Research into Nanofiltration in Wastewater Catalytic Processes

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Technology Evolution and Objectives

Nanofiltration technology emerged in the late 1980s as a specialized membrane separation process positioned between ultrafiltration and reverse osmosis. The evolution of this technology has been marked by significant advancements in membrane materials, design configurations, and operational parameters. Initially developed for drinking water treatment, nanofiltration has progressively expanded its application scope to include industrial wastewater treatment, pharmaceutical processing, and more recently, catalytic wastewater processes.

The historical trajectory of nanofiltration shows a clear shift from simple filtration mechanisms to more sophisticated approaches integrating selective separation capabilities. Early nanofiltration membranes were primarily cellulose-based with limited selectivity and durability. The 1990s witnessed the introduction of thin-film composite membranes, significantly enhancing separation efficiency and chemical resistance. By the early 2000s, research focus shifted toward developing nanofiltration membranes with specialized surface modifications to address specific contaminants and reduce fouling issues.

In the context of wastewater catalytic processes, nanofiltration technology has evolved to address the unique challenges of separating catalysts from reaction mixtures while simultaneously removing contaminants. This dual functionality represents a paradigm shift in wastewater treatment approaches, moving from end-of-pipe solutions to integrated process technologies that enhance both treatment efficiency and resource recovery.

Current technological objectives for nanofiltration in wastewater catalytic processes center around several key areas. First, improving membrane selectivity to effectively separate catalytic materials from complex wastewater matrices while allowing beneficial components to pass through. Second, enhancing membrane durability under harsh chemical environments typical in catalytic processes. Third, developing anti-fouling properties to maintain consistent performance during extended operation periods.

Additionally, research aims to optimize energy efficiency by reducing the pressure requirements for nanofiltration operations, thereby lowering operational costs. Integration capabilities also represent a critical objective, with efforts focused on designing nanofiltration systems that seamlessly incorporate into existing wastewater treatment infrastructures and catalytic process lines.

The ultimate technological goal is to develop "smart" nanofiltration systems capable of adaptive performance based on influent characteristics, featuring real-time monitoring and self-cleaning capabilities. Such advanced systems would revolutionize wastewater treatment by enabling precise control over separation processes, maximizing catalyst recovery, and minimizing waste generation. This evolution toward intelligent, resource-efficient nanofiltration represents the frontier of wastewater treatment technology.

The historical trajectory of nanofiltration shows a clear shift from simple filtration mechanisms to more sophisticated approaches integrating selective separation capabilities. Early nanofiltration membranes were primarily cellulose-based with limited selectivity and durability. The 1990s witnessed the introduction of thin-film composite membranes, significantly enhancing separation efficiency and chemical resistance. By the early 2000s, research focus shifted toward developing nanofiltration membranes with specialized surface modifications to address specific contaminants and reduce fouling issues.

In the context of wastewater catalytic processes, nanofiltration technology has evolved to address the unique challenges of separating catalysts from reaction mixtures while simultaneously removing contaminants. This dual functionality represents a paradigm shift in wastewater treatment approaches, moving from end-of-pipe solutions to integrated process technologies that enhance both treatment efficiency and resource recovery.

Current technological objectives for nanofiltration in wastewater catalytic processes center around several key areas. First, improving membrane selectivity to effectively separate catalytic materials from complex wastewater matrices while allowing beneficial components to pass through. Second, enhancing membrane durability under harsh chemical environments typical in catalytic processes. Third, developing anti-fouling properties to maintain consistent performance during extended operation periods.

Additionally, research aims to optimize energy efficiency by reducing the pressure requirements for nanofiltration operations, thereby lowering operational costs. Integration capabilities also represent a critical objective, with efforts focused on designing nanofiltration systems that seamlessly incorporate into existing wastewater treatment infrastructures and catalytic process lines.

The ultimate technological goal is to develop "smart" nanofiltration systems capable of adaptive performance based on influent characteristics, featuring real-time monitoring and self-cleaning capabilities. Such advanced systems would revolutionize wastewater treatment by enabling precise control over separation processes, maximizing catalyst recovery, and minimizing waste generation. This evolution toward intelligent, resource-efficient nanofiltration represents the frontier of wastewater treatment technology.

Market Analysis for Wastewater Treatment Solutions

The global wastewater treatment market is experiencing significant growth, valued at approximately $250 billion in 2022 and projected to reach $375 billion by 2028, with a compound annual growth rate of 7.1%. This expansion is driven by increasing water scarcity concerns, stricter environmental regulations, and growing industrial activities worldwide. Nanofiltration technologies specifically represent a rapidly growing segment within this market, currently valued at around $23 billion and expected to grow at 8.5% annually through 2030.

Demand for advanced wastewater treatment solutions is particularly strong in regions facing severe water stress, including parts of Asia-Pacific, Middle East, and North America. China and India are emerging as key growth markets due to rapid industrialization coupled with increasingly stringent environmental policies. The European market remains mature but innovative, driven by the EU Water Framework Directive and circular economy initiatives.

Industrial sectors constitute the largest end-user segment for nanofiltration in wastewater catalytic processes, accounting for approximately 65% of market demand. Chemical manufacturing, pharmaceuticals, food and beverage, and textile industries are primary adopters due to their complex wastewater profiles requiring specialized treatment. Municipal applications represent about 30% of the market but are growing faster as cities upgrade aging infrastructure.

Customer requirements are evolving toward more energy-efficient, compact, and automated treatment systems. There is increasing demand for solutions that not only remove contaminants but also enable water reuse and resource recovery. The total cost of ownership, rather than initial capital expenditure, has become a key decision factor for many end-users, creating opportunities for service-based business models.

Competitive dynamics in the nanofiltration segment reveal a market dominated by established water technology companies like Veolia, Suez, DuPont Water Solutions, and Pentair, collectively holding about 45% market share. However, specialized technology providers and innovative startups are gaining ground by offering tailored solutions for specific industrial applications or novel membrane materials with enhanced performance characteristics.

Market barriers include high initial investment costs, technical complexity requiring specialized expertise, and conservative adoption practices in certain industries. The payback period for advanced nanofiltration systems typically ranges from 3-5 years, which can deter some potential customers despite long-term operational benefits.

Future market growth will likely be driven by increasing regulatory pressure on discharge quality, rising water costs, and growing corporate sustainability commitments. The integration of nanofiltration with complementary technologies such as advanced oxidation processes and biological treatment systems represents a significant opportunity for comprehensive wastewater treatment solutions with enhanced efficiency and effectiveness.

Demand for advanced wastewater treatment solutions is particularly strong in regions facing severe water stress, including parts of Asia-Pacific, Middle East, and North America. China and India are emerging as key growth markets due to rapid industrialization coupled with increasingly stringent environmental policies. The European market remains mature but innovative, driven by the EU Water Framework Directive and circular economy initiatives.

Industrial sectors constitute the largest end-user segment for nanofiltration in wastewater catalytic processes, accounting for approximately 65% of market demand. Chemical manufacturing, pharmaceuticals, food and beverage, and textile industries are primary adopters due to their complex wastewater profiles requiring specialized treatment. Municipal applications represent about 30% of the market but are growing faster as cities upgrade aging infrastructure.

Customer requirements are evolving toward more energy-efficient, compact, and automated treatment systems. There is increasing demand for solutions that not only remove contaminants but also enable water reuse and resource recovery. The total cost of ownership, rather than initial capital expenditure, has become a key decision factor for many end-users, creating opportunities for service-based business models.

Competitive dynamics in the nanofiltration segment reveal a market dominated by established water technology companies like Veolia, Suez, DuPont Water Solutions, and Pentair, collectively holding about 45% market share. However, specialized technology providers and innovative startups are gaining ground by offering tailored solutions for specific industrial applications or novel membrane materials with enhanced performance characteristics.

Market barriers include high initial investment costs, technical complexity requiring specialized expertise, and conservative adoption practices in certain industries. The payback period for advanced nanofiltration systems typically ranges from 3-5 years, which can deter some potential customers despite long-term operational benefits.

Future market growth will likely be driven by increasing regulatory pressure on discharge quality, rising water costs, and growing corporate sustainability commitments. The integration of nanofiltration with complementary technologies such as advanced oxidation processes and biological treatment systems represents a significant opportunity for comprehensive wastewater treatment solutions with enhanced efficiency and effectiveness.

Current Nanofiltration Challenges in Catalytic Processes

Nanofiltration technology in wastewater catalytic processes faces several significant challenges that limit its widespread industrial application. The primary obstacle remains membrane fouling, which occurs when contaminants accumulate on membrane surfaces, reducing permeability and separation efficiency. This phenomenon is particularly problematic in catalytic wastewater treatment where reaction byproducts and catalyst particles can rapidly degrade membrane performance, necessitating frequent cleaning or replacement and increasing operational costs.

Selectivity limitations represent another critical challenge. Current nanofiltration membranes struggle to achieve optimal separation of specific contaminants while allowing beneficial components to pass through. This selectivity issue becomes more pronounced when dealing with complex wastewater streams containing multiple pollutants of varying molecular sizes and chemical properties, especially in catalytic processes where precise separation of reactants, catalysts, and products is essential.

Membrane stability under harsh catalytic conditions presents significant technical barriers. Many catalytic wastewater treatment processes operate under extreme pH conditions, elevated temperatures, or in the presence of oxidizing agents. Conventional polymeric nanofiltration membranes often exhibit limited chemical and thermal resistance in these environments, leading to accelerated degradation and shortened operational lifespans.

Energy consumption remains a persistent challenge, as nanofiltration systems require substantial pressure differentials to achieve desired flux rates. This energy demand increases operational costs and carbon footprints, particularly for large-scale industrial applications. The trade-off between energy efficiency and separation performance continues to challenge system designers and operators.

Catalyst recovery and reuse present unique challenges in integrated nanofiltration-catalytic systems. Effective separation and recycling of homogeneous or heterogeneous catalysts from reaction mixtures are essential for process economics but remain difficult to achieve consistently with current membrane technologies.

Scale-up difficulties further complicate industrial implementation. Laboratory-scale successes often fail to translate directly to industrial settings due to flow distribution problems, pressure drop issues, and membrane module design limitations. These scaling challenges significantly impact the economic viability of nanofiltration in large wastewater treatment facilities.

Concentration polarization, where rejected solutes accumulate near the membrane surface, creates localized high-concentration regions that reduce separation efficiency and exacerbate fouling problems. This phenomenon is particularly problematic in catalytic processes where reaction kinetics can be affected by local concentration gradients.

These technical challenges collectively represent significant barriers to the widespread adoption of nanofiltration technology in wastewater catalytic processes, driving current research efforts toward developing more robust, selective, and energy-efficient membrane systems.

Selectivity limitations represent another critical challenge. Current nanofiltration membranes struggle to achieve optimal separation of specific contaminants while allowing beneficial components to pass through. This selectivity issue becomes more pronounced when dealing with complex wastewater streams containing multiple pollutants of varying molecular sizes and chemical properties, especially in catalytic processes where precise separation of reactants, catalysts, and products is essential.

Membrane stability under harsh catalytic conditions presents significant technical barriers. Many catalytic wastewater treatment processes operate under extreme pH conditions, elevated temperatures, or in the presence of oxidizing agents. Conventional polymeric nanofiltration membranes often exhibit limited chemical and thermal resistance in these environments, leading to accelerated degradation and shortened operational lifespans.

Energy consumption remains a persistent challenge, as nanofiltration systems require substantial pressure differentials to achieve desired flux rates. This energy demand increases operational costs and carbon footprints, particularly for large-scale industrial applications. The trade-off between energy efficiency and separation performance continues to challenge system designers and operators.

Catalyst recovery and reuse present unique challenges in integrated nanofiltration-catalytic systems. Effective separation and recycling of homogeneous or heterogeneous catalysts from reaction mixtures are essential for process economics but remain difficult to achieve consistently with current membrane technologies.

Scale-up difficulties further complicate industrial implementation. Laboratory-scale successes often fail to translate directly to industrial settings due to flow distribution problems, pressure drop issues, and membrane module design limitations. These scaling challenges significantly impact the economic viability of nanofiltration in large wastewater treatment facilities.

Concentration polarization, where rejected solutes accumulate near the membrane surface, creates localized high-concentration regions that reduce separation efficiency and exacerbate fouling problems. This phenomenon is particularly problematic in catalytic processes where reaction kinetics can be affected by local concentration gradients.

These technical challenges collectively represent significant barriers to the widespread adoption of nanofiltration technology in wastewater catalytic processes, driving current research efforts toward developing more robust, selective, and energy-efficient membrane systems.

Existing Nanofiltration-Catalysis Integration Methods

01 Nanofiltration membrane materials and structures

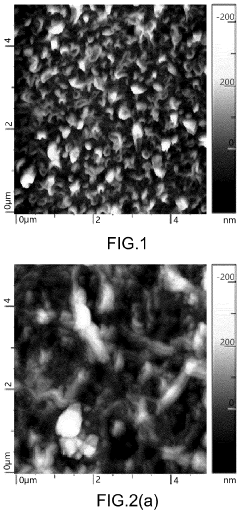

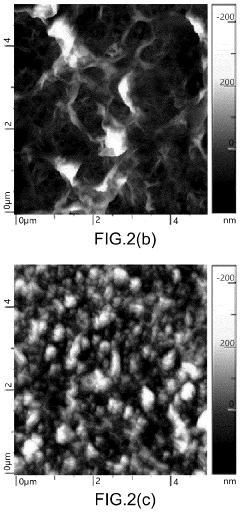

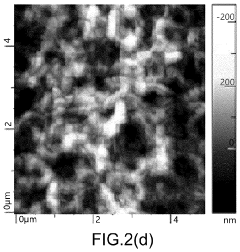

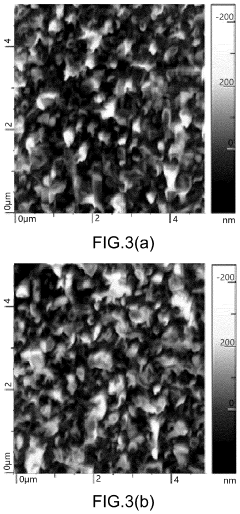

Nanofiltration membranes can be fabricated using various materials and structures to achieve specific separation properties. These membranes typically have pore sizes in the nanometer range and can be made from polymers, ceramics, or composite materials. The structure of the membrane, including its thickness, porosity, and surface characteristics, significantly affects its performance in terms of flux, selectivity, and fouling resistance.- Nanofiltration membrane materials and structures: Nanofiltration membranes can be fabricated from various materials including polymers, ceramics, and composite materials. The structure of these membranes typically consists of a thin selective layer supported by a more porous substrate. Advanced membrane designs incorporate specific functional groups or nanoparticles to enhance selectivity, permeability, and resistance to fouling. These structural innovations allow for more efficient separation of molecules based on size, charge, and other physicochemical properties.

- Water purification and treatment applications: Nanofiltration technology is widely used in water treatment processes for the removal of contaminants such as heavy metals, organic compounds, and dissolved salts. It operates in the range between reverse osmosis and ultrafiltration, allowing for selective removal of multivalent ions while permitting some monovalent ions to pass through. This makes it particularly effective for softening water, removing color, and reducing specific contaminants while maintaining essential minerals in drinking water applications.

- Industrial separation and purification processes: Nanofiltration systems are employed in various industrial applications for separation and purification of valuable components. These include pharmaceutical processing, food and beverage production, textile manufacturing, and chemical processing. The technology enables selective separation of molecules based on size and charge, allowing for concentration of desired compounds, removal of impurities, and recovery of valuable materials from process streams. This results in improved product quality and reduced waste generation in industrial settings.

- Energy-efficient nanofiltration systems: Recent advancements in nanofiltration technology focus on improving energy efficiency through innovative system designs, operational strategies, and membrane materials. These developments include low-pressure operation, energy recovery devices, optimized flow patterns, and reduced membrane fouling. By minimizing energy consumption while maintaining separation performance, these systems offer more sustainable alternatives to conventional separation processes, particularly in applications requiring the processing of large volumes of liquid.

- Fouling prevention and membrane cleaning methods: Membrane fouling is a significant challenge in nanofiltration operations that reduces efficiency and increases operational costs. Innovative approaches to prevent fouling include surface modifications of membranes, incorporation of antimicrobial agents, and development of self-cleaning membrane materials. Additionally, advanced cleaning protocols using chemical agents, physical methods, or combined approaches help restore membrane performance. These methods extend membrane lifetime, maintain separation efficiency, and reduce the frequency of membrane replacement in nanofiltration systems.

02 Water purification and treatment applications

Nanofiltration is widely used in water purification and treatment processes to remove contaminants such as dissolved salts, organic compounds, and microorganisms. It operates at lower pressures than reverse osmosis while providing higher rejection rates than ultrafiltration. This technology is particularly effective for softening water, removing divalent ions, and treating wastewater for reuse applications.Expand Specific Solutions03 Industrial separation processes

Nanofiltration technology is employed in various industrial separation processes to recover valuable components or remove unwanted substances. Applications include the separation of pharmaceuticals, food processing, textile industry effluent treatment, and chemical processing. The selective nature of nanofiltration allows for the concentration of specific compounds while permitting others to pass through, making it valuable for product purification and waste stream management.Expand Specific Solutions04 Fouling prevention and membrane cleaning

Membrane fouling is a significant challenge in nanofiltration operations, leading to reduced performance and increased operational costs. Various strategies have been developed to prevent fouling, including surface modifications, pre-treatment processes, and optimized operating conditions. Effective cleaning protocols using chemical agents, backwashing, or physical methods are essential for maintaining membrane performance and extending service life.Expand Specific Solutions05 Energy-efficient nanofiltration systems

Innovations in nanofiltration system design focus on improving energy efficiency while maintaining separation performance. These advancements include low-pressure operation, energy recovery devices, process optimization, and novel membrane configurations. Energy-efficient nanofiltration systems reduce operational costs and environmental impact, making the technology more sustainable for large-scale applications in water treatment and industrial processes.Expand Specific Solutions

Leading Companies in Nanofiltration and Catalysis

Nanofiltration in wastewater catalytic processes is emerging as a critical technology in the early growth phase of advanced water treatment solutions. The market is expanding rapidly, projected to reach significant scale as global water scarcity and pollution regulations intensify. Leading players demonstrate varying levels of technical maturity: established chemical giants like BASF, Sinopec, and Albemarle bring robust R&D capabilities; specialized water technology firms including Veolia, Aquatech, and Axine Water Technologies offer targeted innovations; while academic institutions such as University of Hong Kong, KU Leuven, and Tianjin University contribute fundamental research. Chinese companies are increasingly competitive, with Boying Technology and Zhejiang Jinmo developing proprietary membrane technologies alongside international corporations like Siemens and Ecolab that integrate nanofiltration into comprehensive industrial solutions.

China Petroleum & Chemical Corp.

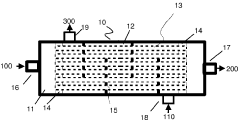

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced nanofiltration membrane technologies specifically designed for petrochemical wastewater treatment. Their approach combines catalytic oxidation with nanofiltration membranes that feature precisely controlled pore sizes (typically 1-10 nm) and surface functionalization. The system employs composite membranes with thin-film polyamide active layers on porous supports, achieving rejection rates of over 95% for multivalent ions while allowing monovalent ions to pass. Sinopec's integrated process incorporates pre-treatment stages, catalytic reactors with noble metal or transition metal oxide catalysts, and nanofiltration units that operate at moderate pressures (5-20 bar). This technology effectively removes persistent organic pollutants, heavy metals, and sulfur compounds from refinery and petrochemical wastewaters, enabling water reuse and reducing environmental impact[1][3].

Strengths: Specialized expertise in treating complex petrochemical wastewaters with high concentrations of organic contaminants and sulfur compounds. Their integrated approach combines catalytic degradation with selective separation, enabling effective removal of recalcitrant compounds. Weaknesses: The technology may require significant energy input for operation and the catalysts used might be susceptible to poisoning or deactivation in certain wastewater streams.

BASF Corp.

Technical Solution: BASF has pioneered innovative nanofiltration solutions for wastewater treatment incorporating catalytic processes. Their technology centers on the inge® ultrafiltration and Ultrason® E membrane platforms, which they've adapted for nanofiltration applications in industrial wastewater treatment. BASF's approach integrates heterogeneous catalysis with membrane separation, using specially designed catalytic nanoparticles (typically 5-50 nm) embedded within or deposited onto membrane surfaces. These catalytic membranes simultaneously perform separation and reaction functions, breaking down complex organic pollutants while filtering out contaminants. The company has developed proprietary surface modification techniques that enhance membrane fouling resistance and catalytic activity, including grafting of functional groups and controlled deposition of metal/metal oxide catalysts. Their systems operate under moderate conditions (temperatures of 20-80°C and pressures of 5-30 bar) and have demonstrated removal efficiencies exceeding 99% for priority pollutants in industrial wastewaters[2][5].

Strengths: BASF's dual-function catalytic membranes offer simultaneous degradation and separation, reducing system complexity and footprint. Their extensive materials science expertise enables precise control of membrane properties and catalyst performance. Weaknesses: The technology may face challenges with catalyst stability over extended operation periods, and the manufacturing process for catalytic membranes is more complex than conventional membranes, potentially increasing costs.

Key Patents in Nanofiltration for Wastewater Treatment

Nanofiltration membrane for treating printing and dyeing wastewater and its preparation method

PatentActiveUS11878921B2

Innovation

- A nanofiltration membrane is prepared using a polysulfone ultrafiltration membrane as a base, with m-phenylenediamine and trimesoyl chloride polymerized to form a polyamide active layer, aided by camphorsulfonic acid as a phase transfer catalyst and triethylamine to control reaction conditions, and interfacial auxiliary polymerization agents like acetone and acetic ester to enhance compatibility and structure, resulting in a membrane with improved water flux and rejection rates at reduced filtration pressure.

Concentration of aqueous electrolyte solutions

PatentPendingDE102022112660A1

Innovation

- A countercurrent process is introduced where an additional aqueous solution is fed to the permeate side without pressure, using a semi-permeable membrane to concentrate the retentate and deplete the permeate of ions, with energy recovery through a turbine or reducing valve, reducing the need for high pressures and equipment.

Environmental Impact Assessment

The implementation of nanofiltration in wastewater catalytic processes presents significant environmental implications that warrant comprehensive assessment. The integration of these advanced filtration technologies fundamentally alters the environmental footprint of wastewater treatment operations across multiple dimensions.

Nanofiltration systems demonstrate remarkable efficiency in removing contaminants, particularly micropollutants, heavy metals, and pharmaceutical residues that conventional treatment methods often fail to address. This enhanced removal capability translates to significantly cleaner effluent discharge, reducing the bioaccumulation of harmful substances in aquatic ecosystems. Studies indicate up to 95% removal rates for certain persistent organic pollutants when nanofiltration is coupled with catalytic processes.

Energy consumption patterns represent another critical environmental consideration. While nanofiltration typically requires higher operational pressure than conventional filtration, the integration with catalytic processes can offset this demand through improved treatment efficiency. Recent advancements have achieved energy optimization through pressure recovery systems and membrane modifications, reducing the carbon footprint by approximately 30% compared to traditional tertiary treatment methods.

Chemical usage in treatment processes undergoes substantial reduction when nanofiltration technologies are implemented. The precision separation capabilities minimize the need for additional chemical treatments, potentially decreasing chemical consumption by 40-60%. This reduction directly correlates with decreased chemical manufacturing demands and associated environmental impacts throughout the supply chain.

Waste generation profiles shift significantly with nanofiltration implementation. The concentrated reject streams require careful management, as they contain higher concentrations of contaminants. However, emerging approaches for resource recovery from these streams present opportunities to transform waste management paradigms, potentially extracting valuable materials like phosphorus and certain metals from wastewater streams.

Life cycle assessment studies indicate that nanofiltration-catalytic systems demonstrate favorable environmental performance when evaluated across their entire operational lifespan. Despite higher initial material and energy investments, the extended operational efficiency and reduced chemical dependencies result in net environmental benefits within 3-5 years of implementation for most applications.

Climate resilience considerations further enhance the environmental case for nanofiltration technologies. These systems demonstrate superior adaptability to varying influent qualities, making them particularly valuable in regions experiencing climate-induced water quality fluctuations or water scarcity issues where water reuse becomes increasingly critical.

Nanofiltration systems demonstrate remarkable efficiency in removing contaminants, particularly micropollutants, heavy metals, and pharmaceutical residues that conventional treatment methods often fail to address. This enhanced removal capability translates to significantly cleaner effluent discharge, reducing the bioaccumulation of harmful substances in aquatic ecosystems. Studies indicate up to 95% removal rates for certain persistent organic pollutants when nanofiltration is coupled with catalytic processes.

Energy consumption patterns represent another critical environmental consideration. While nanofiltration typically requires higher operational pressure than conventional filtration, the integration with catalytic processes can offset this demand through improved treatment efficiency. Recent advancements have achieved energy optimization through pressure recovery systems and membrane modifications, reducing the carbon footprint by approximately 30% compared to traditional tertiary treatment methods.

Chemical usage in treatment processes undergoes substantial reduction when nanofiltration technologies are implemented. The precision separation capabilities minimize the need for additional chemical treatments, potentially decreasing chemical consumption by 40-60%. This reduction directly correlates with decreased chemical manufacturing demands and associated environmental impacts throughout the supply chain.

Waste generation profiles shift significantly with nanofiltration implementation. The concentrated reject streams require careful management, as they contain higher concentrations of contaminants. However, emerging approaches for resource recovery from these streams present opportunities to transform waste management paradigms, potentially extracting valuable materials like phosphorus and certain metals from wastewater streams.

Life cycle assessment studies indicate that nanofiltration-catalytic systems demonstrate favorable environmental performance when evaluated across their entire operational lifespan. Despite higher initial material and energy investments, the extended operational efficiency and reduced chemical dependencies result in net environmental benefits within 3-5 years of implementation for most applications.

Climate resilience considerations further enhance the environmental case for nanofiltration technologies. These systems demonstrate superior adaptability to varying influent qualities, making them particularly valuable in regions experiencing climate-induced water quality fluctuations or water scarcity issues where water reuse becomes increasingly critical.

Scalability and Implementation Considerations

Scaling nanofiltration technologies from laboratory to industrial applications presents significant challenges that must be addressed for successful implementation in wastewater catalytic processes. The primary concern is membrane fouling, which increases exponentially with scale. Industrial wastewater streams contain diverse contaminants that accelerate membrane degradation, necessitating robust pretreatment systems and regular maintenance protocols to ensure operational longevity.

Energy consumption represents another critical consideration, as nanofiltration systems require substantial pressure differentials to maintain effective separation. For large-scale implementations, energy recovery devices such as pressure exchangers and variable frequency drives have demonstrated potential to reduce operational costs by 25-40%, making the technology more economically viable for continuous operation.

Capital expenditure for nanofiltration infrastructure remains high, with installation costs ranging from $500,000 to several million dollars depending on treatment capacity and complexity. However, lifecycle cost analyses indicate that operational savings from recovered materials and reduced disposal costs can provide return on investment within 3-5 years for properly designed systems.

Spatial requirements must be carefully evaluated during implementation planning. Modern nanofiltration systems have become increasingly compact, but still require dedicated space for membrane modules, pumping systems, pretreatment equipment, and control infrastructure. Modular designs have emerged as a preferred approach, allowing for phased implementation and capacity expansion without complete system redesign.

Regulatory compliance adds another layer of complexity to implementation considerations. Discharge permits, waste handling protocols, and recovered material classifications vary significantly across jurisdictions. Successful implementation requires early engagement with regulatory authorities and development of comprehensive monitoring systems to demonstrate compliance with increasingly stringent environmental standards.

Integration with existing wastewater treatment infrastructure presents both challenges and opportunities. Nanofiltration systems can be implemented as standalone units or integrated into conventional treatment trains. Hybrid approaches that combine nanofiltration with biological treatment or advanced oxidation processes have demonstrated superior performance in handling complex industrial wastewaters while maximizing resource recovery potential.

Workforce development cannot be overlooked in implementation planning. Operating advanced nanofiltration systems requires specialized knowledge in membrane technology, process control, and analytical techniques. Comprehensive training programs and operational support systems are essential for maintaining optimal performance and preventing costly operational failures.

Energy consumption represents another critical consideration, as nanofiltration systems require substantial pressure differentials to maintain effective separation. For large-scale implementations, energy recovery devices such as pressure exchangers and variable frequency drives have demonstrated potential to reduce operational costs by 25-40%, making the technology more economically viable for continuous operation.

Capital expenditure for nanofiltration infrastructure remains high, with installation costs ranging from $500,000 to several million dollars depending on treatment capacity and complexity. However, lifecycle cost analyses indicate that operational savings from recovered materials and reduced disposal costs can provide return on investment within 3-5 years for properly designed systems.

Spatial requirements must be carefully evaluated during implementation planning. Modern nanofiltration systems have become increasingly compact, but still require dedicated space for membrane modules, pumping systems, pretreatment equipment, and control infrastructure. Modular designs have emerged as a preferred approach, allowing for phased implementation and capacity expansion without complete system redesign.

Regulatory compliance adds another layer of complexity to implementation considerations. Discharge permits, waste handling protocols, and recovered material classifications vary significantly across jurisdictions. Successful implementation requires early engagement with regulatory authorities and development of comprehensive monitoring systems to demonstrate compliance with increasingly stringent environmental standards.

Integration with existing wastewater treatment infrastructure presents both challenges and opportunities. Nanofiltration systems can be implemented as standalone units or integrated into conventional treatment trains. Hybrid approaches that combine nanofiltration with biological treatment or advanced oxidation processes have demonstrated superior performance in handling complex industrial wastewaters while maximizing resource recovery potential.

Workforce development cannot be overlooked in implementation planning. Operating advanced nanofiltration systems requires specialized knowledge in membrane technology, process control, and analytical techniques. Comprehensive training programs and operational support systems are essential for maintaining optimal performance and preventing costly operational failures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!