Opportunities for AGM Battery Use in High-Rise Buildings

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery Evolution and Objectives

Absorbed Glass Mat (AGM) battery technology has undergone significant evolution since its inception in the 1980s. Initially developed for military and aviation applications, AGM batteries have gradually found their way into various sectors, including the construction industry. The technology's progression has been driven by the increasing demand for reliable, maintenance-free, and high-performance energy storage solutions in diverse environments.

The primary objective of AGM battery technology in high-rise buildings is to provide a stable and efficient power backup system. As urban landscapes continue to evolve with taller structures, the need for dependable emergency power sources becomes paramount. AGM batteries aim to address this requirement by offering a compact, safe, and long-lasting energy storage solution that can be seamlessly integrated into modern building designs.

One of the key evolutionary aspects of AGM batteries has been the improvement in their energy density and cycle life. Over the years, manufacturers have refined the internal structure and materials used in these batteries, resulting in higher capacity and longer operational lifespans. This progress has made AGM batteries increasingly attractive for use in high-rise buildings, where space constraints and the need for durability are critical factors.

Another significant development in AGM battery technology has been the enhancement of safety features. With the growing concern for fire safety in tall buildings, AGM batteries have evolved to incorporate advanced flame-retardant materials and improved sealing techniques. These advancements have positioned AGM batteries as a safer alternative to traditional flooded lead-acid batteries, aligning with the stringent safety regulations governing high-rise constructions.

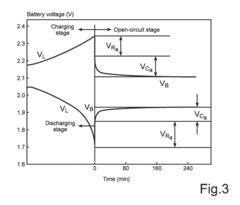

The evolution of AGM batteries has also focused on improving their charge acceptance and discharge characteristics. Modern AGM batteries can handle higher charging currents and maintain stable voltage outputs under varying load conditions. This capability is particularly crucial in high-rise buildings, where power demands can fluctuate significantly across different systems and during emergency situations.

As the technology continues to advance, the objectives for AGM battery use in high-rise buildings are becoming more ambitious. Current goals include further increasing energy density to reduce the physical footprint of battery installations, enhancing thermal management for optimal performance in diverse climatic conditions, and improving integration with smart building management systems for more efficient energy utilization and predictive maintenance.

The ongoing evolution of AGM battery technology is closely aligned with the broader trends in sustainable building practices. As high-rise structures increasingly adopt green technologies, AGM batteries are being developed to support renewable energy integration, such as solar power systems, and to facilitate energy load balancing during peak consumption periods.

The primary objective of AGM battery technology in high-rise buildings is to provide a stable and efficient power backup system. As urban landscapes continue to evolve with taller structures, the need for dependable emergency power sources becomes paramount. AGM batteries aim to address this requirement by offering a compact, safe, and long-lasting energy storage solution that can be seamlessly integrated into modern building designs.

One of the key evolutionary aspects of AGM batteries has been the improvement in their energy density and cycle life. Over the years, manufacturers have refined the internal structure and materials used in these batteries, resulting in higher capacity and longer operational lifespans. This progress has made AGM batteries increasingly attractive for use in high-rise buildings, where space constraints and the need for durability are critical factors.

Another significant development in AGM battery technology has been the enhancement of safety features. With the growing concern for fire safety in tall buildings, AGM batteries have evolved to incorporate advanced flame-retardant materials and improved sealing techniques. These advancements have positioned AGM batteries as a safer alternative to traditional flooded lead-acid batteries, aligning with the stringent safety regulations governing high-rise constructions.

The evolution of AGM batteries has also focused on improving their charge acceptance and discharge characteristics. Modern AGM batteries can handle higher charging currents and maintain stable voltage outputs under varying load conditions. This capability is particularly crucial in high-rise buildings, where power demands can fluctuate significantly across different systems and during emergency situations.

As the technology continues to advance, the objectives for AGM battery use in high-rise buildings are becoming more ambitious. Current goals include further increasing energy density to reduce the physical footprint of battery installations, enhancing thermal management for optimal performance in diverse climatic conditions, and improving integration with smart building management systems for more efficient energy utilization and predictive maintenance.

The ongoing evolution of AGM battery technology is closely aligned with the broader trends in sustainable building practices. As high-rise structures increasingly adopt green technologies, AGM batteries are being developed to support renewable energy integration, such as solar power systems, and to facilitate energy load balancing during peak consumption periods.

High-Rise Energy Storage Demand

The demand for energy storage in high-rise buildings has been steadily increasing due to several factors. Urbanization and population growth have led to a surge in the construction of tall structures, particularly in densely populated metropolitan areas. These buildings require substantial amounts of energy for various systems, including lighting, heating, ventilation, air conditioning, elevators, and security systems. The need for reliable and efficient energy management in these structures has become paramount.

High-rise buildings face unique challenges in terms of energy consumption and distribution. The vertical nature of these structures necessitates complex power distribution systems to ensure consistent energy supply across all floors. This complexity often leads to increased energy losses and inefficiencies. Additionally, the peak energy demand in high-rise buildings can be significantly higher than in low-rise structures, putting strain on the local power grid and potentially leading to power quality issues.

The integration of renewable energy sources, such as rooftop solar panels, into high-rise buildings has further emphasized the need for effective energy storage solutions. These intermittent energy sources require storage capabilities to balance supply and demand, ensuring a stable power supply even when renewable generation is low. Energy storage systems can help smooth out the fluctuations in renewable energy production, making it more viable for high-rise buildings to incorporate sustainable energy solutions.

Another driving factor for energy storage demand in high-rise buildings is the growing focus on energy resilience and emergency preparedness. In the event of power outages or natural disasters, energy storage systems can provide critical backup power to essential building systems, ensuring the safety and comfort of occupants. This aspect has become increasingly important as climate change-related events become more frequent and severe.

The push for smart building technologies and energy management systems has also contributed to the rising demand for energy storage in high-rise structures. These advanced systems require the ability to store and manage energy efficiently, optimizing consumption patterns and reducing overall energy costs. Energy storage solutions enable buildings to participate in demand response programs, shifting energy consumption to off-peak hours and potentially generating revenue through grid services.

As cities worldwide implement stricter energy efficiency regulations and sustainability targets, high-rise buildings are under pressure to reduce their carbon footprint and improve their overall energy performance. Energy storage systems play a crucial role in achieving these goals by enabling better utilization of renewable energy, reducing peak demand charges, and improving the overall energy efficiency of the building.

High-rise buildings face unique challenges in terms of energy consumption and distribution. The vertical nature of these structures necessitates complex power distribution systems to ensure consistent energy supply across all floors. This complexity often leads to increased energy losses and inefficiencies. Additionally, the peak energy demand in high-rise buildings can be significantly higher than in low-rise structures, putting strain on the local power grid and potentially leading to power quality issues.

The integration of renewable energy sources, such as rooftop solar panels, into high-rise buildings has further emphasized the need for effective energy storage solutions. These intermittent energy sources require storage capabilities to balance supply and demand, ensuring a stable power supply even when renewable generation is low. Energy storage systems can help smooth out the fluctuations in renewable energy production, making it more viable for high-rise buildings to incorporate sustainable energy solutions.

Another driving factor for energy storage demand in high-rise buildings is the growing focus on energy resilience and emergency preparedness. In the event of power outages or natural disasters, energy storage systems can provide critical backup power to essential building systems, ensuring the safety and comfort of occupants. This aspect has become increasingly important as climate change-related events become more frequent and severe.

The push for smart building technologies and energy management systems has also contributed to the rising demand for energy storage in high-rise structures. These advanced systems require the ability to store and manage energy efficiently, optimizing consumption patterns and reducing overall energy costs. Energy storage solutions enable buildings to participate in demand response programs, shifting energy consumption to off-peak hours and potentially generating revenue through grid services.

As cities worldwide implement stricter energy efficiency regulations and sustainability targets, high-rise buildings are under pressure to reduce their carbon footprint and improve their overall energy performance. Energy storage systems play a crucial role in achieving these goals by enabling better utilization of renewable energy, reducing peak demand charges, and improving the overall energy efficiency of the building.

AGM Battery Tech Challenges

AGM (Absorbent Glass Mat) batteries face several technical challenges when considered for use in high-rise buildings. One of the primary concerns is the limited energy density compared to newer battery technologies. While AGM batteries offer improved performance over traditional lead-acid batteries, they still lag behind lithium-ion batteries in terms of energy storage capacity per unit weight and volume. This limitation becomes particularly significant in high-rise applications where space is at a premium.

Another challenge is the relatively short cycle life of AGM batteries. Although they outperform flooded lead-acid batteries, AGM batteries typically have a lower cycle life compared to lithium-ion alternatives. In high-rise buildings where frequent cycling is expected for energy management and backup power applications, this could lead to more frequent battery replacements, increasing long-term costs and maintenance requirements.

Temperature sensitivity is also a concern for AGM batteries in high-rise environments. These batteries can be sensitive to extreme temperatures, which can affect their performance and lifespan. High-rise buildings often experience significant temperature variations between lower and upper floors, potentially impacting battery performance across different levels of the building.

The charging efficiency of AGM batteries presents another technical hurdle. While they charge faster than traditional lead-acid batteries, they still require longer charging times compared to more advanced battery technologies. This can be a limitation in applications requiring rapid recharging, such as in emergency power systems or demand response scenarios in high-rise buildings.

Weight is a significant factor when considering AGM batteries for high-rise applications. These batteries are generally heavier than lithium-ion alternatives, which can pose structural challenges and increase installation complexity, especially in retrofitting scenarios for existing high-rise buildings.

Ventilation and safety requirements also present technical challenges. Although AGM batteries are sealed and require less ventilation than flooded lead-acid batteries, they still produce some hydrogen gas during charging. In high-rise buildings, ensuring proper ventilation and safety measures for large battery installations can be complex and costly.

Lastly, the integration of AGM batteries with smart building management systems and renewable energy sources poses technical challenges. While AGM batteries can be used in these applications, they may lack the advanced monitoring and control features found in more modern battery technologies, potentially limiting their effectiveness in sophisticated energy management strategies for high-rise buildings.

Another challenge is the relatively short cycle life of AGM batteries. Although they outperform flooded lead-acid batteries, AGM batteries typically have a lower cycle life compared to lithium-ion alternatives. In high-rise buildings where frequent cycling is expected for energy management and backup power applications, this could lead to more frequent battery replacements, increasing long-term costs and maintenance requirements.

Temperature sensitivity is also a concern for AGM batteries in high-rise environments. These batteries can be sensitive to extreme temperatures, which can affect their performance and lifespan. High-rise buildings often experience significant temperature variations between lower and upper floors, potentially impacting battery performance across different levels of the building.

The charging efficiency of AGM batteries presents another technical hurdle. While they charge faster than traditional lead-acid batteries, they still require longer charging times compared to more advanced battery technologies. This can be a limitation in applications requiring rapid recharging, such as in emergency power systems or demand response scenarios in high-rise buildings.

Weight is a significant factor when considering AGM batteries for high-rise applications. These batteries are generally heavier than lithium-ion alternatives, which can pose structural challenges and increase installation complexity, especially in retrofitting scenarios for existing high-rise buildings.

Ventilation and safety requirements also present technical challenges. Although AGM batteries are sealed and require less ventilation than flooded lead-acid batteries, they still produce some hydrogen gas during charging. In high-rise buildings, ensuring proper ventilation and safety measures for large battery installations can be complex and costly.

Lastly, the integration of AGM batteries with smart building management systems and renewable energy sources poses technical challenges. While AGM batteries can be used in these applications, they may lack the advanced monitoring and control features found in more modern battery technologies, potentially limiting their effectiveness in sophisticated energy management strategies for high-rise buildings.

Current AGM Solutions for Buildings

01 AGM battery structure and design

Innovations in AGM battery structure and design focus on improving performance and efficiency. This includes advancements in electrode design, separator materials, and overall battery construction to enhance capacity, lifespan, and charge-discharge characteristics.- AGM battery structure and design: Advancements in AGM battery structure and design focus on improving performance and efficiency. This includes innovations in electrode arrangements, separator materials, and overall battery construction to enhance capacity, lifespan, and charge-discharge characteristics.

- Electrolyte management in AGM batteries: Techniques for optimizing electrolyte distribution and retention within AGM batteries are crucial for their performance. This involves innovative approaches to electrolyte absorption, distribution, and management to improve battery efficiency and longevity.

- Thermal management of AGM batteries: Effective thermal management is essential for AGM battery performance and safety. Innovations in this area include heat dissipation techniques, temperature control mechanisms, and thermal insulation methods to maintain optimal operating conditions.

- AGM battery manufacturing processes: Advancements in manufacturing processes for AGM batteries aim to improve production efficiency and product quality. This includes innovations in assembly techniques, quality control measures, and automation of production steps.

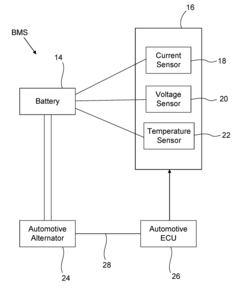

- AGM battery monitoring and management systems: Development of sophisticated monitoring and management systems for AGM batteries enhances their performance and lifespan. These systems include advanced sensors, data analysis algorithms, and control mechanisms to optimize battery operation and maintenance.

02 Thermal management systems for AGM batteries

Thermal management solutions are developed to maintain optimal operating temperatures for AGM batteries. These systems help prevent overheating, extend battery life, and improve overall performance, especially in high-demand applications or extreme environmental conditions.Expand Specific Solutions03 AGM battery monitoring and control systems

Advanced monitoring and control systems are implemented to optimize AGM battery performance. These systems track battery health, manage charging processes, and provide real-time data on battery status, enabling more efficient and reliable operation.Expand Specific Solutions04 AGM battery manufacturing processes

Improved manufacturing techniques are developed to enhance AGM battery production. These processes focus on increasing efficiency, reducing costs, and improving quality control in the production of AGM batteries, resulting in more consistent and reliable products.Expand Specific Solutions05 AGM battery applications and integration

Innovations in AGM battery applications and integration explore new use cases and improved integration methods. This includes advancements in battery pack design, connection systems, and adaptations for specific industries or devices, expanding the versatility of AGM batteries.Expand Specific Solutions

Key AGM Battery Manufacturers

The market for AGM battery use in high-rise buildings is in a growth phase, driven by increasing demand for reliable backup power systems and energy storage solutions in urban environments. The global market size for AGM batteries in this sector is expanding, with projections indicating significant growth potential. Technologically, AGM batteries are relatively mature, offering advantages in terms of safety and maintenance compared to traditional lead-acid batteries. Companies like Johnson Controls, Daramic LLC, and Hoppecke Batterien are at the forefront of AGM battery technology, continuously improving performance and efficiency. Emerging players such as SK Innovation and Stryten Energy are also contributing to market competitiveness through innovative energy storage solutions tailored for high-rise applications.

Hoppecke Batterien GmbH & Co. KG

Technical Solution: Hoppecke has developed specialized AGM battery solutions for high-rise building applications, focusing on reliability and safety. Their AGM batteries feature a unique grid alloy composition that enhances corrosion resistance and reduces self-discharge rates, ensuring long-term performance in standby power applications. Hoppecke's AGM technology incorporates a patented plate design that optimizes current distribution and minimizes internal stress, extending battery life in cyclic use scenarios common in modern high-rise energy management systems[8]. The company has also implemented advanced manufacturing techniques to ensure consistent quality and performance across their AGM battery range. Hoppecke's batteries are equipped with integrated monitoring systems that provide real-time data on battery health and performance, enabling proactive maintenance and reducing the risk of unexpected failures[9]. Their AGM batteries are designed to operate efficiently in a wide temperature range, making them suitable for various climatic conditions encountered in high-rise buildings worldwide.

Strengths: High reliability, advanced monitoring capabilities, and wide operating temperature range. Weaknesses: May have a higher price point compared to some competitors, and potential limitations in very high-power density applications.

Stryten Energy LLC

Technical Solution: Stryten Energy has developed a range of AGM batteries specifically engineered for stationary power applications in high-rise buildings. Their AGM technology features a proprietary separator material that enhances electrolyte absorption and improves charge acceptance rates, crucial for rapid recharging during brief power outages. Stryten's AGM batteries incorporate advanced grid designs that minimize internal resistance and maximize power output, ensuring reliable performance for critical building systems[6]. The company has also implemented flame-retardant battery casings and pressure relief valves to enhance safety in enclosed building environments. Stryten's AGM batteries are designed for long service life, with some models rated for up to 12 years in float service applications[7]. Additionally, they offer modular battery systems that can be easily scaled to meet the varying power requirements of different high-rise structures.

Strengths: High charge acceptance rates, long service life, and modular scalability. Weaknesses: May have limitations in extreme temperature environments compared to some newer battery technologies.

AGM Innovations for Vertical Applications

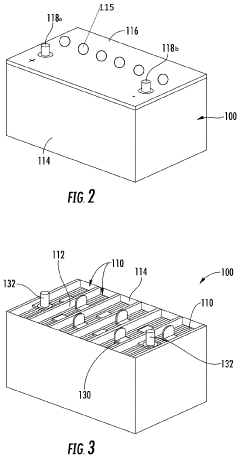

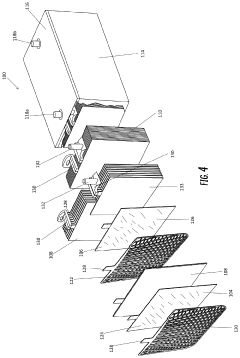

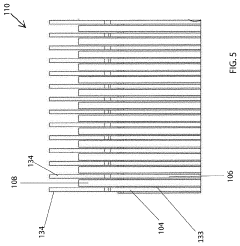

Compact absorbent glass mat battery

PatentPendingUS20200212504A1

Innovation

- A compact AGM lead acid battery design with a reduced lead content and smaller size, utilizing a container with electrically connected cells and an absorbent glass mat interleaved between positive and negative plates, achieving improved cycle life and higher CCA performance.

Method for Charging a Battery Having a Plurality of Battery Cells

PatentActiveUS20180134168A1

Innovation

- A battery management system (BMS) that dynamically controls the charging process using sensors for real-time monitoring of battery current, voltage, and temperature, implementing a multi-stage charging strategy including bulk charging, absorption, equalization, and float phases, with adaptive voltage and current adjustments to optimize charging efficiency and prevent overcharging and undercharging.

Building Code Compliance for AGM Batteries

The integration of AGM (Absorbent Glass Mat) batteries in high-rise buildings requires careful consideration of building codes and safety regulations. These codes are designed to ensure the safe installation, operation, and maintenance of energy storage systems within tall structures.

Most building codes classify AGM batteries as stationary storage battery systems. As such, they must comply with specific requirements outlined in the International Building Code (IBC) and the International Fire Code (IFC). These codes typically mandate that large-scale battery installations be located in dedicated rooms with proper fire-resistant construction and adequate ventilation.

Fire safety is a primary concern in high-rise buildings. AGM batteries, while generally considered safer than flooded lead-acid batteries, still pose potential fire risks. Building codes often require the installation of automatic fire detection and suppression systems in battery rooms. Additionally, these spaces must be equipped with appropriate fire-rated doors and walls to contain potential fires and prevent their spread to other areas of the building.

Ventilation requirements are another critical aspect of code compliance. Although AGM batteries produce minimal gas emissions during normal operation, proper ventilation is still necessary to dissipate heat and prevent the accumulation of any potential off-gassing. Building codes typically specify minimum air exchange rates and may require the installation of dedicated exhaust systems.

Structural considerations are also addressed in building codes for battery installations. The weight of AGM battery systems must be factored into the building's structural design, especially when retrofitting existing structures. Floor loading capacity and seismic resistance are key factors that need to be evaluated and potentially reinforced to meet code requirements.

Electrical safety is paramount in high-rise battery installations. Building codes mandate proper electrical protection systems, including overcurrent protection, disconnect switches, and grounding. These systems must be designed to handle the specific characteristics of AGM batteries and their associated charging and discharging equipment.

Access and egress requirements for battery rooms are also stipulated in building codes. These spaces must have adequate clearances for maintenance and emergency personnel, as well as clearly marked exit routes. In some cases, secondary containment measures may be required to prevent the spread of electrolyte in the event of a battery leak.

Compliance with these building codes often requires close collaboration between battery system designers, architects, and local building officials. Regular inspections and maintenance procedures must be established to ensure ongoing compliance and safety throughout the lifecycle of the AGM battery installation in high-rise buildings.

Most building codes classify AGM batteries as stationary storage battery systems. As such, they must comply with specific requirements outlined in the International Building Code (IBC) and the International Fire Code (IFC). These codes typically mandate that large-scale battery installations be located in dedicated rooms with proper fire-resistant construction and adequate ventilation.

Fire safety is a primary concern in high-rise buildings. AGM batteries, while generally considered safer than flooded lead-acid batteries, still pose potential fire risks. Building codes often require the installation of automatic fire detection and suppression systems in battery rooms. Additionally, these spaces must be equipped with appropriate fire-rated doors and walls to contain potential fires and prevent their spread to other areas of the building.

Ventilation requirements are another critical aspect of code compliance. Although AGM batteries produce minimal gas emissions during normal operation, proper ventilation is still necessary to dissipate heat and prevent the accumulation of any potential off-gassing. Building codes typically specify minimum air exchange rates and may require the installation of dedicated exhaust systems.

Structural considerations are also addressed in building codes for battery installations. The weight of AGM battery systems must be factored into the building's structural design, especially when retrofitting existing structures. Floor loading capacity and seismic resistance are key factors that need to be evaluated and potentially reinforced to meet code requirements.

Electrical safety is paramount in high-rise battery installations. Building codes mandate proper electrical protection systems, including overcurrent protection, disconnect switches, and grounding. These systems must be designed to handle the specific characteristics of AGM batteries and their associated charging and discharging equipment.

Access and egress requirements for battery rooms are also stipulated in building codes. These spaces must have adequate clearances for maintenance and emergency personnel, as well as clearly marked exit routes. In some cases, secondary containment measures may be required to prevent the spread of electrolyte in the event of a battery leak.

Compliance with these building codes often requires close collaboration between battery system designers, architects, and local building officials. Regular inspections and maintenance procedures must be established to ensure ongoing compliance and safety throughout the lifecycle of the AGM battery installation in high-rise buildings.

Environmental Impact of AGM in Buildings

The environmental impact of AGM (Absorbent Glass Mat) batteries in high-rise buildings is a crucial consideration as the adoption of these energy storage solutions increases. AGM batteries offer several environmental advantages over traditional lead-acid batteries, contributing to a more sustainable built environment.

One of the primary environmental benefits of AGM batteries is their sealed design, which eliminates the risk of electrolyte leakage. This feature prevents soil and water contamination, a significant concern in urban areas where high-rise buildings are prevalent. The sealed nature of AGM batteries also reduces the emission of harmful gases, improving indoor air quality and minimizing the potential for atmospheric pollution.

AGM batteries demonstrate superior energy efficiency compared to conventional battery types. This increased efficiency translates to reduced energy consumption during charging cycles, ultimately lowering the overall carbon footprint of the building's energy systems. The improved charge acceptance of AGM batteries also means they can more effectively capture and store energy from renewable sources, such as solar panels, further enhancing the environmental sustainability of high-rise structures.

The longer lifespan of AGM batteries contributes to waste reduction in the long term. With a typical service life of 5-7 years, AGM batteries require less frequent replacement than traditional lead-acid batteries. This longevity reduces the environmental impact associated with battery production, transportation, and disposal. Additionally, AGM batteries are highly recyclable, with up to 99% of their components being recoverable and reusable, minimizing the burden on landfills and conserving natural resources.

In terms of space utilization, AGM batteries offer a more compact solution compared to flooded lead-acid batteries. This space efficiency is particularly valuable in high-rise buildings where floor area is at a premium. The reduced footprint of AGM battery installations allows for more efficient use of building space, potentially decreasing the overall environmental impact of the structure.

The maintenance-free nature of AGM batteries also contributes to their environmental friendliness. Unlike flooded lead-acid batteries, AGM batteries do not require regular water additions or equalization charges. This characteristic reduces the need for maintenance-related transportation and eliminates the use of additional chemicals, further minimizing the environmental footprint of battery upkeep in high-rise buildings.

However, it is important to note that the production of AGM batteries still involves environmental considerations. The manufacturing process requires energy and resources, and the batteries contain lead, which is a toxic material. Proper end-of-life management and recycling programs are essential to mitigate these environmental concerns and maximize the sustainability benefits of AGM battery use in high-rise buildings.

One of the primary environmental benefits of AGM batteries is their sealed design, which eliminates the risk of electrolyte leakage. This feature prevents soil and water contamination, a significant concern in urban areas where high-rise buildings are prevalent. The sealed nature of AGM batteries also reduces the emission of harmful gases, improving indoor air quality and minimizing the potential for atmospheric pollution.

AGM batteries demonstrate superior energy efficiency compared to conventional battery types. This increased efficiency translates to reduced energy consumption during charging cycles, ultimately lowering the overall carbon footprint of the building's energy systems. The improved charge acceptance of AGM batteries also means they can more effectively capture and store energy from renewable sources, such as solar panels, further enhancing the environmental sustainability of high-rise structures.

The longer lifespan of AGM batteries contributes to waste reduction in the long term. With a typical service life of 5-7 years, AGM batteries require less frequent replacement than traditional lead-acid batteries. This longevity reduces the environmental impact associated with battery production, transportation, and disposal. Additionally, AGM batteries are highly recyclable, with up to 99% of their components being recoverable and reusable, minimizing the burden on landfills and conserving natural resources.

In terms of space utilization, AGM batteries offer a more compact solution compared to flooded lead-acid batteries. This space efficiency is particularly valuable in high-rise buildings where floor area is at a premium. The reduced footprint of AGM battery installations allows for more efficient use of building space, potentially decreasing the overall environmental impact of the structure.

The maintenance-free nature of AGM batteries also contributes to their environmental friendliness. Unlike flooded lead-acid batteries, AGM batteries do not require regular water additions or equalization charges. This characteristic reduces the need for maintenance-related transportation and eliminates the use of additional chemicals, further minimizing the environmental footprint of battery upkeep in high-rise buildings.

However, it is important to note that the production of AGM batteries still involves environmental considerations. The manufacturing process requires energy and resources, and the batteries contain lead, which is a toxic material. Proper end-of-life management and recycling programs are essential to mitigate these environmental concerns and maximize the sustainability benefits of AGM battery use in high-rise buildings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!