Electromagnetic compatibility in embedded PMSM systems

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMC in PMSM Background

Electromagnetic compatibility (EMC) in Permanent Magnet Synchronous Motor (PMSM) systems has become a critical concern in the field of embedded systems. As the demand for high-performance, energy-efficient motors continues to grow across various industries, the need to address EMC issues has become increasingly important.

The concept of EMC in PMSM systems encompasses the motor's ability to function correctly in its electromagnetic environment without causing unacceptable electromagnetic disturbances to other equipment. This includes both the motor's susceptibility to external electromagnetic interference (EMI) and its potential to generate EMI that may affect nearby electronic devices.

The evolution of PMSM technology has been driven by advancements in power electronics, control systems, and materials science. Early PMSM designs faced significant EMC challenges due to the high-frequency switching of power electronic converters and the inherent electromagnetic fields generated by the motor's operation. These issues often resulted in conducted and radiated emissions that could interfere with sensitive electronic equipment in the vicinity.

As industrial applications for PMSMs expanded, particularly in sectors such as automotive, aerospace, and robotics, the need for robust EMC solutions became more pressing. The integration of PMSMs into complex embedded systems further complicated the EMC landscape, as these motors now had to coexist with a wide array of electronic control units, sensors, and communication interfaces.

The development of EMC standards and regulations, such as those set by the International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC), has played a crucial role in shaping the approach to EMC in PMSM systems. These standards have established limits for electromagnetic emissions and immunity levels, forcing manufacturers to implement effective EMC mitigation strategies.

Recent years have seen significant progress in addressing EMC issues in PMSM systems. Advanced shielding techniques, improved grounding methods, and sophisticated filtering solutions have been developed to minimize electromagnetic interference. Additionally, the advent of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has enabled the design of more efficient power converters with reduced EMI signatures.

The ongoing miniaturization of electronic components and the trend towards higher power densities in motor systems continue to present new EMC challenges. As PMSMs are integrated into increasingly compact and complex embedded systems, the need for innovative EMC solutions becomes more critical. This has led to a growing focus on EMC considerations during the early stages of motor and system design, rather than as an afterthought.

The concept of EMC in PMSM systems encompasses the motor's ability to function correctly in its electromagnetic environment without causing unacceptable electromagnetic disturbances to other equipment. This includes both the motor's susceptibility to external electromagnetic interference (EMI) and its potential to generate EMI that may affect nearby electronic devices.

The evolution of PMSM technology has been driven by advancements in power electronics, control systems, and materials science. Early PMSM designs faced significant EMC challenges due to the high-frequency switching of power electronic converters and the inherent electromagnetic fields generated by the motor's operation. These issues often resulted in conducted and radiated emissions that could interfere with sensitive electronic equipment in the vicinity.

As industrial applications for PMSMs expanded, particularly in sectors such as automotive, aerospace, and robotics, the need for robust EMC solutions became more pressing. The integration of PMSMs into complex embedded systems further complicated the EMC landscape, as these motors now had to coexist with a wide array of electronic control units, sensors, and communication interfaces.

The development of EMC standards and regulations, such as those set by the International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC), has played a crucial role in shaping the approach to EMC in PMSM systems. These standards have established limits for electromagnetic emissions and immunity levels, forcing manufacturers to implement effective EMC mitigation strategies.

Recent years have seen significant progress in addressing EMC issues in PMSM systems. Advanced shielding techniques, improved grounding methods, and sophisticated filtering solutions have been developed to minimize electromagnetic interference. Additionally, the advent of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), has enabled the design of more efficient power converters with reduced EMI signatures.

The ongoing miniaturization of electronic components and the trend towards higher power densities in motor systems continue to present new EMC challenges. As PMSMs are integrated into increasingly compact and complex embedded systems, the need for innovative EMC solutions becomes more critical. This has led to a growing focus on EMC considerations during the early stages of motor and system design, rather than as an afterthought.

Market Demand Analysis

The market demand for electromagnetic compatibility (EMC) solutions in embedded Permanent Magnet Synchronous Motor (PMSM) systems has been steadily increasing due to the growing adoption of these motors in various industries. The automotive sector, in particular, has emerged as a significant driver of this demand, with electric and hybrid vehicles relying heavily on PMSM technology for propulsion and auxiliary systems.

As the automotive industry continues its shift towards electrification, the need for robust EMC solutions in PMSM systems has become paramount. This trend is further amplified by the increasing integration of advanced driver assistance systems (ADAS) and autonomous driving technologies, which require high levels of electromagnetic compatibility to ensure reliable operation.

Beyond automotive applications, the industrial automation sector has also contributed to the rising demand for EMC solutions in embedded PMSM systems. The adoption of Industry 4.0 principles and the increasing use of smart manufacturing technologies have led to a greater emphasis on electromagnetic compatibility to maintain the integrity of sensitive control systems and communication networks.

The aerospace and defense industries have likewise shown a growing interest in EMC solutions for embedded PMSM systems. The use of these motors in aircraft actuators, fuel pumps, and other critical systems necessitates stringent EMC standards to ensure safety and reliability in high-stakes environments.

Market analysts project that the global EMC market for embedded PMSM systems will experience substantial growth in the coming years. This growth is attributed to the increasing complexity of electronic systems, the proliferation of wireless technologies, and the stringent regulatory requirements across various industries.

The healthcare sector represents another emerging market for EMC solutions in embedded PMSM systems. Medical devices and imaging equipment often utilize PMSM technology, and the need for electromagnetic compatibility is crucial to prevent interference with sensitive diagnostic and therapeutic equipment.

As the Internet of Things (IoT) continues to expand, the demand for EMC solutions in embedded PMSM systems is expected to grow further. The interconnectedness of devices and systems in smart homes, smart cities, and industrial IoT applications necessitates robust EMC measures to ensure reliable operation and prevent electromagnetic interference.

The market demand is also driven by the need for energy-efficient solutions. PMSM systems are known for their high efficiency, and maintaining this efficiency while ensuring electromagnetic compatibility is a key requirement for many applications. This has led to increased research and development efforts focused on innovative EMC solutions that do not compromise the energy efficiency of PMSM systems.

As the automotive industry continues its shift towards electrification, the need for robust EMC solutions in PMSM systems has become paramount. This trend is further amplified by the increasing integration of advanced driver assistance systems (ADAS) and autonomous driving technologies, which require high levels of electromagnetic compatibility to ensure reliable operation.

Beyond automotive applications, the industrial automation sector has also contributed to the rising demand for EMC solutions in embedded PMSM systems. The adoption of Industry 4.0 principles and the increasing use of smart manufacturing technologies have led to a greater emphasis on electromagnetic compatibility to maintain the integrity of sensitive control systems and communication networks.

The aerospace and defense industries have likewise shown a growing interest in EMC solutions for embedded PMSM systems. The use of these motors in aircraft actuators, fuel pumps, and other critical systems necessitates stringent EMC standards to ensure safety and reliability in high-stakes environments.

Market analysts project that the global EMC market for embedded PMSM systems will experience substantial growth in the coming years. This growth is attributed to the increasing complexity of electronic systems, the proliferation of wireless technologies, and the stringent regulatory requirements across various industries.

The healthcare sector represents another emerging market for EMC solutions in embedded PMSM systems. Medical devices and imaging equipment often utilize PMSM technology, and the need for electromagnetic compatibility is crucial to prevent interference with sensitive diagnostic and therapeutic equipment.

As the Internet of Things (IoT) continues to expand, the demand for EMC solutions in embedded PMSM systems is expected to grow further. The interconnectedness of devices and systems in smart homes, smart cities, and industrial IoT applications necessitates robust EMC measures to ensure reliable operation and prevent electromagnetic interference.

The market demand is also driven by the need for energy-efficient solutions. PMSM systems are known for their high efficiency, and maintaining this efficiency while ensuring electromagnetic compatibility is a key requirement for many applications. This has led to increased research and development efforts focused on innovative EMC solutions that do not compromise the energy efficiency of PMSM systems.

EMC Challenges in PMSM

Electromagnetic compatibility (EMC) challenges in Permanent Magnet Synchronous Motor (PMSM) systems have become increasingly significant as these motors gain popularity in various applications. The compact design and high-power density of PMSMs, while advantageous in many aspects, introduce unique EMC issues that require careful consideration and mitigation strategies.

One of the primary EMC challenges in PMSM systems is the generation of electromagnetic interference (EMI) due to the high-frequency switching of power electronic devices used in motor drives. The rapid voltage and current transitions during switching events create broadband electromagnetic emissions that can interfere with nearby electronic systems. These emissions can propagate through both conducted and radiated paths, potentially affecting the performance of sensitive equipment in the vicinity.

Another significant challenge is the susceptibility of PMSM control systems to external electromagnetic disturbances. The precise control algorithms and feedback mechanisms employed in PMSM drives rely on accurate sensor readings and signal processing. External electromagnetic noise can introduce errors in these signals, leading to degraded motor performance, instability, or even system failure in extreme cases.

The presence of strong magnetic fields in PMSMs also contributes to EMC issues. The rotating permanent magnets create time-varying magnetic fields that can induce currents in nearby conductive structures or components. This phenomenon, known as magnetic coupling, can lead to unwanted power losses, heating, and potential interference with other electronic systems in close proximity.

Furthermore, the high-speed operation of PMSMs can exacerbate EMC problems. As motor speeds increase, so does the frequency of electromagnetic emissions, potentially shifting them into frequency ranges that are more problematic for other electronic systems. This high-frequency content can also make it more challenging to implement effective shielding and filtering solutions.

The compact nature of embedded PMSM systems often results in tight integration of power electronics, control circuits, and motor components. While this integration offers advantages in terms of size and efficiency, it also increases the likelihood of electromagnetic coupling between different subsystems. Careful layout and design considerations are necessary to minimize these interactions and maintain system integrity.

Addressing these EMC challenges requires a multifaceted approach. This includes the implementation of advanced EMI suppression techniques, such as optimized PCB layouts, proper shielding, and the use of EMI filters. Additionally, robust control algorithms that can withstand electromagnetic disturbances and maintain stable operation are essential. The selection of appropriate materials and components with good EMC characteristics is also crucial in mitigating these issues.

One of the primary EMC challenges in PMSM systems is the generation of electromagnetic interference (EMI) due to the high-frequency switching of power electronic devices used in motor drives. The rapid voltage and current transitions during switching events create broadband electromagnetic emissions that can interfere with nearby electronic systems. These emissions can propagate through both conducted and radiated paths, potentially affecting the performance of sensitive equipment in the vicinity.

Another significant challenge is the susceptibility of PMSM control systems to external electromagnetic disturbances. The precise control algorithms and feedback mechanisms employed in PMSM drives rely on accurate sensor readings and signal processing. External electromagnetic noise can introduce errors in these signals, leading to degraded motor performance, instability, or even system failure in extreme cases.

The presence of strong magnetic fields in PMSMs also contributes to EMC issues. The rotating permanent magnets create time-varying magnetic fields that can induce currents in nearby conductive structures or components. This phenomenon, known as magnetic coupling, can lead to unwanted power losses, heating, and potential interference with other electronic systems in close proximity.

Furthermore, the high-speed operation of PMSMs can exacerbate EMC problems. As motor speeds increase, so does the frequency of electromagnetic emissions, potentially shifting them into frequency ranges that are more problematic for other electronic systems. This high-frequency content can also make it more challenging to implement effective shielding and filtering solutions.

The compact nature of embedded PMSM systems often results in tight integration of power electronics, control circuits, and motor components. While this integration offers advantages in terms of size and efficiency, it also increases the likelihood of electromagnetic coupling between different subsystems. Careful layout and design considerations are necessary to minimize these interactions and maintain system integrity.

Addressing these EMC challenges requires a multifaceted approach. This includes the implementation of advanced EMI suppression techniques, such as optimized PCB layouts, proper shielding, and the use of EMI filters. Additionally, robust control algorithms that can withstand electromagnetic disturbances and maintain stable operation are essential. The selection of appropriate materials and components with good EMC characteristics is also crucial in mitigating these issues.

Current EMC Solutions

01 EMC design for PMSM systems

Electromagnetic compatibility (EMC) is crucial for embedded Permanent Magnet Synchronous Motor (PMSM) systems. This involves designing the system to minimize electromagnetic interference (EMI) and ensure proper operation in the presence of external electromagnetic disturbances. Techniques include shielding, filtering, and proper grounding to reduce emissions and improve immunity.- EMC design for PMSM systems: Electromagnetic compatibility (EMC) is crucial for embedded Permanent Magnet Synchronous Motor (PMSM) systems. This involves designing the system to minimize electromagnetic interference (EMI) and ensure proper operation in the presence of external electromagnetic disturbances. Techniques include proper shielding, grounding, and layout design to reduce EMI emissions and improve immunity.

- EMC testing and compliance for PMSM systems: EMC testing is essential to ensure that embedded PMSM systems meet regulatory standards and operate reliably in various electromagnetic environments. This includes conducting emissions and immunity tests, identifying potential EMC issues, and implementing necessary modifications to achieve compliance with relevant EMC standards.

- EMI suppression techniques in PMSM drives: Various EMI suppression techniques are employed in PMSM drive systems to reduce electromagnetic noise and improve overall EMC performance. These may include the use of EMI filters, common-mode chokes, and proper cable shielding to minimize conducted and radiated emissions from the motor drive circuitry.

- Sensor integration and EMC considerations: Integrating sensors in embedded PMSM systems requires careful consideration of EMC aspects. This involves selecting appropriate sensor types, implementing proper signal conditioning, and ensuring that sensor signals remain accurate and reliable in the presence of electromagnetic noise generated by the motor and drive system.

- EMC-aware control strategies for PMSM: Developing EMC-aware control strategies for PMSM systems is crucial for maintaining stable and efficient operation in electromagnetically noisy environments. This includes implementing robust control algorithms that can adapt to EMI-induced disturbances and optimize motor performance while minimizing electromagnetic emissions.

02 EMC testing and compliance for PMSM systems

EMC testing is essential to ensure that embedded PMSM systems meet regulatory standards and operate reliably in various electromagnetic environments. This includes conducted and radiated emissions tests, as well as immunity tests to verify the system's robustness against external electromagnetic disturbances.Expand Specific Solutions03 EMI reduction techniques in PMSM drives

Various techniques are employed to reduce electromagnetic interference in PMSM drives. These may include optimizing PWM strategies, using common-mode filters, implementing active EMI cancellation, and designing appropriate PCB layouts to minimize parasitic effects and improve overall EMC performance.Expand Specific Solutions04 EMC-aware control strategies for PMSM

Developing control strategies that consider EMC aspects is important for embedded PMSM systems. This involves designing control algorithms that not only optimize motor performance but also minimize electromagnetic emissions and improve the system's immunity to electromagnetic disturbances.Expand Specific Solutions05 Integration of EMC solutions in compact PMSM designs

As embedded PMSM systems become more compact, integrating effective EMC solutions becomes challenging. This involves developing innovative approaches to incorporate EMC measures within space-constrained designs, such as using advanced materials, integrated shielding techniques, and optimized component placement.Expand Specific Solutions

Key PMSM EMC Players

The research on electromagnetic compatibility in embedded PMSM systems is in a mature development stage, with significant market potential due to the increasing adoption of electric motors across industries. The technology has reached a high level of maturity, as evidenced by the involvement of leading academic institutions and companies. Key players include Tianjin University, Harbin Institute of Technology, and Beijing Institute of Technology, who are contributing to advanced research. Industrial giants like Gree Electric Appliances and Siemens Medical Solutions are likely applying this technology in their products, indicating its commercial viability. The competitive landscape is diverse, with both academic and industrial entities driving innovation and practical applications in this field.

Huazhong University of Science & Technology

Technical Solution: Huazhong University of Science & Technology has made significant contributions to electromagnetic compatibility research in embedded PMSM systems. Their approach focuses on both theoretical analysis and practical implementation. The university has developed a comprehensive EMC modeling framework for PMSM systems, which incorporates both high-frequency and low-frequency electromagnetic effects [7]. This model allows for accurate prediction of EMI generation and propagation within the motor and associated power electronics. Additionally, they have proposed novel control strategies that minimize EMI generation while maintaining high motor performance. These strategies include advanced pulse width modulation (PWM) techniques and harmonic injection methods that reduce common-mode voltages and currents [8]. The university has also conducted extensive research on EMC-optimized PMSM designs, including innovative winding configurations and magnetic core structures that inherently reduce EMI generation.

Strengths: Comprehensive modeling framework, innovative control strategies, EMC-optimized motor designs. Weaknesses: Some solutions may be more theoretical and require further development for practical implementation.

Shanghai Jiao Tong University

Technical Solution: Shanghai Jiao Tong University has conducted extensive research on electromagnetic compatibility in embedded PMSM systems, with a focus on both analytical and experimental approaches. They have developed a novel multi-physics modeling framework that integrates electromagnetic, thermal, and mechanical aspects of PMSM systems to provide a comprehensive EMC analysis [9]. This model allows for accurate prediction of EMI generation and propagation under various operating conditions. The university has also proposed innovative EMC mitigation techniques, including a hybrid shielding approach that combines active and passive shielding methods to effectively suppress both low-frequency and high-frequency electromagnetic emissions [10]. Additionally, they have developed advanced signal processing algorithms for real-time EMI detection and classification in PMSM systems, enabling adaptive EMC management strategies.

Strengths: Multi-physics modeling approach, innovative shielding techniques, advanced signal processing for EMI detection. Weaknesses: Some solutions may require significant computational resources, potentially limiting real-time implementation in embedded systems.

Core EMC Innovations

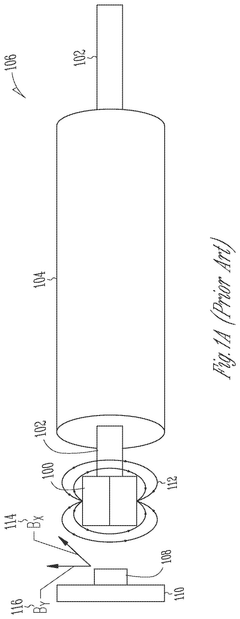

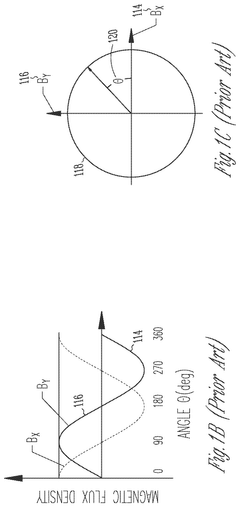

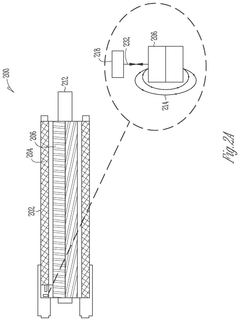

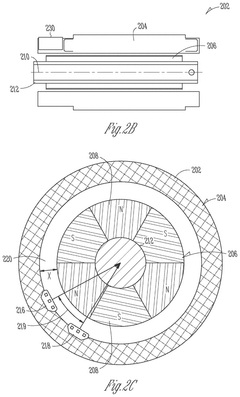

Permanent magnet synchronous motor (PMSM) integrated position sensing

PatentActiveUS12212257B2

Innovation

- The integration of analog magnetic flux sensors within the hollow cylindrical stator of the PMSM, arranged concentrically around the rotational axis at a constant mechanical angle relative to each other, allows for direct measurement of the magnetic flux from the rotor without external obstructions, enabling accurate rotor position sensing and reducing motor size and cost.

EMC Standards & Regs

Electromagnetic Compatibility (EMC) standards and regulations play a crucial role in ensuring the reliable operation of embedded Permanent Magnet Synchronous Motor (PMSM) systems. These standards are designed to limit electromagnetic interference (EMI) and ensure electromagnetic compatibility among various electronic devices and systems.

The International Electrotechnical Commission (IEC) has established several key standards relevant to EMC in PMSM systems. IEC 61000 series, particularly IEC 61000-4, provides comprehensive guidelines for testing and measurement techniques for EMC. This standard covers various aspects, including immunity to conducted disturbances, radiated electromagnetic fields, and electrostatic discharge.

In the context of motor drives, IEC 61800-3 specifically addresses EMC requirements for adjustable speed electrical power drive systems. This standard defines emission and immunity requirements for PMSM systems, categorizing them based on their intended environment and application.

The European Union's EMC Directive 2014/30/EU mandates compliance with EMC standards for all electronic equipment sold within the EU. This directive requires manufacturers to ensure their products meet essential EMC requirements before placing them on the market.

In the United States, the Federal Communications Commission (FCC) regulates EMC through its Code of Federal Regulations (CFR) Title 47. Part 15 of this code specifically deals with radio frequency devices and sets limits on unintentional radiators, which includes PMSM systems.

For automotive applications, ISO 11452 and CISPR 25 are critical standards. ISO 11452 focuses on vehicle component immunity to electromagnetic radiation, while CISPR 25 sets limits and methods of measurement for radio disturbances in vehicles and devices.

Compliance with these standards often requires specific design considerations in PMSM systems. This may include the use of EMI filters, proper shielding techniques, and careful PCB layout design to minimize electromagnetic emissions and improve immunity to external interference.

As technology advances, EMC standards continue to evolve. Recent trends include the development of standards for higher frequency ranges, addressing EMC issues in wireless power transfer systems, and updating requirements for emerging technologies like electric vehicles and renewable energy systems.

Understanding and adhering to these EMC standards and regulations is essential for manufacturers and designers of embedded PMSM systems. Compliance ensures not only legal and regulatory conformity but also enhances the overall reliability and performance of the system in various electromagnetic environments.

The International Electrotechnical Commission (IEC) has established several key standards relevant to EMC in PMSM systems. IEC 61000 series, particularly IEC 61000-4, provides comprehensive guidelines for testing and measurement techniques for EMC. This standard covers various aspects, including immunity to conducted disturbances, radiated electromagnetic fields, and electrostatic discharge.

In the context of motor drives, IEC 61800-3 specifically addresses EMC requirements for adjustable speed electrical power drive systems. This standard defines emission and immunity requirements for PMSM systems, categorizing them based on their intended environment and application.

The European Union's EMC Directive 2014/30/EU mandates compliance with EMC standards for all electronic equipment sold within the EU. This directive requires manufacturers to ensure their products meet essential EMC requirements before placing them on the market.

In the United States, the Federal Communications Commission (FCC) regulates EMC through its Code of Federal Regulations (CFR) Title 47. Part 15 of this code specifically deals with radio frequency devices and sets limits on unintentional radiators, which includes PMSM systems.

For automotive applications, ISO 11452 and CISPR 25 are critical standards. ISO 11452 focuses on vehicle component immunity to electromagnetic radiation, while CISPR 25 sets limits and methods of measurement for radio disturbances in vehicles and devices.

Compliance with these standards often requires specific design considerations in PMSM systems. This may include the use of EMI filters, proper shielding techniques, and careful PCB layout design to minimize electromagnetic emissions and improve immunity to external interference.

As technology advances, EMC standards continue to evolve. Recent trends include the development of standards for higher frequency ranges, addressing EMC issues in wireless power transfer systems, and updating requirements for emerging technologies like electric vehicles and renewable energy systems.

Understanding and adhering to these EMC standards and regulations is essential for manufacturers and designers of embedded PMSM systems. Compliance ensures not only legal and regulatory conformity but also enhances the overall reliability and performance of the system in various electromagnetic environments.

EMC Testing Methodologies

EMC testing methodologies for embedded PMSM systems involve a comprehensive approach to evaluate and ensure electromagnetic compatibility. These methods typically include both conducted and radiated emission tests, as well as immunity tests to assess the system's resilience against external electromagnetic interference.

Conducted emission tests focus on measuring the electromagnetic noise propagated through power and signal lines. For PMSM systems, this often involves using a Line Impedance Stabilization Network (LISN) to measure conducted emissions in the frequency range of 150 kHz to 30 MHz. The test setup requires careful consideration of grounding and shielding to isolate the Device Under Test (DUT) from ambient electromagnetic noise.

Radiated emission tests assess the electromagnetic fields emitted by the PMSM system. These tests are typically conducted in specialized chambers, such as semi-anechoic chambers, to minimize external interference. The frequency range for radiated emissions usually extends from 30 MHz to 1 GHz, with measurements taken at various angles around the DUT to capture the full radiation pattern.

Immunity tests evaluate the PMSM system's ability to operate correctly in the presence of electromagnetic disturbances. These tests include Electrostatic Discharge (ESD) testing, Electrical Fast Transient (EFT) testing, and radiated immunity testing. ESD tests simulate the discharge of static electricity, while EFT tests assess the system's response to rapid voltage spikes. Radiated immunity tests expose the system to electromagnetic fields of varying strengths and frequencies to ensure proper operation under different environmental conditions.

Specific to PMSM systems, additional EMC tests may focus on the motor drive's switching behavior and its impact on electromagnetic emissions. This can involve measuring the common-mode and differential-mode currents in the motor windings and analyzing their spectral content. Power quality measurements, including harmonic distortion and voltage fluctuations, are also crucial for assessing the overall EMC performance of the PMSM system.

Advanced EMC testing methodologies for embedded PMSM systems may incorporate near-field scanning techniques. These methods use specialized probes to map the electromagnetic field distribution around the system, helping to identify specific sources of emissions and potential vulnerabilities to interference. This detailed analysis can guide targeted EMC improvements in the system design.

To ensure comprehensive EMC compliance, testing methodologies often include worst-case scenario evaluations. This involves operating the PMSM system under various load conditions, speeds, and control modes to capture the full range of potential electromagnetic emissions and susceptibilities. The test results are then compared against relevant EMC standards, such as IEC 61800-3 for variable-speed electric drive systems, to determine compliance and identify areas for improvement.

Conducted emission tests focus on measuring the electromagnetic noise propagated through power and signal lines. For PMSM systems, this often involves using a Line Impedance Stabilization Network (LISN) to measure conducted emissions in the frequency range of 150 kHz to 30 MHz. The test setup requires careful consideration of grounding and shielding to isolate the Device Under Test (DUT) from ambient electromagnetic noise.

Radiated emission tests assess the electromagnetic fields emitted by the PMSM system. These tests are typically conducted in specialized chambers, such as semi-anechoic chambers, to minimize external interference. The frequency range for radiated emissions usually extends from 30 MHz to 1 GHz, with measurements taken at various angles around the DUT to capture the full radiation pattern.

Immunity tests evaluate the PMSM system's ability to operate correctly in the presence of electromagnetic disturbances. These tests include Electrostatic Discharge (ESD) testing, Electrical Fast Transient (EFT) testing, and radiated immunity testing. ESD tests simulate the discharge of static electricity, while EFT tests assess the system's response to rapid voltage spikes. Radiated immunity tests expose the system to electromagnetic fields of varying strengths and frequencies to ensure proper operation under different environmental conditions.

Specific to PMSM systems, additional EMC tests may focus on the motor drive's switching behavior and its impact on electromagnetic emissions. This can involve measuring the common-mode and differential-mode currents in the motor windings and analyzing their spectral content. Power quality measurements, including harmonic distortion and voltage fluctuations, are also crucial for assessing the overall EMC performance of the PMSM system.

Advanced EMC testing methodologies for embedded PMSM systems may incorporate near-field scanning techniques. These methods use specialized probes to map the electromagnetic field distribution around the system, helping to identify specific sources of emissions and potential vulnerabilities to interference. This detailed analysis can guide targeted EMC improvements in the system design.

To ensure comprehensive EMC compliance, testing methodologies often include worst-case scenario evaluations. This involves operating the PMSM system under various load conditions, speeds, and control modes to capture the full range of potential electromagnetic emissions and susceptibilities. The test results are then compared against relevant EMC standards, such as IEC 61800-3 for variable-speed electric drive systems, to determine compliance and identify areas for improvement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!