Predictive Maintenance Applications for AGM Battery Systems

AUG 8, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AGM Battery PM Background and Objectives

Predictive maintenance for Absorbent Glass Mat (AGM) battery systems has emerged as a critical technology in the evolving landscape of energy storage solutions. The development of this technology can be traced back to the early 2000s when the need for more reliable and efficient battery management systems became apparent across various industries.

AGM batteries, known for their superior performance and longer lifespan compared to traditional lead-acid batteries, have found widespread applications in automotive, telecommunications, and renewable energy sectors. However, the increasing reliance on these batteries in critical systems has highlighted the importance of proactive maintenance to prevent unexpected failures and optimize battery life.

The evolution of predictive maintenance for AGM batteries has been driven by advancements in sensor technology, data analytics, and machine learning algorithms. Early systems relied on simple voltage and current measurements to estimate battery health. As technology progressed, more sophisticated sensors were developed to monitor parameters such as internal resistance, temperature, and electrolyte levels.

The integration of Internet of Things (IoT) technologies in the mid-2010s marked a significant milestone in AGM battery predictive maintenance. This allowed for real-time data collection and remote monitoring, enabling more accurate predictions of battery performance and potential failures.

Recent years have seen a shift towards AI-powered predictive maintenance systems. These advanced algorithms can analyze vast amounts of historical and real-time data to identify subtle patterns and anomalies that may indicate impending battery issues. This has greatly improved the accuracy and reliability of maintenance predictions.

The primary objectives of AGM battery predictive maintenance applications are multifaceted. Firstly, they aim to extend battery life by identifying and addressing potential issues before they lead to irreversible damage. This not only reduces replacement costs but also minimizes environmental impact by reducing battery waste.

Secondly, these applications seek to optimize battery performance by providing insights into usage patterns and recommending operational adjustments. This is particularly crucial in applications where consistent power supply is critical, such as in telecommunications infrastructure or emergency backup systems.

Another key objective is to enhance safety by predicting and preventing potential battery failures that could lead to hazardous situations. This is especially important in automotive applications, where battery failure could result in vehicle breakdowns or accidents.

Furthermore, predictive maintenance applications aim to reduce operational costs by minimizing unplanned downtime and optimizing maintenance schedules. By accurately predicting when maintenance is needed, organizations can avoid unnecessary servicing while ensuring that critical interventions are performed in a timely manner.

As the technology continues to evolve, future objectives include the development of more accurate prediction models, integration with broader energy management systems, and the exploration of self-healing battery technologies that can automatically address minor issues without human intervention.

AGM batteries, known for their superior performance and longer lifespan compared to traditional lead-acid batteries, have found widespread applications in automotive, telecommunications, and renewable energy sectors. However, the increasing reliance on these batteries in critical systems has highlighted the importance of proactive maintenance to prevent unexpected failures and optimize battery life.

The evolution of predictive maintenance for AGM batteries has been driven by advancements in sensor technology, data analytics, and machine learning algorithms. Early systems relied on simple voltage and current measurements to estimate battery health. As technology progressed, more sophisticated sensors were developed to monitor parameters such as internal resistance, temperature, and electrolyte levels.

The integration of Internet of Things (IoT) technologies in the mid-2010s marked a significant milestone in AGM battery predictive maintenance. This allowed for real-time data collection and remote monitoring, enabling more accurate predictions of battery performance and potential failures.

Recent years have seen a shift towards AI-powered predictive maintenance systems. These advanced algorithms can analyze vast amounts of historical and real-time data to identify subtle patterns and anomalies that may indicate impending battery issues. This has greatly improved the accuracy and reliability of maintenance predictions.

The primary objectives of AGM battery predictive maintenance applications are multifaceted. Firstly, they aim to extend battery life by identifying and addressing potential issues before they lead to irreversible damage. This not only reduces replacement costs but also minimizes environmental impact by reducing battery waste.

Secondly, these applications seek to optimize battery performance by providing insights into usage patterns and recommending operational adjustments. This is particularly crucial in applications where consistent power supply is critical, such as in telecommunications infrastructure or emergency backup systems.

Another key objective is to enhance safety by predicting and preventing potential battery failures that could lead to hazardous situations. This is especially important in automotive applications, where battery failure could result in vehicle breakdowns or accidents.

Furthermore, predictive maintenance applications aim to reduce operational costs by minimizing unplanned downtime and optimizing maintenance schedules. By accurately predicting when maintenance is needed, organizations can avoid unnecessary servicing while ensuring that critical interventions are performed in a timely manner.

As the technology continues to evolve, future objectives include the development of more accurate prediction models, integration with broader energy management systems, and the exploration of self-healing battery technologies that can automatically address minor issues without human intervention.

Market Demand Analysis for AGM Battery PM

The market demand for predictive maintenance (PM) applications in AGM battery systems has been steadily growing, driven by the increasing adoption of AGM batteries across various industries and the need for improved battery performance and longevity. AGM (Absorbent Glass Mat) batteries are widely used in automotive, telecommunications, renewable energy storage, and uninterruptible power supply (UPS) systems due to their superior performance characteristics compared to traditional lead-acid batteries.

In the automotive sector, the rise of start-stop technology and the growing complexity of vehicle electrical systems have led to a surge in AGM battery usage. This has created a significant market for predictive maintenance solutions to ensure optimal battery performance and reduce unexpected failures. The global automotive battery market, which includes AGM batteries, is projected to reach substantial growth in the coming years, with predictive maintenance playing a crucial role in this expansion.

The telecommunications industry represents another major market for AGM battery PM applications. As telecom networks continue to expand and evolve, particularly with the rollout of 5G technology, the demand for reliable backup power solutions has intensified. AGM batteries are widely used in cell towers and data centers, where unexpected failures can result in significant downtime and financial losses. Predictive maintenance solutions for these critical infrastructure components are becoming increasingly essential to ensure network reliability and reduce operational costs.

In the renewable energy sector, the growing adoption of solar and wind power systems has led to increased demand for energy storage solutions, including AGM batteries. As these systems become more prevalent, the need for effective predictive maintenance to maximize battery life and performance has become paramount. The global energy storage market is expected to experience substantial growth, with AGM batteries and associated PM solutions playing a significant role.

The UPS market, particularly in industrial and commercial applications, represents another key area of demand for AGM battery PM solutions. As businesses become increasingly reliant on uninterrupted power supply for their operations, the need for reliable battery systems and predictive maintenance capabilities has grown significantly. The global UPS market is projected to expand considerably, with a focus on improving battery reliability and reducing maintenance costs.

The market demand for AGM battery PM applications is further driven by the overall trend towards digitalization and the Internet of Things (IoT). Advanced sensors, data analytics, and machine learning algorithms are enabling more sophisticated predictive maintenance solutions, allowing for real-time monitoring and accurate failure prediction. This technological advancement is creating new opportunities for PM solution providers and increasing the value proposition for end-users across various industries.

In the automotive sector, the rise of start-stop technology and the growing complexity of vehicle electrical systems have led to a surge in AGM battery usage. This has created a significant market for predictive maintenance solutions to ensure optimal battery performance and reduce unexpected failures. The global automotive battery market, which includes AGM batteries, is projected to reach substantial growth in the coming years, with predictive maintenance playing a crucial role in this expansion.

The telecommunications industry represents another major market for AGM battery PM applications. As telecom networks continue to expand and evolve, particularly with the rollout of 5G technology, the demand for reliable backup power solutions has intensified. AGM batteries are widely used in cell towers and data centers, where unexpected failures can result in significant downtime and financial losses. Predictive maintenance solutions for these critical infrastructure components are becoming increasingly essential to ensure network reliability and reduce operational costs.

In the renewable energy sector, the growing adoption of solar and wind power systems has led to increased demand for energy storage solutions, including AGM batteries. As these systems become more prevalent, the need for effective predictive maintenance to maximize battery life and performance has become paramount. The global energy storage market is expected to experience substantial growth, with AGM batteries and associated PM solutions playing a significant role.

The UPS market, particularly in industrial and commercial applications, represents another key area of demand for AGM battery PM solutions. As businesses become increasingly reliant on uninterrupted power supply for their operations, the need for reliable battery systems and predictive maintenance capabilities has grown significantly. The global UPS market is projected to expand considerably, with a focus on improving battery reliability and reducing maintenance costs.

The market demand for AGM battery PM applications is further driven by the overall trend towards digitalization and the Internet of Things (IoT). Advanced sensors, data analytics, and machine learning algorithms are enabling more sophisticated predictive maintenance solutions, allowing for real-time monitoring and accurate failure prediction. This technological advancement is creating new opportunities for PM solution providers and increasing the value proposition for end-users across various industries.

AGM Battery PM Challenges and Current State

Predictive maintenance for AGM (Absorbent Glass Mat) battery systems presents unique challenges due to the complex nature of these batteries and their widespread use in various applications. The current state of predictive maintenance for AGM batteries is characterized by a blend of traditional methods and emerging technologies, each with its own set of limitations and opportunities.

One of the primary challenges in AGM battery predictive maintenance is the accurate assessment of battery health and remaining useful life. Unlike flooded lead-acid batteries, AGM batteries do not allow for easy visual inspection of electrolyte levels or specific gravity measurements. This opacity necessitates more sophisticated monitoring techniques, often relying on indirect indicators of battery condition.

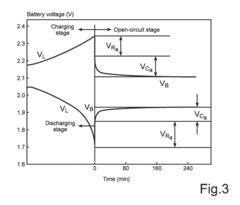

Current predictive maintenance approaches for AGM batteries typically involve a combination of voltage monitoring, impedance testing, and temperature sensing. However, these methods can sometimes provide incomplete or misleading information about the battery's true state of health. Voltage readings, for instance, may not always accurately reflect the battery's capacity, especially in cases of sulfation or internal short circuits.

Another significant challenge is the variability in AGM battery performance across different operating conditions and applications. Factors such as depth of discharge, charge rates, and environmental conditions can significantly impact battery life and performance. This variability makes it difficult to develop universally applicable predictive models, necessitating more tailored approaches for specific use cases.

The integration of AGM batteries into complex systems, such as uninterruptible power supplies (UPS) or renewable energy storage systems, further complicates predictive maintenance efforts. In these scenarios, the interdependencies between the battery and other system components must be considered, requiring a more holistic approach to maintenance prediction.

Currently, many organizations rely on scheduled maintenance and periodic testing for AGM batteries, which can be both inefficient and potentially inadequate. This approach may lead to premature battery replacements or, conversely, unexpected failures between scheduled maintenance intervals.

Advanced data analytics and machine learning algorithms are increasingly being applied to AGM battery maintenance, offering promising results in predicting failure modes and optimizing maintenance schedules. However, the effectiveness of these approaches is often limited by the quality and quantity of available historical data.

The development of more sophisticated sensors and monitoring systems specifically designed for AGM batteries is an ongoing area of research and development. These systems aim to provide more accurate and real-time data on battery health, including internal resistance, state of charge, and early indicators of degradation.

In conclusion, while predictive maintenance for AGM battery systems has made significant strides, there remain substantial challenges in achieving reliable, cost-effective, and widely applicable solutions. The current state of the field reflects a transition from traditional methods to more advanced, data-driven approaches, with ongoing efforts to overcome the inherent complexities of AGM battery technology.

One of the primary challenges in AGM battery predictive maintenance is the accurate assessment of battery health and remaining useful life. Unlike flooded lead-acid batteries, AGM batteries do not allow for easy visual inspection of electrolyte levels or specific gravity measurements. This opacity necessitates more sophisticated monitoring techniques, often relying on indirect indicators of battery condition.

Current predictive maintenance approaches for AGM batteries typically involve a combination of voltage monitoring, impedance testing, and temperature sensing. However, these methods can sometimes provide incomplete or misleading information about the battery's true state of health. Voltage readings, for instance, may not always accurately reflect the battery's capacity, especially in cases of sulfation or internal short circuits.

Another significant challenge is the variability in AGM battery performance across different operating conditions and applications. Factors such as depth of discharge, charge rates, and environmental conditions can significantly impact battery life and performance. This variability makes it difficult to develop universally applicable predictive models, necessitating more tailored approaches for specific use cases.

The integration of AGM batteries into complex systems, such as uninterruptible power supplies (UPS) or renewable energy storage systems, further complicates predictive maintenance efforts. In these scenarios, the interdependencies between the battery and other system components must be considered, requiring a more holistic approach to maintenance prediction.

Currently, many organizations rely on scheduled maintenance and periodic testing for AGM batteries, which can be both inefficient and potentially inadequate. This approach may lead to premature battery replacements or, conversely, unexpected failures between scheduled maintenance intervals.

Advanced data analytics and machine learning algorithms are increasingly being applied to AGM battery maintenance, offering promising results in predicting failure modes and optimizing maintenance schedules. However, the effectiveness of these approaches is often limited by the quality and quantity of available historical data.

The development of more sophisticated sensors and monitoring systems specifically designed for AGM batteries is an ongoing area of research and development. These systems aim to provide more accurate and real-time data on battery health, including internal resistance, state of charge, and early indicators of degradation.

In conclusion, while predictive maintenance for AGM battery systems has made significant strides, there remain substantial challenges in achieving reliable, cost-effective, and widely applicable solutions. The current state of the field reflects a transition from traditional methods to more advanced, data-driven approaches, with ongoing efforts to overcome the inherent complexities of AGM battery technology.

Current AGM Battery PM Solutions

01 Battery monitoring and management systems

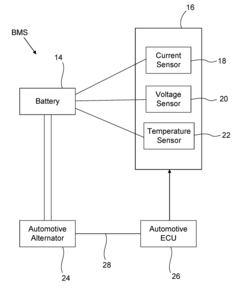

Advanced monitoring and management systems are crucial for maintaining AGM battery systems. These systems typically include sensors and control units that continuously monitor battery parameters such as voltage, current, temperature, and state of charge. They can provide real-time data, predict potential issues, and optimize battery performance and lifespan through intelligent charging and discharging strategies.- Battery monitoring and management systems: Advanced monitoring and management systems are crucial for AGM battery maintenance. These systems continuously track battery parameters such as voltage, current, temperature, and state of charge. They can provide real-time data, predict potential issues, and optimize battery performance, thereby extending the lifespan of AGM batteries and ensuring their reliable operation.

- Charging and discharging control techniques: Proper charging and discharging control is essential for AGM battery maintenance. This involves implementing sophisticated algorithms and control mechanisms to regulate charging rates, prevent overcharging or deep discharging, and balance cells within battery packs. These techniques help maintain optimal battery health and performance over time.

- Thermal management solutions: Effective thermal management is critical for AGM battery systems. This includes implementing cooling systems, heat dissipation mechanisms, and temperature monitoring devices. Proper thermal management helps prevent overheating, ensures uniform temperature distribution across battery cells, and maintains optimal operating conditions, thereby enhancing battery life and performance.

- Maintenance scheduling and predictive diagnostics: Implementing regular maintenance schedules and predictive diagnostic tools is crucial for AGM battery systems. This involves using data analytics, machine learning algorithms, and sensor technologies to predict potential failures, schedule timely maintenance, and optimize battery performance. Such proactive approaches can significantly reduce downtime and extend battery life.

- Safety features and protection mechanisms: Incorporating robust safety features and protection mechanisms is essential for AGM battery system maintenance. This includes implementing overcharge protection, short circuit prevention, and emergency shutdown systems. These safety measures help prevent accidents, protect the battery from damage, and ensure the overall reliability and longevity of the AGM battery system.

02 Thermal management techniques

Effective thermal management is essential for AGM battery systems maintenance. This involves implementing cooling systems, heat dissipation methods, and temperature control mechanisms to prevent overheating and ensure optimal operating conditions. Proper thermal management can significantly extend battery life and improve overall system efficiency.Expand Specific Solutions03 Charging and balancing strategies

Implementing proper charging and balancing strategies is crucial for maintaining AGM battery systems. This includes using intelligent charging algorithms, employing cell balancing techniques to ensure uniform charge distribution across all cells, and implementing periodic equalization charges to prevent sulfation and extend battery life.Expand Specific Solutions04 Preventive maintenance procedures

Regular preventive maintenance is key to ensuring the longevity and reliability of AGM battery systems. This includes visual inspections, cleaning of battery terminals and connections, checking for corrosion, and performing capacity tests. Implementing a structured maintenance schedule and following manufacturer-recommended procedures can help identify and address potential issues before they escalate.Expand Specific Solutions05 Remote monitoring and diagnostics

Remote monitoring and diagnostic systems enable proactive maintenance of AGM battery systems. These systems use advanced sensors, data analytics, and communication technologies to provide real-time insights into battery health and performance. They can detect anomalies, predict failures, and facilitate timely interventions, reducing downtime and maintenance costs.Expand Specific Solutions

Key Players in AGM Battery PM Industry

The predictive maintenance market for AGM battery systems is in a growth phase, driven by increasing demand for reliable energy storage solutions. The market size is expanding rapidly, with a projected CAGR of over 25% in the coming years. Technologically, the field is advancing quickly, with companies like Robert Bosch GmbH, Siemens Corp., and Johnson Controls leading innovation. These firms are developing sophisticated AI-driven algorithms and IoT-enabled sensors to enhance battery performance prediction and lifespan. Emerging players like Averroes.ai and Stryten Energy are also contributing to the competitive landscape, focusing on specialized AI applications and sustainable energy storage solutions, respectively.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced predictive maintenance system for AGM batteries, leveraging IoT and machine learning technologies. Their solution incorporates real-time monitoring of battery parameters such as voltage, current, temperature, and internal resistance. The system uses sophisticated algorithms to analyze these data points and predict potential failures before they occur. Bosch's approach includes a cloud-based platform that aggregates data from multiple batteries across various applications, enabling more accurate predictions and trend analysis[1]. The system also integrates with Bosch's broader ecosystem of automotive and industrial solutions, allowing for seamless integration with existing infrastructure[3].

Strengths: Comprehensive data analysis, integration with existing Bosch ecosystems, and extensive automotive industry experience. Weaknesses: Potential dependency on Bosch-specific hardware and software ecosystems.

Siemens Corp.

Technical Solution: Siemens has developed a comprehensive predictive maintenance solution for AGM battery systems, integrating their MindSphere IoT operating system with advanced analytics. Their approach combines real-time sensor data with historical performance records to create digital twins of battery systems. These digital twins enable accurate simulation and prediction of battery behavior under various conditions. Siemens' solution incorporates machine learning algorithms that continuously improve prediction accuracy over time[2]. The system also features a user-friendly dashboard for easy monitoring and decision-making, and can be integrated with existing industrial control systems[4].

Strengths: Robust IoT platform, digital twin technology, and extensive industrial automation experience. Weaknesses: May require significant infrastructure investment for full implementation.

Core AGM Battery PM Innovations

Method for Charging a Battery Having a Plurality of Battery Cells

PatentActiveUS20180134168A1

Innovation

- A battery management system (BMS) that dynamically controls the charging process using sensors for real-time monitoring of battery current, voltage, and temperature, implementing a multi-stage charging strategy including bulk charging, absorption, equalization, and float phases, with adaptive voltage and current adjustments to optimize charging efficiency and prevent overcharging and undercharging.

Over-Saturated Absorbed Glass Mat Valve Regulated Lead-Acid Battery Comprising Carbon Additives

PatentInactiveUS20140120386A1

Innovation

- An AGM VRLA battery design with a positive plate, negative plate containing a carbon additive, an AGM separator, and an electrolyte present in an amount ranging from 100 to 150% by volume based on the total pore volume of the separator, utilizing various carbon additives such as graphite, carbon black, activated carbon, and graphene to enhance charge acceptance and durability.

AGM Battery PM Data Analytics

Data analytics plays a crucial role in predictive maintenance applications for AGM (Absorbent Glass Mat) battery systems. By leveraging advanced analytical techniques, organizations can extract valuable insights from vast amounts of battery-related data, enabling proactive maintenance strategies and optimizing battery performance.

One of the primary focuses of AGM battery PM data analytics is the collection and processing of real-time battery performance data. This includes parameters such as voltage, current, temperature, and state of charge. Advanced sensors and monitoring systems are employed to capture these metrics continuously, providing a comprehensive view of battery health and operational status.

Machine learning algorithms are extensively utilized to analyze historical and real-time data, identifying patterns and trends that may indicate potential battery failures or degradation. These algorithms can detect subtle changes in battery behavior that might be imperceptible to human operators, allowing for early intervention and preventive maintenance actions.

Predictive models are developed using statistical techniques and artificial intelligence to forecast battery lifespan and estimate the remaining useful life of AGM batteries. These models take into account various factors such as usage patterns, environmental conditions, and historical performance data to provide accurate predictions of when maintenance or replacement may be necessary.

Data visualization tools are employed to present complex battery data in an easily understandable format. Interactive dashboards and graphical representations enable maintenance teams to quickly assess battery health, identify potential issues, and make informed decisions regarding maintenance schedules and resource allocation.

Anomaly detection algorithms are implemented to identify unusual battery behavior or performance deviations that may indicate impending failures. These algorithms can trigger alerts and notifications, allowing maintenance personnel to address potential issues before they escalate into critical problems.

Integration of AGM battery data with other relevant systems, such as asset management and maintenance scheduling platforms, enables a holistic approach to predictive maintenance. This integration facilitates seamless workflow management and ensures that maintenance activities are aligned with overall operational objectives.

Advanced analytics techniques, such as time series analysis and regression modeling, are applied to historical battery data to identify long-term trends and patterns. This information can be used to optimize battery replacement strategies, improve inventory management, and enhance overall system reliability.

By leveraging AGM battery PM data analytics, organizations can achieve significant benefits, including reduced downtime, extended battery life, optimized maintenance schedules, and improved overall system reliability. The insights gained from data analytics enable proactive decision-making and help organizations maximize the performance and longevity of their AGM battery systems.

One of the primary focuses of AGM battery PM data analytics is the collection and processing of real-time battery performance data. This includes parameters such as voltage, current, temperature, and state of charge. Advanced sensors and monitoring systems are employed to capture these metrics continuously, providing a comprehensive view of battery health and operational status.

Machine learning algorithms are extensively utilized to analyze historical and real-time data, identifying patterns and trends that may indicate potential battery failures or degradation. These algorithms can detect subtle changes in battery behavior that might be imperceptible to human operators, allowing for early intervention and preventive maintenance actions.

Predictive models are developed using statistical techniques and artificial intelligence to forecast battery lifespan and estimate the remaining useful life of AGM batteries. These models take into account various factors such as usage patterns, environmental conditions, and historical performance data to provide accurate predictions of when maintenance or replacement may be necessary.

Data visualization tools are employed to present complex battery data in an easily understandable format. Interactive dashboards and graphical representations enable maintenance teams to quickly assess battery health, identify potential issues, and make informed decisions regarding maintenance schedules and resource allocation.

Anomaly detection algorithms are implemented to identify unusual battery behavior or performance deviations that may indicate impending failures. These algorithms can trigger alerts and notifications, allowing maintenance personnel to address potential issues before they escalate into critical problems.

Integration of AGM battery data with other relevant systems, such as asset management and maintenance scheduling platforms, enables a holistic approach to predictive maintenance. This integration facilitates seamless workflow management and ensures that maintenance activities are aligned with overall operational objectives.

Advanced analytics techniques, such as time series analysis and regression modeling, are applied to historical battery data to identify long-term trends and patterns. This information can be used to optimize battery replacement strategies, improve inventory management, and enhance overall system reliability.

By leveraging AGM battery PM data analytics, organizations can achieve significant benefits, including reduced downtime, extended battery life, optimized maintenance schedules, and improved overall system reliability. The insights gained from data analytics enable proactive decision-making and help organizations maximize the performance and longevity of their AGM battery systems.

Environmental Impact of AGM Battery PM

The environmental impact of predictive maintenance (PM) applications for AGM battery systems is a crucial consideration in the broader context of sustainable energy solutions. AGM (Absorbent Glass Mat) batteries, known for their efficiency and reliability, are widely used in various applications, including renewable energy storage and automotive systems. Implementing predictive maintenance strategies for these batteries can significantly reduce their environmental footprint throughout their lifecycle.

One of the primary environmental benefits of PM for AGM batteries is the extension of battery life. By accurately predicting and addressing potential issues before they escalate, PM helps prevent premature battery failures. This extended lifespan reduces the frequency of battery replacements, consequently decreasing the demand for raw materials and energy required for manufacturing new batteries. The reduced production needs translate to lower carbon emissions and less strain on natural resources.

PM applications also contribute to optimizing the performance of AGM batteries, ensuring they operate at peak efficiency. This optimization leads to improved energy utilization, reducing overall energy consumption and associated environmental impacts. In renewable energy systems, for instance, more efficient battery performance can enhance the integration of intermittent energy sources, further supporting the transition to cleaner energy alternatives.

The reduction of unexpected battery failures through PM has cascading environmental benefits. Fewer emergency replacements mean less transportation for urgent deliveries and reduced waste from prematurely discarded batteries. This aspect is particularly significant in remote or off-grid applications where battery replacement can involve substantial logistical challenges and environmental costs.

Furthermore, PM enables more precise and timely recycling of AGM batteries. By accurately predicting the end-of-life stage, batteries can be collected and recycled at the optimal time, maximizing the recovery of valuable materials such as lead and plastic. This efficient recycling process not only conserves resources but also minimizes the potential for environmental contamination from improperly disposed batteries.

The data-driven nature of PM applications for AGM batteries also contributes to broader environmental research and policy-making. The extensive data collected on battery performance and lifecycle can inform the development of more environmentally friendly battery technologies and guide regulations on battery management and disposal.

However, it's important to consider the potential environmental trade-offs of implementing PM systems. The infrastructure required for data collection, transmission, and processing in PM applications does have its own environmental footprint, primarily in terms of energy consumption and electronic waste. Nevertheless, when balanced against the significant environmental benefits, the overall impact of PM for AGM batteries is overwhelmingly positive.

One of the primary environmental benefits of PM for AGM batteries is the extension of battery life. By accurately predicting and addressing potential issues before they escalate, PM helps prevent premature battery failures. This extended lifespan reduces the frequency of battery replacements, consequently decreasing the demand for raw materials and energy required for manufacturing new batteries. The reduced production needs translate to lower carbon emissions and less strain on natural resources.

PM applications also contribute to optimizing the performance of AGM batteries, ensuring they operate at peak efficiency. This optimization leads to improved energy utilization, reducing overall energy consumption and associated environmental impacts. In renewable energy systems, for instance, more efficient battery performance can enhance the integration of intermittent energy sources, further supporting the transition to cleaner energy alternatives.

The reduction of unexpected battery failures through PM has cascading environmental benefits. Fewer emergency replacements mean less transportation for urgent deliveries and reduced waste from prematurely discarded batteries. This aspect is particularly significant in remote or off-grid applications where battery replacement can involve substantial logistical challenges and environmental costs.

Furthermore, PM enables more precise and timely recycling of AGM batteries. By accurately predicting the end-of-life stage, batteries can be collected and recycled at the optimal time, maximizing the recovery of valuable materials such as lead and plastic. This efficient recycling process not only conserves resources but also minimizes the potential for environmental contamination from improperly disposed batteries.

The data-driven nature of PM applications for AGM batteries also contributes to broader environmental research and policy-making. The extensive data collected on battery performance and lifecycle can inform the development of more environmentally friendly battery technologies and guide regulations on battery management and disposal.

However, it's important to consider the potential environmental trade-offs of implementing PM systems. The infrastructure required for data collection, transmission, and processing in PM applications does have its own environmental footprint, primarily in terms of energy consumption and electronic waste. Nevertheless, when balanced against the significant environmental benefits, the overall impact of PM for AGM batteries is overwhelmingly positive.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!