Ethylene Vinyl Acetate in Advanced Materials Science

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a versatile and significant material in advanced materials science over the past few decades. This copolymer, composed of ethylene and vinyl acetate, has garnered substantial attention due to its unique combination of properties that make it suitable for a wide range of applications. The evolution of EVA technology can be traced back to the 1950s when it was first developed, but its potential in advanced materials has only been fully realized in recent years.

The primary objective of research on EVA in advanced materials science is to explore and exploit its exceptional characteristics, such as flexibility, toughness, and transparency, while addressing its limitations. Scientists and engineers aim to enhance EVA's performance in various applications, including solar panel encapsulation, footwear manufacturing, and packaging materials. The focus is on improving its durability, weather resistance, and thermal properties to meet the demanding requirements of modern industries.

One of the key trends in EVA research is the development of nanocomposites, where nanoparticles are incorporated into the EVA matrix to enhance its mechanical, thermal, and barrier properties. This approach has shown promising results in improving the material's overall performance and expanding its potential applications. Another significant trend is the modification of EVA's chemical structure to tailor its properties for specific end-uses, such as increasing its adhesion strength or enhancing its flame-retardant characteristics.

The global demand for sustainable and eco-friendly materials has also influenced the direction of EVA research. Scientists are exploring bio-based alternatives and investigating methods to improve the recyclability and biodegradability of EVA products. This aligns with the growing emphasis on circular economy principles and the need to reduce the environmental impact of plastic materials.

In the context of advanced materials science, EVA serves as a model system for studying polymer physics and chemistry. Researchers are delving into the fundamental aspects of EVA's molecular structure, crystallization behavior, and phase transitions to gain deeper insights into polymer science. This knowledge not only contributes to the improvement of EVA-based materials but also aids in the development of novel polymeric systems with enhanced properties.

The objectives of current EVA research extend beyond material improvement to include the exploration of new applications in emerging fields such as flexible electronics, biomedical devices, and energy storage systems. By leveraging EVA's unique properties and combining it with other advanced materials, researchers aim to create innovative solutions that address contemporary technological challenges and pave the way for future breakthroughs in materials science.

The primary objective of research on EVA in advanced materials science is to explore and exploit its exceptional characteristics, such as flexibility, toughness, and transparency, while addressing its limitations. Scientists and engineers aim to enhance EVA's performance in various applications, including solar panel encapsulation, footwear manufacturing, and packaging materials. The focus is on improving its durability, weather resistance, and thermal properties to meet the demanding requirements of modern industries.

One of the key trends in EVA research is the development of nanocomposites, where nanoparticles are incorporated into the EVA matrix to enhance its mechanical, thermal, and barrier properties. This approach has shown promising results in improving the material's overall performance and expanding its potential applications. Another significant trend is the modification of EVA's chemical structure to tailor its properties for specific end-uses, such as increasing its adhesion strength or enhancing its flame-retardant characteristics.

The global demand for sustainable and eco-friendly materials has also influenced the direction of EVA research. Scientists are exploring bio-based alternatives and investigating methods to improve the recyclability and biodegradability of EVA products. This aligns with the growing emphasis on circular economy principles and the need to reduce the environmental impact of plastic materials.

In the context of advanced materials science, EVA serves as a model system for studying polymer physics and chemistry. Researchers are delving into the fundamental aspects of EVA's molecular structure, crystallization behavior, and phase transitions to gain deeper insights into polymer science. This knowledge not only contributes to the improvement of EVA-based materials but also aids in the development of novel polymeric systems with enhanced properties.

The objectives of current EVA research extend beyond material improvement to include the exploration of new applications in emerging fields such as flexible electronics, biomedical devices, and energy storage systems. By leveraging EVA's unique properties and combining it with other advanced materials, researchers aim to create innovative solutions that address contemporary technological challenges and pave the way for future breakthroughs in materials science.

Market Analysis for EVA Applications

The global market for Ethylene Vinyl Acetate (EVA) has experienced significant growth in recent years, driven by its versatile applications in advanced materials science. The EVA market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong through the next decade. This growth is primarily attributed to the increasing demand for EVA in various industries, including solar energy, footwear, packaging, and automotive sectors.

In the solar energy industry, EVA has become an indispensable material for the encapsulation of photovoltaic modules. As the global push for renewable energy sources intensifies, the demand for solar panels continues to rise, consequently boosting the EVA market. The material's excellent properties, such as high transparency, low water absorption, and good adhesion to glass and silicon cells, make it ideal for this application.

The footwear industry represents another significant market for EVA applications. The material's lightweight nature, excellent cushioning properties, and durability have made it a popular choice for shoe soles, particularly in sports and casual footwear. As consumer preferences shift towards more comfortable and performance-oriented footwear, the demand for EVA in this sector is expected to grow steadily.

In the packaging industry, EVA finds extensive use in flexible packaging applications due to its excellent sealing properties, clarity, and impact resistance. The growth of e-commerce and the increasing demand for convenient, lightweight packaging solutions are driving factors for EVA consumption in this sector. Additionally, the material's compatibility with food contact applications further expands its market potential in the packaging industry.

The automotive sector presents another promising market for EVA applications. The material is used in various automotive components, including gaskets, hoses, and wire and cable insulation. As the automotive industry continues to evolve, with a focus on lightweight materials and improved fuel efficiency, the demand for EVA in this sector is expected to increase.

Geographically, Asia-Pacific dominates the global EVA market, with China being the largest consumer and producer. The region's rapid industrialization, growing population, and increasing disposable income are key factors driving the demand for EVA-based products. North America and Europe also represent significant markets, particularly in high-value applications such as solar panel encapsulation and specialty packaging.

Despite the positive market outlook, challenges such as volatile raw material prices and environmental concerns regarding the disposal of EVA-based products may impact market growth. However, ongoing research and development efforts aimed at improving EVA's properties and exploring new applications are expected to create additional opportunities for market expansion in the coming years.

In the solar energy industry, EVA has become an indispensable material for the encapsulation of photovoltaic modules. As the global push for renewable energy sources intensifies, the demand for solar panels continues to rise, consequently boosting the EVA market. The material's excellent properties, such as high transparency, low water absorption, and good adhesion to glass and silicon cells, make it ideal for this application.

The footwear industry represents another significant market for EVA applications. The material's lightweight nature, excellent cushioning properties, and durability have made it a popular choice for shoe soles, particularly in sports and casual footwear. As consumer preferences shift towards more comfortable and performance-oriented footwear, the demand for EVA in this sector is expected to grow steadily.

In the packaging industry, EVA finds extensive use in flexible packaging applications due to its excellent sealing properties, clarity, and impact resistance. The growth of e-commerce and the increasing demand for convenient, lightweight packaging solutions are driving factors for EVA consumption in this sector. Additionally, the material's compatibility with food contact applications further expands its market potential in the packaging industry.

The automotive sector presents another promising market for EVA applications. The material is used in various automotive components, including gaskets, hoses, and wire and cable insulation. As the automotive industry continues to evolve, with a focus on lightweight materials and improved fuel efficiency, the demand for EVA in this sector is expected to increase.

Geographically, Asia-Pacific dominates the global EVA market, with China being the largest consumer and producer. The region's rapid industrialization, growing population, and increasing disposable income are key factors driving the demand for EVA-based products. North America and Europe also represent significant markets, particularly in high-value applications such as solar panel encapsulation and specialty packaging.

Despite the positive market outlook, challenges such as volatile raw material prices and environmental concerns regarding the disposal of EVA-based products may impact market growth. However, ongoing research and development efforts aimed at improving EVA's properties and exploring new applications are expected to create additional opportunities for market expansion in the coming years.

EVA Technical Challenges

Ethylene Vinyl Acetate (EVA) has gained significant attention in advanced materials science due to its versatile properties. However, several technical challenges persist in its development and application. One of the primary issues is the optimization of EVA's thermal stability. At higher temperatures, EVA tends to degrade, leading to the release of acetic acid and the formation of unsaturated structures. This degradation not only affects the material's performance but also poses environmental concerns.

Another challenge lies in enhancing the mechanical properties of EVA without compromising its flexibility. While EVA offers excellent elasticity, its strength and tear resistance are often insufficient for certain high-performance applications. Researchers are exploring various reinforcement techniques, such as the incorporation of nanofillers or the development of novel copolymer structures, to address this limitation.

The control of crystallinity in EVA copolymers presents a significant technical hurdle. The degree of crystallinity directly influences the material's properties, including transparency, flexibility, and barrier characteristics. Achieving precise control over the crystallization process, especially in products with varying vinyl acetate content, remains a complex task that requires advanced processing techniques and formulation strategies.

Adhesion properties of EVA, particularly in multi-layer structures, pose another technical challenge. While EVA exhibits good adhesion to many substrates, improving its bonding strength and compatibility with a wider range of materials is crucial for expanding its applications in advanced composites and packaging solutions.

The development of EVA with enhanced barrier properties is an ongoing challenge in the field. Improving gas and moisture barrier characteristics without significantly altering other desirable properties of EVA is essential for its use in packaging and encapsulation applications, particularly in the food and electronics industries.

Recyclability and environmental impact of EVA products have become increasingly important technical challenges. Developing effective recycling methods for EVA-based materials, especially those used in complex multi-layer structures, is crucial for meeting sustainability goals and regulatory requirements.

Lastly, the scalability of advanced EVA production processes presents a significant challenge. While laboratory-scale innovations show promise, translating these advancements to industrial-scale production while maintaining consistency in quality and properties remains a hurdle for many manufacturers.

Another challenge lies in enhancing the mechanical properties of EVA without compromising its flexibility. While EVA offers excellent elasticity, its strength and tear resistance are often insufficient for certain high-performance applications. Researchers are exploring various reinforcement techniques, such as the incorporation of nanofillers or the development of novel copolymer structures, to address this limitation.

The control of crystallinity in EVA copolymers presents a significant technical hurdle. The degree of crystallinity directly influences the material's properties, including transparency, flexibility, and barrier characteristics. Achieving precise control over the crystallization process, especially in products with varying vinyl acetate content, remains a complex task that requires advanced processing techniques and formulation strategies.

Adhesion properties of EVA, particularly in multi-layer structures, pose another technical challenge. While EVA exhibits good adhesion to many substrates, improving its bonding strength and compatibility with a wider range of materials is crucial for expanding its applications in advanced composites and packaging solutions.

The development of EVA with enhanced barrier properties is an ongoing challenge in the field. Improving gas and moisture barrier characteristics without significantly altering other desirable properties of EVA is essential for its use in packaging and encapsulation applications, particularly in the food and electronics industries.

Recyclability and environmental impact of EVA products have become increasingly important technical challenges. Developing effective recycling methods for EVA-based materials, especially those used in complex multi-layer structures, is crucial for meeting sustainability goals and regulatory requirements.

Lastly, the scalability of advanced EVA production processes presents a significant challenge. While laboratory-scale innovations show promise, translating these advancements to industrial-scale production while maintaining consistency in quality and properties remains a hurdle for many manufacturers.

Current EVA Solutions

01 Composition and synthesis of EVA copolymers

Ethylene Vinyl Acetate (EVA) copolymers are synthesized through the copolymerization of ethylene and vinyl acetate monomers. The composition and ratio of these monomers can be adjusted to achieve desired properties. Various polymerization methods and catalysts are employed to control the molecular weight, branching, and vinyl acetate content of the resulting copolymer.- Composition and synthesis of EVA copolymers: Ethylene Vinyl Acetate (EVA) copolymers are synthesized through the copolymerization of ethylene and vinyl acetate monomers. The composition and properties of EVA can be adjusted by varying the ratio of these monomers, allowing for customization of the material's characteristics such as flexibility, toughness, and adhesion properties.

- EVA blends and composites: EVA can be blended with other polymers or materials to create composites with enhanced properties. These blends can improve characteristics such as impact resistance, thermal stability, or specific functional properties. The selection of blend components and their ratios are crucial in achieving desired performance characteristics.

- Modification and functionalization of EVA: EVA copolymers can be modified or functionalized to enhance specific properties or introduce new functionalities. This can involve grafting of functional groups, crosslinking, or other chemical modifications. Such modifications can improve properties like adhesion, compatibility with other materials, or introduce specific reactive sites.

- Processing and manufacturing of EVA products: Various processing techniques are employed in the manufacturing of EVA products, including extrusion, injection molding, and film blowing. The processing conditions and methods significantly influence the final properties of EVA products. Optimization of these processes is crucial for achieving desired product characteristics and performance.

- Applications of EVA in various industries: EVA finds applications in diverse industries due to its versatile properties. It is used in the production of flexible packaging, adhesives, solar cell encapsulants, footwear, and various consumer products. The specific grade and formulation of EVA are tailored to meet the requirements of each application, considering factors such as flexibility, transparency, and weatherability.

02 Modification and blending of EVA

EVA copolymers can be modified or blended with other polymers to enhance their properties. This includes crosslinking, grafting, or mixing with additives to improve characteristics such as thermal stability, mechanical strength, or adhesion. Blending EVA with other polymers can result in materials with tailored properties for specific applications.Expand Specific Solutions03 EVA foam production and applications

EVA foams are produced by incorporating blowing agents into the polymer matrix and subjecting it to specific processing conditions. These foams find applications in various industries due to their lightweight nature, cushioning properties, and flexibility. The foam structure and density can be controlled to suit different end-use requirements.Expand Specific Solutions04 EVA in adhesive and sealant formulations

EVA copolymers are widely used in adhesive and sealant formulations due to their excellent adhesion properties, flexibility, and compatibility with various substrates. The vinyl acetate content and molecular weight of the EVA can be adjusted to optimize adhesive performance for different applications, such as hot melt adhesives or pressure-sensitive adhesives.Expand Specific Solutions05 EVA in film and packaging applications

EVA copolymers are extensively used in film and packaging applications due to their flexibility, clarity, and barrier properties. The copolymer can be processed into films with varying thicknesses and properties, suitable for food packaging, agricultural films, and other protective coverings. EVA films can also be coextruded or laminated with other materials to enhance their performance.Expand Specific Solutions

Key EVA Industry Players

The research on Ethylene Vinyl Acetate (EVA) in Advanced Materials Science is in a mature stage, with a significant global market presence. The industry is characterized by established players and ongoing innovation. Key competitors include major petrochemical corporations like China Petroleum & Chemical Corp., LyondellBasell, and DuPont, alongside specialized chemical manufacturers such as Celanese and Kuraray. These companies are investing in R&D to enhance EVA properties and explore new applications. The market is driven by growing demand in sectors like solar panels, packaging, and footwear. Technological advancements focus on improving EVA's performance characteristics, sustainability, and cost-effectiveness, with a trend towards developing bio-based alternatives.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced EVA copolymers with improved thermal stability and mechanical properties. Their research focuses on optimizing the VA content and molecular weight distribution to enhance performance in various applications. Sinopec has implemented a proprietary catalytic system that allows for precise control of copolymerization, resulting in EVA grades with superior clarity, flexibility, and adhesion strength[1]. They have also developed a novel crosslinking technology that significantly improves the heat resistance and creep resistance of EVA materials, making them suitable for demanding applications in the automotive and solar panel industries[3].

Strengths: Extensive R&D capabilities, vertically integrated production, and a strong market presence in Asia. Weaknesses: Potential environmental concerns associated with petrochemical production and limited global market share compared to some international competitors.

Celanese International Corp.

Technical Solution: Celanese has pioneered the development of high-performance EVA copolymers through their proprietary VitalDose™ technology platform. This innovative approach allows for the precise control of VA content, ranging from 0-40%, enabling tailored solutions for various applications. Their research has focused on enhancing the drug delivery capabilities of EVA, particularly in controlled release formulations. Celanese has developed EVA grades with optimized crystallinity and melt flow properties, resulting in improved processability and consistent drug release profiles[2]. Additionally, they have introduced EVA grades with enhanced barrier properties and chemical resistance, making them suitable for advanced packaging and medical device applications[4].

Strengths: Strong expertise in specialty polymers, global manufacturing footprint, and a diverse product portfolio. Weaknesses: Dependence on volatile raw material prices and potential regulatory challenges in certain markets.

EVA Core Innovations

Method for preparing ethylene-vinyl acetate with low melt index

PatentWO2014181991A1

Innovation

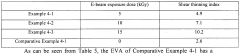

- Applying an electron beam with a defined exposure dose to an ethylene-vinyl acetate resin composition with a vinyl acetate content of 15 to 50 wt% to reduce the melt index to 10 g/10 min or less, thereby enhancing mechanical properties and processability without the need for additional modifiers like peroxides.

Ethylene vinyl acetate resin and preparation method thereof

PatentActiveKR1020200051376A

Innovation

- A method involving a vinyl acetate content of 30 to 60 wt% with a melt index of 10 g/10 min or less and a molecular weight distribution (PDI) of 10 or less is achieved through a very slight crosslinking reaction, using a crosslinking agent and aid, and controlled polymerization conditions.

EVA Environmental Impact

Ethylene Vinyl Acetate (EVA) has become a widely used material in various industries due to its versatile properties. However, its environmental impact has raised concerns among researchers and environmentalists. The production of EVA involves the use of fossil fuels and energy-intensive processes, contributing to greenhouse gas emissions and climate change. The manufacturing process also generates volatile organic compounds (VOCs) and other pollutants, which can have adverse effects on air quality and human health if not properly managed.

One of the primary environmental challenges associated with EVA is its end-of-life disposal. As a thermoplastic material, EVA can be recycled, but the recycling process is often complex and energy-intensive. Many EVA products end up in landfills or incineration facilities, contributing to waste accumulation and potential soil and water contamination. The slow degradation rate of EVA in natural environments further exacerbates this issue, as it can persist for many years, potentially harming ecosystems and wildlife.

In recent years, efforts have been made to improve the environmental profile of EVA. Researchers are exploring bio-based alternatives and developing more sustainable production methods. Some manufacturers have implemented closed-loop recycling systems to reduce waste and improve resource efficiency. Additionally, there is growing interest in developing biodegradable or compostable EVA formulations to address end-of-life concerns.

The use of EVA in solar panel encapsulation has both positive and negative environmental implications. While it contributes to the production of clean energy, the long-term durability of EVA in this application can make solar panel recycling challenging. As the solar industry continues to grow, finding effective ways to recycle or dispose of EVA-containing panels at the end of their lifecycle is becoming increasingly important.

In the footwear industry, EVA's lightweight and cushioning properties have made it a popular choice for shoe soles. However, the environmental impact of EVA-based footwear has come under scrutiny. Some companies are now exploring more sustainable alternatives or incorporating recycled EVA into their products to reduce their environmental footprint.

As awareness of environmental issues grows, there is an increasing demand for more sustainable EVA alternatives and improved lifecycle management. This has led to ongoing research and development efforts focused on enhancing the environmental performance of EVA throughout its lifecycle, from production to disposal. The future of EVA in advanced materials science will likely involve a balance between its beneficial properties and the need for greater environmental responsibility.

One of the primary environmental challenges associated with EVA is its end-of-life disposal. As a thermoplastic material, EVA can be recycled, but the recycling process is often complex and energy-intensive. Many EVA products end up in landfills or incineration facilities, contributing to waste accumulation and potential soil and water contamination. The slow degradation rate of EVA in natural environments further exacerbates this issue, as it can persist for many years, potentially harming ecosystems and wildlife.

In recent years, efforts have been made to improve the environmental profile of EVA. Researchers are exploring bio-based alternatives and developing more sustainable production methods. Some manufacturers have implemented closed-loop recycling systems to reduce waste and improve resource efficiency. Additionally, there is growing interest in developing biodegradable or compostable EVA formulations to address end-of-life concerns.

The use of EVA in solar panel encapsulation has both positive and negative environmental implications. While it contributes to the production of clean energy, the long-term durability of EVA in this application can make solar panel recycling challenging. As the solar industry continues to grow, finding effective ways to recycle or dispose of EVA-containing panels at the end of their lifecycle is becoming increasingly important.

In the footwear industry, EVA's lightweight and cushioning properties have made it a popular choice for shoe soles. However, the environmental impact of EVA-based footwear has come under scrutiny. Some companies are now exploring more sustainable alternatives or incorporating recycled EVA into their products to reduce their environmental footprint.

As awareness of environmental issues grows, there is an increasing demand for more sustainable EVA alternatives and improved lifecycle management. This has led to ongoing research and development efforts focused on enhancing the environmental performance of EVA throughout its lifecycle, from production to disposal. The future of EVA in advanced materials science will likely involve a balance between its beneficial properties and the need for greater environmental responsibility.

EVA Regulatory Framework

The regulatory framework for Ethylene Vinyl Acetate (EVA) in advanced materials science is a complex and evolving landscape that encompasses various aspects of safety, environmental impact, and quality control. Globally, regulatory bodies have established guidelines and standards to ensure the responsible use of EVA in diverse applications, from solar panel encapsulation to medical devices.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA used in food contact materials and medical devices. The FDA's 21 CFR 177.1350 specifically addresses EVA copolymers intended for use in contact with food, setting limits on the vinyl acetate content and specifying extraction tests to ensure safety. For medical applications, EVA must comply with biocompatibility standards outlined in ISO 10993.

The European Union's regulatory approach to EVA is governed by the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers and importers of EVA must register the substance and provide safety data. The European Food Safety Authority (EFSA) also evaluates EVA for use in food contact materials, ensuring compliance with Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food.

In the context of advanced materials science, particularly in the renewable energy sector, EVA used in photovoltaic modules must adhere to IEC 61730 and IEC 61215 standards. These standards ensure the long-term reliability and safety of solar panels, addressing aspects such as UV resistance, thermal cycling, and humidity-freeze performance of EVA encapsulants.

Environmental regulations also play a significant role in the EVA regulatory framework. Many countries have implemented restrictions on volatile organic compound (VOC) emissions, which affect the production and use of EVA-based adhesives and sealants. For instance, the California Air Resources Board (CARB) has set stringent VOC limits for adhesives and sealants, influencing the formulation of EVA products used in construction and automotive applications.

As sustainability becomes increasingly important, regulations are evolving to address the end-of-life management of EVA-containing products. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive, for example, impacts the recycling and disposal of solar panels, prompting research into more recyclable EVA formulations for photovoltaic encapsulants.

The global nature of EVA supply chains necessitates compliance with international trade regulations. The Harmonized System (HS) codes for EVA and its products are crucial for proper classification in international trade, ensuring compliance with tariffs and trade agreements. Additionally, transportation of EVA materials must adhere to regulations such as the International Maritime Dangerous Goods (IMDG) Code for sea transport and the International Air Transport Association (IATA) Dangerous Goods Regulations for air shipments.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating EVA used in food contact materials and medical devices. The FDA's 21 CFR 177.1350 specifically addresses EVA copolymers intended for use in contact with food, setting limits on the vinyl acetate content and specifying extraction tests to ensure safety. For medical applications, EVA must comply with biocompatibility standards outlined in ISO 10993.

The European Union's regulatory approach to EVA is governed by the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers and importers of EVA must register the substance and provide safety data. The European Food Safety Authority (EFSA) also evaluates EVA for use in food contact materials, ensuring compliance with Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food.

In the context of advanced materials science, particularly in the renewable energy sector, EVA used in photovoltaic modules must adhere to IEC 61730 and IEC 61215 standards. These standards ensure the long-term reliability and safety of solar panels, addressing aspects such as UV resistance, thermal cycling, and humidity-freeze performance of EVA encapsulants.

Environmental regulations also play a significant role in the EVA regulatory framework. Many countries have implemented restrictions on volatile organic compound (VOC) emissions, which affect the production and use of EVA-based adhesives and sealants. For instance, the California Air Resources Board (CARB) has set stringent VOC limits for adhesives and sealants, influencing the formulation of EVA products used in construction and automotive applications.

As sustainability becomes increasingly important, regulations are evolving to address the end-of-life management of EVA-containing products. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive, for example, impacts the recycling and disposal of solar panels, prompting research into more recyclable EVA formulations for photovoltaic encapsulants.

The global nature of EVA supply chains necessitates compliance with international trade regulations. The Harmonized System (HS) codes for EVA and its products are crucial for proper classification in international trade, ensuring compliance with tariffs and trade agreements. Additionally, transportation of EVA materials must adhere to regulations such as the International Maritime Dangerous Goods (IMDG) Code for sea transport and the International Air Transport Association (IATA) Dangerous Goods Regulations for air shipments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!