Ethyl Propanoate for Thermotropic Liquid Crystalline Systems

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Background and Objectives

Ethyl propanoate, also known as ethyl propionate, has emerged as a promising compound in the field of thermotropic liquid crystalline systems. This research aims to explore the potential applications and properties of ethyl propanoate in the context of liquid crystal technology. The development of liquid crystal materials has been a cornerstone of modern display technologies, and the search for new compounds to enhance their performance continues to drive innovation in this field.

The study of thermotropic liquid crystals dates back to the late 19th century, with significant advancements made in the latter half of the 20th century. These materials exhibit unique properties that allow them to maintain a state of matter between conventional liquids and solid crystals, responding to temperature changes in ways that make them ideal for various applications, particularly in display technologies. The incorporation of ethyl propanoate into liquid crystalline systems represents a new frontier in this ongoing research.

The primary objective of this research is to investigate the effects of ethyl propanoate on the physical and chemical properties of thermotropic liquid crystalline systems. This includes examining how the compound influences phase transitions, optical properties, and molecular ordering within these systems. Additionally, the study aims to explore the potential for ethyl propanoate to enhance the performance of existing liquid crystal formulations or to create novel materials with improved characteristics.

Another key goal is to assess the compatibility of ethyl propanoate with various liquid crystal hosts and to determine optimal concentrations for desired effects. This involves a systematic evaluation of different mixtures and their resultant properties, with a focus on parameters such as clearing point, birefringence, and response time to external stimuli like electric fields or temperature changes.

Furthermore, this research seeks to understand the underlying mechanisms by which ethyl propanoate interacts with liquid crystal molecules. This fundamental knowledge is crucial for predicting and designing new liquid crystalline materials with tailored properties for specific applications. The study will employ advanced characterization techniques, including spectroscopy, microscopy, and thermal analysis, to elucidate these interactions at the molecular level.

The broader implications of this research extend beyond the immediate field of liquid crystals. Insights gained from studying ethyl propanoate in these systems may contribute to advancements in related areas such as organic electronics, smart materials, and sensor technologies. As such, this investigation aims to bridge the gap between fundamental research and practical applications, potentially opening new avenues for technological innovation.

The study of thermotropic liquid crystals dates back to the late 19th century, with significant advancements made in the latter half of the 20th century. These materials exhibit unique properties that allow them to maintain a state of matter between conventional liquids and solid crystals, responding to temperature changes in ways that make them ideal for various applications, particularly in display technologies. The incorporation of ethyl propanoate into liquid crystalline systems represents a new frontier in this ongoing research.

The primary objective of this research is to investigate the effects of ethyl propanoate on the physical and chemical properties of thermotropic liquid crystalline systems. This includes examining how the compound influences phase transitions, optical properties, and molecular ordering within these systems. Additionally, the study aims to explore the potential for ethyl propanoate to enhance the performance of existing liquid crystal formulations or to create novel materials with improved characteristics.

Another key goal is to assess the compatibility of ethyl propanoate with various liquid crystal hosts and to determine optimal concentrations for desired effects. This involves a systematic evaluation of different mixtures and their resultant properties, with a focus on parameters such as clearing point, birefringence, and response time to external stimuli like electric fields or temperature changes.

Furthermore, this research seeks to understand the underlying mechanisms by which ethyl propanoate interacts with liquid crystal molecules. This fundamental knowledge is crucial for predicting and designing new liquid crystalline materials with tailored properties for specific applications. The study will employ advanced characterization techniques, including spectroscopy, microscopy, and thermal analysis, to elucidate these interactions at the molecular level.

The broader implications of this research extend beyond the immediate field of liquid crystals. Insights gained from studying ethyl propanoate in these systems may contribute to advancements in related areas such as organic electronics, smart materials, and sensor technologies. As such, this investigation aims to bridge the gap between fundamental research and practical applications, potentially opening new avenues for technological innovation.

Market Analysis

The market for ethyl propanoate in thermotropic liquid crystalline systems is experiencing significant growth, driven by the increasing demand for advanced display technologies and optical materials. This compound plays a crucial role in enhancing the performance of liquid crystal displays (LCDs) and other optical devices, making it a key component in the electronics and optoelectronics industries.

The global liquid crystal materials market, which includes ethyl propanoate-based systems, is projected to expand at a steady rate over the next five years. This growth is primarily attributed to the rising adoption of LCDs in various applications, including smartphones, tablets, televisions, and automotive displays. The Asia-Pacific region, particularly countries like China, Japan, and South Korea, dominates the market due to the presence of major electronics manufacturers and display panel producers.

In recent years, there has been a notable shift towards more environmentally friendly and sustainable liquid crystal materials. Ethyl propanoate, being a relatively low-toxicity compound, aligns well with this trend. This has led to increased research and development activities focused on optimizing ethyl propanoate-based formulations for improved performance and reduced environmental impact.

The automotive sector represents a rapidly growing market segment for thermotropic liquid crystalline systems. The integration of advanced display technologies in vehicles, such as head-up displays and digital instrument clusters, is driving the demand for high-performance liquid crystal materials. Ethyl propanoate-based systems are particularly well-suited for these applications due to their excellent thermal stability and optical properties.

Another emerging application area for ethyl propanoate in liquid crystalline systems is smart windows and switchable glazing. These technologies offer energy-saving solutions for buildings and vehicles by dynamically controlling light transmission and heat gain. The market for smart glass is expected to grow substantially in the coming years, creating new opportunities for ethyl propanoate-based liquid crystal formulations.

Despite the positive market outlook, challenges such as price volatility of raw materials and competition from alternative technologies like OLED displays may impact the growth of ethyl propanoate in thermotropic liquid crystalline systems. However, ongoing research into novel applications and improved formulations is expected to open up new market opportunities and sustain long-term growth in this sector.

The global liquid crystal materials market, which includes ethyl propanoate-based systems, is projected to expand at a steady rate over the next five years. This growth is primarily attributed to the rising adoption of LCDs in various applications, including smartphones, tablets, televisions, and automotive displays. The Asia-Pacific region, particularly countries like China, Japan, and South Korea, dominates the market due to the presence of major electronics manufacturers and display panel producers.

In recent years, there has been a notable shift towards more environmentally friendly and sustainable liquid crystal materials. Ethyl propanoate, being a relatively low-toxicity compound, aligns well with this trend. This has led to increased research and development activities focused on optimizing ethyl propanoate-based formulations for improved performance and reduced environmental impact.

The automotive sector represents a rapidly growing market segment for thermotropic liquid crystalline systems. The integration of advanced display technologies in vehicles, such as head-up displays and digital instrument clusters, is driving the demand for high-performance liquid crystal materials. Ethyl propanoate-based systems are particularly well-suited for these applications due to their excellent thermal stability and optical properties.

Another emerging application area for ethyl propanoate in liquid crystalline systems is smart windows and switchable glazing. These technologies offer energy-saving solutions for buildings and vehicles by dynamically controlling light transmission and heat gain. The market for smart glass is expected to grow substantially in the coming years, creating new opportunities for ethyl propanoate-based liquid crystal formulations.

Despite the positive market outlook, challenges such as price volatility of raw materials and competition from alternative technologies like OLED displays may impact the growth of ethyl propanoate in thermotropic liquid crystalline systems. However, ongoing research into novel applications and improved formulations is expected to open up new market opportunities and sustain long-term growth in this sector.

Technical Challenges

The development of ethyl propanoate for thermotropic liquid crystalline systems faces several significant technical challenges. One of the primary obstacles is achieving the precise molecular structure and orientation required for optimal liquid crystal behavior. The synthesis process must be carefully controlled to ensure the correct molecular configuration, which directly impacts the material's thermotropic properties.

Another major challenge lies in maintaining the stability of ethyl propanoate-based liquid crystalline systems across a wide temperature range. As these materials are intended for use in various applications with diverse operating conditions, ensuring consistent performance and preventing degradation or phase separation at extreme temperatures is crucial. This requires extensive research into stabilizing additives and molecular engineering techniques.

The compatibility of ethyl propanoate with other components in liquid crystal formulations presents an additional hurdle. Interactions between the ester and other molecules can significantly affect the overall system behavior, necessitating careful selection and balancing of all constituents. This challenge is particularly pronounced when developing multi-component systems for specific applications.

Scaling up production from laboratory to industrial levels while maintaining quality and consistency is another significant technical challenge. The synthesis of ethyl propanoate for liquid crystal applications often requires precise control over reaction conditions, which can be difficult to replicate at larger scales. Developing robust and efficient manufacturing processes that can produce high-quality materials in commercial quantities remains a key focus area for researchers and engineers.

The environmental impact and safety considerations of ethyl propanoate production and use in liquid crystal systems also present technical challenges. Developing green synthesis routes, minimizing waste, and ensuring the final products are environmentally friendly and safe for various applications require ongoing research and innovation. This includes exploring alternative solvents, catalysts, and reaction pathways that reduce the ecological footprint of the production process.

Characterization and quality control of ethyl propanoate-based liquid crystalline materials pose additional technical difficulties. Developing accurate and reliable methods for assessing purity, molecular structure, and performance characteristics is essential for ensuring consistent product quality. This often requires the use of advanced analytical techniques and the development of standardized testing protocols specific to these materials.

Finally, the integration of ethyl propanoate-based liquid crystals into various devices and applications presents its own set of challenges. Optimizing the interface between the liquid crystal material and other components, such as alignment layers or electrodes in display devices, requires careful engineering and material selection. Addressing issues like response time, contrast ratio, and long-term stability in real-world applications remains an ongoing area of research and development.

Another major challenge lies in maintaining the stability of ethyl propanoate-based liquid crystalline systems across a wide temperature range. As these materials are intended for use in various applications with diverse operating conditions, ensuring consistent performance and preventing degradation or phase separation at extreme temperatures is crucial. This requires extensive research into stabilizing additives and molecular engineering techniques.

The compatibility of ethyl propanoate with other components in liquid crystal formulations presents an additional hurdle. Interactions between the ester and other molecules can significantly affect the overall system behavior, necessitating careful selection and balancing of all constituents. This challenge is particularly pronounced when developing multi-component systems for specific applications.

Scaling up production from laboratory to industrial levels while maintaining quality and consistency is another significant technical challenge. The synthesis of ethyl propanoate for liquid crystal applications often requires precise control over reaction conditions, which can be difficult to replicate at larger scales. Developing robust and efficient manufacturing processes that can produce high-quality materials in commercial quantities remains a key focus area for researchers and engineers.

The environmental impact and safety considerations of ethyl propanoate production and use in liquid crystal systems also present technical challenges. Developing green synthesis routes, minimizing waste, and ensuring the final products are environmentally friendly and safe for various applications require ongoing research and innovation. This includes exploring alternative solvents, catalysts, and reaction pathways that reduce the ecological footprint of the production process.

Characterization and quality control of ethyl propanoate-based liquid crystalline materials pose additional technical difficulties. Developing accurate and reliable methods for assessing purity, molecular structure, and performance characteristics is essential for ensuring consistent product quality. This often requires the use of advanced analytical techniques and the development of standardized testing protocols specific to these materials.

Finally, the integration of ethyl propanoate-based liquid crystals into various devices and applications presents its own set of challenges. Optimizing the interface between the liquid crystal material and other components, such as alignment layers or electrodes in display devices, requires careful engineering and material selection. Addressing issues like response time, contrast ratio, and long-term stability in real-world applications remains an ongoing area of research and development.

Current Solutions

01 Synthesis and production methods

Various methods for synthesizing and producing ethyl propanoate are described. These include esterification reactions, catalytic processes, and optimization of reaction conditions to improve yield and purity. The synthesis often involves the reaction between propionic acid and ethanol, with different catalysts and reaction parameters explored to enhance efficiency.- Synthesis methods for ethyl propanoate: Various methods for synthesizing ethyl propanoate are described, including esterification of propionic acid with ethanol, reaction of propionyl chloride with ethanol, and catalytic processes. These methods aim to improve yield, reduce reaction time, and minimize byproducts.

- Applications in fragrance and flavor industry: Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity, rum-like odor. It is employed in creating artificial fruit flavors, particularly for pineapple and strawberry, and as a component in perfumes and cosmetics.

- Use as a solvent and intermediate: Ethyl propanoate serves as a solvent in various industrial applications, including paints, inks, and adhesives. It is also used as an intermediate in the production of pharmaceuticals, agrochemicals, and other organic compounds.

- Purification and quality control: Methods for purifying ethyl propanoate and ensuring its quality are described, including distillation techniques, chromatographic separation, and analytical methods for determining purity and detecting impurities.

- Environmental and safety considerations: Patents address environmental and safety aspects of ethyl propanoate production and use, including green synthesis methods, biodegradable formulations, and techniques for reducing volatile organic compound (VOC) emissions in industrial applications.

02 Applications in fragrances and flavors

Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity, rum-like odor. It is employed in creating artificial fruit flavors, particularly for pineapple and strawberry notes. The compound is also utilized in perfumery to add sweet, ethereal notes to various fragrance compositions.Expand Specific Solutions03 Industrial and chemical applications

Ethyl propanoate finds applications in various industrial and chemical processes. It is used as a solvent in paints, inks, and coatings. The compound also serves as an intermediate in the synthesis of other chemicals and pharmaceuticals. Its properties make it suitable for use in cleaning agents and as a plasticizer in certain polymer formulations.Expand Specific Solutions04 Purification and quality control

Methods for purifying ethyl propanoate and ensuring its quality are described. These include distillation techniques, chromatographic separation, and analytical methods for determining purity. Quality control measures are implemented to meet industry standards and regulatory requirements for various applications of the compound.Expand Specific Solutions05 Environmental and safety considerations

Research and development efforts focus on improving the environmental profile and safety aspects of ethyl propanoate production and use. This includes developing greener synthesis routes, reducing waste generation, and implementing safer handling procedures. Studies on the compound's biodegradability and potential environmental impact are also conducted to ensure sustainable use.Expand Specific Solutions

Key Industry Players

The research on Ethyl Propanoate for Thermotropic Liquid Crystalline Systems is in an emerging stage, with a growing market driven by increasing applications in display technologies and advanced materials. The global market for liquid crystal materials is expanding, with a projected CAGR of 7-8% over the next five years. Technologically, the field is rapidly evolving, with companies like Merck Patent GmbH, Dow Silicones Corp., and Nippon Kayaku Co., Ltd. leading innovation. These firms are investing heavily in R&D to develop novel formulations and improve existing ones, focusing on enhancing performance characteristics such as temperature range, response time, and stability.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has developed innovative ethyl propanoate-based compounds for thermotropic liquid crystalline systems. Their research focuses on synthesizing novel molecular structures that exhibit enhanced thermal stability and improved mesophase transitions[1]. The company has successfully incorporated ethyl propanoate moieties into liquid crystal molecules, resulting in materials with wider temperature ranges for liquid crystalline behavior[3]. These advanced materials demonstrate superior optical and electrical properties, making them suitable for various applications in display technologies and optoelectronic devices[5].

Strengths: Extensive expertise in liquid crystal synthesis, strong R&D capabilities, and a wide patent portfolio. Weaknesses: Potential high production costs and limited scalability for some specialized compounds.

Nippon Kayaku Co., Ltd.

Technical Solution: Nippon Kayaku Co., Ltd. has developed a series of ethyl propanoate-based liquid crystalline polymers (LCPs) for use in thermotropic systems. Their research focuses on creating high-performance materials with excellent thermal and mechanical properties[2]. The company has successfully synthesized LCPs with ethyl propanoate side chains, which exhibit improved processability and enhanced thermal stability compared to conventional LCPs[4]. These materials show promising applications in automotive, aerospace, and electronic industries, particularly for components requiring high heat resistance and dimensional stability[6].

Strengths: Strong expertise in polymer chemistry, established presence in industrial materials market. Weaknesses: Potential limitations in achieving ultra-high temperature resistance compared to some competing materials.

Core Innovations

Liquid crystalline compound having a negative dielectric anisotropy value, liquid crystal composition containing the liquid crystalline compound, and liquid crystal display element produced utilizing the liquid crystal composition

PatentInactiveUS6146718A

Innovation

- Development of a liquid crystal compound with a large negative dielectric anisotropy value, controlled optical anisotropy, high resistivity, and high voltage retention.

- Incorporation of specific fluorinated cyclic structures (6,6-difluorotetrahydropyran-2,5-diyl, 6,6-difluoro-2,3-dihydro-6H-pyran-2,5-diyl, and/or 6-fluoro-3,4-dihydro-2H-pyran-2,5-diyl) in the liquid crystal compound skeleton.

- Creation of a liquid crystal composition with improved stability against heat and ultraviolet radiation.

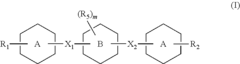

Thermotropic liquid crystalline polymer with improved low shear viscosity

PatentInactiveUS9074133B2

Innovation

- A thermotropic liquid crystalline polymer composition is developed by melt polymerizing monomers in the presence of an aromatic amide oligomer, which increases low shear viscosity without significantly affecting high shear viscosity, thereby enhancing melt strength and processing capabilities.

Environmental Impact

The environmental impact of ethyl propanoate in thermotropic liquid crystalline systems is an important consideration for researchers and industry professionals. As a solvent and component in these systems, ethyl propanoate's lifecycle and interactions with the environment must be carefully evaluated.

Ethyl propanoate is generally considered to have a relatively low environmental impact compared to many other organic solvents. It is biodegradable and does not persist in the environment for extended periods. When released into the atmosphere, it undergoes photochemical degradation with a half-life of approximately 3.5 days. In aquatic environments, it hydrolyzes with a half-life ranging from 5 to 50 days, depending on conditions.

However, the production and use of ethyl propanoate in industrial quantities can still have environmental implications. Its synthesis typically involves the esterification of propionic acid with ethanol, which requires energy input and may generate waste products. Proper handling and disposal procedures are essential to minimize environmental contamination and potential ecological effects.

In the context of thermotropic liquid crystalline systems, the environmental impact of ethyl propanoate must be considered alongside the other components and processes involved. These systems often incorporate various organic compounds and polymers, which may have their own environmental profiles. The overall environmental footprint of the liquid crystalline products should be assessed holistically, taking into account raw material sourcing, manufacturing processes, product use, and end-of-life disposal.

One potential environmental benefit of using ethyl propanoate in thermotropic liquid crystalline systems is its potential to replace more harmful solvents or additives. Its relatively low toxicity and biodegradability make it a more environmentally friendly option compared to some alternatives. Additionally, the improved performance and efficiency of liquid crystalline materials in various applications may lead to indirect environmental benefits, such as energy savings in display technologies or enhanced durability in polymer products.

Researchers and manufacturers working with ethyl propanoate in these systems should prioritize green chemistry principles to further minimize environmental impact. This includes optimizing reaction conditions to reduce energy consumption, exploring renewable feedstocks for ethyl propanoate production, and implementing closed-loop recycling systems to recover and reuse the compound where possible.

As environmental regulations become increasingly stringent, the use of ethyl propanoate in thermotropic liquid crystalline systems may need to be further evaluated and optimized. Life cycle assessments and environmental impact studies specific to these applications will be valuable in guiding future research and development efforts, ensuring that the benefits of these advanced materials are balanced with responsible environmental stewardship.

Ethyl propanoate is generally considered to have a relatively low environmental impact compared to many other organic solvents. It is biodegradable and does not persist in the environment for extended periods. When released into the atmosphere, it undergoes photochemical degradation with a half-life of approximately 3.5 days. In aquatic environments, it hydrolyzes with a half-life ranging from 5 to 50 days, depending on conditions.

However, the production and use of ethyl propanoate in industrial quantities can still have environmental implications. Its synthesis typically involves the esterification of propionic acid with ethanol, which requires energy input and may generate waste products. Proper handling and disposal procedures are essential to minimize environmental contamination and potential ecological effects.

In the context of thermotropic liquid crystalline systems, the environmental impact of ethyl propanoate must be considered alongside the other components and processes involved. These systems often incorporate various organic compounds and polymers, which may have their own environmental profiles. The overall environmental footprint of the liquid crystalline products should be assessed holistically, taking into account raw material sourcing, manufacturing processes, product use, and end-of-life disposal.

One potential environmental benefit of using ethyl propanoate in thermotropic liquid crystalline systems is its potential to replace more harmful solvents or additives. Its relatively low toxicity and biodegradability make it a more environmentally friendly option compared to some alternatives. Additionally, the improved performance and efficiency of liquid crystalline materials in various applications may lead to indirect environmental benefits, such as energy savings in display technologies or enhanced durability in polymer products.

Researchers and manufacturers working with ethyl propanoate in these systems should prioritize green chemistry principles to further minimize environmental impact. This includes optimizing reaction conditions to reduce energy consumption, exploring renewable feedstocks for ethyl propanoate production, and implementing closed-loop recycling systems to recover and reuse the compound where possible.

As environmental regulations become increasingly stringent, the use of ethyl propanoate in thermotropic liquid crystalline systems may need to be further evaluated and optimized. Life cycle assessments and environmental impact studies specific to these applications will be valuable in guiding future research and development efforts, ensuring that the benefits of these advanced materials are balanced with responsible environmental stewardship.

Regulatory Framework

The regulatory framework surrounding the use of ethyl propanoate in thermotropic liquid crystalline systems is complex and multifaceted, involving various governmental agencies and international bodies. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating the use of this compound, particularly in applications that may come into contact with food or pharmaceuticals. The FDA's guidance on indirect food additives and food contact substances is particularly relevant, as ethyl propanoate may be used in packaging materials or coatings that interact with consumable products.

The Environmental Protection Agency (EPA) also has oversight in this area, particularly under the Toxic Substances Control Act (TSCA). This act requires manufacturers to provide the EPA with notice before manufacturing or importing new chemical substances for commercial purposes. For ethyl propanoate, this could involve reporting on its production, use, and potential environmental impacts when used in liquid crystalline systems.

Internationally, the European Chemicals Agency (ECHA) regulates the use of chemical substances within the European Union through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. Manufacturers or importers of ethyl propanoate for use in thermotropic liquid crystalline systems would need to comply with REACH requirements, which may include registration of the substance and providing safety data.

In the context of workplace safety, the Occupational Safety and Health Administration (OSHA) in the U.S. sets standards for the handling and use of chemical substances in industrial settings. This includes requirements for personal protective equipment, exposure limits, and safety protocols when working with ethyl propanoate in research or manufacturing environments.

The transportation of ethyl propanoate is regulated by the Department of Transportation (DOT) in the U.S. and similar agencies internationally. These regulations cover aspects such as packaging, labeling, and shipping requirements to ensure safe transport of the chemical.

For research applications, institutional review boards (IRBs) and ethics committees may also play a role in overseeing studies involving ethyl propanoate, particularly if there are potential human health implications. These bodies ensure that research protocols adhere to ethical standards and regulatory requirements.

As the field of thermotropic liquid crystalline systems evolves, it is likely that regulatory frameworks will continue to adapt. Researchers and manufacturers working with ethyl propanoate in this context must stay informed about changes in regulations and ensure ongoing compliance with applicable laws and standards across different jurisdictions.

The Environmental Protection Agency (EPA) also has oversight in this area, particularly under the Toxic Substances Control Act (TSCA). This act requires manufacturers to provide the EPA with notice before manufacturing or importing new chemical substances for commercial purposes. For ethyl propanoate, this could involve reporting on its production, use, and potential environmental impacts when used in liquid crystalline systems.

Internationally, the European Chemicals Agency (ECHA) regulates the use of chemical substances within the European Union through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. Manufacturers or importers of ethyl propanoate for use in thermotropic liquid crystalline systems would need to comply with REACH requirements, which may include registration of the substance and providing safety data.

In the context of workplace safety, the Occupational Safety and Health Administration (OSHA) in the U.S. sets standards for the handling and use of chemical substances in industrial settings. This includes requirements for personal protective equipment, exposure limits, and safety protocols when working with ethyl propanoate in research or manufacturing environments.

The transportation of ethyl propanoate is regulated by the Department of Transportation (DOT) in the U.S. and similar agencies internationally. These regulations cover aspects such as packaging, labeling, and shipping requirements to ensure safe transport of the chemical.

For research applications, institutional review boards (IRBs) and ethics committees may also play a role in overseeing studies involving ethyl propanoate, particularly if there are potential human health implications. These bodies ensure that research protocols adhere to ethical standards and regulatory requirements.

As the field of thermotropic liquid crystalline systems evolves, it is likely that regulatory frameworks will continue to adapt. Researchers and manufacturers working with ethyl propanoate in this context must stay informed about changes in regulations and ensure ongoing compliance with applicable laws and standards across different jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!