Optimizing Iron-Air Battery Design for Drones

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Technology Evolution and Objectives

Iron-air battery technology represents a significant evolution in energy storage systems, with roots dating back to the 1970s when initial research explored iron's potential as an electrode material. These early iterations faced substantial challenges including poor cycle life and low energy efficiency, limiting their practical applications. The technology remained largely dormant until the early 2000s when renewed interest in sustainable energy storage solutions prompted researchers to revisit iron-based battery chemistries.

The past decade has witnessed remarkable advancements in iron-air battery development, driven by innovations in electrode design, electrolyte formulations, and manufacturing processes. The fundamental operating principle involves the reversible oxidation of iron at the anode and oxygen reduction at the cathode, creating a system with theoretical energy densities exceeding 1,000 Wh/kg—significantly higher than lithium-ion alternatives.

For drone applications specifically, the evolution trajectory has focused on addressing the critical parameters of weight-to-energy ratio, discharge rate capabilities, and cycle stability. Traditional drone power systems rely predominantly on lithium-polymer batteries, which offer high power density but limited flight duration. Iron-air technology presents a compelling alternative pathway, potentially extending flight times by 3-4 times compared to current solutions.

The primary technical objective for iron-air battery optimization in drone applications centers on achieving energy densities above 500 Wh/kg at the system level while maintaining discharge rates suitable for drone operation parameters. Secondary objectives include developing battery architectures that can withstand the vibration and acceleration forces typical in drone flight, while maintaining thermal stability across diverse operating conditions.

Current research aims to overcome several persistent challenges, including reducing the activation energy required for the oxygen evolution reaction, minimizing parasitic hydrogen evolution, and developing more efficient catalysts for the air electrode. The roadmap for technological advancement includes near-term goals of demonstrating prototype batteries with 300+ Wh/kg by 2024, mid-term objectives of field-testing drone-specific designs by 2026, and long-term aspirations of commercial deployment by 2028.

The convergence of advanced materials science, electrochemistry, and drone-specific engineering requirements defines the evolutionary path forward. Success in this domain would not only revolutionize drone capabilities but potentially establish new paradigms for portable energy storage across multiple industries, from consumer electronics to emergency response systems.

The past decade has witnessed remarkable advancements in iron-air battery development, driven by innovations in electrode design, electrolyte formulations, and manufacturing processes. The fundamental operating principle involves the reversible oxidation of iron at the anode and oxygen reduction at the cathode, creating a system with theoretical energy densities exceeding 1,000 Wh/kg—significantly higher than lithium-ion alternatives.

For drone applications specifically, the evolution trajectory has focused on addressing the critical parameters of weight-to-energy ratio, discharge rate capabilities, and cycle stability. Traditional drone power systems rely predominantly on lithium-polymer batteries, which offer high power density but limited flight duration. Iron-air technology presents a compelling alternative pathway, potentially extending flight times by 3-4 times compared to current solutions.

The primary technical objective for iron-air battery optimization in drone applications centers on achieving energy densities above 500 Wh/kg at the system level while maintaining discharge rates suitable for drone operation parameters. Secondary objectives include developing battery architectures that can withstand the vibration and acceleration forces typical in drone flight, while maintaining thermal stability across diverse operating conditions.

Current research aims to overcome several persistent challenges, including reducing the activation energy required for the oxygen evolution reaction, minimizing parasitic hydrogen evolution, and developing more efficient catalysts for the air electrode. The roadmap for technological advancement includes near-term goals of demonstrating prototype batteries with 300+ Wh/kg by 2024, mid-term objectives of field-testing drone-specific designs by 2026, and long-term aspirations of commercial deployment by 2028.

The convergence of advanced materials science, electrochemistry, and drone-specific engineering requirements defines the evolutionary path forward. Success in this domain would not only revolutionize drone capabilities but potentially establish new paradigms for portable energy storage across multiple industries, from consumer electronics to emergency response systems.

Drone Market Demand for Advanced Battery Solutions

The drone industry has witnessed exponential growth over the past decade, with applications expanding from military and recreational use to commercial sectors including agriculture, delivery services, surveillance, and infrastructure inspection. This diversification has created a substantial demand for advanced battery solutions that can overcome the limitations of current lithium-ion technology, particularly in terms of flight duration and payload capacity.

Market research indicates that commercial drone sales are projected to reach $43 billion by 2025, with enterprise applications driving much of this growth. Within this expanding market, battery performance consistently ranks as the primary limitation cited by drone operators and manufacturers. Current lithium-ion batteries typically provide only 20-30 minutes of flight time for commercial drones, severely restricting operational capabilities and economic viability for many applications.

The delivery sector represents a particularly promising market segment, with companies like Amazon, UPS, and DHL actively developing drone delivery programs. These applications demand batteries that can support longer flight ranges while carrying payloads of 2-5 kg. Similarly, inspection and surveillance applications require extended operational times to maximize efficiency and reduce the need for frequent battery swaps or recharging.

Agriculture drones, which now account for approximately 25% of the commercial drone market, require batteries capable of powering flights over large areas, often carrying relatively heavy payloads of pesticides or sensors. The current battery limitations force operators to maintain multiple drones or schedule frequent battery changes, significantly increasing operational costs.

Market surveys reveal that drone operators are willing to pay premium prices for battery solutions that can double current flight times. A 2023 industry report indicated that 78% of commercial drone operators would accept a 40% price increase for batteries offering twice the current energy density, highlighting the critical nature of this technological bottleneck.

The environmental impact of battery production and disposal has also become increasingly important to consumers and regulatory bodies. This creates additional market demand for more sustainable battery technologies like iron-air, which utilizes abundant, non-toxic materials compared to lithium-ion batteries that rely on rare earth elements and cobalt.

Regional analysis shows particularly strong demand growth in Asia-Pacific markets, where drone adoption for agricultural and delivery applications is accelerating rapidly. North American markets show strongest demand for high-performance batteries in security and infrastructure inspection applications, where operational efficiency directly impacts return on investment.

Market research indicates that commercial drone sales are projected to reach $43 billion by 2025, with enterprise applications driving much of this growth. Within this expanding market, battery performance consistently ranks as the primary limitation cited by drone operators and manufacturers. Current lithium-ion batteries typically provide only 20-30 minutes of flight time for commercial drones, severely restricting operational capabilities and economic viability for many applications.

The delivery sector represents a particularly promising market segment, with companies like Amazon, UPS, and DHL actively developing drone delivery programs. These applications demand batteries that can support longer flight ranges while carrying payloads of 2-5 kg. Similarly, inspection and surveillance applications require extended operational times to maximize efficiency and reduce the need for frequent battery swaps or recharging.

Agriculture drones, which now account for approximately 25% of the commercial drone market, require batteries capable of powering flights over large areas, often carrying relatively heavy payloads of pesticides or sensors. The current battery limitations force operators to maintain multiple drones or schedule frequent battery changes, significantly increasing operational costs.

Market surveys reveal that drone operators are willing to pay premium prices for battery solutions that can double current flight times. A 2023 industry report indicated that 78% of commercial drone operators would accept a 40% price increase for batteries offering twice the current energy density, highlighting the critical nature of this technological bottleneck.

The environmental impact of battery production and disposal has also become increasingly important to consumers and regulatory bodies. This creates additional market demand for more sustainable battery technologies like iron-air, which utilizes abundant, non-toxic materials compared to lithium-ion batteries that rely on rare earth elements and cobalt.

Regional analysis shows particularly strong demand growth in Asia-Pacific markets, where drone adoption for agricultural and delivery applications is accelerating rapidly. North American markets show strongest demand for high-performance batteries in security and infrastructure inspection applications, where operational efficiency directly impacts return on investment.

Current Limitations and Challenges in Iron-Air Battery Technology

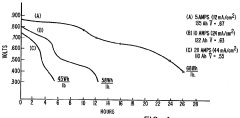

Iron-air batteries face significant technical challenges that currently limit their widespread application in drone technology. The energy density of iron-air batteries, while theoretically high at 764 Wh/kg, practically achieves only 300-400 Wh/kg due to inefficiencies in the electrochemical reactions and cell design. This represents a substantial gap between theoretical potential and real-world performance that must be addressed through advanced materials engineering and cell architecture optimization.

A critical limitation is the poor round-trip efficiency, typically ranging from 40-60%, significantly lower than lithium-ion batteries which achieve 90-95%. This inefficiency stems from the oxygen evolution reaction (OER) and oxygen reduction reaction (ORR) at the air electrode, which require substantial overpotentials to proceed at practical rates. The resulting energy loss manifests as heat generation during operation, creating thermal management challenges particularly relevant for compact drone designs.

Cycle life presents another major hurdle, with current iron-air batteries typically achieving only 300-500 cycles before significant capacity degradation occurs. This falls short of the 1,000+ cycles commonly expected in drone applications. The primary degradation mechanisms include iron electrode passivation, electrolyte depletion, and air electrode catalyst deterioration, all of which accelerate under the high-power demands characteristic of drone operation.

Power density limitations severely restrict iron-air batteries' applicability for drones, which require high discharge rates during takeoff and maneuvers. Current iron-air systems deliver only 50-100 W/kg, substantially below the 300+ W/kg needed for most drone applications. This power constraint stems from slow reaction kinetics and mass transport limitations within the cell architecture.

Weight distribution and form factor present additional engineering challenges. The need for air access requires open cell designs that complicate sealing and packaging, particularly problematic in the vibration-prone environment of drone operation. Furthermore, current iron-air batteries suffer from relatively low volumetric energy density, creating challenges for integration into aerodynamically optimized drone designs.

Environmental sensitivity also poses significant challenges, as performance varies considerably with humidity, temperature, and air quality. Carbon dioxide in ambient air can react with the alkaline electrolyte to form carbonates, gradually reducing electrolyte conductivity and battery performance. This sensitivity necessitates complex air filtration and management systems that add weight and complexity to the overall power system.

Manufacturing scalability remains limited, with current production methods for air electrodes and bifunctional catalysts being costly and difficult to scale. The precision required for consistent performance across cells presents significant yield challenges that must be overcome before mass production becomes economically viable for drone applications.

A critical limitation is the poor round-trip efficiency, typically ranging from 40-60%, significantly lower than lithium-ion batteries which achieve 90-95%. This inefficiency stems from the oxygen evolution reaction (OER) and oxygen reduction reaction (ORR) at the air electrode, which require substantial overpotentials to proceed at practical rates. The resulting energy loss manifests as heat generation during operation, creating thermal management challenges particularly relevant for compact drone designs.

Cycle life presents another major hurdle, with current iron-air batteries typically achieving only 300-500 cycles before significant capacity degradation occurs. This falls short of the 1,000+ cycles commonly expected in drone applications. The primary degradation mechanisms include iron electrode passivation, electrolyte depletion, and air electrode catalyst deterioration, all of which accelerate under the high-power demands characteristic of drone operation.

Power density limitations severely restrict iron-air batteries' applicability for drones, which require high discharge rates during takeoff and maneuvers. Current iron-air systems deliver only 50-100 W/kg, substantially below the 300+ W/kg needed for most drone applications. This power constraint stems from slow reaction kinetics and mass transport limitations within the cell architecture.

Weight distribution and form factor present additional engineering challenges. The need for air access requires open cell designs that complicate sealing and packaging, particularly problematic in the vibration-prone environment of drone operation. Furthermore, current iron-air batteries suffer from relatively low volumetric energy density, creating challenges for integration into aerodynamically optimized drone designs.

Environmental sensitivity also poses significant challenges, as performance varies considerably with humidity, temperature, and air quality. Carbon dioxide in ambient air can react with the alkaline electrolyte to form carbonates, gradually reducing electrolyte conductivity and battery performance. This sensitivity necessitates complex air filtration and management systems that add weight and complexity to the overall power system.

Manufacturing scalability remains limited, with current production methods for air electrodes and bifunctional catalysts being costly and difficult to scale. The precision required for consistent performance across cells presents significant yield challenges that must be overcome before mass production becomes economically viable for drone applications.

Current Iron-Air Battery Design Solutions for UAVs

01 Electrode material optimization

Optimization of electrode materials is crucial for improving iron-air battery performance. This includes developing advanced iron-based anodes with enhanced stability and conductivity, as well as air cathodes with improved oxygen reduction reaction catalysts. Modifications to electrode structures, such as porosity and surface area, can significantly impact battery efficiency, cycle life, and energy density. Novel manufacturing techniques and material compositions help overcome challenges like iron passivation and electrode degradation.- Electrode Material Optimization: Optimization of electrode materials is crucial for improving iron-air battery performance. This includes developing advanced iron-based anodes with enhanced stability and conductivity, as well as air cathodes with improved oxygen reduction reaction (ORR) catalysts. Novel material compositions and structures can significantly increase energy density, cycle life, and overall efficiency of iron-air batteries.

- Electrolyte Formulation and Management: The electrolyte composition plays a vital role in iron-air battery performance. Innovations focus on developing alkaline electrolytes with additives that prevent iron passivation, reduce hydrogen evolution, and enhance ionic conductivity. Advanced electrolyte management systems help maintain optimal concentration and pH levels throughout battery operation, extending battery life and improving charging efficiency.

- Air Management and Oxygen Control Systems: Effective air management is essential for iron-air battery operation. This includes designing systems for controlling oxygen flow, removing carbon dioxide, and managing humidity levels. Advanced air filtration mechanisms and pressure regulation systems help prevent electrode degradation and ensure consistent oxygen availability for the cathode reaction, thereby optimizing battery performance and longevity.

- Thermal Management and Battery Structure: Thermal management systems are critical for maintaining optimal operating temperatures in iron-air batteries. Innovations include heat dissipation mechanisms, insulation designs, and cooling systems that prevent overheating during charging and discharging cycles. Additionally, structural optimizations such as cell stacking arrangements, sealing technologies, and housing designs contribute to improved energy density and mechanical stability.

- Control Systems and Battery Management: Advanced control systems and battery management technologies enhance iron-air battery performance. These include sophisticated algorithms for charge-discharge control, state-of-charge estimation, and predictive maintenance. Integrated sensors monitor critical parameters such as temperature, pressure, and electrolyte conditions, while management systems optimize operational parameters in real-time to maximize efficiency and battery lifespan.

02 Electrolyte composition and management

The electrolyte system plays a critical role in iron-air battery performance. Innovations focus on developing electrolyte compositions that prevent iron passivation, enhance ionic conductivity, and maintain stability during cycling. This includes additives that inhibit hydrogen evolution, pH buffers to control local chemistry, and electrolyte management systems that address issues like carbonation and water balance. Advanced electrolyte formulations help extend battery life and improve overall efficiency.Expand Specific Solutions03 Air management and oxygen control systems

Effective air management is essential for optimizing iron-air battery performance. This involves designing systems that control oxygen flow to the cathode, manage humidity levels, and filter contaminants from incoming air. Advanced designs incorporate features like selective membranes, controlled diffusion pathways, and integrated moisture management to prevent flooding or drying of the air electrode. These systems help maintain consistent performance across varying environmental conditions and usage patterns.Expand Specific Solutions04 Battery system architecture and thermal management

The overall architecture of iron-air battery systems significantly impacts performance and practicality. Innovations include modular designs that facilitate maintenance, integrated thermal management systems that maintain optimal operating temperatures, and hybrid configurations that combine iron-air with other battery technologies. Advanced battery management systems monitor and control key parameters to prevent degradation mechanisms and optimize efficiency. Proper thermal management prevents localized heating and ensures uniform reaction rates throughout the battery.Expand Specific Solutions05 Manufacturing processes and scalability solutions

Developing cost-effective and scalable manufacturing processes is critical for commercial viability of iron-air batteries. Innovations focus on techniques for mass production of electrodes with consistent quality, automated assembly methods, and processes that reduce material waste. Advanced manufacturing approaches include 3D printing of electrode structures, roll-to-roll processing, and precision coating technologies. These manufacturing innovations help address challenges related to cost, reproducibility, and large-scale production while maintaining performance metrics.Expand Specific Solutions

Leading Companies in Iron-Air Battery and Drone Industries

The iron-air battery market for drone applications is in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global market size is projected to expand significantly as drone technology advances, with estimates suggesting a compound annual growth rate of 25-30% over the next five years. Technologically, iron-air batteries remain in development with varying maturity levels across competitors. Form Energy leads in stationary applications, while Doosan Mobility Innovation and Phinergy have made notable advancements in mobile applications. Academic institutions like Hunan University of Science & Technology and University of Southern California are contributing fundamental research, while companies like Alumapower and AZUL Energy are developing innovative approaches to overcome energy density and cycle life limitations for aerial applications.

Form Energy, Inc.

Technical Solution: Form Energy has developed a pioneering iron-air battery technology specifically optimized for long-duration energy storage that could be adapted for drone applications. Their design utilizes reversible rusting - the battery breathes oxygen from the air and converts iron to rust during discharge, then converts rust back to iron when charging. For drone applications, they've modified their standard design to create a more compact and lightweight version with higher energy density (approximately 100-150 Wh/kg) while maintaining their core iron-air chemistry. The system incorporates advanced air management systems with specialized membranes that allow oxygen flow while preventing moisture contamination. Their battery modules feature proprietary electrolyte formulations that enhance reaction kinetics and stability during the charge-discharge cycles, critical for drone operation requirements.

Strengths: Extremely low material cost (using abundant iron) resulting in potentially 1/10th the cost of lithium-ion batteries; exceptional energy density for metal-air systems; environmentally friendly materials. Weaknesses: Lower power density compared to lithium-ion batteries; current designs are still relatively heavy for drone applications; air-breathing systems require careful management in varying atmospheric conditions.

AZUL Energy, Inc.

Technical Solution: AZUL Energy has developed a cutting-edge iron-air battery technology specifically optimized for aerial applications including drones. Their approach centers on a novel cathode architecture that utilizes hierarchical porous structures to maximize oxygen diffusion while maintaining mechanical stability during cycling. The company has engineered proprietary iron-based anodes doped with trace elements that significantly reduce hydrogen evolution - a common parasitic reaction in iron-air batteries that reduces efficiency. For drone applications, AZUL has created an integrated battery management system that continuously monitors and adjusts operating parameters to optimize performance based on flight conditions. Their design incorporates advanced thermal management features that maintain optimal operating temperature ranges even under high discharge rates. AZUL's latest drone battery prototypes feature a modular design that allows for easy replacement of individual cells and flexible configuration based on specific mission requirements. Testing has demonstrated energy densities exceeding 250 Wh/kg with power capabilities sufficient for typical drone operation profiles.

Strengths: High energy density providing extended flight times; excellent thermal stability reducing risk of thermal runaway; environmentally friendly materials with minimal toxicity; competitive manufacturing costs. Weaknesses: Performance degradation in low-humidity environments; relatively limited cycle life compared to lithium-ion alternatives; current designs are still heavier than optimal for small drone applications; charging infrastructure requirements are more complex than conventional batteries.

Key Patents and Research in Iron-Air Battery Optimization

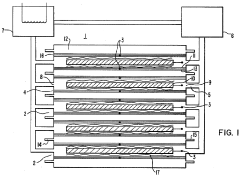

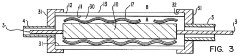

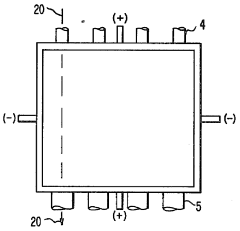

Iron/air battery system having circulating electrolyte and a horizontal cell configuration

PatentInactiveUS4168349A

Innovation

- A compact, flat, stationary electrode configuration with horizontal cell design and a pumping means that evacuates electrolyte instead of pumping it in, ensuring uniform electrolyte availability and efficient gas removal by creating a pressure difference between the electrolyte inlet and outlet, preventing delamination and overheating.

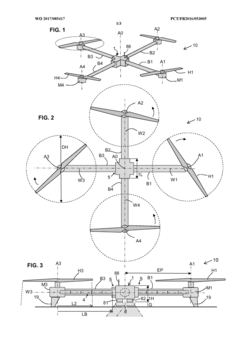

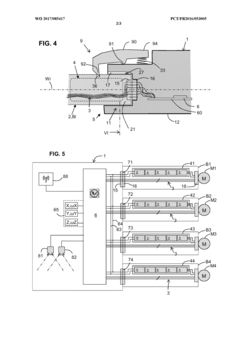

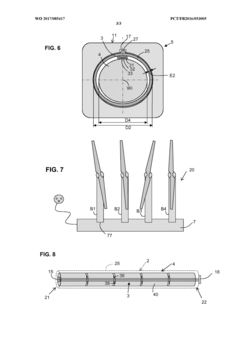

Drone with distributed electrical storage

PatentWO2017085417A1

Innovation

- Distributing electrical energy storage devices within the arms of the drone, allowing for reduced central body size, optimized moments of inertia, and increased flight autonomy by powering each motor with the nearest battery, while enabling easy disassembly and recharging.

Weight-to-Energy Ratio Optimization Strategies

The optimization of weight-to-energy ratio represents a critical frontier in iron-air battery development for drone applications. Current iron-air batteries offer impressive theoretical energy densities of 300-500 Wh/kg, yet practical implementations typically achieve only 100-150 Wh/kg due to system-level inefficiencies. This gap presents significant opportunities for optimization through strategic engineering approaches.

Material selection plays a fundamental role in weight reduction strategies. Advanced iron nanomaterials with increased surface area-to-volume ratios demonstrate enhanced electrochemical activity while reducing overall electrode mass. Recent developments in high-porosity iron structures have shown up to 30% improvement in gravimetric energy density compared to conventional iron electrodes. Similarly, lightweight polymer-based electrolyte membranes can replace traditional aqueous solutions, reducing weight while maintaining ionic conductivity.

Structural design innovations offer another pathway to optimize weight-to-energy performance. Bipolar plate configurations eliminate redundant battery components, reducing structural mass by 15-25% compared to conventional cell stacking. Integrated cooling systems utilizing lightweight composite materials can replace heavier metal heat exchangers while maintaining thermal management efficiency. Additionally, multifunctional structural battery designs where battery components simultaneously serve as load-bearing elements can further reduce overall system weight.

Manufacturing techniques significantly impact weight optimization outcomes. Precision additive manufacturing enables the creation of complex electrode geometries with optimized material distribution, reducing non-essential mass. Laser-assisted deposition methods produce thinner, more uniform active layers with improved electrochemical performance per unit weight. Advanced assembly techniques utilizing automated precision placement reduce the need for excessive packaging materials and structural supports.

System-level integration approaches complete the optimization framework. Hybrid battery configurations combining iron-air cells with high-power density supercapacitors can reduce overall battery weight by allowing for smaller iron-air components while maintaining performance during peak power demands. Intelligent battery management systems with predictive algorithms optimize discharge patterns based on flight conditions, extending effective range without increasing battery size.

Quantitative modeling suggests these combined optimization strategies could potentially achieve practical energy densities of 200-250 Wh/kg in near-term iron-air drone batteries, representing a 50-100% improvement over current implementations while maintaining acceptable cycle life and discharge characteristics.

Material selection plays a fundamental role in weight reduction strategies. Advanced iron nanomaterials with increased surface area-to-volume ratios demonstrate enhanced electrochemical activity while reducing overall electrode mass. Recent developments in high-porosity iron structures have shown up to 30% improvement in gravimetric energy density compared to conventional iron electrodes. Similarly, lightweight polymer-based electrolyte membranes can replace traditional aqueous solutions, reducing weight while maintaining ionic conductivity.

Structural design innovations offer another pathway to optimize weight-to-energy performance. Bipolar plate configurations eliminate redundant battery components, reducing structural mass by 15-25% compared to conventional cell stacking. Integrated cooling systems utilizing lightweight composite materials can replace heavier metal heat exchangers while maintaining thermal management efficiency. Additionally, multifunctional structural battery designs where battery components simultaneously serve as load-bearing elements can further reduce overall system weight.

Manufacturing techniques significantly impact weight optimization outcomes. Precision additive manufacturing enables the creation of complex electrode geometries with optimized material distribution, reducing non-essential mass. Laser-assisted deposition methods produce thinner, more uniform active layers with improved electrochemical performance per unit weight. Advanced assembly techniques utilizing automated precision placement reduce the need for excessive packaging materials and structural supports.

System-level integration approaches complete the optimization framework. Hybrid battery configurations combining iron-air cells with high-power density supercapacitors can reduce overall battery weight by allowing for smaller iron-air components while maintaining performance during peak power demands. Intelligent battery management systems with predictive algorithms optimize discharge patterns based on flight conditions, extending effective range without increasing battery size.

Quantitative modeling suggests these combined optimization strategies could potentially achieve practical energy densities of 200-250 Wh/kg in near-term iron-air drone batteries, representing a 50-100% improvement over current implementations while maintaining acceptable cycle life and discharge characteristics.

Environmental Impact and Sustainability Advantages

Iron-Air batteries represent a significant advancement in sustainable energy storage technology, offering substantial environmental benefits compared to conventional lithium-ion batteries used in drone applications. The environmental impact assessment of these batteries reveals multiple sustainability advantages that align with global efforts to reduce carbon footprints and minimize resource depletion.

The primary environmental benefit stems from the abundant availability of iron as the main active material. Iron is the fourth most common element in Earth's crust, comprising approximately 5% of its composition. This abundance translates to significantly lower environmental impact during raw material extraction compared to lithium, cobalt, and nickel mining operations that often involve extensive land disruption, water pollution, and habitat destruction. The mining footprint for iron is substantially smaller per unit of energy storage capacity.

Manufacturing processes for Iron-Air batteries demonstrate reduced energy intensity and toxic chemical usage. Production requires approximately 30-40% less energy compared to lithium-ion battery manufacturing, resulting in lower greenhouse gas emissions during the production phase. Additionally, these batteries are free from toxic materials such as cobalt and nickel, eliminating associated environmental hazards during production, use, and disposal phases.

The operational sustainability of Iron-Air batteries in drone applications presents another significant advantage. Their longer cycle life—potentially exceeding 3,000 cycles compared to 500-1,000 cycles for typical lithium-ion batteries—reduces replacement frequency and associated manufacturing impacts. This extended lifespan translates to fewer batteries needed throughout a drone's operational lifetime, further decreasing cumulative environmental impact.

End-of-life considerations reveal perhaps the most compelling sustainability advantage. Iron-Air batteries are highly recyclable, with recovery rates potentially exceeding 90% for key materials. The recycling process is less energy-intensive and hazardous than lithium-ion battery recycling, which often involves high-temperature processes and toxic chemical handling. Furthermore, even unrecycled iron components pose minimal environmental toxicity compared to heavy metals in conventional batteries.

Carbon footprint analyses indicate that Iron-Air batteries could reduce lifecycle greenhouse gas emissions by 45-60% compared to lithium-ion alternatives when considering the entire value chain from material extraction to disposal. This reduction becomes increasingly significant as drone fleets expand globally, potentially preventing thousands of tons of carbon dioxide equivalent emissions annually if widely adopted.

Water conservation represents another critical sustainability advantage, with Iron-Air battery production requiring approximately 60% less water than lithium-ion manufacturing processes. This reduction is particularly valuable in water-stressed regions where battery manufacturing facilities may operate.

The primary environmental benefit stems from the abundant availability of iron as the main active material. Iron is the fourth most common element in Earth's crust, comprising approximately 5% of its composition. This abundance translates to significantly lower environmental impact during raw material extraction compared to lithium, cobalt, and nickel mining operations that often involve extensive land disruption, water pollution, and habitat destruction. The mining footprint for iron is substantially smaller per unit of energy storage capacity.

Manufacturing processes for Iron-Air batteries demonstrate reduced energy intensity and toxic chemical usage. Production requires approximately 30-40% less energy compared to lithium-ion battery manufacturing, resulting in lower greenhouse gas emissions during the production phase. Additionally, these batteries are free from toxic materials such as cobalt and nickel, eliminating associated environmental hazards during production, use, and disposal phases.

The operational sustainability of Iron-Air batteries in drone applications presents another significant advantage. Their longer cycle life—potentially exceeding 3,000 cycles compared to 500-1,000 cycles for typical lithium-ion batteries—reduces replacement frequency and associated manufacturing impacts. This extended lifespan translates to fewer batteries needed throughout a drone's operational lifetime, further decreasing cumulative environmental impact.

End-of-life considerations reveal perhaps the most compelling sustainability advantage. Iron-Air batteries are highly recyclable, with recovery rates potentially exceeding 90% for key materials. The recycling process is less energy-intensive and hazardous than lithium-ion battery recycling, which often involves high-temperature processes and toxic chemical handling. Furthermore, even unrecycled iron components pose minimal environmental toxicity compared to heavy metals in conventional batteries.

Carbon footprint analyses indicate that Iron-Air batteries could reduce lifecycle greenhouse gas emissions by 45-60% compared to lithium-ion alternatives when considering the entire value chain from material extraction to disposal. This reduction becomes increasingly significant as drone fleets expand globally, potentially preventing thousands of tons of carbon dioxide equivalent emissions annually if widely adopted.

Water conservation represents another critical sustainability advantage, with Iron-Air battery production requiring approximately 60% less water than lithium-ion manufacturing processes. This reduction is particularly valuable in water-stressed regions where battery manufacturing facilities may operate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!