Machine learning approaches for PMSM control systems

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Control ML Background

Permanent Magnet Synchronous Motors (PMSMs) have gained significant traction in various industrial applications due to their high efficiency, power density, and precise control capabilities. The integration of machine learning approaches into PMSM control systems represents a paradigm shift in motor control technology, offering enhanced performance and adaptability.

The evolution of PMSM control systems has been marked by continuous advancements in control theory and power electronics. Traditional control methods, such as field-oriented control (FOC) and direct torque control (DTC), have been widely used for decades. However, these conventional approaches often struggle to maintain optimal performance under varying operating conditions and system uncertainties.

Machine learning techniques have emerged as a promising solution to address the limitations of conventional control methods. By leveraging data-driven algorithms, machine learning approaches can adapt to changing motor parameters, load conditions, and environmental factors, potentially improving the overall system performance and efficiency.

The application of machine learning in PMSM control systems encompasses various techniques, including artificial neural networks (ANNs), fuzzy logic systems, and reinforcement learning. These methods have demonstrated the ability to enhance motor control in terms of speed regulation, torque ripple reduction, and efficiency optimization.

Artificial neural networks, in particular, have shown remarkable potential in PMSM control. ANNs can learn complex nonlinear relationships between system inputs and outputs, enabling more accurate modeling and control of the motor dynamics. This capability is especially valuable in scenarios where precise mathematical models of the motor are challenging to obtain or when system parameters vary over time.

Fuzzy logic systems have also been successfully applied to PMSM control, offering a framework for incorporating expert knowledge and handling uncertainties in the control process. By utilizing linguistic rules and membership functions, fuzzy logic controllers can provide robust and adaptive control strategies for PMSMs.

Reinforcement learning, a subset of machine learning, has gained attention in recent years for its potential in optimizing PMSM control policies. This approach allows the control system to learn optimal actions through interaction with the environment, potentially leading to improved performance and energy efficiency over time.

The integration of machine learning approaches in PMSM control systems opens up new possibilities for advanced motor drive applications. These techniques offer the potential for self-tuning controllers, fault-tolerant operation, and predictive maintenance strategies. As research in this field continues to progress, it is expected that machine learning will play an increasingly important role in shaping the future of electric motor control technology.

The evolution of PMSM control systems has been marked by continuous advancements in control theory and power electronics. Traditional control methods, such as field-oriented control (FOC) and direct torque control (DTC), have been widely used for decades. However, these conventional approaches often struggle to maintain optimal performance under varying operating conditions and system uncertainties.

Machine learning techniques have emerged as a promising solution to address the limitations of conventional control methods. By leveraging data-driven algorithms, machine learning approaches can adapt to changing motor parameters, load conditions, and environmental factors, potentially improving the overall system performance and efficiency.

The application of machine learning in PMSM control systems encompasses various techniques, including artificial neural networks (ANNs), fuzzy logic systems, and reinforcement learning. These methods have demonstrated the ability to enhance motor control in terms of speed regulation, torque ripple reduction, and efficiency optimization.

Artificial neural networks, in particular, have shown remarkable potential in PMSM control. ANNs can learn complex nonlinear relationships between system inputs and outputs, enabling more accurate modeling and control of the motor dynamics. This capability is especially valuable in scenarios where precise mathematical models of the motor are challenging to obtain or when system parameters vary over time.

Fuzzy logic systems have also been successfully applied to PMSM control, offering a framework for incorporating expert knowledge and handling uncertainties in the control process. By utilizing linguistic rules and membership functions, fuzzy logic controllers can provide robust and adaptive control strategies for PMSMs.

Reinforcement learning, a subset of machine learning, has gained attention in recent years for its potential in optimizing PMSM control policies. This approach allows the control system to learn optimal actions through interaction with the environment, potentially leading to improved performance and energy efficiency over time.

The integration of machine learning approaches in PMSM control systems opens up new possibilities for advanced motor drive applications. These techniques offer the potential for self-tuning controllers, fault-tolerant operation, and predictive maintenance strategies. As research in this field continues to progress, it is expected that machine learning will play an increasingly important role in shaping the future of electric motor control technology.

Market Demand Analysis

The market demand for machine learning approaches in Permanent Magnet Synchronous Motor (PMSM) control systems has been experiencing significant growth in recent years. This surge is primarily driven by the increasing adoption of electric vehicles (EVs) and the growing emphasis on energy efficiency in industrial applications.

In the automotive sector, the global EV market is projected to expand at a compound annual growth rate (CAGR) of over 20% from 2021 to 2028. This rapid growth is fueling the demand for advanced motor control systems, with PMSM being a preferred choice due to its high efficiency and power density. Machine learning approaches for PMSM control systems offer enhanced performance, adaptability, and efficiency, making them particularly attractive for EV manufacturers seeking to optimize their powertrains.

The industrial automation sector is another key driver of market demand. As industries worldwide strive for greater energy efficiency and operational optimization, the adoption of smart motor control systems is on the rise. The global industrial automation market is expected to reach a value of over $300 billion by 2027, with motor control systems playing a crucial role in this growth.

Machine learning approaches for PMSM control systems offer several advantages that align with market needs. These include improved motor efficiency, reduced energy consumption, enhanced fault detection and diagnosis, and adaptive control capabilities. Such features are particularly valuable in industries such as manufacturing, robotics, and renewable energy, where precise motor control and energy optimization are critical.

The market demand is further bolstered by the increasing focus on Industry 4.0 and the Internet of Things (IoT). As factories and industrial processes become more interconnected and data-driven, there is a growing need for intelligent motor control systems that can integrate seamlessly with broader automation and analytics platforms. Machine learning approaches enable PMSM control systems to leverage real-time data for predictive maintenance, performance optimization, and energy management.

In the HVAC (Heating, Ventilation, and Air Conditioning) sector, which is a significant consumer of electric motors, there is a rising demand for energy-efficient solutions. Machine learning-based PMSM control systems can significantly reduce energy consumption in HVAC applications, aligning with global energy efficiency regulations and sustainability goals.

The market demand is also influenced by regional factors. Developed economies in North America and Europe are focusing on upgrading their industrial infrastructure with smart technologies, driving the adoption of advanced motor control systems. Meanwhile, rapidly industrializing countries in Asia-Pacific, particularly China and India, are experiencing a surge in demand for efficient motor control solutions across various sectors.

As the technology matures and becomes more accessible, small and medium-sized enterprises (SMEs) are also expected to contribute to the market demand. This broadening of the customer base is likely to further accelerate the adoption of machine learning approaches in PMSM control systems across diverse industries and applications.

In the automotive sector, the global EV market is projected to expand at a compound annual growth rate (CAGR) of over 20% from 2021 to 2028. This rapid growth is fueling the demand for advanced motor control systems, with PMSM being a preferred choice due to its high efficiency and power density. Machine learning approaches for PMSM control systems offer enhanced performance, adaptability, and efficiency, making them particularly attractive for EV manufacturers seeking to optimize their powertrains.

The industrial automation sector is another key driver of market demand. As industries worldwide strive for greater energy efficiency and operational optimization, the adoption of smart motor control systems is on the rise. The global industrial automation market is expected to reach a value of over $300 billion by 2027, with motor control systems playing a crucial role in this growth.

Machine learning approaches for PMSM control systems offer several advantages that align with market needs. These include improved motor efficiency, reduced energy consumption, enhanced fault detection and diagnosis, and adaptive control capabilities. Such features are particularly valuable in industries such as manufacturing, robotics, and renewable energy, where precise motor control and energy optimization are critical.

The market demand is further bolstered by the increasing focus on Industry 4.0 and the Internet of Things (IoT). As factories and industrial processes become more interconnected and data-driven, there is a growing need for intelligent motor control systems that can integrate seamlessly with broader automation and analytics platforms. Machine learning approaches enable PMSM control systems to leverage real-time data for predictive maintenance, performance optimization, and energy management.

In the HVAC (Heating, Ventilation, and Air Conditioning) sector, which is a significant consumer of electric motors, there is a rising demand for energy-efficient solutions. Machine learning-based PMSM control systems can significantly reduce energy consumption in HVAC applications, aligning with global energy efficiency regulations and sustainability goals.

The market demand is also influenced by regional factors. Developed economies in North America and Europe are focusing on upgrading their industrial infrastructure with smart technologies, driving the adoption of advanced motor control systems. Meanwhile, rapidly industrializing countries in Asia-Pacific, particularly China and India, are experiencing a surge in demand for efficient motor control solutions across various sectors.

As the technology matures and becomes more accessible, small and medium-sized enterprises (SMEs) are also expected to contribute to the market demand. This broadening of the customer base is likely to further accelerate the adoption of machine learning approaches in PMSM control systems across diverse industries and applications.

Current ML-PMSM Challenges

The integration of machine learning (ML) approaches into Permanent Magnet Synchronous Motor (PMSM) control systems has shown great promise, yet it also presents several significant challenges. One of the primary obstacles is the real-time implementation of ML algorithms in PMSM control systems. The computational complexity of many ML models, particularly deep learning architectures, can lead to latency issues that are incompatible with the high-speed requirements of motor control applications.

Another challenge lies in the data quality and quantity needed for effective ML model training. PMSM systems operate in diverse and dynamic environments, making it difficult to collect comprehensive datasets that cover all possible operating conditions. This limitation can result in models that perform well in certain scenarios but fail to generalize across the full spectrum of motor operations.

The interpretability of ML models in PMSM control systems is also a significant concern. Many advanced ML algorithms, such as neural networks, operate as "black boxes," making it challenging to understand and explain their decision-making processes. This lack of transparency can be problematic in critical applications where safety and reliability are paramount.

Robustness and stability of ML-based control systems pose another challenge. PMSM systems are often subject to external disturbances, parameter variations, and sensor noise. Ensuring that ML models can maintain stable and reliable performance under these varying conditions is crucial but remains a complex task.

The integration of ML models with traditional control techniques is yet another hurdle. While ML approaches offer advantages in handling nonlinearities and uncertainties, they may lack the theoretical guarantees of stability and performance that conventional control methods provide. Developing hybrid approaches that combine the strengths of both ML and classical control theory is an ongoing challenge.

Lastly, the adaptability of ML models to changing motor characteristics over time presents a significant challenge. PMSMs may experience wear, temperature variations, and other factors that alter their behavior. Developing ML models that can continuously learn and adapt to these changes without compromising performance or stability is a complex task that requires sophisticated online learning techniques.

Another challenge lies in the data quality and quantity needed for effective ML model training. PMSM systems operate in diverse and dynamic environments, making it difficult to collect comprehensive datasets that cover all possible operating conditions. This limitation can result in models that perform well in certain scenarios but fail to generalize across the full spectrum of motor operations.

The interpretability of ML models in PMSM control systems is also a significant concern. Many advanced ML algorithms, such as neural networks, operate as "black boxes," making it challenging to understand and explain their decision-making processes. This lack of transparency can be problematic in critical applications where safety and reliability are paramount.

Robustness and stability of ML-based control systems pose another challenge. PMSM systems are often subject to external disturbances, parameter variations, and sensor noise. Ensuring that ML models can maintain stable and reliable performance under these varying conditions is crucial but remains a complex task.

The integration of ML models with traditional control techniques is yet another hurdle. While ML approaches offer advantages in handling nonlinearities and uncertainties, they may lack the theoretical guarantees of stability and performance that conventional control methods provide. Developing hybrid approaches that combine the strengths of both ML and classical control theory is an ongoing challenge.

Lastly, the adaptability of ML models to changing motor characteristics over time presents a significant challenge. PMSMs may experience wear, temperature variations, and other factors that alter their behavior. Developing ML models that can continuously learn and adapt to these changes without compromising performance or stability is a complex task that requires sophisticated online learning techniques.

Existing ML-PMSM Solutions

01 Control strategies for PMSM systems

Various control strategies are employed in Permanent Magnet Synchronous Motor (PMSM) systems to optimize performance. These may include vector control, direct torque control, and model predictive control. Advanced control algorithms are implemented to improve efficiency, reduce torque ripple, and enhance dynamic response.- Control strategies for PMSM systems: Various control strategies are employed in Permanent Magnet Synchronous Motor (PMSM) systems to optimize performance. These may include vector control, direct torque control, and model predictive control. Advanced algorithms are implemented to enhance efficiency, reduce torque ripple, and improve dynamic response in different operating conditions.

- Sensorless control techniques for PMSM: Sensorless control methods are developed to eliminate the need for position sensors in PMSM systems. These techniques estimate rotor position and speed using motor parameters and electrical measurements. This approach reduces system cost and improves reliability, particularly in harsh environments where sensors may be prone to failure.

- Fault diagnosis and tolerance in PMSM control systems: Fault diagnosis and tolerance mechanisms are integrated into PMSM control systems to enhance reliability. These systems can detect and isolate faults in motor windings, power electronics, or sensors. Adaptive control strategies are implemented to maintain operation under fault conditions, ensuring system continuity and safety.

- Efficiency optimization in PMSM drives: Control techniques are developed to optimize the efficiency of PMSM drives across various operating points. These methods may involve flux weakening, loss minimization algorithms, and adaptive parameter tuning. The goal is to reduce energy consumption and heat generation, particularly in applications such as electric vehicles and industrial automation.

- Integration of PMSM control with power electronics: Advanced integration of PMSM control systems with power electronic converters is explored to improve overall system performance. This includes the development of compact, efficient drive systems with improved power density. Novel modulation techniques and converter topologies are investigated to reduce harmonics, improve dynamic response, and enhance electromagnetic compatibility.

02 Sensorless control techniques for PMSM

Sensorless control methods are developed for PMSM systems to eliminate the need for position sensors. These techniques often utilize observers or estimators to determine rotor position and speed, improving reliability and reducing system cost. Advanced algorithms may be employed to enhance the accuracy of position estimation, especially at low speeds.Expand Specific Solutions03 Efficiency optimization in PMSM control

Control systems for PMSM focus on optimizing efficiency across various operating conditions. This may involve techniques such as flux weakening, maximum torque per ampere control, and loss minimization algorithms. Advanced control strategies are implemented to reduce power consumption and improve overall system efficiency.Expand Specific Solutions04 Fault-tolerant control for PMSM systems

Fault-tolerant control strategies are developed for PMSM systems to maintain operation under various fault conditions. These may include techniques for detecting and isolating faults, as well as reconfiguring the control system to maintain performance. Redundancy and adaptive control methods may be employed to enhance system reliability.Expand Specific Solutions05 Integration of power electronics in PMSM control

Advanced power electronic devices and topologies are integrated into PMSM control systems to improve performance and efficiency. This may include the use of wide bandgap semiconductors, multilevel inverters, and advanced modulation techniques. The integration of power electronics aims to enhance system response, reduce losses, and improve overall control capabilities.Expand Specific Solutions

Key Players in ML-PMSM

The machine learning approaches for PMSM control systems market is in a growth phase, driven by increasing demand for efficient motor control in various industries. The market size is expanding, with a projected CAGR of around 8-10% over the next five years. Technologically, the field is advancing rapidly, with companies like ABB Oy and State Grid Corp. of China leading innovation. Universities such as Huazhong University of Science & Technology and Nanjing University of Aeronautics & Astronautics are contributing significantly to research and development. The technology is maturing, but there's still room for improvement in areas like real-time adaptability and energy efficiency.

Huazhong University of Science & Technology

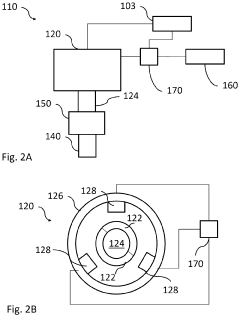

Technical Solution: Huazhong University of Science & Technology has developed a machine learning approach for PMSM control systems focusing on robustness and adaptability. Their solution employs a multi-agent reinforcement learning framework, where multiple control agents collaborate to optimize different aspects of motor performance[7]. The system utilizes a distributed learning architecture, allowing for parallel processing and rapid adaptation to changing motor conditions. Additionally, the university has implemented advanced feature extraction techniques using wavelet transforms to enhance the system's ability to detect and respond to subtle changes in motor behavior[8].

Strengths: Highly adaptable and robust control system; Efficient distributed learning architecture. Weaknesses: Complexity in coordinating multiple learning agents may pose implementation challenges.

Nanjing University of Aeronautics & Astronautics

Technical Solution: Nanjing University of Aeronautics & Astronautics has developed a machine learning approach for PMSM control systems tailored for aerospace applications. Their solution utilizes a combination of model predictive control (MPC) and reinforcement learning to achieve high-precision motor control under extreme conditions[5]. The system employs a digital twin concept, creating a virtual model of the PMSM that is continuously updated based on real-time data. This allows for predictive maintenance and fault-tolerant operation, crucial for aerospace reliability standards. The university's approach also incorporates advanced sensor fusion techniques to enhance the accuracy of motor state estimation[6].

Strengths: Specialized for aerospace applications; High-precision control under extreme conditions. Weaknesses: May have limited applicability in more general industrial settings.

Core ML-PMSM Innovations

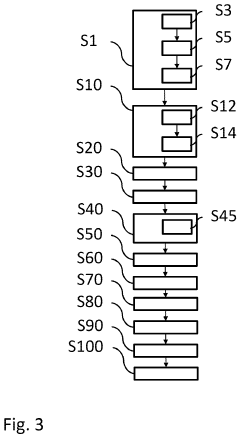

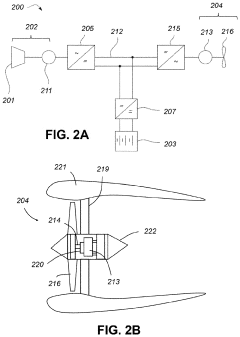

Method for adapting the control parameters of an electric traction machine being a permanent magnetic synchronous motor

PatentActiveUS11870374B2

Innovation

- A method that involves estimating the linked magnetic flux as a function of current, combining it with the permanent magnet flux, and adapting control parameters to optimize PMSM operation, including current control, by performing standstill characterization and retardation tests to determine flux characteristics and no-load power losses.

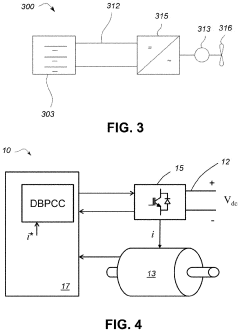

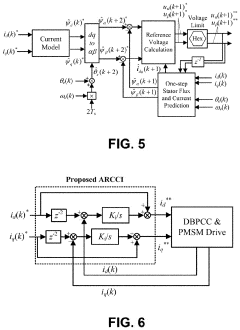

Permanent magnet electric machine control

PatentActiveUS20220399841A1

Innovation

- A Deadbeat Predictive Current Control (DBPCC) scheme that determines d-axis and q-axis current correction values independently of machine parameters and power electronics parameters, using adaptive gain values and harmonic correction components to improve control accuracy and robustness, and estimates the inductance of the PMSM to enhance control performance.

Energy Efficiency Impact

The implementation of machine learning approaches in Permanent Magnet Synchronous Motor (PMSM) control systems has significant implications for energy efficiency. These advanced control techniques optimize motor performance, leading to substantial energy savings across various applications.

Machine learning algorithms, particularly reinforcement learning and neural networks, enable adaptive control strategies that continuously adjust motor parameters based on real-time operating conditions. This dynamic optimization results in reduced energy losses and improved overall system efficiency. For instance, neural network-based controllers can predict and compensate for motor nonlinearities, minimizing energy waste due to suboptimal control actions.

Furthermore, machine learning approaches facilitate more accurate motor parameter estimation, crucial for efficient operation. By leveraging data-driven techniques, these systems can adapt to changes in motor characteristics over time, such as temperature variations and aging effects. This adaptability ensures that the motor operates at peak efficiency throughout its lifecycle, reducing long-term energy consumption.

In industrial applications, where PMSMs are widely used, the energy efficiency impact of machine learning control systems is particularly pronounced. Studies have shown that implementing these advanced control strategies can lead to energy savings of up to 20% compared to traditional control methods. This translates to significant cost reductions and environmental benefits, especially in energy-intensive industries.

The integration of machine learning with PMSM control systems also enables more effective energy recovery during braking or deceleration phases. By optimizing regenerative braking processes, these systems can capture and reuse energy that would otherwise be dissipated as heat, further enhancing overall system efficiency.

Moreover, machine learning approaches allow for predictive maintenance strategies, which indirectly contribute to energy efficiency. By detecting early signs of motor degradation or inefficiencies, these systems can prompt timely interventions, preventing energy waste due to suboptimal motor performance or unexpected failures.

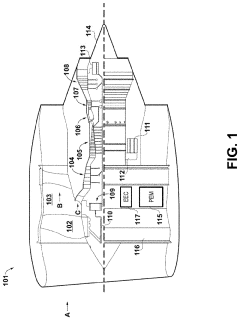

In the context of renewable energy systems, such as wind turbines, machine learning-enhanced PMSM control plays a crucial role in maximizing energy capture. These intelligent control systems can adapt to varying wind conditions, optimizing generator efficiency across a wide range of operating points and contributing to increased renewable energy production.

Machine learning algorithms, particularly reinforcement learning and neural networks, enable adaptive control strategies that continuously adjust motor parameters based on real-time operating conditions. This dynamic optimization results in reduced energy losses and improved overall system efficiency. For instance, neural network-based controllers can predict and compensate for motor nonlinearities, minimizing energy waste due to suboptimal control actions.

Furthermore, machine learning approaches facilitate more accurate motor parameter estimation, crucial for efficient operation. By leveraging data-driven techniques, these systems can adapt to changes in motor characteristics over time, such as temperature variations and aging effects. This adaptability ensures that the motor operates at peak efficiency throughout its lifecycle, reducing long-term energy consumption.

In industrial applications, where PMSMs are widely used, the energy efficiency impact of machine learning control systems is particularly pronounced. Studies have shown that implementing these advanced control strategies can lead to energy savings of up to 20% compared to traditional control methods. This translates to significant cost reductions and environmental benefits, especially in energy-intensive industries.

The integration of machine learning with PMSM control systems also enables more effective energy recovery during braking or deceleration phases. By optimizing regenerative braking processes, these systems can capture and reuse energy that would otherwise be dissipated as heat, further enhancing overall system efficiency.

Moreover, machine learning approaches allow for predictive maintenance strategies, which indirectly contribute to energy efficiency. By detecting early signs of motor degradation or inefficiencies, these systems can prompt timely interventions, preventing energy waste due to suboptimal motor performance or unexpected failures.

In the context of renewable energy systems, such as wind turbines, machine learning-enhanced PMSM control plays a crucial role in maximizing energy capture. These intelligent control systems can adapt to varying wind conditions, optimizing generator efficiency across a wide range of operating points and contributing to increased renewable energy production.

Industrial Implementation

The industrial implementation of machine learning approaches for PMSM control systems has gained significant traction in recent years. Major manufacturers and industrial automation companies have begun integrating these advanced control techniques into their product lines, recognizing the potential for improved performance and efficiency.

Leading industrial automation firms such as ABB, Siemens, and Rockwell Automation have incorporated machine learning algorithms into their motor control systems. These implementations typically involve the use of neural networks or other AI-based models to optimize motor parameters in real-time, adapting to changing load conditions and environmental factors.

One common application is in predictive maintenance, where machine learning models analyze motor performance data to detect potential issues before they lead to failures. This proactive approach has resulted in reduced downtime and maintenance costs for industrial users across various sectors, including manufacturing, oil and gas, and renewable energy.

In the automotive industry, electric vehicle manufacturers have embraced machine learning techniques for PMSM control in their powertrains. Companies like Tesla and BMW utilize adaptive control algorithms that continuously optimize motor efficiency and torque output based on driving conditions and battery state.

The implementation of these advanced control systems often requires significant computational resources. As a result, many industrial solutions incorporate dedicated hardware accelerators or edge computing devices to ensure real-time processing capabilities. This has led to the development of specialized industrial IoT platforms that can handle the data processing and model inference requirements of machine learning-based PMSM control.

Challenges in industrial implementation include the need for robust and reliable operation in harsh environments, as well as the requirement for seamless integration with existing industrial control systems. To address these concerns, companies are developing hardened hardware solutions and standardized communication protocols that facilitate the adoption of machine learning-based control in industrial settings.

As the technology matures, there is a growing trend towards the development of more generalized and adaptable machine learning models for PMSM control. These models aim to reduce the need for extensive system-specific training, making implementation more cost-effective and scalable across different motor types and applications.

Leading industrial automation firms such as ABB, Siemens, and Rockwell Automation have incorporated machine learning algorithms into their motor control systems. These implementations typically involve the use of neural networks or other AI-based models to optimize motor parameters in real-time, adapting to changing load conditions and environmental factors.

One common application is in predictive maintenance, where machine learning models analyze motor performance data to detect potential issues before they lead to failures. This proactive approach has resulted in reduced downtime and maintenance costs for industrial users across various sectors, including manufacturing, oil and gas, and renewable energy.

In the automotive industry, electric vehicle manufacturers have embraced machine learning techniques for PMSM control in their powertrains. Companies like Tesla and BMW utilize adaptive control algorithms that continuously optimize motor efficiency and torque output based on driving conditions and battery state.

The implementation of these advanced control systems often requires significant computational resources. As a result, many industrial solutions incorporate dedicated hardware accelerators or edge computing devices to ensure real-time processing capabilities. This has led to the development of specialized industrial IoT platforms that can handle the data processing and model inference requirements of machine learning-based PMSM control.

Challenges in industrial implementation include the need for robust and reliable operation in harsh environments, as well as the requirement for seamless integration with existing industrial control systems. To address these concerns, companies are developing hardened hardware solutions and standardized communication protocols that facilitate the adoption of machine learning-based control in industrial settings.

As the technology matures, there is a growing trend towards the development of more generalized and adaptable machine learning models for PMSM control. These models aim to reduce the need for extensive system-specific training, making implementation more cost-effective and scalable across different motor types and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!