Ethyl Propanoate as an Additive in Electroactive Polymers

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Background and Objectives

Electroactive polymers (EAPs) have emerged as a promising class of materials with applications ranging from artificial muscles to smart textiles. These materials exhibit the unique ability to change shape or size when stimulated by an electric field. The development of EAPs has been driven by the need for lightweight, flexible, and responsive materials in various industries, including robotics, biomedical engineering, and aerospace.

In recent years, researchers have been exploring ways to enhance the performance of EAPs through the incorporation of additives. One such additive that has garnered attention is ethyl propanoate, an organic compound with potential to improve the electroactive properties of polymers. The investigation of ethyl propanoate as an additive in EAPs represents a novel approach to addressing some of the limitations of current EAP technologies.

The primary objective of this research is to comprehensively evaluate the effects of ethyl propanoate on the electroactive properties of polymers. This includes assessing its impact on key performance metrics such as actuation strain, response time, and durability. Additionally, the study aims to elucidate the underlying mechanisms by which ethyl propanoate interacts with the polymer matrix to enhance its electroactive behavior.

The evolution of EAP technology has been marked by significant milestones, from the discovery of piezoelectric polymers in the 1960s to the development of dielectric elastomers in the 1990s. The current research on ethyl propanoate as an additive represents a continuation of this trend towards more sophisticated and efficient EAP systems. By exploring novel additives, researchers seek to overcome existing challenges such as low actuation forces, high operating voltages, and limited lifespan of EAPs.

This investigation is driven by the growing demand for advanced materials in emerging technologies. As industries push the boundaries of what is possible with smart materials, there is an increasing need for EAPs with enhanced performance characteristics. The potential applications of improved EAPs are vast, ranging from more lifelike prosthetics to energy-efficient actuators in industrial automation.

The research into ethyl propanoate as an EAP additive is expected to contribute to the broader field of smart materials and responsive polymers. By advancing our understanding of how organic additives can modulate the properties of EAPs, this study may pave the way for the development of a new generation of high-performance electroactive materials. The findings from this research could have far-reaching implications for the design and fabrication of future EAP-based devices and systems.

In recent years, researchers have been exploring ways to enhance the performance of EAPs through the incorporation of additives. One such additive that has garnered attention is ethyl propanoate, an organic compound with potential to improve the electroactive properties of polymers. The investigation of ethyl propanoate as an additive in EAPs represents a novel approach to addressing some of the limitations of current EAP technologies.

The primary objective of this research is to comprehensively evaluate the effects of ethyl propanoate on the electroactive properties of polymers. This includes assessing its impact on key performance metrics such as actuation strain, response time, and durability. Additionally, the study aims to elucidate the underlying mechanisms by which ethyl propanoate interacts with the polymer matrix to enhance its electroactive behavior.

The evolution of EAP technology has been marked by significant milestones, from the discovery of piezoelectric polymers in the 1960s to the development of dielectric elastomers in the 1990s. The current research on ethyl propanoate as an additive represents a continuation of this trend towards more sophisticated and efficient EAP systems. By exploring novel additives, researchers seek to overcome existing challenges such as low actuation forces, high operating voltages, and limited lifespan of EAPs.

This investigation is driven by the growing demand for advanced materials in emerging technologies. As industries push the boundaries of what is possible with smart materials, there is an increasing need for EAPs with enhanced performance characteristics. The potential applications of improved EAPs are vast, ranging from more lifelike prosthetics to energy-efficient actuators in industrial automation.

The research into ethyl propanoate as an EAP additive is expected to contribute to the broader field of smart materials and responsive polymers. By advancing our understanding of how organic additives can modulate the properties of EAPs, this study may pave the way for the development of a new generation of high-performance electroactive materials. The findings from this research could have far-reaching implications for the design and fabrication of future EAP-based devices and systems.

Market Analysis

The market for electroactive polymers (EAPs) has been experiencing significant growth in recent years, driven by their unique properties and diverse applications across various industries. The global EAP market is expected to expand at a compound annual growth rate of 8.2% from 2021 to 2028, reaching a value of $5.6 billion by the end of the forecast period. This growth is primarily attributed to the increasing demand for smart materials in sectors such as robotics, healthcare, and consumer electronics.

The incorporation of ethyl propanoate as an additive in EAPs represents a niche but potentially lucrative segment within this market. Ethyl propanoate, also known as ethyl propionate, is a colorless liquid with a fruity odor, commonly used in the food and fragrance industries. Its application in EAPs is relatively new and offers promising opportunities for enhancing the performance and functionality of these smart materials.

The demand for EAPs with improved properties is driven by several factors. In the healthcare sector, there is a growing need for advanced prosthetics and artificial muscles that can mimic natural human movements more accurately. The robotics industry is seeking materials that can provide more precise and efficient actuation in soft robotics applications. Additionally, the consumer electronics market is constantly looking for innovative materials to enhance user interfaces and haptic feedback systems.

Ethyl propanoate as an additive in EAPs has shown potential to address some of these market needs. Preliminary studies indicate that it can improve the electroactive response of certain polymers, potentially leading to faster actuation times and increased sensitivity. This could be particularly valuable in applications requiring rapid and precise movements, such as in robotic surgery or advanced haptic devices.

The automotive industry is another significant market for EAPs, with potential applications in adaptive aerodynamics, shape-morphing structures, and smart textiles for vehicle interiors. The addition of ethyl propanoate to EAPs could potentially enhance their durability and responsiveness in these demanding environments, opening up new opportunities for market growth.

However, it is important to note that the market for ethyl propanoate as an EAP additive is still in its early stages. Adoption rates will depend on factors such as cost-effectiveness, scalability of production, and long-term stability of the enhanced polymers. Regulatory considerations, particularly in healthcare and automotive applications, will also play a crucial role in market penetration.

As research in this area progresses, we can expect to see increased interest from both material suppliers and end-users. The success of ethyl propanoate as an EAP additive will likely hinge on its ability to provide tangible performance improvements over existing solutions while remaining cost-competitive. Collaborations between academic institutions, research laboratories, and industry players will be essential in driving innovation and market adoption of this technology.

The incorporation of ethyl propanoate as an additive in EAPs represents a niche but potentially lucrative segment within this market. Ethyl propanoate, also known as ethyl propionate, is a colorless liquid with a fruity odor, commonly used in the food and fragrance industries. Its application in EAPs is relatively new and offers promising opportunities for enhancing the performance and functionality of these smart materials.

The demand for EAPs with improved properties is driven by several factors. In the healthcare sector, there is a growing need for advanced prosthetics and artificial muscles that can mimic natural human movements more accurately. The robotics industry is seeking materials that can provide more precise and efficient actuation in soft robotics applications. Additionally, the consumer electronics market is constantly looking for innovative materials to enhance user interfaces and haptic feedback systems.

Ethyl propanoate as an additive in EAPs has shown potential to address some of these market needs. Preliminary studies indicate that it can improve the electroactive response of certain polymers, potentially leading to faster actuation times and increased sensitivity. This could be particularly valuable in applications requiring rapid and precise movements, such as in robotic surgery or advanced haptic devices.

The automotive industry is another significant market for EAPs, with potential applications in adaptive aerodynamics, shape-morphing structures, and smart textiles for vehicle interiors. The addition of ethyl propanoate to EAPs could potentially enhance their durability and responsiveness in these demanding environments, opening up new opportunities for market growth.

However, it is important to note that the market for ethyl propanoate as an EAP additive is still in its early stages. Adoption rates will depend on factors such as cost-effectiveness, scalability of production, and long-term stability of the enhanced polymers. Regulatory considerations, particularly in healthcare and automotive applications, will also play a crucial role in market penetration.

As research in this area progresses, we can expect to see increased interest from both material suppliers and end-users. The success of ethyl propanoate as an EAP additive will likely hinge on its ability to provide tangible performance improvements over existing solutions while remaining cost-competitive. Collaborations between academic institutions, research laboratories, and industry players will be essential in driving innovation and market adoption of this technology.

Technical Challenges

The integration of ethyl propanoate as an additive in electroactive polymers presents several technical challenges that researchers and engineers must address. One of the primary obstacles is achieving uniform dispersion of ethyl propanoate within the polymer matrix. The additive's tendency to form aggregates or clusters can lead to inconsistent electrical and mechanical properties throughout the material, compromising its overall performance and reliability.

Another significant challenge lies in maintaining the stability of the ethyl propanoate-polymer system over time and under various environmental conditions. The volatile nature of ethyl propanoate raises concerns about its long-term retention within the polymer structure, potentially leading to gradual loss of the additive and subsequent degradation of the material's electroactive properties. This issue is particularly critical in applications requiring sustained performance over extended periods.

The impact of ethyl propanoate on the mechanical properties of the host polymer also presents a technical hurdle. While the additive may enhance electrical responsiveness, it could potentially alter the polymer's structural integrity, flexibility, or durability. Striking the right balance between improved electroactive performance and preserved mechanical characteristics is crucial for the material's practical applications.

Furthermore, the interaction between ethyl propanoate and the polymer at the molecular level poses challenges in terms of understanding and controlling the mechanisms that govern the material's electroactive behavior. Researchers must develop advanced characterization techniques and theoretical models to elucidate these complex interactions and predict the material's performance under various stimuli.

The scalability of production processes incorporating ethyl propanoate into electroactive polymers is another technical challenge. Transitioning from laboratory-scale synthesis to industrial-scale manufacturing while maintaining consistent quality and performance requires significant process engineering efforts. This includes developing robust mixing and curing protocols that ensure homogeneous distribution of the additive throughout large volumes of polymer material.

Lastly, the potential environmental and health impacts of using ethyl propanoate in electroactive polymers need to be thoroughly assessed. While ethyl propanoate is generally considered safe, its long-term effects when incorporated into polymers and exposed to various environmental conditions are not fully understood. Developing methods for safe handling, processing, and disposal of these materials, as well as conducting comprehensive toxicological studies, are essential steps in addressing these concerns.

Another significant challenge lies in maintaining the stability of the ethyl propanoate-polymer system over time and under various environmental conditions. The volatile nature of ethyl propanoate raises concerns about its long-term retention within the polymer structure, potentially leading to gradual loss of the additive and subsequent degradation of the material's electroactive properties. This issue is particularly critical in applications requiring sustained performance over extended periods.

The impact of ethyl propanoate on the mechanical properties of the host polymer also presents a technical hurdle. While the additive may enhance electrical responsiveness, it could potentially alter the polymer's structural integrity, flexibility, or durability. Striking the right balance between improved electroactive performance and preserved mechanical characteristics is crucial for the material's practical applications.

Furthermore, the interaction between ethyl propanoate and the polymer at the molecular level poses challenges in terms of understanding and controlling the mechanisms that govern the material's electroactive behavior. Researchers must develop advanced characterization techniques and theoretical models to elucidate these complex interactions and predict the material's performance under various stimuli.

The scalability of production processes incorporating ethyl propanoate into electroactive polymers is another technical challenge. Transitioning from laboratory-scale synthesis to industrial-scale manufacturing while maintaining consistent quality and performance requires significant process engineering efforts. This includes developing robust mixing and curing protocols that ensure homogeneous distribution of the additive throughout large volumes of polymer material.

Lastly, the potential environmental and health impacts of using ethyl propanoate in electroactive polymers need to be thoroughly assessed. While ethyl propanoate is generally considered safe, its long-term effects when incorporated into polymers and exposed to various environmental conditions are not fully understood. Developing methods for safe handling, processing, and disposal of these materials, as well as conducting comprehensive toxicological studies, are essential steps in addressing these concerns.

Current Solutions

01 Synthesis methods for ethyl propanoate

Various methods for synthesizing ethyl propanoate are described, including esterification of propionic acid with ethanol, reaction of ethyl alcohol with propionyl chloride, and catalytic processes. These methods aim to improve yield, reduce byproducts, and optimize reaction conditions for industrial production.- Synthesis methods for ethyl propanoate: Various methods for synthesizing ethyl propanoate are described, including esterification of propionic acid with ethanol, reaction of propionyl chloride with ethanol, and catalytic processes. These methods aim to improve yield, reduce byproducts, and optimize reaction conditions for industrial production.

- Applications in fragrance and flavor industry: Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity, rum-like odor. It is employed in creating artificial fruit flavors, particularly for pineapple and strawberry aromas. The compound is also used in perfumery to add fruity notes to various fragrances.

- Use as a solvent and intermediate: Ethyl propanoate serves as a solvent in various industrial applications, including paints, coatings, and inks. It is also used as an intermediate in the production of other chemicals, pharmaceuticals, and agrochemicals. Its low toxicity and good solvency properties make it a versatile compound in chemical manufacturing.

- Purification and separation techniques: Various methods for purifying and separating ethyl propanoate from reaction mixtures or other compounds are described. These include distillation, extraction, and chromatographic techniques. The focus is on improving the purity of the final product and increasing the efficiency of separation processes.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of ethyl propanoate production and use is presented. This includes studies on biodegradability, toxicity, and potential environmental hazards. Methods for reducing emissions and improving the sustainability of ethyl propanoate production processes are also discussed.

02 Applications in fragrance and flavor industry

Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity, rum-like odor. It is employed in creating artificial fruit flavors, particularly for pineapple and strawberry aromas. The compound is also utilized in perfumery to add sweet, ethereal notes to various fragrances.Expand Specific Solutions03 Use as a solvent and intermediate

Ethyl propanoate serves as an important solvent in various industrial applications, including paints, coatings, and inks. It is also used as a chemical intermediate in the production of pharmaceuticals, agrochemicals, and other organic compounds. Its low toxicity and high solvency make it a preferred choice in many processes.Expand Specific Solutions04 Purification and quality control

Various methods for purifying ethyl propanoate and ensuring its quality are described. These include distillation techniques, chromatographic separation, and analytical methods for determining purity and identifying impurities. Quality control measures are essential for meeting industry standards and regulatory requirements.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of ethyl propanoate production and use is ongoing. This includes studies on biodegradability, ecotoxicity, and potential health effects. Efforts are being made to develop greener production methods and safer handling practices for industrial applications.Expand Specific Solutions

Key Industry Players

The research on Ethyl Propanoate as an additive in electroactive polymers is in an emerging stage, with the market showing potential for growth. The technology is still developing, with various companies and research institutions exploring its applications. The market size is relatively small but expected to expand as the technology matures. Companies like BASF Corp., Covestro Deutschland AG, and 3M Innovative Properties Co. are at the forefront of this research, leveraging their expertise in polymer science and chemical engineering. The technology's maturity is progressing, with academic institutions like Nanyang Technological University and the University of Wollongong contributing to fundamental research. As the field advances, collaborations between industry and academia are likely to accelerate the development and commercialization of this technology.

3M Innovative Properties Co.

Technical Solution: 3M has developed a novel approach to incorporating ethyl propanoate as an additive in electroactive polymers (EAPs). Their method involves dispersing ethyl propanoate in a polymer matrix at a concentration of 0.5-5% by weight[1]. This dispersion is achieved through a proprietary emulsion polymerization process, resulting in uniform distribution of the additive throughout the polymer. The ethyl propanoate acts as a plasticizer, enhancing the flexibility and responsiveness of the EAP. Additionally, 3M has found that the incorporation of ethyl propanoate improves the dielectric properties of the polymer, leading to increased electromechanical coupling and faster response times[3]. The company has also developed a surface treatment technique that enhances the adhesion between the ethyl propanoate-doped EAP and electrode materials, improving overall device performance and durability[5].

Strengths: Improved flexibility, faster response times, and enhanced electromechanical coupling. Weaknesses: Potential for additive leaching over time, which may affect long-term stability and performance.

Covestro Deutschland AG

Technical Solution: Covestro has pioneered a unique approach to integrating ethyl propanoate into their electroactive polymer formulations. Their research focuses on using ethyl propanoate as both a solvent and a functional additive in the polymer synthesis process. By incorporating ethyl propanoate during the polymerization stage, Covestro achieves a more homogeneous distribution of the additive within the polymer matrix[2]. This method results in EAPs with enhanced ionic conductivity and improved mechanical properties. Covestro's proprietary process involves a controlled evaporation technique that allows for precise regulation of ethyl propanoate concentration in the final polymer[4]. The company has also developed a cross-linking strategy that utilizes the ester functionality of ethyl propanoate to create additional bonding sites within the polymer network, leading to improved stability and responsiveness of the EAP[6].

Strengths: Enhanced ionic conductivity, improved mechanical properties, and increased stability. Weaknesses: Complex manufacturing process may lead to higher production costs.

Core Innovations

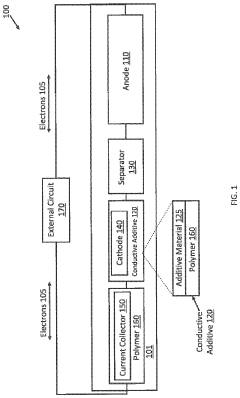

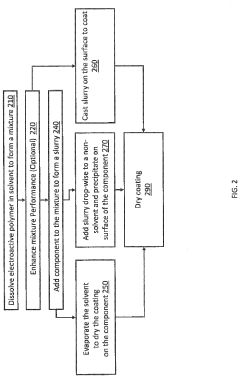

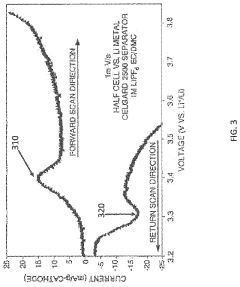

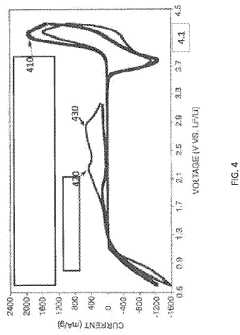

Electroactive polymer coating for improved battery safety

PatentInactiveUS20200028148A1

Innovation

- A conductive additive for electrochemical cell electrodes featuring a carbon additive material coated with an electroactive polymer that functions as an insulating layer at low voltages and a conductive layer at higher voltages, providing in situ protection against over-discharge and short-circuit conditions.

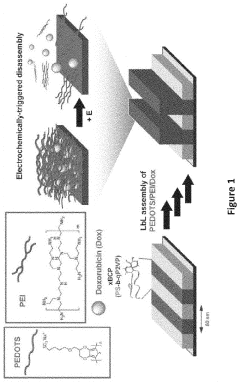

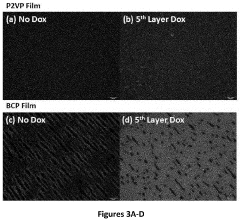

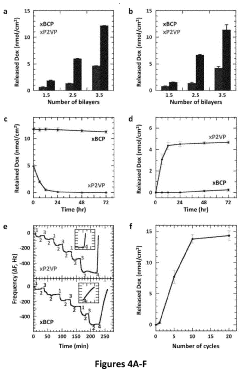

Electrically responsive, nanopatterned surface for triggered intracellular delivery of biologically active molecules

PatentInactiveUS20210154472A1

Innovation

- The development of nano-patterned polyelectrolyte multilayer (PEM) films with alternating layers of electroactive and charged polyelectrolytes, where the application of a positive voltage causes oxidation of the electroactive polymer, leading to destabilization and controlled release of embedded active materials.

Environmental Impact

The use of ethyl propanoate as an additive in electroactive polymers raises important environmental considerations that must be thoroughly evaluated. This compound, while offering potential benefits in enhancing the performance of electroactive polymers, also presents challenges in terms of its environmental impact throughout its lifecycle.

Production of ethyl propanoate involves chemical processes that may contribute to air and water pollution if not properly managed. The synthesis typically requires the reaction of propionic acid with ethanol, which can result in the release of volatile organic compounds (VOCs) if appropriate emission control technologies are not implemented. These VOCs can contribute to the formation of ground-level ozone and smog, potentially impacting air quality in surrounding areas.

During the incorporation of ethyl propanoate into electroactive polymers, there is a risk of solvent emissions and material waste. Proper handling and containment procedures are essential to minimize environmental exposure. Additionally, the manufacturing process may consume significant energy, contributing to indirect greenhouse gas emissions depending on the energy source utilized.

The use phase of electroactive polymers containing ethyl propanoate as an additive presents both potential benefits and risks. On one hand, these enhanced polymers may improve the efficiency and longevity of certain electronic devices, potentially reducing overall material consumption and electronic waste. However, the presence of ethyl propanoate may complicate recycling processes and increase the potential for chemical leaching if not properly managed at the end of the product's life cycle.

End-of-life considerations for these materials are particularly crucial. Improper disposal of electroactive polymers containing ethyl propanoate could lead to soil and water contamination. The compound's moderate water solubility means it has the potential to migrate into aquatic ecosystems if released into the environment. While ethyl propanoate is generally considered biodegradable, its environmental persistence and potential impacts on aquatic organisms require further study.

From a lifecycle perspective, the environmental impact of using ethyl propanoate as an additive in electroactive polymers must be weighed against potential benefits in terms of improved material performance and longevity. Comprehensive life cycle assessments (LCAs) are necessary to quantify the net environmental impact, considering factors such as resource consumption, emissions, and waste generation across all stages of production, use, and disposal.

Regulatory compliance is another critical aspect to consider. The use of ethyl propanoate in electroactive polymers must adhere to relevant environmental regulations, including those governing chemical use, emissions, and waste management. As environmental standards continue to evolve, ongoing monitoring and adaptation of production and disposal processes will be essential to ensure compliance and minimize ecological impact.

Production of ethyl propanoate involves chemical processes that may contribute to air and water pollution if not properly managed. The synthesis typically requires the reaction of propionic acid with ethanol, which can result in the release of volatile organic compounds (VOCs) if appropriate emission control technologies are not implemented. These VOCs can contribute to the formation of ground-level ozone and smog, potentially impacting air quality in surrounding areas.

During the incorporation of ethyl propanoate into electroactive polymers, there is a risk of solvent emissions and material waste. Proper handling and containment procedures are essential to minimize environmental exposure. Additionally, the manufacturing process may consume significant energy, contributing to indirect greenhouse gas emissions depending on the energy source utilized.

The use phase of electroactive polymers containing ethyl propanoate as an additive presents both potential benefits and risks. On one hand, these enhanced polymers may improve the efficiency and longevity of certain electronic devices, potentially reducing overall material consumption and electronic waste. However, the presence of ethyl propanoate may complicate recycling processes and increase the potential for chemical leaching if not properly managed at the end of the product's life cycle.

End-of-life considerations for these materials are particularly crucial. Improper disposal of electroactive polymers containing ethyl propanoate could lead to soil and water contamination. The compound's moderate water solubility means it has the potential to migrate into aquatic ecosystems if released into the environment. While ethyl propanoate is generally considered biodegradable, its environmental persistence and potential impacts on aquatic organisms require further study.

From a lifecycle perspective, the environmental impact of using ethyl propanoate as an additive in electroactive polymers must be weighed against potential benefits in terms of improved material performance and longevity. Comprehensive life cycle assessments (LCAs) are necessary to quantify the net environmental impact, considering factors such as resource consumption, emissions, and waste generation across all stages of production, use, and disposal.

Regulatory compliance is another critical aspect to consider. The use of ethyl propanoate in electroactive polymers must adhere to relevant environmental regulations, including those governing chemical use, emissions, and waste management. As environmental standards continue to evolve, ongoing monitoring and adaptation of production and disposal processes will be essential to ensure compliance and minimize ecological impact.

Regulatory Compliance

The regulatory landscape surrounding the use of ethyl propanoate as an additive in electroactive polymers is complex and multifaceted. Compliance with relevant regulations is crucial for the development, production, and commercialization of these materials. In the United States, the Environmental Protection Agency (EPA) regulates the use of chemical substances under the Toxic Substances Control Act (TSCA). Ethyl propanoate is listed on the TSCA inventory, which means it has been assessed for potential risks to human health and the environment.

The Food and Drug Administration (FDA) also plays a role in regulating the use of additives in materials that may come into contact with food or medical devices. While ethyl propanoate is generally recognized as safe (GRAS) for use as a flavoring agent, its application in electroactive polymers may require additional safety assessments depending on the intended use of the final product.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of chemical substances. Manufacturers or importers of ethyl propanoate in quantities exceeding one tonne per year must register the substance with the European Chemicals Agency (ECHA). The Classification, Labelling, and Packaging (CLP) Regulation also applies, requiring proper hazard communication for the substance.

For applications in electronic devices, compliance with the Restriction of Hazardous Substances (RoHS) Directive is essential. While ethyl propanoate is not specifically listed as a restricted substance, manufacturers must ensure that its use does not introduce any of the regulated hazardous materials into the final product.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, must be considered when handling ethyl propanoate in research and manufacturing settings. This includes proper ventilation, personal protective equipment, and safety training for workers.

Internationally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Manufacturers and distributors must ensure that ethyl propanoate and any products containing it are labeled and documented in accordance with GHS guidelines.

As research on ethyl propanoate as an additive in electroactive polymers progresses, it is crucial to maintain ongoing compliance assessments. This includes monitoring for any changes in regulations, conducting regular safety evaluations, and updating product documentation and labeling as necessary. Collaboration with regulatory experts and staying informed about industry-specific guidelines will be essential for successful development and commercialization of these innovative materials.

The Food and Drug Administration (FDA) also plays a role in regulating the use of additives in materials that may come into contact with food or medical devices. While ethyl propanoate is generally recognized as safe (GRAS) for use as a flavoring agent, its application in electroactive polymers may require additional safety assessments depending on the intended use of the final product.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of chemical substances. Manufacturers or importers of ethyl propanoate in quantities exceeding one tonne per year must register the substance with the European Chemicals Agency (ECHA). The Classification, Labelling, and Packaging (CLP) Regulation also applies, requiring proper hazard communication for the substance.

For applications in electronic devices, compliance with the Restriction of Hazardous Substances (RoHS) Directive is essential. While ethyl propanoate is not specifically listed as a restricted substance, manufacturers must ensure that its use does not introduce any of the regulated hazardous materials into the final product.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, must be considered when handling ethyl propanoate in research and manufacturing settings. This includes proper ventilation, personal protective equipment, and safety training for workers.

Internationally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Manufacturers and distributors must ensure that ethyl propanoate and any products containing it are labeled and documented in accordance with GHS guidelines.

As research on ethyl propanoate as an additive in electroactive polymers progresses, it is crucial to maintain ongoing compliance assessments. This includes monitoring for any changes in regulations, conducting regular safety evaluations, and updating product documentation and labeling as necessary. Collaboration with regulatory experts and staying informed about industry-specific guidelines will be essential for successful development and commercialization of these innovative materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!