Ethylene Vinyl Acetate in Renewable Energy Applications

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EVA in Renewable Energy: Background and Objectives

Ethylene Vinyl Acetate (EVA) has emerged as a crucial material in the renewable energy sector, particularly in solar photovoltaic (PV) applications. The evolution of EVA in this field dates back to the 1980s when it was first introduced as an encapsulant material for solar panels. Since then, its role has expanded significantly, driven by the growing demand for more efficient and durable solar energy solutions.

The primary objective of researching EVA in renewable energy applications is to enhance the performance, longevity, and cost-effectiveness of solar PV modules. EVA serves as a protective layer, encapsulating solar cells and shielding them from environmental factors such as moisture, dust, and mechanical stress. Its unique properties, including high transparency, excellent adhesion, and resistance to UV radiation, make it an ideal candidate for this purpose.

As the renewable energy sector continues to grow rapidly, the demand for advanced materials like EVA is expected to surge. The global solar PV market is projected to expand at a compound annual growth rate (CAGR) of over 20% in the coming years, driving the need for innovative EVA formulations and applications. This growth is fueled by increasing environmental concerns, government initiatives promoting clean energy, and the declining costs of solar technology.

The technological evolution of EVA in renewable energy applications has focused on several key areas. These include improving its UV stability to extend the lifespan of solar modules, enhancing its adhesion properties to prevent delamination, and optimizing its optical properties to maximize light transmission to the solar cells. Recent advancements have also explored the incorporation of additives to EVA to improve its thermal management capabilities and resistance to potential induced degradation (PID).

Looking ahead, the research objectives for EVA in renewable energy applications are multifaceted. Scientists and engineers are working towards developing EVA formulations with even higher transparency and lower yellowness index to improve solar cell efficiency. There is also a growing emphasis on creating more environmentally friendly EVA compositions, aligning with the broader sustainability goals of the renewable energy sector.

Another critical research direction is the development of EVA materials that can withstand extreme environmental conditions, enabling the deployment of solar PV systems in diverse geographical locations. This includes improving EVA's resistance to high temperatures, humidity, and salt spray, which are crucial for expanding solar energy adoption in tropical and coastal regions.

In conclusion, the background and objectives of EVA research in renewable energy applications reflect a dynamic and evolving field. As the renewable energy sector continues to grow and face new challenges, the role of materials like EVA becomes increasingly critical in driving innovation and sustainability in solar energy technology.

The primary objective of researching EVA in renewable energy applications is to enhance the performance, longevity, and cost-effectiveness of solar PV modules. EVA serves as a protective layer, encapsulating solar cells and shielding them from environmental factors such as moisture, dust, and mechanical stress. Its unique properties, including high transparency, excellent adhesion, and resistance to UV radiation, make it an ideal candidate for this purpose.

As the renewable energy sector continues to grow rapidly, the demand for advanced materials like EVA is expected to surge. The global solar PV market is projected to expand at a compound annual growth rate (CAGR) of over 20% in the coming years, driving the need for innovative EVA formulations and applications. This growth is fueled by increasing environmental concerns, government initiatives promoting clean energy, and the declining costs of solar technology.

The technological evolution of EVA in renewable energy applications has focused on several key areas. These include improving its UV stability to extend the lifespan of solar modules, enhancing its adhesion properties to prevent delamination, and optimizing its optical properties to maximize light transmission to the solar cells. Recent advancements have also explored the incorporation of additives to EVA to improve its thermal management capabilities and resistance to potential induced degradation (PID).

Looking ahead, the research objectives for EVA in renewable energy applications are multifaceted. Scientists and engineers are working towards developing EVA formulations with even higher transparency and lower yellowness index to improve solar cell efficiency. There is also a growing emphasis on creating more environmentally friendly EVA compositions, aligning with the broader sustainability goals of the renewable energy sector.

Another critical research direction is the development of EVA materials that can withstand extreme environmental conditions, enabling the deployment of solar PV systems in diverse geographical locations. This includes improving EVA's resistance to high temperatures, humidity, and salt spray, which are crucial for expanding solar energy adoption in tropical and coastal regions.

In conclusion, the background and objectives of EVA research in renewable energy applications reflect a dynamic and evolving field. As the renewable energy sector continues to grow and face new challenges, the role of materials like EVA becomes increasingly critical in driving innovation and sustainability in solar energy technology.

Market Analysis for EVA in Clean Energy Sector

The market for Ethylene Vinyl Acetate (EVA) in the clean energy sector has experienced significant growth in recent years, driven by the increasing adoption of renewable energy technologies. EVA plays a crucial role in the production of solar panels, particularly in the encapsulation of photovoltaic cells, which has become its primary application in the clean energy industry.

The global solar energy market has been expanding rapidly, with a compound annual growth rate (CAGR) exceeding 20% over the past decade. This growth has directly contributed to the increased demand for EVA in solar panel manufacturing. The photovoltaic industry accounts for a substantial portion of the total EVA consumption, with estimates suggesting that over 80% of EVA used in clean energy applications is dedicated to solar panel production.

In terms of regional distribution, Asia-Pacific dominates the EVA market for clean energy applications, with China being the largest consumer and producer. This is primarily due to China's position as the world's leading manufacturer of solar panels. Europe and North America follow as significant markets, driven by their strong commitment to renewable energy adoption and supportive government policies.

The demand for EVA in the clean energy sector is expected to continue its upward trajectory, fueled by several factors. Firstly, the global push towards sustainable energy sources and the reduction of carbon emissions is driving investments in solar energy infrastructure. Secondly, technological advancements in solar panel efficiency and durability are increasing the need for high-quality EVA encapsulants. Lastly, the decreasing costs of solar energy systems are making them more accessible to a broader range of consumers, further boosting demand.

However, the market also faces certain challenges. The volatility in raw material prices, particularly ethylene and vinyl acetate monomer, can impact the production costs and, consequently, the market dynamics of EVA. Additionally, the emergence of alternative encapsulant materials, such as polyolefin elastomers (POE), poses a potential threat to EVA's market share in solar panel applications.

Despite these challenges, the overall outlook for EVA in the clean energy sector remains positive. The material's excellent properties, including high transparency, low water absorption, and good adhesion to glass and silicon cells, continue to make it a preferred choice for solar panel manufacturers. Furthermore, ongoing research and development efforts are focused on enhancing EVA's performance characteristics, potentially opening up new applications within the clean energy sector beyond solar panels.

The global solar energy market has been expanding rapidly, with a compound annual growth rate (CAGR) exceeding 20% over the past decade. This growth has directly contributed to the increased demand for EVA in solar panel manufacturing. The photovoltaic industry accounts for a substantial portion of the total EVA consumption, with estimates suggesting that over 80% of EVA used in clean energy applications is dedicated to solar panel production.

In terms of regional distribution, Asia-Pacific dominates the EVA market for clean energy applications, with China being the largest consumer and producer. This is primarily due to China's position as the world's leading manufacturer of solar panels. Europe and North America follow as significant markets, driven by their strong commitment to renewable energy adoption and supportive government policies.

The demand for EVA in the clean energy sector is expected to continue its upward trajectory, fueled by several factors. Firstly, the global push towards sustainable energy sources and the reduction of carbon emissions is driving investments in solar energy infrastructure. Secondly, technological advancements in solar panel efficiency and durability are increasing the need for high-quality EVA encapsulants. Lastly, the decreasing costs of solar energy systems are making them more accessible to a broader range of consumers, further boosting demand.

However, the market also faces certain challenges. The volatility in raw material prices, particularly ethylene and vinyl acetate monomer, can impact the production costs and, consequently, the market dynamics of EVA. Additionally, the emergence of alternative encapsulant materials, such as polyolefin elastomers (POE), poses a potential threat to EVA's market share in solar panel applications.

Despite these challenges, the overall outlook for EVA in the clean energy sector remains positive. The material's excellent properties, including high transparency, low water absorption, and good adhesion to glass and silicon cells, continue to make it a preferred choice for solar panel manufacturers. Furthermore, ongoing research and development efforts are focused on enhancing EVA's performance characteristics, potentially opening up new applications within the clean energy sector beyond solar panels.

Current Challenges in EVA for Renewable Applications

Despite the widespread adoption of Ethylene Vinyl Acetate (EVA) in renewable energy applications, particularly in solar panel encapsulation, several challenges persist that hinder its optimal performance and longevity. One of the primary concerns is the material's susceptibility to degradation under prolonged exposure to UV radiation and high temperatures. This degradation can lead to discoloration, reduced light transmission, and compromised structural integrity of solar modules, ultimately affecting their efficiency and lifespan.

Another significant challenge is the potential for moisture ingress in EVA-encapsulated solar panels. While EVA provides good initial moisture resistance, long-term exposure to humid environments can result in water vapor permeation, leading to delamination, corrosion of metal components, and reduced module performance. This issue is particularly pronounced in coastal or high-humidity regions, necessitating improved moisture barrier properties in EVA formulations.

The thermal management of EVA in solar applications also presents ongoing challenges. As solar panels operate at elevated temperatures, the thermal expansion and contraction of EVA can induce stress on the module components, potentially leading to microcracks in solar cells or delamination at interfaces. Developing EVA formulations with enhanced thermal stability and reduced coefficient of thermal expansion remains a key focus area for researchers and manufacturers.

Furthermore, the crosslinking process of EVA during module lamination poses challenges in terms of process control and quality assurance. Achieving uniform and optimal crosslinking across large-area modules is critical for ensuring consistent performance and durability. Variations in crosslinking density can lead to localized degradation and reduced module reliability over time.

The environmental impact and end-of-life management of EVA-based solar modules also present significant challenges. As the solar industry grows, the volume of decommissioned panels is expected to increase substantially. The current limitations in recycling EVA-encapsulated modules efficiently and cost-effectively pose environmental concerns and hinder the circular economy goals of the renewable energy sector.

Lastly, the balance between cost and performance remains a persistent challenge in EVA formulation for renewable energy applications. While advanced additives and co-polymers can enhance EVA's properties, their incorporation often comes at a higher cost. Striking the right balance between improved performance characteristics and economic viability is crucial for the widespread adoption of next-generation EVA materials in the renewable energy market.

Another significant challenge is the potential for moisture ingress in EVA-encapsulated solar panels. While EVA provides good initial moisture resistance, long-term exposure to humid environments can result in water vapor permeation, leading to delamination, corrosion of metal components, and reduced module performance. This issue is particularly pronounced in coastal or high-humidity regions, necessitating improved moisture barrier properties in EVA formulations.

The thermal management of EVA in solar applications also presents ongoing challenges. As solar panels operate at elevated temperatures, the thermal expansion and contraction of EVA can induce stress on the module components, potentially leading to microcracks in solar cells or delamination at interfaces. Developing EVA formulations with enhanced thermal stability and reduced coefficient of thermal expansion remains a key focus area for researchers and manufacturers.

Furthermore, the crosslinking process of EVA during module lamination poses challenges in terms of process control and quality assurance. Achieving uniform and optimal crosslinking across large-area modules is critical for ensuring consistent performance and durability. Variations in crosslinking density can lead to localized degradation and reduced module reliability over time.

The environmental impact and end-of-life management of EVA-based solar modules also present significant challenges. As the solar industry grows, the volume of decommissioned panels is expected to increase substantially. The current limitations in recycling EVA-encapsulated modules efficiently and cost-effectively pose environmental concerns and hinder the circular economy goals of the renewable energy sector.

Lastly, the balance between cost and performance remains a persistent challenge in EVA formulation for renewable energy applications. While advanced additives and co-polymers can enhance EVA's properties, their incorporation often comes at a higher cost. Striking the right balance between improved performance characteristics and economic viability is crucial for the widespread adoption of next-generation EVA materials in the renewable energy market.

Existing EVA Solutions for Renewable Energy

01 Composition and properties of EVA

Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to achieve specific material characteristics for various applications.- Composition and properties of EVA: Ethylene Vinyl Acetate (EVA) is a copolymer of ethylene and vinyl acetate. It exhibits properties such as flexibility, toughness, and resistance to stress-cracking. The composition and ratio of ethylene to vinyl acetate can be adjusted to modify the properties of the resulting material, making it suitable for various applications.

- EVA in adhesive applications: EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It can be used in hot melt adhesives, pressure-sensitive adhesives, and as a base polymer in adhesive blends. The adhesive strength and performance can be tailored by adjusting the EVA composition and incorporating additives.

- EVA in foam and insulation materials: EVA is utilized in the production of foam and insulation materials due to its low density, good cushioning properties, and thermal insulation characteristics. It can be processed into closed-cell foams for applications such as footwear, sports equipment, and building insulation. The foam density and properties can be controlled through formulation and processing techniques.

- EVA in solar panel encapsulation: EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and protection for solar cells. The material's ability to withstand UV radiation and environmental factors makes it suitable for long-term outdoor applications in solar panel manufacturing.

- Modifications and blends of EVA: EVA can be modified or blended with other polymers and additives to enhance its properties or create new materials with specific characteristics. This includes crosslinking, grafting, and compounding with fillers or other polymers. Such modifications can improve properties like heat resistance, mechanical strength, or compatibility with other materials for various industrial applications.

02 EVA in adhesive applications

EVA is widely used in adhesive formulations due to its excellent adhesion properties and compatibility with various substrates. It is particularly useful in hot melt adhesives, providing good bond strength and flexibility. EVA-based adhesives find applications in packaging, bookbinding, and product assembly.Expand Specific Solutions03 EVA in foam and insulation materials

EVA is utilized in the production of foam and insulation materials. Its closed-cell structure and low thermal conductivity make it suitable for applications such as footwear, sports equipment, and building insulation. EVA foams offer cushioning, shock absorption, and thermal insulation properties.Expand Specific Solutions04 EVA in solar panel encapsulation

EVA is commonly used as an encapsulant material in photovoltaic modules. It provides excellent transparency, weatherability, and electrical insulation properties. EVA encapsulants protect solar cells from environmental factors and enhance the overall performance and durability of solar panels.Expand Specific Solutions05 EVA in film and packaging applications

EVA is employed in the production of flexible films and packaging materials. Its properties such as clarity, flexibility, and heat-sealing capabilities make it suitable for food packaging, agricultural films, and stretch wraps. EVA films offer good barrier properties and can be easily processed using various film extrusion techniques.Expand Specific Solutions

Key Players in EVA and Renewable Energy Market

The research on Ethylene Vinyl Acetate (EVA) in renewable energy applications is in a growth phase, with increasing market size and technological advancements. The global EVA market is expanding, driven by its versatile properties and growing demand in solar panel encapsulation. Technologically, EVA is evolving from a mature material to an advanced one with enhanced properties for renewable energy applications. Companies like China Petroleum & Chemical Corp., Celanese International Corp., and Hanwha Chemical Co., Ltd. are leading the development, while research institutions such as Tianjin University and Washington State University contribute to innovation. Emerging players like Velocys, Inc. and Resonac Corp. are also making strides in this field, indicating a competitive and dynamic market landscape.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced EVA copolymer technology for renewable energy applications, particularly in solar panel encapsulation. Their research focuses on improving the crosslinking density and weatherability of EVA films, resulting in enhanced durability and performance of photovoltaic modules. Sinopec has implemented a proprietary manufacturing process that allows for precise control of vinyl acetate content, typically ranging from 28-33% for solar applications[1]. This optimized composition ensures excellent light transmission, low yellowing index, and superior adhesion to solar cells. Additionally, Sinopec has invested in developing EVA grades with improved thermal stability and UV resistance, addressing key challenges in long-term outdoor exposure of solar panels[2].

Strengths: Extensive petrochemical expertise, large-scale production capabilities, and strong R&D infrastructure. Weaknesses: Potential environmental concerns associated with fossil fuel-based raw materials and production processes.

Celanese International Corp.

Technical Solution: Celanese International Corp. has made significant strides in EVA research for renewable energy applications, particularly focusing on wind turbine blade manufacturing. Their innovative EVA-based structural adhesives offer improved bonding strength and fatigue resistance, critical for the longevity of wind turbine blades. Celanese has developed a range of EVA grades with varying vinyl acetate content (15-40%) to meet specific requirements of different blade designs[3]. Their proprietary crosslinking technology ensures optimal curing profiles, resulting in enhanced mechanical properties and moisture resistance. Furthermore, Celanese has introduced EVA formulations with nano-reinforcements, which have shown a 20-30% improvement in interfacial shear strength compared to conventional adhesives[4].

Strengths: Strong polymer science expertise, global manufacturing presence, and diverse product portfolio. Weaknesses: Potential cost challenges in scaling up advanced formulations for widespread adoption in the renewable energy sector.

Innovations in EVA for Clean Energy Applications

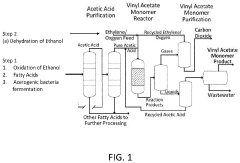

Bio-based eva compositions and articles and methods thereof

PatentPendingUS20220185922A1

Innovation

- The development of bio-based ethylene vinyl acetate copolymers where ethylene is partially sourced from renewable carbon sources, such as plant materials, through fermentation and dehydration processes, combined with peroxide agents and blowing agents to create curable and expandable polymer compositions.

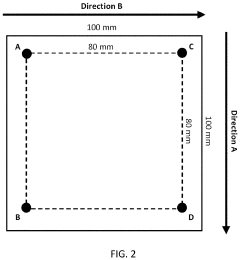

Polymer, and solar cell sealant using same

PatentWO2013073708A1

Innovation

- A polymer with specific repeating units and structural requirements, including a ratio of repeating units and a melting point range, is developed to enhance weather resistance, transparency, and processability, comprising repeating units represented by formulas (1) and (2), with a melting point between 42°C and 90°C, and a ratio of repeating units (2) to the total carbon atoms in the polymer main chain between 3.8% and 7.5%, ensuring improved encapsulant performance.

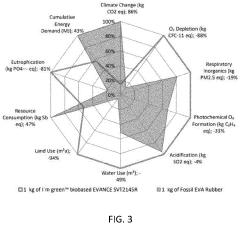

Environmental Impact of EVA in Clean Energy

The environmental impact of Ethylene Vinyl Acetate (EVA) in clean energy applications is a critical consideration as the renewable energy sector continues to grow. EVA, a copolymer of ethylene and vinyl acetate, has found widespread use in solar panel encapsulation due to its excellent optical properties, durability, and weather resistance. However, its environmental footprint throughout its lifecycle warrants careful examination.

In the production phase, EVA manufacturing involves the use of petrochemical feedstocks, which contribute to greenhouse gas emissions and resource depletion. The polymerization process requires significant energy input, further adding to its carbon footprint. However, compared to alternative materials, EVA production generally has a lower environmental impact due to its relatively simple manufacturing process and the ability to recycle production waste.

During the use phase in solar panels, EVA plays a crucial role in extending the lifespan of photovoltaic modules. Its protective properties help maintain panel efficiency over time, indirectly contributing to increased clean energy generation and reduced reliance on fossil fuels. This positive impact partially offsets the initial environmental costs associated with its production.

End-of-life considerations for EVA in solar panels present both challenges and opportunities. While EVA is not biodegradable, recent advancements in recycling technologies have made it possible to recover and repurpose EVA from decommissioned solar panels. This development significantly reduces the potential environmental burden of EVA waste in landfills and promotes a more circular economy approach in the renewable energy sector.

The environmental impact of EVA also extends to its potential for reducing the overall carbon footprint of renewable energy technologies. By enhancing the durability and performance of solar panels, EVA indirectly contributes to the increased adoption of clean energy solutions, potentially leading to a net positive environmental impact when considering the broader context of energy transition and climate change mitigation.

However, concerns remain regarding the potential release of microplastics from weathered EVA in outdoor applications. While the extent of this issue is still under investigation, it highlights the need for ongoing research into more environmentally friendly alternatives or improved end-of-life management strategies for EVA in clean energy applications.

In conclusion, while EVA's use in renewable energy technologies presents some environmental challenges, its overall impact appears to be largely positive when considering its role in advancing clean energy adoption. Continued research into greener production methods, enhanced recycling techniques, and potential bio-based alternatives will be crucial in further improving the environmental profile of EVA in the clean energy sector.

In the production phase, EVA manufacturing involves the use of petrochemical feedstocks, which contribute to greenhouse gas emissions and resource depletion. The polymerization process requires significant energy input, further adding to its carbon footprint. However, compared to alternative materials, EVA production generally has a lower environmental impact due to its relatively simple manufacturing process and the ability to recycle production waste.

During the use phase in solar panels, EVA plays a crucial role in extending the lifespan of photovoltaic modules. Its protective properties help maintain panel efficiency over time, indirectly contributing to increased clean energy generation and reduced reliance on fossil fuels. This positive impact partially offsets the initial environmental costs associated with its production.

End-of-life considerations for EVA in solar panels present both challenges and opportunities. While EVA is not biodegradable, recent advancements in recycling technologies have made it possible to recover and repurpose EVA from decommissioned solar panels. This development significantly reduces the potential environmental burden of EVA waste in landfills and promotes a more circular economy approach in the renewable energy sector.

The environmental impact of EVA also extends to its potential for reducing the overall carbon footprint of renewable energy technologies. By enhancing the durability and performance of solar panels, EVA indirectly contributes to the increased adoption of clean energy solutions, potentially leading to a net positive environmental impact when considering the broader context of energy transition and climate change mitigation.

However, concerns remain regarding the potential release of microplastics from weathered EVA in outdoor applications. While the extent of this issue is still under investigation, it highlights the need for ongoing research into more environmentally friendly alternatives or improved end-of-life management strategies for EVA in clean energy applications.

In conclusion, while EVA's use in renewable energy technologies presents some environmental challenges, its overall impact appears to be largely positive when considering its role in advancing clean energy adoption. Continued research into greener production methods, enhanced recycling techniques, and potential bio-based alternatives will be crucial in further improving the environmental profile of EVA in the clean energy sector.

Cost-Benefit Analysis of EVA in Renewable Energy

The cost-benefit analysis of Ethylene Vinyl Acetate (EVA) in renewable energy applications reveals a complex interplay of economic factors and performance advantages. Initial investment in EVA-based components, such as encapsulants for solar panels, may be higher compared to traditional materials. However, the long-term benefits often outweigh these upfront costs.

EVA's superior durability and weather resistance contribute to extended lifespans of renewable energy systems, particularly in solar photovoltaic (PV) installations. This longevity translates to reduced maintenance and replacement costs over the operational life of the equipment. Studies have shown that EVA-encapsulated solar panels can maintain over 90% of their initial efficiency after 25 years, significantly enhancing the return on investment for solar projects.

The flexibility and adhesive properties of EVA allow for more efficient manufacturing processes in renewable energy equipment production. This streamlined manufacturing can lead to cost savings in large-scale production scenarios, partially offsetting the higher material costs. Additionally, EVA's excellent electrical insulation properties contribute to improved safety and reliability, potentially reducing insurance costs and minimizing downtime due to equipment failures.

In wind energy applications, EVA-based composites used in turbine blades offer a balance between strength and weight. This optimization results in improved energy capture efficiency and reduced structural loads on the turbine, potentially extending the operational lifespan and reducing maintenance requirements. The cost benefits here are realized through increased energy output and decreased lifecycle costs.

However, the volatility of raw material prices for EVA production can impact the cost-benefit equation. Fluctuations in ethylene and vinyl acetate prices may affect the overall economics of EVA use in renewable energy applications. This necessitates careful supply chain management and potentially long-term contracts to stabilize costs.

Environmental considerations also play a role in the cost-benefit analysis. EVA's recyclability at the end of its life cycle can contribute to reduced waste management costs and align with circular economy principles, potentially offering both economic and environmental benefits in the long run.

In conclusion, while the initial costs of incorporating EVA in renewable energy applications may be higher, the long-term economic benefits derived from improved performance, durability, and efficiency often justify the investment. As the renewable energy sector continues to grow and evolve, ongoing research and development in EVA applications are likely to further enhance its cost-effectiveness and expand its role in sustainable energy solutions.

EVA's superior durability and weather resistance contribute to extended lifespans of renewable energy systems, particularly in solar photovoltaic (PV) installations. This longevity translates to reduced maintenance and replacement costs over the operational life of the equipment. Studies have shown that EVA-encapsulated solar panels can maintain over 90% of their initial efficiency after 25 years, significantly enhancing the return on investment for solar projects.

The flexibility and adhesive properties of EVA allow for more efficient manufacturing processes in renewable energy equipment production. This streamlined manufacturing can lead to cost savings in large-scale production scenarios, partially offsetting the higher material costs. Additionally, EVA's excellent electrical insulation properties contribute to improved safety and reliability, potentially reducing insurance costs and minimizing downtime due to equipment failures.

In wind energy applications, EVA-based composites used in turbine blades offer a balance between strength and weight. This optimization results in improved energy capture efficiency and reduced structural loads on the turbine, potentially extending the operational lifespan and reducing maintenance requirements. The cost benefits here are realized through increased energy output and decreased lifecycle costs.

However, the volatility of raw material prices for EVA production can impact the cost-benefit equation. Fluctuations in ethylene and vinyl acetate prices may affect the overall economics of EVA use in renewable energy applications. This necessitates careful supply chain management and potentially long-term contracts to stabilize costs.

Environmental considerations also play a role in the cost-benefit analysis. EVA's recyclability at the end of its life cycle can contribute to reduced waste management costs and align with circular economy principles, potentially offering both economic and environmental benefits in the long run.

In conclusion, while the initial costs of incorporating EVA in renewable energy applications may be higher, the long-term economic benefits derived from improved performance, durability, and efficiency often justify the investment. As the renewable energy sector continues to grow and evolve, ongoing research and development in EVA applications are likely to further enhance its cost-effectiveness and expand its role in sustainable energy solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!