Pioneering Applications of Ethylene Vinyl Acetate

EVA Technology Evolution

Ethylene Vinyl Acetate (EVA) has undergone significant technological evolution since its inception in the 1950s. Initially developed as a copolymer of ethylene and vinyl acetate, EVA's unique properties have driven its continuous improvement and diversification of applications over the decades.

In the early stages, EVA was primarily used in the packaging industry due to its flexibility and low-temperature toughness. The 1960s and 1970s saw the refinement of EVA production processes, leading to enhanced control over the vinyl acetate content, which directly influences the material's properties. This advancement allowed for the tailoring of EVA characteristics to suit specific applications, expanding its use in footwear, toys, and sports equipment.

The 1980s marked a significant milestone in EVA technology with the development of cross-linking techniques. This innovation dramatically improved the material's heat resistance and elasticity, opening up new possibilities in industries such as solar panel encapsulation and hot-melt adhesives. Concurrently, advancements in extrusion and molding technologies enabled more complex and precise EVA product manufacturing.

The 1990s and early 2000s witnessed a surge in EVA foam technology. Improved blowing agents and processing methods resulted in EVA foams with superior cushioning properties and durability. This evolution led to widespread adoption in orthopedic products, sports equipment, and automotive interiors.

In recent years, the focus has shifted towards enhancing EVA's sustainability profile. Research efforts have been directed at developing bio-based EVA variants and improving the material's recyclability. Additionally, nanotechnology has been employed to create EVA nanocomposites with enhanced barrier properties and mechanical strength, finding applications in advanced packaging and medical devices.

The latest frontier in EVA technology involves smart and responsive materials. Researchers are exploring ways to incorporate sensors and stimuli-responsive elements into EVA, potentially leading to applications in wearable technology and smart packaging. Furthermore, advancements in 3D printing technology are enabling the production of complex EVA structures with customized properties, opening up new possibilities in personalized products and rapid prototyping.

As we look to the future, the evolution of EVA technology is likely to continue along several key trajectories. These include further improvements in sustainability, the development of high-performance grades for specialized applications, and the integration of EVA with other advanced materials to create hybrid solutions with unique property combinations.

Market Demand Analysis

The market demand for Ethylene Vinyl Acetate (EVA) has been steadily growing across various industries due to its versatile properties and wide range of applications. The global EVA market size was valued at USD 7.9 billion in 2020 and is projected to reach USD 11.2 billion by 2026, exhibiting a compound annual growth rate (CAGR) of 6.1% during the forecast period.

One of the primary drivers of market demand is the increasing use of EVA in the solar photovoltaic industry. EVA is extensively used as an encapsulant material in solar panels, providing excellent adhesion, weatherability, and UV resistance. With the growing emphasis on renewable energy sources and the rapid expansion of solar power installations worldwide, the demand for EVA in this sector is expected to surge significantly.

The packaging industry represents another major market for EVA, particularly in flexible packaging applications. EVA's properties, such as flexibility, transparency, and low-temperature toughness, make it an ideal material for food packaging, shrink wrap, and stretch films. The rising demand for convenient and sustainable packaging solutions is fueling the growth of EVA in this sector.

In the footwear industry, EVA has gained popularity as a material for shoe soles and midsoles due to its lightweight nature, cushioning properties, and durability. The growing sports and athleisure market is driving the demand for EVA in footwear applications, with major brands incorporating EVA-based components in their products.

The automotive sector is another significant consumer of EVA, particularly in the production of car interiors, dashboards, and wire and cable insulation. The increasing focus on lightweight materials and improved fuel efficiency in vehicles is expected to boost the demand for EVA in automotive applications.

The construction industry is also contributing to the market growth of EVA, with applications in adhesives, sealants, and waterproofing membranes. The expanding construction activities in emerging economies and the growing trend of green buildings are likely to drive the demand for EVA-based products in this sector.

Geographically, Asia Pacific dominates the EVA market, accounting for the largest share of global consumption. This can be attributed to the rapid industrialization, growing automotive and construction sectors, and increasing solar panel installations in countries like China and India. North America and Europe follow as significant markets, driven by technological advancements and stringent regulations promoting sustainable materials.

EVA Technical Challenges

Despite its widespread use and versatility, Ethylene Vinyl Acetate (EVA) faces several technical challenges that hinder its further development and application in various industries. One of the primary issues is the material's limited thermal stability. EVA tends to degrade at temperatures above 150°C, which restricts its use in high-temperature applications and poses challenges in processing and manufacturing.

Another significant challenge is the material's susceptibility to weathering and UV radiation. When exposed to sunlight and environmental factors for extended periods, EVA can undergo photodegradation, leading to discoloration, loss of mechanical properties, and reduced lifespan. This limitation is particularly problematic in outdoor applications such as solar panel encapsulation and construction materials.

The adhesion properties of EVA, while generally good, can be inconsistent across different substrates. This variability in adhesion strength can lead to delamination issues in multi-layer structures, affecting the performance and durability of products such as safety glass and photovoltaic modules. Improving the adhesion consistency of EVA across various materials remains a key technical challenge.

EVA's gas permeability is another area of concern, especially in packaging applications. While EVA provides good barrier properties against water vapor, its permeability to oxygen and other gases is relatively high. This characteristic limits its effectiveness in certain food packaging and medical applications where gas barrier properties are crucial.

The material's flammability and smoke generation during combustion pose safety concerns in some applications. Enhancing the fire resistance of EVA without compromising its other desirable properties is an ongoing challenge for researchers and manufacturers.

In the realm of sustainability, the recyclability of EVA-based products presents technical difficulties. The cross-linked structure of EVA, particularly in foams and encapsulants, makes it challenging to recycle effectively. Developing eco-friendly recycling methods or designing EVA formulations that are easier to recycle is becoming increasingly important as environmental regulations tighten.

Lastly, controlling the vinyl acetate (VA) content and its distribution within the EVA copolymer remains a technical challenge. The VA content significantly influences the material's properties, and achieving precise control over its distribution is crucial for maintaining consistent product quality across different batches and applications.

Current EVA Applications

01 Composition and synthesis of EVA copolymers

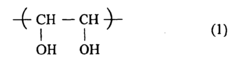

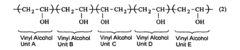

Ethylene Vinyl Acetate (EVA) copolymers are synthesized through the copolymerization of ethylene and vinyl acetate monomers. The composition and properties of EVA can be adjusted by varying the ratio of these monomers, allowing for a wide range of applications. The synthesis process often involves high-pressure polymerization techniques and may include the use of catalysts to control the reaction.- Composition and synthesis of EVA copolymers: Ethylene Vinyl Acetate (EVA) copolymers are synthesized through the copolymerization of ethylene and vinyl acetate monomers. The composition and ratio of these monomers can be adjusted to achieve desired properties. Various polymerization methods and catalysts are employed to control the molecular weight, distribution, and branching of the resulting copolymer.

- Modification and blending of EVA: EVA copolymers can be modified or blended with other polymers to enhance their properties. This includes crosslinking, grafting, or mixing with additives to improve characteristics such as thermal stability, mechanical strength, or adhesion. Blending EVA with other polymers can result in materials with tailored properties for specific applications.

- EVA foam production and applications: EVA foams are produced through various foaming processes, including chemical and physical blowing methods. These foams find applications in areas such as footwear, sports equipment, and packaging. The foam properties can be tailored by adjusting the EVA composition, foaming agents, and processing conditions.

- EVA in adhesive and sealant formulations: EVA copolymers are widely used in adhesive and sealant formulations due to their excellent adhesion properties and flexibility. They can be formulated with various additives to enhance specific characteristics such as tack, peel strength, or heat resistance. Hot melt adhesives based on EVA are particularly popular in packaging and product assembly applications.

- EVA in film and packaging applications: EVA copolymers are extensively used in film and packaging applications due to their flexibility, clarity, and barrier properties. They can be processed into various forms such as sheets, bags, or multilayer films. EVA films find use in food packaging, agricultural films, and solar cell encapsulation, among other applications.

02 EVA blends and composites

EVA copolymers are often blended with other polymers or materials to create composites with enhanced properties. These blends can improve characteristics such as flexibility, impact resistance, or thermal stability. Common blend components include polyethylene, polypropylene, and various fillers or reinforcing agents. The resulting composites find applications in diverse industries, including packaging, automotive, and construction.Expand Specific Solutions03 Foam and cellular EVA products

EVA can be processed into foam or cellular structures, which are widely used in applications requiring cushioning, insulation, or buoyancy. The foaming process typically involves the use of blowing agents and specific processing conditions to create a cellular structure within the EVA material. These foams can be tailored to have different densities and cell structures, allowing for customization of properties such as compressibility and thermal insulation.Expand Specific Solutions04 EVA in adhesive and sealant applications

EVA copolymers are extensively used in adhesive and sealant formulations due to their excellent adhesion properties, flexibility, and compatibility with various substrates. These formulations often include additional components such as tackifiers, plasticizers, and stabilizers to enhance specific properties. EVA-based adhesives find applications in packaging, bookbinding, and construction industries, among others.Expand Specific Solutions05 Modification and functionalization of EVA

EVA copolymers can be chemically modified or functionalized to impart specific properties or improve compatibility with other materials. Common modification techniques include grafting, crosslinking, and the incorporation of functional groups. These modifications can enhance properties such as adhesion, heat resistance, or chemical resistance, expanding the range of applications for EVA-based materials.Expand Specific Solutions

Key EVA Industry Players

The market for Ethylene Vinyl Acetate (EVA) applications is in a mature growth stage, with a global market size expected to reach $9.7 billion by 2027. The technology's maturity is evident in its widespread use across various industries, including packaging, solar panels, and footwear. Key players like Celanese International Corp., DuPont de Nemours, Inc., and Wacker Chemie AG have established strong positions in the market, leveraging their extensive R&D capabilities and global presence. Chinese companies such as China Petroleum & Chemical Corp. and Jiangsu Sailboat Petrochemical Co., Ltd. are also making significant strides, particularly in the Asia-Pacific region, which is the fastest-growing market for EVA applications. The competitive landscape is characterized by ongoing innovation in product formulations and manufacturing processes, with a focus on enhancing performance characteristics and sustainability.

Wacker Chemie AG

Kuraray Co., Ltd.

EVA Patent Landscape

- A poly(vinyl acetate) emulsion is prepared through seed polymerization in the presence of an ethylene-vinyl acetate copolymer emulsion using a specific dispersing agent, a vinyl alcohol polymer with 1.9% or more 1,2-dihydroxyethylene units, to achieve transparent cured articles without VOCs or high-boiling solvents.

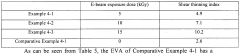

- Applying an electron beam with a defined exposure dose to an ethylene-vinyl acetate resin composition with a vinyl acetate content of 15 to 50 wt% to reduce the melt index to 10 g/10 min or less, thereby enhancing mechanical properties and processability without the need for additional modifiers like peroxides.

EVA Sustainability Impact

The sustainability impact of Ethylene Vinyl Acetate (EVA) is a critical consideration in its pioneering applications. As industries increasingly prioritize environmental responsibility, EVA's role in sustainable practices has become more prominent.

EVA's recyclability is a key factor in its sustainability profile. The material can be effectively recycled through mechanical and chemical processes, reducing waste and conserving resources. This recyclability aligns with circular economy principles, allowing for the reuse of EVA in various applications and minimizing its environmental footprint.

In the renewable energy sector, EVA plays a crucial role in solar panel encapsulation. Its use in photovoltaic modules contributes to the longevity and efficiency of solar panels, indirectly supporting the transition to clean energy sources. The durability of EVA in this application extends the lifespan of solar panels, reducing the need for frequent replacements and associated resource consumption.

EVA's impact on energy efficiency is notable in the construction industry. When used in insulation materials, EVA enhances thermal performance, leading to improved energy conservation in buildings. This application contributes to reduced energy consumption for heating and cooling, aligning with global efforts to decrease carbon emissions in the built environment.

The material's lightweight nature also contributes to sustainability in transportation applications. By reducing the overall weight of vehicles, EVA helps improve fuel efficiency and reduce emissions. This aspect is particularly relevant in the automotive industry's push towards more environmentally friendly transportation solutions.

In packaging applications, EVA's versatility allows for the development of thinner, yet durable materials. This property enables the reduction of material usage while maintaining product protection, contributing to waste reduction in the packaging industry. Additionally, EVA's potential as a biodegradable polymer when blended with certain additives opens avenues for more environmentally friendly packaging solutions.

The production process of EVA, however, presents some sustainability challenges. The use of fossil fuel-derived raw materials in its manufacture raises concerns about its carbon footprint. Efforts are underway to explore bio-based alternatives and more sustainable production methods to address these issues.

As industries continue to innovate, the sustainability impact of EVA is likely to evolve. Research into bio-based EVA and improved recycling technologies holds promise for enhancing its environmental profile. The ongoing development of EVA applications in renewable energy, energy-efficient construction, and sustainable packaging underscores its potential to contribute positively to global sustainability goals.

Regulatory Framework

The regulatory framework surrounding Ethylene Vinyl Acetate (EVA) applications is complex and multifaceted, reflecting the diverse uses of this versatile copolymer across various industries. At the core of EVA regulation are safety and environmental considerations, which are primarily overseen by governmental agencies and international organizations.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA applications in food contact materials and medical devices. The FDA has established specific guidelines for EVA use in food packaging, ensuring that it meets stringent safety standards and does not leach harmful substances into food products. Similarly, for medical applications, EVA must comply with biocompatibility requirements set forth in ISO 10993 standards.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which affects EVA production and use within the EU market. Manufacturers and importers of EVA are required to register the substance and provide detailed safety information. Additionally, the EU's RoHS (Restriction of Hazardous Substances) directive impacts EVA applications in electrical and electronic equipment, mandating the absence of certain hazardous substances.

In the construction industry, EVA-based materials must adhere to building codes and fire safety regulations. These regulations vary by country and region but generally focus on fire resistance, smoke emission, and toxicity in case of combustion. The International Building Code (IBC) and local adaptations provide guidelines for the use of EVA in construction materials.

Environmental regulations also play a significant role in shaping EVA applications. Many countries have implemented policies to promote the recycling and proper disposal of EVA-containing products. For instance, the EU's Waste Electrical and Electronic Equipment (WEEE) directive includes provisions for the recycling of EVA components in electronic devices.

As sustainability becomes an increasingly important focus, regulations are evolving to encourage the development of bio-based and biodegradable EVA alternatives. This trend is particularly evident in packaging applications, where several countries have introduced legislation to reduce plastic waste and promote eco-friendly materials.

The automotive industry, a significant user of EVA, must comply with regulations related to vehicle safety and emissions. EVA components in automobiles are subject to standards set by organizations such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) in Europe.