offshore drilling operations.

The current PMSM technology in offshore environments is characterized by robust design and advanced control strategies. These motors are typically designed with enhanced protection against saltwater corrosion, utilizing specialized coatings and sealing techniques to ensure longevity in marine conditions. The use of rare-earth permanent magnets, such as neodymium-iron-boron (NdFeB), enables high power density and improved thermal management, crucial for the confined spaces on offshore platforms.

One of the key advancements in PMSM technology for offshore applications is the development of sensorless control systems. These systems eliminate the need for position sensors, which are often vulnerable to failure in harsh environments. By employing sophisticated algorithms and advanced estimation techniques, sensorless control enhances the reliability and reduces maintenance requirements of PMSM-driven equipment in offshore drilling operations.

Variable frequency drives (VFDs) play a crucial role in the integration of PMSMs in offshore drilling. Modern VFDs specifically designed for marine applications offer improved power quality, reduced harmonics, and enhanced efficiency. These drives often incorporate advanced features such as regenerative braking capabilities, which can recover energy during the lowering of drill strings, contributing to overall system efficiency.

The integration of PMSMs in offshore drilling has also led to the development of specialized cooling systems. Liquid cooling solutions, often using seawater or a closed-loop system with a heat exchanger, have been implemented to maintain optimal motor temperatures in the confined and high-temperature environments typical of offshore platforms. This approach not only enhances motor performance but also extends the operational life of the equipment.

Recent advancements in PMSM technology for offshore applications include the use of high-temperature superconducting (HTS) materials in motor windings. While still in the early stages of adoption, HTS PMSMs offer the potential for even higher power densities and efficiencies, which could revolutionize offshore drilling operations in the future.

The current state of PMSM technology in offshore environments also encompasses advanced condition monitoring and predictive maintenance systems. These systems utilize real-time data analytics and machine learning algorithms to detect potential issues before they lead to equipment failure, thereby minimizing downtime and improving overall operational efficiency in offshore drilling operations.

PMSM Integration Solutions for Offshore Drilling

01 Motor design and structure

Permanent Magnet Synchronous Motors (PMSMs) have specific design features and structural elements that enhance their performance. These may include optimized rotor configurations, stator winding arrangements, and magnetic circuit designs. Innovations in motor structure can improve efficiency, power density, and overall performance of PMSMs.- Motor design and structure: Permanent Magnet Synchronous Motors (PMSMs) have specific design features and structural elements that enhance their performance. These may include optimized rotor configurations, stator winding arrangements, and magnetic circuit designs. Innovations in motor structure can lead to improved efficiency, power density, and overall performance of PMSMs.

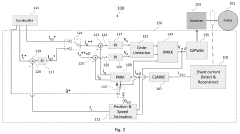

- Control systems and algorithms: Advanced control systems and algorithms are crucial for optimizing PMSM operation. These may include sensorless control techniques, adaptive control strategies, and advanced modulation methods. Improved control systems can enhance motor efficiency, reduce torque ripple, and provide better dynamic performance across various operating conditions.

- Thermal management and cooling: Effective thermal management is essential for maintaining PMSM performance and longevity. Innovations in cooling systems, heat dissipation techniques, and temperature monitoring can help prevent overheating, reduce losses, and improve overall motor efficiency. This may include novel cooling channel designs or advanced thermal materials.

- Magnet materials and arrangements: The choice and arrangement of permanent magnets significantly impact PMSM performance. Research focuses on developing new magnetic materials, optimizing magnet shapes and placements, and exploring alternative magnet configurations. These advancements aim to improve magnetic flux density, reduce cogging torque, and enhance overall motor efficiency.

- Integration with power electronics: Integrating PMSMs with advanced power electronic systems is crucial for optimal performance in various applications. This includes developing efficient inverter topologies, implementing sophisticated modulation techniques, and designing integrated motor-drive systems. Such integration can lead to improved system efficiency, reduced size, and enhanced control capabilities.

02 Control systems and algorithms

Advanced control systems and algorithms are crucial for optimizing PMSM operation. These may include sensorless control techniques, adaptive control strategies, and advanced modulation methods. Improved control systems can enhance motor efficiency, reduce torque ripple, and provide better dynamic performance across various operating conditions.Expand Specific Solutions03 Thermal management and cooling

Effective thermal management is essential for maintaining PMSM performance and longevity. Innovations in cooling systems, heat dissipation techniques, and temperature monitoring can help prevent overheating, reduce losses, and improve overall motor efficiency. This may include novel cooling channel designs or advanced thermal materials.Expand Specific Solutions04 Magnet materials and arrangements

The choice and arrangement of permanent magnets significantly impact PMSM performance. Research focuses on developing new magnetic materials, optimizing magnet shapes and placements, and exploring alternative magnet configurations. These innovations aim to improve magnetic flux density, reduce cogging torque, and enhance overall motor efficiency.Expand Specific Solutions05 Integration with power electronics

Integrating PMSMs with advanced power electronics can lead to improved system-level performance. This may include developing specialized inverters, implementing novel switching strategies, or designing integrated motor-drive systems. Such integration can enhance overall efficiency, reduce system size, and improve control capabilities.Expand Specific Solutions

Key Players in Offshore PMSM Integration

The integration of Permanent Magnet Synchronous Motors (PMSM) in offshore drilling operations is in a growth phase, with increasing market size and technological advancements. The global offshore drilling market is projected to expand significantly, driven by rising energy demands and deep-water exploration. Companies like Technip Energies France SAS, ExxonMobil Upstream Research Co., and Sinopec Oilfield Service Corp. are at the forefront of this technology adoption. Academic institutions such as Shandong University and China Petroleum University Beijing are contributing to research and development. The technology's maturity is advancing, with firms like CRRC Yongji Moto Co., Ltd. and Gree Electric Appliances, Inc. of Zhuhai leading in PMSM innovations for industrial applications, including offshore drilling.

Exxonmobil Upstream Research Co.

Technical Solution: Exxonmobil has developed an advanced PMSM integration system for offshore drilling operations. Their solution incorporates a high-efficiency PMSM motor with a specialized control system designed to withstand harsh marine environments. The system utilizes advanced cooling techniques to maintain optimal motor performance in deep-sea conditions. Exxonmobil's PMSM integration also features real-time monitoring and predictive maintenance capabilities, enhancing the reliability of drilling operations[1][3]. The company has implemented a regenerative braking system that captures energy during the lowering of drill strings, improving overall energy efficiency[5].

Strengths: Robust design for marine environments, high energy efficiency, and advanced monitoring capabilities. Weaknesses: Potentially higher initial costs and complexity in implementation compared to traditional systems.

Schlumberger Canada Ltd.

Technical Solution: Schlumberger has pioneered a PMSM integration solution specifically tailored for offshore drilling rigs. Their system incorporates a compact, high-torque PMSM motor design that reduces the overall footprint on space-constrained offshore platforms. The company has developed a proprietary control algorithm that optimizes motor performance across various drilling conditions, including varying depths and geological formations[2]. Schlumberger's solution also includes an advanced power management system that balances load across multiple PMSM units, ensuring consistent power delivery and minimizing downtime[4]. The integration includes a sophisticated fault detection and isolation system, enhancing safety in critical offshore environments[6].

Strengths: Space-efficient design, adaptive performance optimization, and enhanced safety features. Weaknesses: May require specialized training for operation and maintenance, potential compatibility issues with existing equipment.

Core PMSM Innovations for Offshore Operations

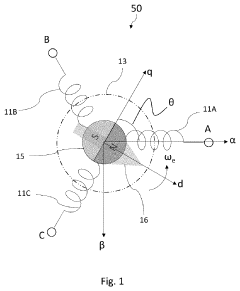

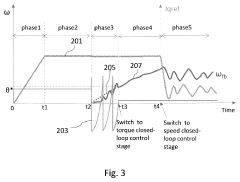

Permanent magnet synchronous motor (PMSM) and method for starting the pmsm

PatentActiveUS20230387845A1

Innovation

- A multi-stage control method involving opening and closing control loops in specific modes to align and asynchronously drive the rotor, utilizing field-oriented control (FOC) with a first control loop in open-loop mode to set initial directions and then transition to closed-loop modes for speed control, ensuring synchronization and stable startup.

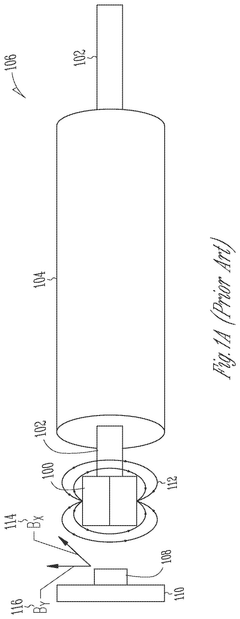

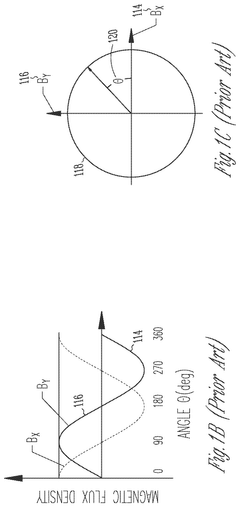

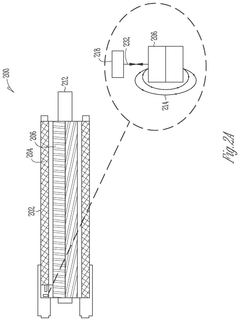

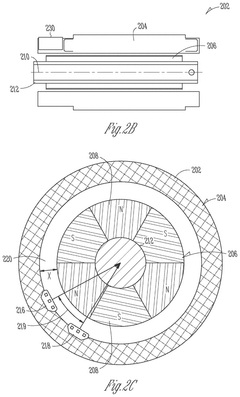

Permanent magnet synchronous motor (PMSM) integrated position sensing

PatentActiveUS12212257B2

Innovation

- The integration of analog magnetic flux sensors within the hollow cylindrical stator of the PMSM, arranged concentrically around the rotational axis at a constant mechanical angle relative to each other, allows for direct measurement of the magnetic flux from the rotor without external obstructions, enabling accurate rotor position sensing and reducing motor size and cost.

Environmental Impact of PMSM in Offshore Operations

The integration of Permanent Magnet Synchronous Motors (PMSM) in offshore drilling operations has significant environmental implications. These motors offer several advantages that contribute to reduced environmental impact compared to traditional systems. Firstly, PMSMs are known for their high energy efficiency, which translates to lower power consumption during drilling operations. This reduction in energy usage leads to decreased fuel consumption and, consequently, lower greenhouse gas emissions from power generation sources on offshore platforms.

Furthermore, PMSMs exhibit excellent torque control characteristics, allowing for more precise drilling operations. This precision can result in reduced drilling time and fewer errors, potentially minimizing the overall environmental footprint of drilling activities. The improved control also enables better management of drilling fluids and cuttings, reducing the risk of environmental contamination.

Another environmental benefit of PMSMs is their compact size and lightweight design. This characteristic allows for smaller and lighter drilling equipment, which can lead to reduced material usage in the construction of offshore platforms and drilling rigs. Additionally, the compact nature of PMSMs can contribute to more efficient space utilization on offshore platforms, potentially reducing the overall size of these structures and their impact on marine ecosystems.

PMSMs also generate less noise and vibration compared to conventional motors, which is particularly important in offshore environments. Reduced noise pollution can minimize disturbances to marine life, including fish, marine mammals, and other organisms sensitive to acoustic disturbances. This aspect is crucial for maintaining the ecological balance in offshore drilling areas.

The reliability and longevity of PMSMs contribute to reduced maintenance requirements and fewer replacements over time. This durability translates to less frequent need for parts replacement and servicing, which in turn reduces the environmental impact associated with manufacturing, transporting, and disposing of motor components.

However, it is important to consider the potential environmental challenges associated with PMSM technology. The production of permanent magnets used in these motors often involves rare earth elements, the mining and processing of which can have significant environmental impacts. Responsible sourcing and recycling of these materials are crucial to mitigate these concerns.

In conclusion, while the integration of PMSMs in offshore drilling operations offers numerous environmental benefits, a holistic approach considering the entire lifecycle of these motors is necessary to fully assess their environmental impact. Ongoing research and development in PMSM technology and sustainable material sourcing will be key to maximizing their positive environmental contributions in offshore operations.

Furthermore, PMSMs exhibit excellent torque control characteristics, allowing for more precise drilling operations. This precision can result in reduced drilling time and fewer errors, potentially minimizing the overall environmental footprint of drilling activities. The improved control also enables better management of drilling fluids and cuttings, reducing the risk of environmental contamination.

Another environmental benefit of PMSMs is their compact size and lightweight design. This characteristic allows for smaller and lighter drilling equipment, which can lead to reduced material usage in the construction of offshore platforms and drilling rigs. Additionally, the compact nature of PMSMs can contribute to more efficient space utilization on offshore platforms, potentially reducing the overall size of these structures and their impact on marine ecosystems.

PMSMs also generate less noise and vibration compared to conventional motors, which is particularly important in offshore environments. Reduced noise pollution can minimize disturbances to marine life, including fish, marine mammals, and other organisms sensitive to acoustic disturbances. This aspect is crucial for maintaining the ecological balance in offshore drilling areas.

The reliability and longevity of PMSMs contribute to reduced maintenance requirements and fewer replacements over time. This durability translates to less frequent need for parts replacement and servicing, which in turn reduces the environmental impact associated with manufacturing, transporting, and disposing of motor components.

However, it is important to consider the potential environmental challenges associated with PMSM technology. The production of permanent magnets used in these motors often involves rare earth elements, the mining and processing of which can have significant environmental impacts. Responsible sourcing and recycling of these materials are crucial to mitigate these concerns.

In conclusion, while the integration of PMSMs in offshore drilling operations offers numerous environmental benefits, a holistic approach considering the entire lifecycle of these motors is necessary to fully assess their environmental impact. Ongoing research and development in PMSM technology and sustainable material sourcing will be key to maximizing their positive environmental contributions in offshore operations.

Safety Standards for PMSM in Offshore Applications

Safety standards for Permanent Magnet Synchronous Motors (PMSM) in offshore applications are critical to ensure the reliable and secure operation of these motors in challenging marine environments. These standards address various aspects of PMSM integration, focusing on the unique challenges posed by offshore drilling operations.

The International Electrotechnical Commission (IEC) has established specific guidelines for electrical equipment used in offshore applications, including IEC 61892 for mobile and fixed offshore units. These standards outline requirements for electrical systems, emphasizing safety, reliability, and environmental protection.

For PMSMs used in offshore drilling, compliance with explosion-proof (Ex) standards is paramount. The IEC 60079 series provides guidelines for electrical equipment in explosive atmospheres, with specific provisions for motors. These standards define protection techniques, such as flameproof enclosures (Ex d) and increased safety (Ex e), which are crucial for PMSMs operating in potentially hazardous areas on drilling platforms.

Ingress protection (IP) ratings, as defined by IEC 60529, are essential for PMSMs in offshore environments. Motors typically require a minimum rating of IP56 to withstand high-pressure water jets and dust ingress. In some cases, higher ratings like IP68 may be necessary for submersible applications.

Corrosion resistance is another critical factor addressed by safety standards. Materials used in PMSM construction must comply with NACE MR0175/ISO 15156 standards for materials resistant to sulfide stress cracking and corrosion in oil and gas production environments.

Vibration and shock resistance standards, such as IEC 60068-2, ensure that PMSMs can withstand the dynamic conditions encountered during offshore drilling operations. These standards define testing procedures to verify motor performance under various mechanical stresses.

Thermal management is crucial in offshore applications, and standards like IEC 60034-1 provide guidelines for temperature rise limits and cooling systems. PMSMs must maintain safe operating temperatures despite potentially high ambient temperatures and limited cooling options on offshore platforms.

Electromagnetic compatibility (EMC) standards, including IEC 61000 series, are vital to ensure that PMSMs do not interfere with other sensitive equipment on drilling platforms. These standards define emission limits and immunity requirements for electrical and electronic equipment.

Safety standards also address the integration of PMSMs with variable frequency drives (VFDs) commonly used in offshore drilling. IEC 61800-5-2 provides functional safety requirements for adjustable speed electrical power drive systems, ensuring safe operation and control of PMSMs in critical applications.

Regular inspection and maintenance procedures are outlined in standards such as IEC 60079-17 for electrical installations in hazardous areas. These guidelines ensure ongoing compliance and safe operation of PMSMs throughout their lifecycle in offshore environments.

The International Electrotechnical Commission (IEC) has established specific guidelines for electrical equipment used in offshore applications, including IEC 61892 for mobile and fixed offshore units. These standards outline requirements for electrical systems, emphasizing safety, reliability, and environmental protection.

For PMSMs used in offshore drilling, compliance with explosion-proof (Ex) standards is paramount. The IEC 60079 series provides guidelines for electrical equipment in explosive atmospheres, with specific provisions for motors. These standards define protection techniques, such as flameproof enclosures (Ex d) and increased safety (Ex e), which are crucial for PMSMs operating in potentially hazardous areas on drilling platforms.

Ingress protection (IP) ratings, as defined by IEC 60529, are essential for PMSMs in offshore environments. Motors typically require a minimum rating of IP56 to withstand high-pressure water jets and dust ingress. In some cases, higher ratings like IP68 may be necessary for submersible applications.

Corrosion resistance is another critical factor addressed by safety standards. Materials used in PMSM construction must comply with NACE MR0175/ISO 15156 standards for materials resistant to sulfide stress cracking and corrosion in oil and gas production environments.

Vibration and shock resistance standards, such as IEC 60068-2, ensure that PMSMs can withstand the dynamic conditions encountered during offshore drilling operations. These standards define testing procedures to verify motor performance under various mechanical stresses.

Thermal management is crucial in offshore applications, and standards like IEC 60034-1 provide guidelines for temperature rise limits and cooling systems. PMSMs must maintain safe operating temperatures despite potentially high ambient temperatures and limited cooling options on offshore platforms.

Electromagnetic compatibility (EMC) standards, including IEC 61000 series, are vital to ensure that PMSMs do not interfere with other sensitive equipment on drilling platforms. These standards define emission limits and immunity requirements for electrical and electronic equipment.

Safety standards also address the integration of PMSMs with variable frequency drives (VFDs) commonly used in offshore drilling. IEC 61800-5-2 provides functional safety requirements for adjustable speed electrical power drive systems, ensuring safe operation and control of PMSMs in critical applications.

Regular inspection and maintenance procedures are outlined in standards such as IEC 60079-17 for electrical installations in hazardous areas. These guidelines ensure ongoing compliance and safe operation of PMSMs throughout their lifecycle in offshore environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!