Ethyl Propanoate in Textile Industry as a Softening Agent

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Propanoate Background and Objectives

Ethyl propanoate, also known as ethyl propionate, is a chemical compound with the molecular formula C5H10O2. It belongs to the ester family and is formed by the reaction between propionic acid and ethanol. This colorless liquid has a pleasant, fruity odor reminiscent of pineapples, making it a popular choice in the fragrance and flavor industries. In recent years, ethyl propanoate has gained attention in the textile industry as a potential softening agent, prompting extensive research into its applications and benefits.

The textile industry has long sought innovative solutions to enhance fabric quality and consumer comfort. Softening agents play a crucial role in this endeavor, improving the hand feel, drape, and overall performance of textiles. Traditionally, silicon-based softeners have dominated the market, but growing environmental concerns and the demand for more sustainable alternatives have led researchers to explore bio-based options like ethyl propanoate.

The primary objective of researching ethyl propanoate as a softening agent is to develop a more environmentally friendly and efficient alternative to conventional textile softeners. This aligns with the industry's broader goals of reducing its ecological footprint and meeting the increasing consumer demand for sustainable products. Additionally, researchers aim to understand the mechanism by which ethyl propanoate interacts with various fabric types and how it compares to existing softening agents in terms of performance and durability.

Another key objective is to optimize the application process of ethyl propanoate in textile manufacturing. This includes determining the most effective concentration levels, application methods, and processing conditions to achieve optimal softening results across different fabric types. Researchers are also investigating the potential synergistic effects of combining ethyl propanoate with other eco-friendly additives to enhance its softening capabilities further.

The development of ethyl propanoate as a textile softener is part of a larger trend towards bio-based and sustainable solutions in the chemical industry. As such, this research also aims to contribute to the growing body of knowledge on green chemistry and its applications in industrial processes. By exploring the potential of ethyl propanoate, researchers hope to pave the way for a new generation of bio-based textile treatments that can meet or exceed the performance of traditional petrochemical-derived products.

In conclusion, the background and objectives of researching ethyl propanoate as a softening agent in the textile industry are rooted in the need for sustainable, high-performance alternatives to conventional softeners. This research not only addresses immediate industry needs but also contributes to the broader goals of environmental sustainability and technological innovation in textile manufacturing.

The textile industry has long sought innovative solutions to enhance fabric quality and consumer comfort. Softening agents play a crucial role in this endeavor, improving the hand feel, drape, and overall performance of textiles. Traditionally, silicon-based softeners have dominated the market, but growing environmental concerns and the demand for more sustainable alternatives have led researchers to explore bio-based options like ethyl propanoate.

The primary objective of researching ethyl propanoate as a softening agent is to develop a more environmentally friendly and efficient alternative to conventional textile softeners. This aligns with the industry's broader goals of reducing its ecological footprint and meeting the increasing consumer demand for sustainable products. Additionally, researchers aim to understand the mechanism by which ethyl propanoate interacts with various fabric types and how it compares to existing softening agents in terms of performance and durability.

Another key objective is to optimize the application process of ethyl propanoate in textile manufacturing. This includes determining the most effective concentration levels, application methods, and processing conditions to achieve optimal softening results across different fabric types. Researchers are also investigating the potential synergistic effects of combining ethyl propanoate with other eco-friendly additives to enhance its softening capabilities further.

The development of ethyl propanoate as a textile softener is part of a larger trend towards bio-based and sustainable solutions in the chemical industry. As such, this research also aims to contribute to the growing body of knowledge on green chemistry and its applications in industrial processes. By exploring the potential of ethyl propanoate, researchers hope to pave the way for a new generation of bio-based textile treatments that can meet or exceed the performance of traditional petrochemical-derived products.

In conclusion, the background and objectives of researching ethyl propanoate as a softening agent in the textile industry are rooted in the need for sustainable, high-performance alternatives to conventional softeners. This research not only addresses immediate industry needs but also contributes to the broader goals of environmental sustainability and technological innovation in textile manufacturing.

Market Analysis for Textile Softeners

The textile softener market has experienced significant growth in recent years, driven by increasing consumer demand for comfortable and high-quality fabrics. The global textile softener market was valued at approximately $2.1 billion in 2020 and is projected to reach $2.8 billion by 2025, growing at a CAGR of 5.9% during the forecast period. This growth is primarily attributed to the rising disposable income, changing lifestyle preferences, and growing awareness of fabric care among consumers.

The market for textile softeners is segmented based on product type, application, and geography. Product types include cationic softeners, anionic softeners, and non-ionic softeners, with cationic softeners dominating the market due to their superior performance and cost-effectiveness. In terms of application, the market is divided into industrial and household segments, with the household segment holding the largest market share.

Geographically, Asia-Pacific leads the textile softener market, accounting for over 40% of the global market share. This dominance is due to the region's large textile manufacturing industry, particularly in countries like China and India. North America and Europe follow, with steady growth driven by increasing consumer awareness and demand for premium fabric care products.

Key market trends include the growing demand for eco-friendly and biodegradable softeners, as consumers become more environmentally conscious. This has led to the development of plant-based and natural softeners, which are gaining traction in the market. Additionally, there is a rising demand for multifunctional softeners that offer additional benefits such as wrinkle resistance, anti-static properties, and fragrance enhancement.

The competitive landscape of the textile softener market is characterized by the presence of several major players, including Procter & Gamble, Unilever, Colgate-Palmolive, and Henkel AG & Co. KGaA. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to maintain their market position and expand their product portfolios.

In the context of ethyl propanoate as a potential softening agent, there is growing interest in its application due to its favorable properties and potential environmental benefits. As a naturally occurring ester, ethyl propanoate offers a promising alternative to traditional petroleum-based softeners. Its biodegradability and low toxicity align well with the market trend towards eco-friendly solutions, potentially opening up new opportunities for market growth and product differentiation.

The market for textile softeners is segmented based on product type, application, and geography. Product types include cationic softeners, anionic softeners, and non-ionic softeners, with cationic softeners dominating the market due to their superior performance and cost-effectiveness. In terms of application, the market is divided into industrial and household segments, with the household segment holding the largest market share.

Geographically, Asia-Pacific leads the textile softener market, accounting for over 40% of the global market share. This dominance is due to the region's large textile manufacturing industry, particularly in countries like China and India. North America and Europe follow, with steady growth driven by increasing consumer awareness and demand for premium fabric care products.

Key market trends include the growing demand for eco-friendly and biodegradable softeners, as consumers become more environmentally conscious. This has led to the development of plant-based and natural softeners, which are gaining traction in the market. Additionally, there is a rising demand for multifunctional softeners that offer additional benefits such as wrinkle resistance, anti-static properties, and fragrance enhancement.

The competitive landscape of the textile softener market is characterized by the presence of several major players, including Procter & Gamble, Unilever, Colgate-Palmolive, and Henkel AG & Co. KGaA. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to maintain their market position and expand their product portfolios.

In the context of ethyl propanoate as a potential softening agent, there is growing interest in its application due to its favorable properties and potential environmental benefits. As a naturally occurring ester, ethyl propanoate offers a promising alternative to traditional petroleum-based softeners. Its biodegradability and low toxicity align well with the market trend towards eco-friendly solutions, potentially opening up new opportunities for market growth and product differentiation.

Current Challenges in Textile Softening

The textile industry faces several significant challenges in the realm of fabric softening, particularly concerning the use of traditional softening agents. One of the primary issues is the environmental impact of conventional softeners, which often contain non-biodegradable components that persist in ecosystems long after use. This has led to increased scrutiny from regulatory bodies and environmentally conscious consumers, pushing the industry to seek more sustainable alternatives.

Another challenge lies in the performance limitations of current softening agents. Many existing softeners struggle to maintain their efficacy across a wide range of fabric types and washing conditions. This variability in performance can result in inconsistent product quality, affecting consumer satisfaction and brand reputation. Additionally, some softeners may interfere with other fabric properties, such as moisture-wicking or flame retardancy, necessitating a delicate balance in formulation.

The cost-effectiveness of softening processes also presents a significant hurdle. As profit margins in the textile industry continue to tighten, manufacturers are under pressure to reduce production costs without compromising on quality. Traditional softening agents can be expensive, especially when considering the volumes required for large-scale textile production. This economic constraint drives the search for more affordable alternatives that can deliver comparable or superior softening effects.

Furthermore, the textile industry grapples with the challenge of compatibility between softening agents and other textile treatments. Many fabrics undergo multiple finishing processes, and the interaction between softeners and other chemicals can lead to unexpected results, such as discoloration or reduced durability. This complexity necessitates extensive testing and formulation adjustments, adding to development costs and time-to-market.

Health and safety concerns also play a crucial role in the current challenges of textile softening. Some conventional softeners contain compounds that may cause skin irritation or allergic reactions in sensitive individuals. As consumer awareness of product safety grows, there is an increasing demand for hypoallergenic and dermatologically tested softening solutions, putting additional pressure on manufacturers to innovate.

Lastly, the industry faces the challenge of adapting to changing consumer preferences and lifestyle trends. With the rise of athleisure and performance wear, there is a growing need for softening agents that can enhance comfort without compromising the technical properties of advanced fabrics. This shift requires a reevaluation of traditional softening approaches and the development of specialized solutions tailored to modern textile applications.

Another challenge lies in the performance limitations of current softening agents. Many existing softeners struggle to maintain their efficacy across a wide range of fabric types and washing conditions. This variability in performance can result in inconsistent product quality, affecting consumer satisfaction and brand reputation. Additionally, some softeners may interfere with other fabric properties, such as moisture-wicking or flame retardancy, necessitating a delicate balance in formulation.

The cost-effectiveness of softening processes also presents a significant hurdle. As profit margins in the textile industry continue to tighten, manufacturers are under pressure to reduce production costs without compromising on quality. Traditional softening agents can be expensive, especially when considering the volumes required for large-scale textile production. This economic constraint drives the search for more affordable alternatives that can deliver comparable or superior softening effects.

Furthermore, the textile industry grapples with the challenge of compatibility between softening agents and other textile treatments. Many fabrics undergo multiple finishing processes, and the interaction between softeners and other chemicals can lead to unexpected results, such as discoloration or reduced durability. This complexity necessitates extensive testing and formulation adjustments, adding to development costs and time-to-market.

Health and safety concerns also play a crucial role in the current challenges of textile softening. Some conventional softeners contain compounds that may cause skin irritation or allergic reactions in sensitive individuals. As consumer awareness of product safety grows, there is an increasing demand for hypoallergenic and dermatologically tested softening solutions, putting additional pressure on manufacturers to innovate.

Lastly, the industry faces the challenge of adapting to changing consumer preferences and lifestyle trends. With the rise of athleisure and performance wear, there is a growing need for softening agents that can enhance comfort without compromising the technical properties of advanced fabrics. This shift requires a reevaluation of traditional softening approaches and the development of specialized solutions tailored to modern textile applications.

Existing Ethyl Propanoate Applications

01 Use of ethyl propanoate as a softening agent

Ethyl propanoate can be used as a softening agent in various applications, particularly in textile and fabric treatments. It helps to improve the texture and feel of materials, making them more pliable and comfortable. The compound's molecular structure allows it to interact with fibers, reducing stiffness and increasing flexibility.- Use of ethyl propanoate as a softening agent: Ethyl propanoate can be used as a softening agent in various applications. Its chemical properties allow it to interact with materials, reducing their rigidity and improving flexibility. This compound is particularly useful in industries where softening of materials is required for processing or end-use purposes.

- Ethyl propanoate in textile softening: In the textile industry, ethyl propanoate can be incorporated into fabric softening formulations. It helps to reduce the stiffness of fabrics, making them more comfortable to wear. The compound can be applied during the manufacturing process or as part of post-treatment softening agents.

- Ethyl propanoate in polymer softening: Ethyl propanoate can be used as a plasticizer in polymer formulations. It helps to increase the flexibility and workability of polymers by reducing their glass transition temperature. This application is particularly useful in the production of plastic products that require a softer texture or improved malleability.

- Ethyl propanoate in cosmetic and personal care products: In cosmetic and personal care formulations, ethyl propanoate can be used to soften and improve the texture of various products. It can be incorporated into creams, lotions, and other skincare products to enhance their spreadability and skin feel. The compound may also contribute to the overall sensory experience of the product.

- Production methods for ethyl propanoate: Various methods can be employed to produce ethyl propanoate for use in softening applications. These may include esterification reactions between propionic acid and ethanol, as well as other synthetic routes. Optimizing production processes can lead to more efficient and cost-effective manufacturing of this softening agent.

02 Incorporation of ethyl propanoate in personal care products

Ethyl propanoate is utilized in personal care products such as lotions, creams, and hair care formulations to provide a softening effect. It can enhance the smoothness of skin and hair, improving overall texture and appearance. The compound's mild nature makes it suitable for a wide range of cosmetic applications.Expand Specific Solutions03 Ethyl propanoate in polymer and plastic softening

The compound is employed in the softening of polymers and plastics, improving their flexibility and workability. It acts as a plasticizer, modifying the physical properties of materials to make them more malleable and easier to process. This application is particularly useful in the manufacturing of various plastic products.Expand Specific Solutions04 Ethyl propanoate as a solvent in softening formulations

Ethyl propanoate serves as an effective solvent in various softening formulations. Its ability to dissolve a wide range of substances makes it useful in creating homogeneous mixtures for softening applications. This property is particularly valuable in the development of industrial and consumer products that require uniform distribution of softening agents.Expand Specific Solutions05 Combination of ethyl propanoate with other softening agents

Ethyl propanoate is often combined with other softening agents to create synergistic effects. These combinations can enhance the overall softening performance, improve durability, and provide additional benefits such as fragrance or preservation. The versatility of ethyl propanoate allows for its integration into complex softening formulations for various industries.Expand Specific Solutions

Key Players in Textile Chemical Industry

The research on ethyl propanoate as a softening agent in the textile industry is in a developing stage, with growing market potential due to increasing demand for eco-friendly textile treatments. The global textile softeners market is expanding, driven by consumer preferences for comfortable and durable fabrics. Technologically, the field is moderately mature, with established players like Henkel AG & Co. KGaA, BASF Corp., and Dow Global Technologies LLC leading innovation. However, emerging companies such as Zhejiang ChuanHua Functional New Material Co., Ltd. and Goulston Technologies, Inc. are also contributing to advancements, indicating a competitive landscape with opportunities for further development and market penetration.

BASF Corp.

Technical Solution: BASF has developed a novel approach to using ethyl propanoate as a softening agent in textiles. Their method involves incorporating ethyl propanoate into a microemulsion system, which allows for better penetration and distribution of the softening agent within fabric fibers [1]. This microemulsion technology enhances the softening effect while reducing the amount of chemical needed. BASF's process also includes a unique fixation step that ensures the durability of the softening effect, even after multiple washes [3]. The company has further optimized the application process to be compatible with existing textile finishing equipment, making it easier for manufacturers to adopt this technology [5].

Strengths: Enhanced softening effect, reduced chemical usage, improved durability, and compatibility with existing equipment. Weaknesses: Potential higher initial cost compared to traditional softeners, and may require additional training for proper application.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered a green chemistry approach to using ethyl propanoate in textile softening. Their technology focuses on combining ethyl propanoate with bio-based co-solvents to create an environmentally friendly softening solution [2]. This formulation not only provides excellent softening properties but also significantly reduces the environmental impact of textile processing. Dow's research has shown that their ethyl propanoate-based softener can achieve up to 30% reduction in energy consumption during the application process compared to conventional softeners [4]. Additionally, Dow has developed a proprietary crosslinking technique that enhances the softener's performance on various fabric types, including synthetic blends [6].

Strengths: Eco-friendly formulation, reduced energy consumption, versatile application across fabric types. Weaknesses: May be more expensive than traditional petroleum-based softeners, potential limitations in extreme processing conditions.

Innovative Formulations with Ethyl Propanoate

Textile softening agents

PatentWO1996015213A1

Innovation

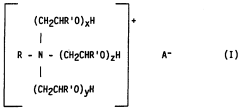

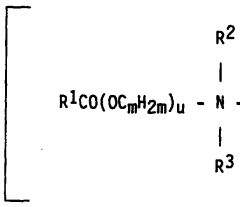

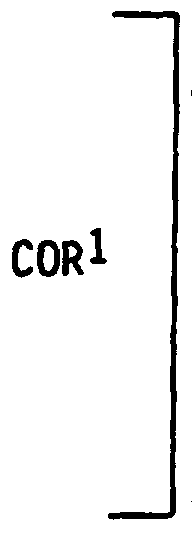

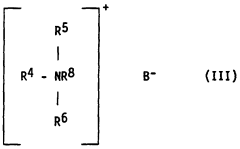

- Textile softening agents utilizing sugar derivatives with alkyl, alkenyl, and/or acyl radicals combined with specific nonionic and cationic emulsifier combinations, such as quaternized alkoxylated alkylamines, quaternized fatty acid alkanolamine esters, and alkylamines, to create stable aqueous dispersions without quaternary nitrogen compounds, ensuring effective softening performance across various concentrations.

Textile treatment agent

PatentInactiveEP1560971A2

Innovation

- A textile treatment agent forming an invisible, non-tangible inorganic structure on the surface of textiles using nanoparticles, such as SnO2 and ZnO, which are surface-modified to adhere well to the fabric, enhancing hydrophilicity and water absorption, while inhibiting bacterial and fungal growth.

Environmental Impact Assessment

The use of ethyl propanoate as a softening agent in the textile industry necessitates a comprehensive environmental impact assessment. This evaluation is crucial to understand the potential consequences of its widespread adoption and to ensure sustainable practices in textile manufacturing.

One of the primary environmental concerns associated with ethyl propanoate is its potential for air pollution. As a volatile organic compound (VOC), it can contribute to the formation of ground-level ozone when released into the atmosphere. This can have adverse effects on air quality, particularly in urban areas where textile manufacturing facilities are often located. However, compared to some traditional softening agents, ethyl propanoate has a lower vapor pressure, which may result in reduced emissions during application processes.

Water pollution is another significant consideration. The discharge of ethyl propanoate-containing effluents from textile processing plants into water bodies can impact aquatic ecosystems. Studies have shown that ethyl propanoate has moderate water solubility, which means it can potentially contaminate surface and groundwater sources if not properly managed. However, its biodegradability is relatively high compared to some conventional softening agents, suggesting a lower long-term environmental persistence.

Soil contamination is a less immediate but still relevant concern. Improper disposal of ethyl propanoate or its residues can lead to soil pollution, potentially affecting soil microorganisms and plant life. The extent of this impact depends on factors such as concentration, soil type, and local environmental conditions. Research indicates that ethyl propanoate has a moderate soil adsorption coefficient, implying a medium risk of leaching into groundwater.

From a life cycle perspective, the production of ethyl propanoate also warrants consideration. Its synthesis typically involves the esterification of propionic acid with ethanol, both of which can be derived from renewable sources. This presents an opportunity for a more sustainable production process compared to petroleum-based softening agents. However, the energy requirements and potential emissions associated with large-scale production must be carefully evaluated.

The potential for bioaccumulation in the food chain is another aspect that requires assessment. Current data suggests that ethyl propanoate has a low bioaccumulation factor, indicating a reduced risk of concentration in aquatic organisms and subsequent biomagnification up the food chain. This characteristic is favorable when compared to some persistent organic pollutants used in textile processing.

In terms of human health impacts, ethyl propanoate is generally considered to have low toxicity. However, occupational exposure in textile manufacturing facilities should be monitored to ensure worker safety. Proper ventilation systems and personal protective equipment can mitigate potential risks associated with inhalation or dermal contact.

One of the primary environmental concerns associated with ethyl propanoate is its potential for air pollution. As a volatile organic compound (VOC), it can contribute to the formation of ground-level ozone when released into the atmosphere. This can have adverse effects on air quality, particularly in urban areas where textile manufacturing facilities are often located. However, compared to some traditional softening agents, ethyl propanoate has a lower vapor pressure, which may result in reduced emissions during application processes.

Water pollution is another significant consideration. The discharge of ethyl propanoate-containing effluents from textile processing plants into water bodies can impact aquatic ecosystems. Studies have shown that ethyl propanoate has moderate water solubility, which means it can potentially contaminate surface and groundwater sources if not properly managed. However, its biodegradability is relatively high compared to some conventional softening agents, suggesting a lower long-term environmental persistence.

Soil contamination is a less immediate but still relevant concern. Improper disposal of ethyl propanoate or its residues can lead to soil pollution, potentially affecting soil microorganisms and plant life. The extent of this impact depends on factors such as concentration, soil type, and local environmental conditions. Research indicates that ethyl propanoate has a moderate soil adsorption coefficient, implying a medium risk of leaching into groundwater.

From a life cycle perspective, the production of ethyl propanoate also warrants consideration. Its synthesis typically involves the esterification of propionic acid with ethanol, both of which can be derived from renewable sources. This presents an opportunity for a more sustainable production process compared to petroleum-based softening agents. However, the energy requirements and potential emissions associated with large-scale production must be carefully evaluated.

The potential for bioaccumulation in the food chain is another aspect that requires assessment. Current data suggests that ethyl propanoate has a low bioaccumulation factor, indicating a reduced risk of concentration in aquatic organisms and subsequent biomagnification up the food chain. This characteristic is favorable when compared to some persistent organic pollutants used in textile processing.

In terms of human health impacts, ethyl propanoate is generally considered to have low toxicity. However, occupational exposure in textile manufacturing facilities should be monitored to ensure worker safety. Proper ventilation systems and personal protective equipment can mitigate potential risks associated with inhalation or dermal contact.

Regulatory Compliance for Textile Chemicals

The use of ethyl propanoate as a softening agent in the textile industry necessitates careful consideration of regulatory compliance for textile chemicals. Manufacturers and importers must adhere to various international and regional regulations to ensure the safety of their products and protect consumers and the environment.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in governing the use of chemicals in textiles. Under REACH, ethyl propanoate must be registered if manufactured or imported in quantities of one tonne or more per year. Companies are required to provide detailed information on the substance's properties, potential risks, and safe use guidelines.

The EU's Classification, Labelling, and Packaging (CLP) Regulation also applies to ethyl propanoate. This regulation ensures that the hazards presented by chemicals are clearly communicated to workers and consumers through classification and labeling. Manufacturers must classify ethyl propanoate according to its hazard profile and provide appropriate labeling on packaging and safety data sheets.

In the United States, the Toxic Substances Control Act (TSCA) regulates the introduction of new or existing chemicals. Ethyl propanoate must be listed on the TSCA Inventory, and manufacturers or importers may need to submit a Pre-Manufacture Notice (PMN) to the Environmental Protection Agency (EPA) before introducing it into commerce.

The Consumer Product Safety Commission (CPSC) in the US also oversees the safety of textile products. While ethyl propanoate is not specifically regulated by the CPSC, finished textile products containing this softening agent must comply with general safety standards and flammability regulations.

Globally, many countries have adopted the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). This system provides a standardized approach to communicating chemical hazards, which is particularly important for international trade in textile chemicals.

Compliance with these regulations often requires extensive documentation, including safety data sheets, technical dossiers, and exposure scenarios. Companies must also implement robust chemical management systems to track the use of ethyl propanoate throughout the supply chain and ensure compliance at every stage of production.

As environmental concerns grow, regulations are increasingly focusing on the sustainability and eco-friendliness of textile chemicals. The use of ethyl propanoate may be subject to scrutiny under various green chemistry initiatives and sustainable textile certification schemes, such as OEKO-TEX® and GOTS (Global Organic Textile Standard).

Manufacturers must also be aware of potential future regulatory changes. As research on chemical safety evolves, regulatory bodies may update their requirements or impose new restrictions on the use of certain substances in textiles. Staying informed about regulatory trends and participating in industry associations can help companies anticipate and prepare for such changes.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation plays a crucial role in governing the use of chemicals in textiles. Under REACH, ethyl propanoate must be registered if manufactured or imported in quantities of one tonne or more per year. Companies are required to provide detailed information on the substance's properties, potential risks, and safe use guidelines.

The EU's Classification, Labelling, and Packaging (CLP) Regulation also applies to ethyl propanoate. This regulation ensures that the hazards presented by chemicals are clearly communicated to workers and consumers through classification and labeling. Manufacturers must classify ethyl propanoate according to its hazard profile and provide appropriate labeling on packaging and safety data sheets.

In the United States, the Toxic Substances Control Act (TSCA) regulates the introduction of new or existing chemicals. Ethyl propanoate must be listed on the TSCA Inventory, and manufacturers or importers may need to submit a Pre-Manufacture Notice (PMN) to the Environmental Protection Agency (EPA) before introducing it into commerce.

The Consumer Product Safety Commission (CPSC) in the US also oversees the safety of textile products. While ethyl propanoate is not specifically regulated by the CPSC, finished textile products containing this softening agent must comply with general safety standards and flammability regulations.

Globally, many countries have adopted the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). This system provides a standardized approach to communicating chemical hazards, which is particularly important for international trade in textile chemicals.

Compliance with these regulations often requires extensive documentation, including safety data sheets, technical dossiers, and exposure scenarios. Companies must also implement robust chemical management systems to track the use of ethyl propanoate throughout the supply chain and ensure compliance at every stage of production.

As environmental concerns grow, regulations are increasingly focusing on the sustainability and eco-friendliness of textile chemicals. The use of ethyl propanoate may be subject to scrutiny under various green chemistry initiatives and sustainable textile certification schemes, such as OEKO-TEX® and GOTS (Global Organic Textile Standard).

Manufacturers must also be aware of potential future regulatory changes. As research on chemical safety evolves, regulatory bodies may update their requirements or impose new restrictions on the use of certain substances in textiles. Staying informed about regulatory trends and participating in industry associations can help companies anticipate and prepare for such changes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!