Piezoelectric sensors in PMSM condition monitoring

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Monitoring Evolution

The evolution of Permanent Magnet Synchronous Motor (PMSM) monitoring has been marked by significant advancements in sensor technology, data analysis techniques, and diagnostic algorithms. Initially, PMSM monitoring relied on basic electrical measurements and visual inspections. As industrial demands for higher efficiency and reliability grew, more sophisticated monitoring methods emerged.

In the early stages, current and voltage sensors were primarily used to detect major faults. These sensors provided basic information about the motor's electrical performance but lacked the sensitivity to detect subtle changes in motor condition. The introduction of temperature sensors marked a significant improvement, allowing for the detection of overheating issues that could lead to insulation breakdown and motor failure.

The advent of vibration sensors in PMSM monitoring represented a major leap forward. These sensors enabled the detection of mechanical faults such as bearing defects, rotor imbalance, and misalignment. Vibration analysis techniques, including Fast Fourier Transform (FFT) and envelope analysis, became standard tools for condition monitoring.

As technology progressed, the integration of multiple sensor types led to more comprehensive monitoring systems. The combination of electrical, thermal, and vibration data provided a holistic view of motor health. This multi-sensor approach improved fault detection accuracy and enabled the development of more sophisticated diagnostic algorithms.

The introduction of piezoelectric sensors marked another significant milestone in PMSM monitoring evolution. These sensors offered high sensitivity to mechanical vibrations and acoustic emissions, enabling the detection of incipient faults at an earlier stage. Piezoelectric sensors' wide frequency range and high resolution allowed for the capture of subtle changes in motor behavior that were previously undetectable.

With the rise of digital technologies, PMSM monitoring systems began incorporating advanced signal processing and machine learning techniques. This shift allowed for real-time data analysis and predictive maintenance strategies. Artificial Intelligence (AI) and Machine Learning (ML) algorithms were developed to process the vast amounts of data generated by multiple sensors, leading to more accurate fault diagnosis and prognosis.

The most recent developments in PMSM monitoring include the integration of wireless sensor networks and Internet of Things (IoT) technologies. These advancements have enabled remote monitoring and cloud-based data analysis, facilitating centralized monitoring of multiple motors across different locations. The ability to collect and analyze data from a large number of motors has led to improved fault pattern recognition and more accurate predictive maintenance models.

In the early stages, current and voltage sensors were primarily used to detect major faults. These sensors provided basic information about the motor's electrical performance but lacked the sensitivity to detect subtle changes in motor condition. The introduction of temperature sensors marked a significant improvement, allowing for the detection of overheating issues that could lead to insulation breakdown and motor failure.

The advent of vibration sensors in PMSM monitoring represented a major leap forward. These sensors enabled the detection of mechanical faults such as bearing defects, rotor imbalance, and misalignment. Vibration analysis techniques, including Fast Fourier Transform (FFT) and envelope analysis, became standard tools for condition monitoring.

As technology progressed, the integration of multiple sensor types led to more comprehensive monitoring systems. The combination of electrical, thermal, and vibration data provided a holistic view of motor health. This multi-sensor approach improved fault detection accuracy and enabled the development of more sophisticated diagnostic algorithms.

The introduction of piezoelectric sensors marked another significant milestone in PMSM monitoring evolution. These sensors offered high sensitivity to mechanical vibrations and acoustic emissions, enabling the detection of incipient faults at an earlier stage. Piezoelectric sensors' wide frequency range and high resolution allowed for the capture of subtle changes in motor behavior that were previously undetectable.

With the rise of digital technologies, PMSM monitoring systems began incorporating advanced signal processing and machine learning techniques. This shift allowed for real-time data analysis and predictive maintenance strategies. Artificial Intelligence (AI) and Machine Learning (ML) algorithms were developed to process the vast amounts of data generated by multiple sensors, leading to more accurate fault diagnosis and prognosis.

The most recent developments in PMSM monitoring include the integration of wireless sensor networks and Internet of Things (IoT) technologies. These advancements have enabled remote monitoring and cloud-based data analysis, facilitating centralized monitoring of multiple motors across different locations. The ability to collect and analyze data from a large number of motors has led to improved fault pattern recognition and more accurate predictive maintenance models.

Market Demand Analysis

The market demand for piezoelectric sensors in Permanent Magnet Synchronous Motor (PMSM) condition monitoring has been experiencing significant growth in recent years. This surge is primarily driven by the increasing adoption of PMSMs across various industries, including automotive, industrial automation, and renewable energy sectors. As these motors become more prevalent, the need for reliable and efficient condition monitoring systems has become paramount.

The automotive industry, in particular, has been a major contributor to this market demand. With the rapid expansion of electric vehicle (EV) production, PMSMs have become the preferred choice for EV powertrains due to their high efficiency and power density. This has created a substantial market for piezoelectric sensors that can monitor the health and performance of these critical components, ensuring optimal operation and preventing unexpected failures.

In the industrial automation sector, the push towards Industry 4.0 and smart manufacturing has led to increased implementation of PMSMs in various applications, from robotic systems to advanced manufacturing equipment. This trend has further fueled the demand for sophisticated condition monitoring solutions, with piezoelectric sensors playing a crucial role in detecting early signs of motor degradation and optimizing maintenance schedules.

The renewable energy sector, especially wind power generation, has also contributed to the growing market for piezoelectric sensors in PMSM condition monitoring. As wind turbines become larger and more powerful, the reliability of their generators becomes increasingly critical. Piezoelectric sensors offer a robust solution for monitoring the health of these generators, helping to maximize uptime and reduce maintenance costs.

The market demand is further bolstered by the increasing focus on predictive maintenance strategies across industries. Companies are recognizing the value of real-time condition monitoring in reducing downtime, extending equipment life, and optimizing operational efficiency. Piezoelectric sensors, with their ability to detect subtle changes in vibration, pressure, and other parameters, are well-positioned to meet this demand.

Moreover, the integration of advanced analytics and machine learning algorithms with sensor data has opened up new possibilities in PMSM condition monitoring. This has created a demand for more sophisticated sensor systems that can provide high-quality, real-time data for these advanced analytics platforms. Piezoelectric sensors, known for their high sensitivity and wide frequency range, are increasingly being sought after to meet these requirements.

As industries continue to prioritize energy efficiency and sustainability, the demand for high-performance motors like PMSMs is expected to grow further. This, in turn, will drive the market for advanced condition monitoring solutions, with piezoelectric sensors playing a central role in ensuring the reliability and longevity of these critical components.

The automotive industry, in particular, has been a major contributor to this market demand. With the rapid expansion of electric vehicle (EV) production, PMSMs have become the preferred choice for EV powertrains due to their high efficiency and power density. This has created a substantial market for piezoelectric sensors that can monitor the health and performance of these critical components, ensuring optimal operation and preventing unexpected failures.

In the industrial automation sector, the push towards Industry 4.0 and smart manufacturing has led to increased implementation of PMSMs in various applications, from robotic systems to advanced manufacturing equipment. This trend has further fueled the demand for sophisticated condition monitoring solutions, with piezoelectric sensors playing a crucial role in detecting early signs of motor degradation and optimizing maintenance schedules.

The renewable energy sector, especially wind power generation, has also contributed to the growing market for piezoelectric sensors in PMSM condition monitoring. As wind turbines become larger and more powerful, the reliability of their generators becomes increasingly critical. Piezoelectric sensors offer a robust solution for monitoring the health of these generators, helping to maximize uptime and reduce maintenance costs.

The market demand is further bolstered by the increasing focus on predictive maintenance strategies across industries. Companies are recognizing the value of real-time condition monitoring in reducing downtime, extending equipment life, and optimizing operational efficiency. Piezoelectric sensors, with their ability to detect subtle changes in vibration, pressure, and other parameters, are well-positioned to meet this demand.

Moreover, the integration of advanced analytics and machine learning algorithms with sensor data has opened up new possibilities in PMSM condition monitoring. This has created a demand for more sophisticated sensor systems that can provide high-quality, real-time data for these advanced analytics platforms. Piezoelectric sensors, known for their high sensitivity and wide frequency range, are increasingly being sought after to meet these requirements.

As industries continue to prioritize energy efficiency and sustainability, the demand for high-performance motors like PMSMs is expected to grow further. This, in turn, will drive the market for advanced condition monitoring solutions, with piezoelectric sensors playing a central role in ensuring the reliability and longevity of these critical components.

Piezoelectric Tech Status

Piezoelectric sensors have emerged as a promising technology for condition monitoring in Permanent Magnet Synchronous Motors (PMSMs). The current state of this technology reflects significant advancements in both sensor design and implementation strategies. These sensors leverage the piezoelectric effect to convert mechanical stress into electrical signals, enabling precise detection of vibrations and other physical phenomena within PMSMs.

In recent years, there has been a notable shift towards miniaturization and integration of piezoelectric sensors in PMSM systems. This trend has led to the development of compact, high-sensitivity sensors capable of capturing a wide range of motor parameters. The latest piezoelectric sensors boast improved frequency response and signal-to-noise ratios, allowing for more accurate detection of subtle changes in motor condition.

One of the key challenges in this field has been the development of robust sensor mounting techniques that can withstand the harsh operating conditions of PMSMs. Researchers have made significant progress in creating adhesive and mechanical mounting solutions that ensure stable sensor performance over extended periods. Additionally, advancements in signal processing algorithms have enhanced the ability to filter out noise and extract meaningful data from piezoelectric sensor outputs.

The integration of piezoelectric sensors with wireless communication technologies represents another important development. This combination allows for real-time monitoring and data transmission, facilitating predictive maintenance strategies and reducing downtime in industrial applications. However, challenges remain in terms of power management for these wireless sensor nodes, particularly in environments where frequent battery replacement is impractical.

From a global perspective, research and development in piezoelectric sensor technology for PMSM monitoring is concentrated in several key regions. North America and Europe lead in terms of innovative sensor designs and advanced signal processing techniques. Meanwhile, Asian countries, particularly China and Japan, have made significant strides in large-scale manufacturing and cost-effective implementation of these sensors in industrial settings.

The current technological landscape also sees a growing emphasis on multi-modal sensing approaches. Researchers are exploring ways to combine piezoelectric sensors with other sensing technologies, such as temperature and magnetic field sensors, to create more comprehensive PMSM monitoring systems. This holistic approach aims to provide a more complete picture of motor health and performance.

Despite these advancements, several technical challenges persist. These include improving the long-term stability of piezoelectric materials under continuous stress, enhancing sensor sensitivity to detect incipient faults, and developing more sophisticated data interpretation models to accurately predict motor failures. Addressing these challenges remains a focus of ongoing research and development efforts in the field.

In recent years, there has been a notable shift towards miniaturization and integration of piezoelectric sensors in PMSM systems. This trend has led to the development of compact, high-sensitivity sensors capable of capturing a wide range of motor parameters. The latest piezoelectric sensors boast improved frequency response and signal-to-noise ratios, allowing for more accurate detection of subtle changes in motor condition.

One of the key challenges in this field has been the development of robust sensor mounting techniques that can withstand the harsh operating conditions of PMSMs. Researchers have made significant progress in creating adhesive and mechanical mounting solutions that ensure stable sensor performance over extended periods. Additionally, advancements in signal processing algorithms have enhanced the ability to filter out noise and extract meaningful data from piezoelectric sensor outputs.

The integration of piezoelectric sensors with wireless communication technologies represents another important development. This combination allows for real-time monitoring and data transmission, facilitating predictive maintenance strategies and reducing downtime in industrial applications. However, challenges remain in terms of power management for these wireless sensor nodes, particularly in environments where frequent battery replacement is impractical.

From a global perspective, research and development in piezoelectric sensor technology for PMSM monitoring is concentrated in several key regions. North America and Europe lead in terms of innovative sensor designs and advanced signal processing techniques. Meanwhile, Asian countries, particularly China and Japan, have made significant strides in large-scale manufacturing and cost-effective implementation of these sensors in industrial settings.

The current technological landscape also sees a growing emphasis on multi-modal sensing approaches. Researchers are exploring ways to combine piezoelectric sensors with other sensing technologies, such as temperature and magnetic field sensors, to create more comprehensive PMSM monitoring systems. This holistic approach aims to provide a more complete picture of motor health and performance.

Despite these advancements, several technical challenges persist. These include improving the long-term stability of piezoelectric materials under continuous stress, enhancing sensor sensitivity to detect incipient faults, and developing more sophisticated data interpretation models to accurately predict motor failures. Addressing these challenges remains a focus of ongoing research and development efforts in the field.

Current Sensing Solutions

01 Piezoelectric sensor design and fabrication

This category focuses on the design and manufacturing processes of piezoelectric sensors. It includes innovative approaches to sensor construction, material selection, and fabrication techniques to enhance sensitivity and performance. These advancements aim to improve the overall efficiency and reliability of piezoelectric sensors for various applications.- Piezoelectric sensor design and fabrication: This category focuses on the design and manufacturing processes of piezoelectric sensors. It includes innovative approaches to sensor construction, material selection, and fabrication techniques to enhance sensitivity and performance. These advancements aim to improve the overall efficiency and reliability of piezoelectric sensors for various applications.

- Applications of piezoelectric sensors: Piezoelectric sensors find applications in diverse fields. This category explores their use in areas such as automotive systems, industrial monitoring, consumer electronics, and medical devices. The versatility of these sensors allows for precise measurements of pressure, acceleration, and vibration in various environments.

- Signal processing and data analysis for piezoelectric sensors: This category covers techniques for processing and analyzing signals from piezoelectric sensors. It includes methods for noise reduction, signal amplification, and data interpretation. Advanced algorithms and software solutions are developed to extract meaningful information from sensor outputs, enhancing the accuracy and reliability of measurements.

- Integration of piezoelectric sensors in systems: This category focuses on the integration of piezoelectric sensors into larger systems and devices. It includes techniques for sensor placement, interfacing with other components, and optimizing overall system performance. The integration process considers factors such as power consumption, size constraints, and compatibility with existing technologies.

- Piezoelectric sensor calibration and testing: This category covers methods for calibrating and testing piezoelectric sensors to ensure accuracy and reliability. It includes procedures for characterizing sensor performance, compensating for environmental factors, and validating sensor outputs. These techniques are crucial for maintaining the quality and consistency of measurements across different applications and operating conditions.

02 Applications of piezoelectric sensors

Piezoelectric sensors find diverse applications across multiple industries. This category explores their use in areas such as automotive systems, consumer electronics, industrial monitoring, and medical devices. The versatility of these sensors allows for precise measurement of pressure, acceleration, and vibration in various environments.Expand Specific Solutions03 Signal processing and data analysis for piezoelectric sensors

This category covers techniques for processing and analyzing signals from piezoelectric sensors. It includes methods for noise reduction, signal amplification, and data interpretation. Advanced algorithms and software solutions are developed to extract meaningful information from sensor outputs, enhancing the accuracy and reliability of measurements.Expand Specific Solutions04 Integration of piezoelectric sensors in smart systems

The integration of piezoelectric sensors into smart systems and Internet of Things (IoT) devices is a growing trend. This category explores how these sensors are incorporated into larger networks, enabling real-time monitoring, data collection, and automated responses. It also covers the development of sensor arrays and multi-functional sensing platforms.Expand Specific Solutions05 Energy harvesting and self-powered piezoelectric sensors

This category focuses on the development of self-powered piezoelectric sensors and energy harvesting technologies. It includes innovative designs that utilize the piezoelectric effect to generate electricity from ambient vibrations or mechanical stress, enabling long-term operation without external power sources. This approach is particularly valuable for remote sensing applications and wearable devices.Expand Specific Solutions

Key Industry Players

The piezoelectric sensor market for PMSM condition monitoring is in a growth phase, driven by increasing demand for predictive maintenance in industrial applications. The market size is expanding, with a projected CAGR of around 5-7% over the next five years. Technologically, piezoelectric sensors are mature but continue to evolve, with companies like Siemens AG, ABB Group, and Texas Instruments leading innovation. These firms are developing more sensitive, compact, and integrated sensor solutions. Emerging players like Ionix Advanced Technologies and NanJing GOVA Technology are also contributing to advancements in sensor materials and designs, enhancing the overall market competitiveness and technological sophistication.

Siemens AG

Technical Solution: Siemens AG has developed advanced piezoelectric sensor systems for PMSM condition monitoring. Their solution integrates high-sensitivity piezoelectric sensors with intelligent signal processing algorithms to detect early signs of motor faults. The system employs multi-parameter analysis, combining vibration, temperature, and electrical signals for comprehensive health assessment[1]. Siemens' approach includes real-time data acquisition and cloud-based analytics, enabling predictive maintenance strategies. The sensors are designed to withstand harsh industrial environments, with high temperature and EMI resistance[3]. Their solution also incorporates machine learning algorithms to improve fault detection accuracy over time, adapting to specific motor characteristics and operating conditions[5].

Strengths: Comprehensive multi-parameter analysis, robust sensor design, and adaptive machine learning capabilities. Weaknesses: Potentially higher initial cost and complexity compared to simpler monitoring systems.

ABB Group

Technical Solution: ABB Group has pioneered a piezoelectric sensor-based condition monitoring system for PMSMs that focuses on high-frequency vibration analysis. Their solution utilizes an array of miniaturized piezoelectric sensors strategically placed on the motor housing to capture detailed vibration signatures[2]. ABB's system employs advanced signal processing techniques, including wavelet transform and spectral kurtosis, to extract fault-specific features from the vibration data. The monitoring system is integrated with ABB's industrial IoT platform, enabling remote monitoring and fleet-wide analytics[4]. A key feature is the use of adaptive thresholding algorithms that adjust to varying motor speeds and loads, minimizing false alarms while maintaining high sensitivity to developing faults[6].

Strengths: High-frequency vibration analysis capability, integration with IoT platform, and adaptive thresholding for improved reliability. Weaknesses: May require more complex installation and setup compared to traditional monitoring methods.

Core Piezo Innovations

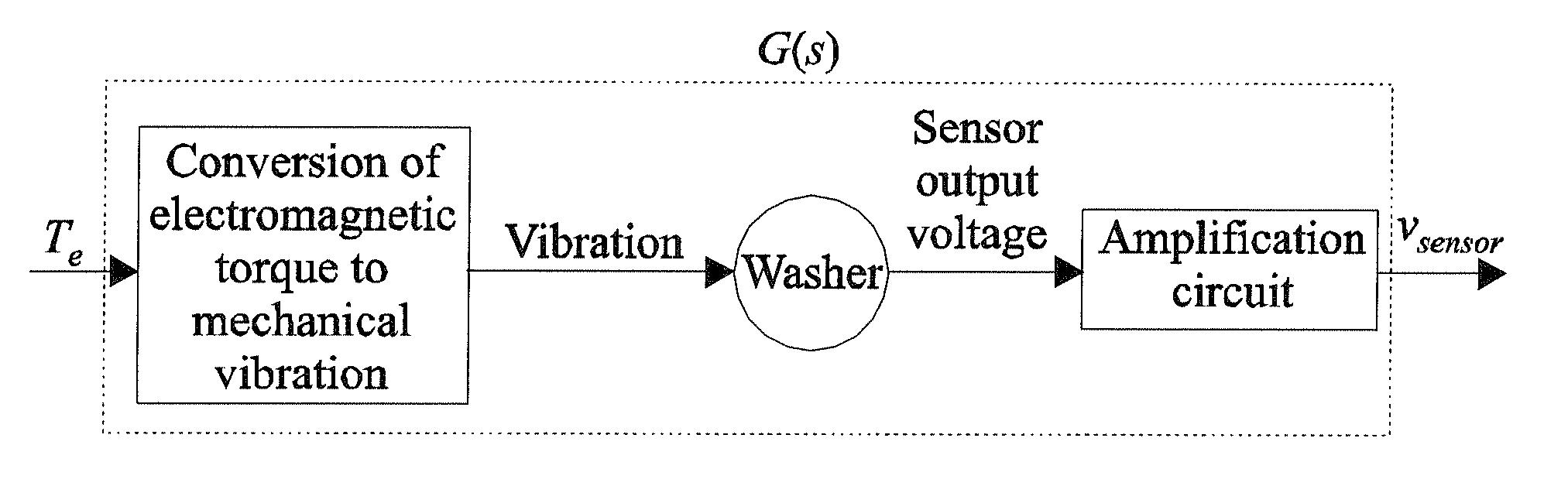

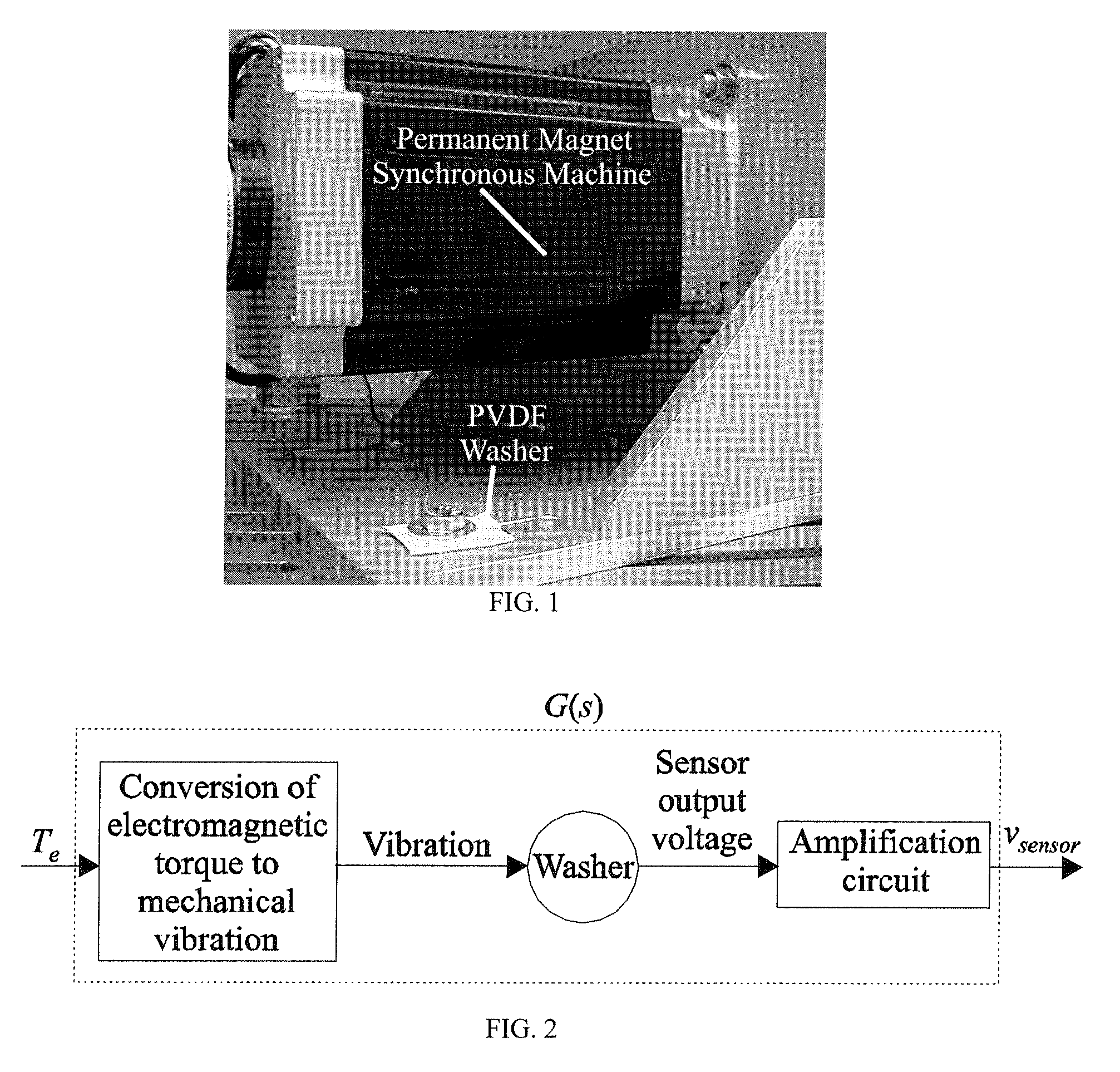

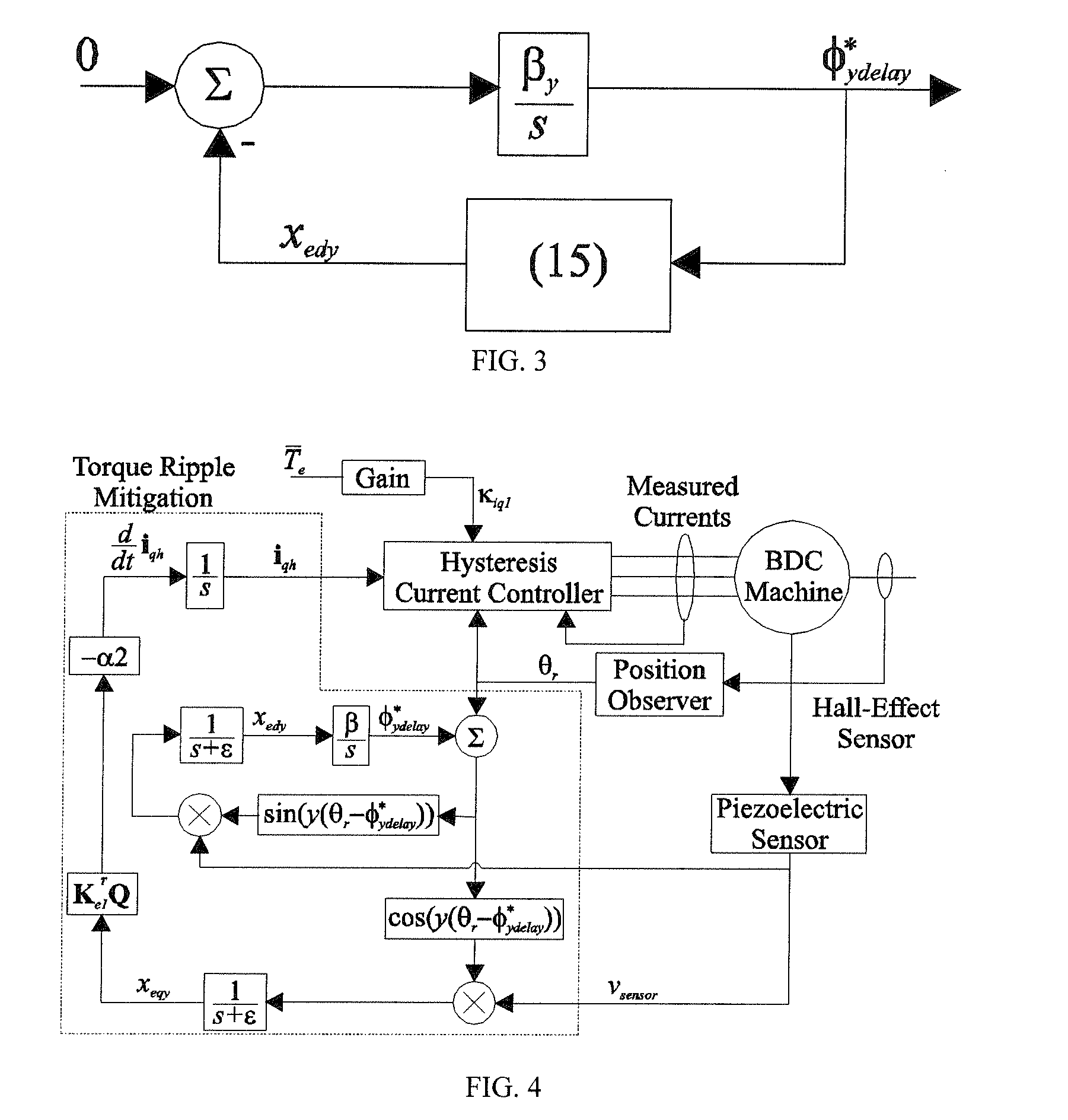

Rotor position sensing apparatus and method using piezoelectric sensor and hall-effect sensor

PatentInactiveUS7885785B1

Innovation

- A coupled piezoelectric/single-Hall-effect (CPSH) sensor-based position observer is developed, utilizing a piezoelectric sensor for initial position detection and a single Hall-effect sensor for high-speed detection, which estimates rotor position using a zero-order Taylor Series approximation of rotor velocity, eliminating the need for back-emf and cogging torque harmonic knowledge and allowing for torque harmonic control without reverse rotation during startup.

Permanent magnet flux linkage determination for permanent magnet synchronous motors

PatentInactiveUS20230358809A1

Innovation

- A method and system that applies phase voltages to PMSM leads at standstill, measures currents, and determines flux linkage, PM strength, and demagnetization using a controller, with an inverter and current sensors to diagnose demagnetization by analyzing RMS values of phase currents, eliminating the need for extra hardware and reducing the impact of load variations and mechanical issues.

Regulatory Considerations

The implementation of piezoelectric sensors in Permanent Magnet Synchronous Motor (PMSM) condition monitoring systems is subject to various regulatory considerations. These regulations aim to ensure safety, reliability, and compliance with industry standards across different jurisdictions.

In the United States, the Federal Communications Commission (FCC) regulates electromagnetic compatibility (EMC) of electronic devices, including sensor systems used in motor monitoring. Piezoelectric sensors and associated monitoring equipment must comply with FCC Part 15 regulations to prevent electromagnetic interference with other devices. Additionally, the Occupational Safety and Health Administration (OSHA) sets guidelines for workplace safety, which may impact the installation and operation of monitoring systems in industrial environments.

The European Union enforces the Electromagnetic Compatibility Directive (2014/30/EU) and the Low Voltage Directive (2014/35/EU), which are crucial for piezoelectric sensor systems in PMSM monitoring. These directives ensure that electrical and electronic equipment does not generate electromagnetic disturbances and operates safely within specified voltage limits. Compliance with these regulations is demonstrated through CE marking.

In the automotive sector, where PMSMs are increasingly used in electric vehicles, the United Nations Economic Commission for Europe (UNECE) Regulation No. 10 addresses EMC requirements for vehicles and their components. This regulation is adopted by many countries and impacts the design and implementation of motor monitoring systems.

International standards such as IEC 60034 for rotating electrical machines and ISO 20816 for mechanical vibration measurement provide guidelines that influence the use of piezoelectric sensors in PMSM monitoring. These standards define measurement techniques, acceptable vibration levels, and sensor mounting requirements, ensuring consistency and reliability in condition monitoring practices across different industries.

Data privacy and security regulations, such as the General Data Protection Regulation (GDPR) in the EU and the California Consumer Privacy Act (CCPA) in the US, may also apply when sensor data is collected, processed, and stored as part of a comprehensive motor monitoring system. These regulations mandate proper handling and protection of potentially sensitive operational data.

Manufacturers and implementers of piezoelectric sensor systems for PMSM condition monitoring must navigate these regulatory landscapes to ensure compliance. This often involves conducting thorough EMC testing, obtaining necessary certifications, and implementing appropriate data management practices. As the technology evolves and finds new applications, staying abreast of regulatory changes and proactively addressing compliance issues becomes crucial for successful deployment and operation of these monitoring systems.

In the United States, the Federal Communications Commission (FCC) regulates electromagnetic compatibility (EMC) of electronic devices, including sensor systems used in motor monitoring. Piezoelectric sensors and associated monitoring equipment must comply with FCC Part 15 regulations to prevent electromagnetic interference with other devices. Additionally, the Occupational Safety and Health Administration (OSHA) sets guidelines for workplace safety, which may impact the installation and operation of monitoring systems in industrial environments.

The European Union enforces the Electromagnetic Compatibility Directive (2014/30/EU) and the Low Voltage Directive (2014/35/EU), which are crucial for piezoelectric sensor systems in PMSM monitoring. These directives ensure that electrical and electronic equipment does not generate electromagnetic disturbances and operates safely within specified voltage limits. Compliance with these regulations is demonstrated through CE marking.

In the automotive sector, where PMSMs are increasingly used in electric vehicles, the United Nations Economic Commission for Europe (UNECE) Regulation No. 10 addresses EMC requirements for vehicles and their components. This regulation is adopted by many countries and impacts the design and implementation of motor monitoring systems.

International standards such as IEC 60034 for rotating electrical machines and ISO 20816 for mechanical vibration measurement provide guidelines that influence the use of piezoelectric sensors in PMSM monitoring. These standards define measurement techniques, acceptable vibration levels, and sensor mounting requirements, ensuring consistency and reliability in condition monitoring practices across different industries.

Data privacy and security regulations, such as the General Data Protection Regulation (GDPR) in the EU and the California Consumer Privacy Act (CCPA) in the US, may also apply when sensor data is collected, processed, and stored as part of a comprehensive motor monitoring system. These regulations mandate proper handling and protection of potentially sensitive operational data.

Manufacturers and implementers of piezoelectric sensor systems for PMSM condition monitoring must navigate these regulatory landscapes to ensure compliance. This often involves conducting thorough EMC testing, obtaining necessary certifications, and implementing appropriate data management practices. As the technology evolves and finds new applications, staying abreast of regulatory changes and proactively addressing compliance issues becomes crucial for successful deployment and operation of these monitoring systems.

Energy Harvesting Potential

The integration of piezoelectric sensors in Permanent Magnet Synchronous Motor (PMSM) condition monitoring systems presents a unique opportunity for energy harvesting. This potential stems from the inherent ability of piezoelectric materials to convert mechanical stress into electrical energy. In the context of PMSM operation, various sources of mechanical energy can be harnessed, including vibrations, thermal expansions, and rotational forces.

The primary source of harvestable energy in PMSMs is vibration. During motor operation, mechanical vibrations are generated due to rotor imbalance, bearing defects, and electromagnetic forces. These vibrations, typically in the frequency range of 10 Hz to 1 kHz, can be captured by strategically placed piezoelectric sensors. The amount of energy that can be harvested depends on several factors, including the amplitude and frequency of vibrations, the size and efficiency of the piezoelectric element, and the overall system design.

Thermal energy is another potential source for harvesting in PMSMs. As the motor operates, temperature gradients develop across different components. Piezoelectric materials with high thermal sensitivity can be utilized to convert these temperature differences into electrical energy. While the energy yield from thermal harvesting is generally lower compared to vibration-based harvesting, it can still contribute to the overall energy budget of the monitoring system.

Rotational forces present in PMSMs also offer energy harvesting opportunities. The centrifugal forces acting on the rotor and the periodic stress variations in the stator can be exploited using specially designed piezoelectric harvesters. These harvesters can be integrated into the motor structure without significantly affecting its performance or efficiency.

The energy harvested from these sources can be used to power the condition monitoring system itself, reducing or eliminating the need for external power sources or battery replacements. This self-powered approach enhances the reliability and longevity of the monitoring system, particularly in hard-to-reach or hazardous environments where regular maintenance is challenging.

However, the implementation of energy harvesting in PMSM condition monitoring systems faces several challenges. The harvested energy is often intermittent and low in magnitude, necessitating efficient power management and storage solutions. Additionally, the integration of energy harvesting components must not interfere with the primary function of the sensors in condition monitoring.

Despite these challenges, the potential benefits of energy harvesting in PMSM condition monitoring are significant. As piezoelectric materials and energy harvesting technologies continue to advance, we can expect to see more efficient and integrated solutions. These developments will likely lead to fully self-sustained monitoring systems, contributing to the overall efficiency and reliability of PMSM applications across various industries.

The primary source of harvestable energy in PMSMs is vibration. During motor operation, mechanical vibrations are generated due to rotor imbalance, bearing defects, and electromagnetic forces. These vibrations, typically in the frequency range of 10 Hz to 1 kHz, can be captured by strategically placed piezoelectric sensors. The amount of energy that can be harvested depends on several factors, including the amplitude and frequency of vibrations, the size and efficiency of the piezoelectric element, and the overall system design.

Thermal energy is another potential source for harvesting in PMSMs. As the motor operates, temperature gradients develop across different components. Piezoelectric materials with high thermal sensitivity can be utilized to convert these temperature differences into electrical energy. While the energy yield from thermal harvesting is generally lower compared to vibration-based harvesting, it can still contribute to the overall energy budget of the monitoring system.

Rotational forces present in PMSMs also offer energy harvesting opportunities. The centrifugal forces acting on the rotor and the periodic stress variations in the stator can be exploited using specially designed piezoelectric harvesters. These harvesters can be integrated into the motor structure without significantly affecting its performance or efficiency.

The energy harvested from these sources can be used to power the condition monitoring system itself, reducing or eliminating the need for external power sources or battery replacements. This self-powered approach enhances the reliability and longevity of the monitoring system, particularly in hard-to-reach or hazardous environments where regular maintenance is challenging.

However, the implementation of energy harvesting in PMSM condition monitoring systems faces several challenges. The harvested energy is often intermittent and low in magnitude, necessitating efficient power management and storage solutions. Additionally, the integration of energy harvesting components must not interfere with the primary function of the sensors in condition monitoring.

Despite these challenges, the potential benefits of energy harvesting in PMSM condition monitoring are significant. As piezoelectric materials and energy harvesting technologies continue to advance, we can expect to see more efficient and integrated solutions. These developments will likely lead to fully self-sustained monitoring systems, contributing to the overall efficiency and reliability of PMSM applications across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!