High-Entropy Alloys in Developing Lightweight Automotive Components

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Alloys Background and Objectives

High-entropy alloys (HEAs) represent a revolutionary paradigm shift in metallurgical science that emerged in the early 2000s. Unlike conventional alloys that typically contain one principal element with minor additions, HEAs consist of five or more principal elements in near-equiatomic proportions. This fundamental departure from traditional alloy design has opened new frontiers in materials science, particularly for automotive applications where the simultaneous demands for weight reduction, strength enhancement, and improved durability present significant engineering challenges.

The evolution of HEAs has progressed through several distinct phases, beginning with conceptual development and fundamental characterization, followed by exploration of processing techniques, and now advancing toward targeted application development. Recent technological trends indicate a growing interest in leveraging the unique properties of HEAs—including exceptional strength-to-weight ratios, superior wear resistance, and remarkable thermal stability—specifically for automotive component design.

The automotive industry's push toward electrification and sustainability has intensified the need for lightweight materials that do not compromise on performance or safety. Traditional lightweight materials such as aluminum and magnesium alloys often face limitations in terms of strength, corrosion resistance, or high-temperature performance. HEAs present a promising alternative that potentially addresses these shortcomings through their customizable microstructures and adaptable property profiles.

The primary technical objectives of this research are multifaceted. First, to systematically investigate composition-processing-structure-property relationships in HEAs specifically tailored for automotive applications. Second, to develop scalable manufacturing processes that enable cost-effective production of HEA components with consistent properties. Third, to design and validate HEA-based automotive components that achieve at least 25% weight reduction compared to conventional steel components while maintaining or improving mechanical performance.

Additionally, this research aims to establish comprehensive material property databases for automotive-relevant HEAs, enabling computational modeling and accelerated alloy design. The development of non-destructive testing methodologies specific to HEA components represents another critical objective, as these will be essential for quality assurance in production environments.

The long-term technological trajectory suggests that HEAs could fundamentally transform automotive material selection paradigms, potentially enabling vehicle weight reductions that contribute significantly to improved fuel efficiency and reduced emissions in conventional vehicles, as well as extended range in electric vehicles. This research positions our organization at the forefront of this transformative materials revolution.

The evolution of HEAs has progressed through several distinct phases, beginning with conceptual development and fundamental characterization, followed by exploration of processing techniques, and now advancing toward targeted application development. Recent technological trends indicate a growing interest in leveraging the unique properties of HEAs—including exceptional strength-to-weight ratios, superior wear resistance, and remarkable thermal stability—specifically for automotive component design.

The automotive industry's push toward electrification and sustainability has intensified the need for lightweight materials that do not compromise on performance or safety. Traditional lightweight materials such as aluminum and magnesium alloys often face limitations in terms of strength, corrosion resistance, or high-temperature performance. HEAs present a promising alternative that potentially addresses these shortcomings through their customizable microstructures and adaptable property profiles.

The primary technical objectives of this research are multifaceted. First, to systematically investigate composition-processing-structure-property relationships in HEAs specifically tailored for automotive applications. Second, to develop scalable manufacturing processes that enable cost-effective production of HEA components with consistent properties. Third, to design and validate HEA-based automotive components that achieve at least 25% weight reduction compared to conventional steel components while maintaining or improving mechanical performance.

Additionally, this research aims to establish comprehensive material property databases for automotive-relevant HEAs, enabling computational modeling and accelerated alloy design. The development of non-destructive testing methodologies specific to HEA components represents another critical objective, as these will be essential for quality assurance in production environments.

The long-term technological trajectory suggests that HEAs could fundamentally transform automotive material selection paradigms, potentially enabling vehicle weight reductions that contribute significantly to improved fuel efficiency and reduced emissions in conventional vehicles, as well as extended range in electric vehicles. This research positions our organization at the forefront of this transformative materials revolution.

Market Demand for Lightweight Automotive Materials

The automotive industry is experiencing a significant shift towards lightweight materials driven by stringent fuel efficiency regulations and growing environmental concerns. Global CO2 emission standards have tightened considerably, with the European Union mandating fleet-wide average emissions of 95g CO2/km by 2021 and further reductions planned for 2025 and 2030. Similarly, the United States CAFE standards require manufacturers to achieve an average of 54.5 mpg by 2025. These regulatory pressures have created an urgent market demand for innovative lightweight materials.

Weight reduction directly correlates with improved fuel efficiency, with studies showing that a 10% reduction in vehicle weight can improve fuel economy by 6-8%. For electric vehicles, weight reduction extends range capabilities, addressing a primary consumer concern. This has catalyzed market growth for lightweight automotive materials, with the global market valued at $88.5 billion in 2020 and projected to reach $126.7 billion by 2026, growing at a CAGR of 7.3%.

Traditional lightweight materials such as aluminum, magnesium, and carbon fiber composites have dominated the market. However, these materials face limitations in terms of cost, manufacturing complexity, or performance characteristics. Aluminum, while offering a 40% weight reduction compared to steel, provides lower strength. Carbon fiber composites deliver superior strength-to-weight ratios but at significantly higher costs, limiting widespread adoption to premium vehicle segments.

This creates a substantial market gap for innovative materials that can deliver the optimal balance of weight reduction, strength, manufacturability, and cost-effectiveness. High-entropy alloys (HEAs) have emerged as promising candidates to fill this gap, potentially offering superior mechanical properties, excellent corrosion resistance, and high-temperature stability compared to conventional alloys.

Automotive manufacturers are increasingly willing to invest in advanced materials research, with major OEMs allocating substantial R&D budgets toward lightweight material development. BMW's investment in carbon fiber technology and Tesla's continuous material innovation exemplify this trend. Tier 1 suppliers are similarly expanding their lightweight material capabilities through strategic acquisitions and partnerships.

Consumer preferences are also driving demand for lightweight materials, with growing awareness of environmental impacts and fuel costs. Premium vehicle buyers increasingly value sustainability credentials, creating market pull for advanced materials with superior environmental performance. The rapid growth of the electric vehicle segment further amplifies demand for lightweight solutions that can extend range capabilities without compromising safety or performance.

Weight reduction directly correlates with improved fuel efficiency, with studies showing that a 10% reduction in vehicle weight can improve fuel economy by 6-8%. For electric vehicles, weight reduction extends range capabilities, addressing a primary consumer concern. This has catalyzed market growth for lightweight automotive materials, with the global market valued at $88.5 billion in 2020 and projected to reach $126.7 billion by 2026, growing at a CAGR of 7.3%.

Traditional lightweight materials such as aluminum, magnesium, and carbon fiber composites have dominated the market. However, these materials face limitations in terms of cost, manufacturing complexity, or performance characteristics. Aluminum, while offering a 40% weight reduction compared to steel, provides lower strength. Carbon fiber composites deliver superior strength-to-weight ratios but at significantly higher costs, limiting widespread adoption to premium vehicle segments.

This creates a substantial market gap for innovative materials that can deliver the optimal balance of weight reduction, strength, manufacturability, and cost-effectiveness. High-entropy alloys (HEAs) have emerged as promising candidates to fill this gap, potentially offering superior mechanical properties, excellent corrosion resistance, and high-temperature stability compared to conventional alloys.

Automotive manufacturers are increasingly willing to invest in advanced materials research, with major OEMs allocating substantial R&D budgets toward lightweight material development. BMW's investment in carbon fiber technology and Tesla's continuous material innovation exemplify this trend. Tier 1 suppliers are similarly expanding their lightweight material capabilities through strategic acquisitions and partnerships.

Consumer preferences are also driving demand for lightweight materials, with growing awareness of environmental impacts and fuel costs. Premium vehicle buyers increasingly value sustainability credentials, creating market pull for advanced materials with superior environmental performance. The rapid growth of the electric vehicle segment further amplifies demand for lightweight solutions that can extend range capabilities without compromising safety or performance.

Current Status and Challenges in HEA Development

High-entropy alloys (HEAs) have emerged as a promising class of materials in the global materials science landscape, with significant research activities concentrated in China, the United States, Europe, and Japan. Currently, the development of HEAs for lightweight automotive applications faces several critical challenges despite notable progress in recent years. The fundamental challenge lies in simultaneously achieving weight reduction while maintaining or enhancing mechanical properties required for automotive structural components.

The current state of HEA development shows promising results in laboratory settings, with some alloys demonstrating exceptional combinations of strength, ductility, and corrosion resistance. However, scaling these laboratory successes to industrial production volumes remains problematic. Manufacturing processes for HEAs, particularly those containing lightweight elements like aluminum, magnesium, and titanium, require precise control of processing parameters to achieve desired microstructures and properties.

A significant technical barrier is the inherent trade-off between density reduction and mechanical performance. While conventional lightweight alloys sacrifice strength for weight reduction, HEAs offer potential solutions through their unique solid-solution strengthening mechanisms. Nevertheless, the incorporation of lightweight elements often leads to phase separation or intermetallic compound formation, compromising the high-entropy effect that gives these alloys their desirable properties.

Cost factors present another substantial challenge. The inclusion of expensive elements like titanium, niobium, or scandium—often necessary for property enhancement—significantly increases material costs, making mass production economically unfeasible for automotive applications. Additionally, many promising HEA compositions contain critical raw materials with supply chain vulnerabilities.

Processing challenges further complicate HEA development. Traditional casting methods often result in segregation and inhomogeneity in HEAs, while powder metallurgy approaches face issues with oxidation of reactive elements. Advanced manufacturing techniques like additive manufacturing show promise but currently lack the throughput needed for automotive-scale production.

Characterization and testing methodologies for HEAs also require standardization. The complex microstructures of these alloys necessitate sophisticated analytical techniques, and accelerated testing protocols for predicting long-term performance in automotive environments are still under development.

Regulatory and sustainability considerations add another layer of complexity. Environmental regulations increasingly demand recyclability and life-cycle assessment of automotive materials, areas where HEAs have limited established protocols. Furthermore, the environmental impact of extracting and processing the diverse elements used in HEAs requires thorough evaluation to ensure alignment with sustainability goals in the automotive industry.

The current state of HEA development shows promising results in laboratory settings, with some alloys demonstrating exceptional combinations of strength, ductility, and corrosion resistance. However, scaling these laboratory successes to industrial production volumes remains problematic. Manufacturing processes for HEAs, particularly those containing lightweight elements like aluminum, magnesium, and titanium, require precise control of processing parameters to achieve desired microstructures and properties.

A significant technical barrier is the inherent trade-off between density reduction and mechanical performance. While conventional lightweight alloys sacrifice strength for weight reduction, HEAs offer potential solutions through their unique solid-solution strengthening mechanisms. Nevertheless, the incorporation of lightweight elements often leads to phase separation or intermetallic compound formation, compromising the high-entropy effect that gives these alloys their desirable properties.

Cost factors present another substantial challenge. The inclusion of expensive elements like titanium, niobium, or scandium—often necessary for property enhancement—significantly increases material costs, making mass production economically unfeasible for automotive applications. Additionally, many promising HEA compositions contain critical raw materials with supply chain vulnerabilities.

Processing challenges further complicate HEA development. Traditional casting methods often result in segregation and inhomogeneity in HEAs, while powder metallurgy approaches face issues with oxidation of reactive elements. Advanced manufacturing techniques like additive manufacturing show promise but currently lack the throughput needed for automotive-scale production.

Characterization and testing methodologies for HEAs also require standardization. The complex microstructures of these alloys necessitate sophisticated analytical techniques, and accelerated testing protocols for predicting long-term performance in automotive environments are still under development.

Regulatory and sustainability considerations add another layer of complexity. Environmental regulations increasingly demand recyclability and life-cycle assessment of automotive materials, areas where HEAs have limited established protocols. Furthermore, the environmental impact of extracting and processing the diverse elements used in HEAs requires thorough evaluation to ensure alignment with sustainability goals in the automotive industry.

Current HEA Solutions for Automotive Components

01 Composition and design of high-entropy alloys for weight reduction

High-entropy alloys can be designed with specific elemental compositions to achieve reduced weight while maintaining structural integrity. These alloys typically incorporate lightweight elements such as aluminum, titanium, or magnesium alongside transition metals to create multi-principal element systems with favorable strength-to-weight ratios. The careful selection of elements with varying atomic weights allows for the development of lightweight high-entropy alloys suitable for aerospace and automotive applications.- Lightweight high-entropy alloys composition: High-entropy alloys can be formulated with lightweight elements to reduce overall weight while maintaining desirable properties. These compositions typically incorporate elements like aluminum, titanium, magnesium, and lithium in specific proportions to create lightweight alloys with high strength-to-weight ratios. The careful selection of elements and their proportions allows for the development of alloys that combine low density with excellent mechanical properties.

- Manufacturing methods for weight-optimized HEAs: Various manufacturing techniques can be employed to produce high-entropy alloys with optimized weight characteristics. These methods include mechanical alloying, powder metallurgy, additive manufacturing, and rapid solidification processes. Each technique offers different advantages in controlling the microstructure, grain size, and phase formation, which directly impact the weight and mechanical properties of the final alloy. Process parameters can be adjusted to achieve the desired balance between weight reduction and performance characteristics.

- Density control in high-entropy alloys: Controlling the density of high-entropy alloys is crucial for weight-sensitive applications. This can be achieved through precise element selection, controlling phase formation, and manipulating the atomic packing factor. By incorporating elements with lower atomic weights in specific ratios, researchers can develop high-entropy alloys with reduced density while maintaining or enhancing other desirable properties such as strength, corrosion resistance, and thermal stability.

- Weight-strength balance in high-entropy alloys: Achieving an optimal balance between weight reduction and mechanical strength is a key consideration in high-entropy alloy development. This involves careful selection of constituent elements, precise control of microstructure, and strategic incorporation of strengthening mechanisms such as solid solution strengthening, precipitation hardening, and grain refinement. Advanced characterization techniques help in understanding the relationship between composition, structure, and properties, enabling the design of alloys with exceptional strength-to-weight ratios.

- Applications of lightweight high-entropy alloys: Lightweight high-entropy alloys find applications in various industries where weight reduction is critical. These include aerospace components, automotive parts, sporting equipment, and medical implants. The combination of low weight, high strength, excellent corrosion resistance, and good thermal stability makes these alloys particularly valuable for structural applications in transportation and energy sectors. Their unique properties also make them suitable for specialized applications such as radiation shielding and ballistic protection.

02 Manufacturing processes affecting weight characteristics of high-entropy alloys

Various manufacturing processes can be employed to control the density and weight properties of high-entropy alloys. Techniques such as powder metallurgy, selective laser melting, and mechanical alloying enable the creation of alloys with controlled porosity and microstructure, which directly influence the weight characteristics. Post-processing treatments like heat treatment and hot isostatic pressing can further optimize the weight-to-strength ratio by refining grain structure and eliminating defects.Expand Specific Solutions03 Lightweight high-entropy alloys for structural applications

Specialized high-entropy alloys have been developed specifically for structural applications where weight is a critical factor. These alloys combine the benefits of compositional complexity with reduced density, making them suitable for load-bearing components in weight-sensitive industries. The unique combination of strength, ductility, and reduced weight makes these alloys particularly valuable for aerospace structures, transportation systems, and energy applications where weight reduction directly impacts efficiency.Expand Specific Solutions04 Characterization and testing methods for weight properties of high-entropy alloys

Various analytical and testing methodologies are employed to characterize the weight properties of high-entropy alloys. These include density measurements, specific gravity testing, and advanced techniques like X-ray diffraction and neutron scattering to understand atomic packing and its relationship to weight. Computational methods and modeling approaches are also used to predict and optimize the weight characteristics of high-entropy alloys before physical production.Expand Specific Solutions05 Relationship between phase formation and weight in high-entropy alloys

The phase composition and crystal structure of high-entropy alloys significantly impact their weight properties. Research has shown that controlling phase formation through composition adjustment and processing parameters can lead to optimized weight characteristics. Single-phase solid solutions typically offer different weight properties compared to multi-phase structures, and the presence of intermetallic compounds can also affect the overall density and weight of the alloy system.Expand Specific Solutions

Key Industry Players in HEA Research and Automotive Applications

High-entropy alloys (HEAs) for lightweight automotive components represent an emerging field in the early growth stage, with significant research momentum but limited commercial applications. The global market for advanced automotive materials is projected to reach $125 billion by 2025, with HEAs poised to capture an increasing share as weight reduction becomes critical for electric vehicles. Academic institutions lead current research efforts, with universities like Central South University, Shanghai University, and Korea University developing fundamental technologies. Commercial players including LG Electronics, RTX Corp., and Mazda are beginning to transition research into practical applications, though technical challenges in manufacturing scalability and cost-effectiveness remain. The collaboration between academic institutions and industry partners suggests HEAs are approaching the technology readiness level needed for broader automotive implementation.

Central South University

Technical Solution: Central South University has pioneered a comprehensive research program on lightweight high-entropy alloys (LWHEAs) specifically designed for automotive applications. Their "ULTRA-HEA" technology platform focuses on aluminum-magnesium-based high-entropy alloys with carefully selected transition metal additions to achieve exceptional specific strength. Their research has developed novel Al-Mg-Li-Cu-Zn-based HEAs that demonstrate tensile strengths exceeding 600 MPa while maintaining densities below 3.0 g/cm³, representing a significant advancement for automotive structural components. The university's manufacturing approach employs a combination of conventional casting followed by severe plastic deformation (SPD) techniques such as equal channel angular pressing (ECAP) to refine grain structure to the nanoscale. Their most recent innovation involves the incorporation of small amounts of scandium and zirconium to create nanoscale Al₃(Sc,Zr) precipitates that significantly enhance strength while maintaining good ductility. For automotive applications, they've developed specialized HEAs for crash structures that demonstrate superior energy absorption compared to conventional aluminum alloys, with crash test results showing up to 15% improvement in specific energy absorption capacity. The university has also pioneered cost-effective processing routes to make these advanced materials more accessible to mass-market automotive applications.

Strengths: Central South University's materials demonstrate exceptional specific strength and energy absorption capabilities critical for automotive safety applications. Their focus on cost-effective processing makes industrial implementation more feasible. Weaknesses: Some compositions show limited weldability which complicates manufacturing integration, and long-term environmental stability (particularly corrosion resistance) requires further optimization.

Mazda Motor Corp.

Technical Solution: Mazda has developed a comprehensive approach to high-entropy alloys (HEAs) for automotive applications, focusing on their SKYACTIV Vehicle Architecture. Their technology involves creating multi-principal element alloys with five or more elements in near-equiatomic proportions to achieve superior strength-to-weight ratios. Mazda's process includes computational alloy design using CALPHAD (CALculation of PHAse Diagrams) methods to predict stable compositions, followed by rapid solidification techniques to create amorphous or nanocrystalline structures. They've specifically engineered aluminum-based HEAs incorporating elements like magnesium, zinc, copper, and scandium for chassis components, achieving up to 20% weight reduction compared to conventional aluminum alloys while maintaining comparable strength properties. Their manufacturing process involves specialized casting methods and subsequent thermomechanical processing to optimize microstructure and mechanical properties.

Strengths: Mazda's approach leverages their extensive automotive manufacturing infrastructure and deep understanding of vehicle weight requirements. Their HEAs demonstrate excellent fatigue resistance and corrosion properties critical for automotive applications. Weaknesses: The complex manufacturing process increases production costs, and the long-term durability of these novel materials in real-world automotive conditions remains under evaluation.

Critical Patents and Technical Literature on Automotive HEAs

Rapidly solidified high-temperature aluminum iron silicon alloys

PatentActiveUS10435773B2

Innovation

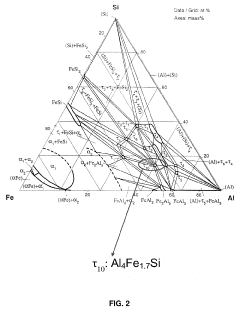

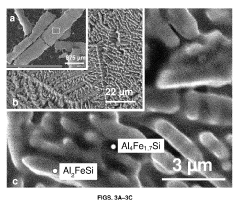

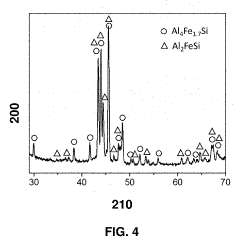

- A method involving high-energy processing, such as laser or electron beam treatment, is used to rapidly cool precursor materials containing aluminum, silicon, and iron, stabilizing high-symmetry phases like Al4Fe1.7Si or Al5Fe2Si, which are then formed into solid high-strength, lightweight alloy components with enhanced properties.

Environmental Impact and Sustainability Considerations

The development of high-entropy alloys (HEAs) for lightweight automotive components presents significant environmental implications that warrant careful consideration. The automotive industry's shift toward sustainability necessitates evaluating the entire lifecycle environmental impact of these innovative materials, from raw material extraction to end-of-life disposal.

HEAs offer promising environmental benefits through weight reduction in vehicles, directly contributing to improved fuel efficiency and reduced greenhouse gas emissions. Studies indicate that a 10% reduction in vehicle weight can improve fuel economy by 6-8%, translating to substantial carbon footprint reductions over a vehicle's operational lifetime. This aligns with increasingly stringent global emissions regulations and sustainability targets established by major automotive markets.

The production processes for HEAs currently present environmental challenges that require optimization. Traditional manufacturing methods for these complex alloys often involve energy-intensive processes with considerable carbon emissions. However, emerging technologies such as additive manufacturing and powder metallurgy are demonstrating potential for more environmentally efficient production pathways, reducing energy consumption by up to 30% compared to conventional methods.

Material resource efficiency represents another critical environmental dimension. HEAs typically incorporate elements with varying degrees of abundance and extraction impacts. The inclusion of rare earth elements in some HEA formulations raises concerns regarding resource depletion and mining-related environmental degradation. Research into HEA compositions that prioritize abundant and less environmentally problematic elements shows promise for mitigating these concerns while maintaining performance characteristics.

Recyclability and circular economy principles are increasingly central to automotive materials development. HEAs present both opportunities and challenges in this regard. Their complex multi-element compositions can complicate traditional recycling streams, potentially requiring specialized separation technologies. Current research focuses on designing HEAs with end-of-life considerations, including compositional strategies that facilitate recycling without performance compromises.

Lifecycle assessment (LCA) studies comparing HEA components with traditional automotive materials demonstrate that despite potentially higher production-phase environmental impacts, the operational benefits often yield net positive environmental outcomes. These assessments typically show break-even points occurring within 2-4 years of vehicle operation, after which the lightweight advantages provide cumulative environmental benefits throughout the remaining service life.

Regulatory frameworks worldwide are evolving to address advanced materials' environmental implications, with particular attention to potential toxicity concerns and end-of-life management. HEA developers must navigate these emerging requirements while demonstrating comprehensive sustainability credentials to automotive manufacturers increasingly focused on supply chain environmental performance.

HEAs offer promising environmental benefits through weight reduction in vehicles, directly contributing to improved fuel efficiency and reduced greenhouse gas emissions. Studies indicate that a 10% reduction in vehicle weight can improve fuel economy by 6-8%, translating to substantial carbon footprint reductions over a vehicle's operational lifetime. This aligns with increasingly stringent global emissions regulations and sustainability targets established by major automotive markets.

The production processes for HEAs currently present environmental challenges that require optimization. Traditional manufacturing methods for these complex alloys often involve energy-intensive processes with considerable carbon emissions. However, emerging technologies such as additive manufacturing and powder metallurgy are demonstrating potential for more environmentally efficient production pathways, reducing energy consumption by up to 30% compared to conventional methods.

Material resource efficiency represents another critical environmental dimension. HEAs typically incorporate elements with varying degrees of abundance and extraction impacts. The inclusion of rare earth elements in some HEA formulations raises concerns regarding resource depletion and mining-related environmental degradation. Research into HEA compositions that prioritize abundant and less environmentally problematic elements shows promise for mitigating these concerns while maintaining performance characteristics.

Recyclability and circular economy principles are increasingly central to automotive materials development. HEAs present both opportunities and challenges in this regard. Their complex multi-element compositions can complicate traditional recycling streams, potentially requiring specialized separation technologies. Current research focuses on designing HEAs with end-of-life considerations, including compositional strategies that facilitate recycling without performance compromises.

Lifecycle assessment (LCA) studies comparing HEA components with traditional automotive materials demonstrate that despite potentially higher production-phase environmental impacts, the operational benefits often yield net positive environmental outcomes. These assessments typically show break-even points occurring within 2-4 years of vehicle operation, after which the lightweight advantages provide cumulative environmental benefits throughout the remaining service life.

Regulatory frameworks worldwide are evolving to address advanced materials' environmental implications, with particular attention to potential toxicity concerns and end-of-life management. HEA developers must navigate these emerging requirements while demonstrating comprehensive sustainability credentials to automotive manufacturers increasingly focused on supply chain environmental performance.

Manufacturing Processes and Scalability Analysis

The manufacturing processes for high-entropy alloys (HEAs) present unique challenges compared to conventional alloys due to their complex multi-element compositions. Traditional manufacturing methods such as casting have been adapted for HEAs, with vacuum arc melting and induction melting being the most common approaches for laboratory-scale production. These methods ensure homogeneous mixing of multiple principal elements while minimizing oxidation and contamination issues that are particularly problematic for HEAs.

Powder metallurgy has emerged as a promising route for HEA component production, offering advantages in controlling microstructure and reducing segregation. The process typically involves mechanical alloying through high-energy ball milling, followed by consolidation via hot isostatic pressing or spark plasma sintering. This approach has demonstrated success in creating HEAs with refined grain structures and enhanced mechanical properties relevant to automotive applications.

Additive manufacturing technologies, particularly selective laser melting and electron beam melting, represent cutting-edge approaches for HEA fabrication. These methods enable complex geometries and functionally graded structures that can be optimized for specific automotive requirements. The rapid solidification inherent in these processes produces unique microstructures that often enhance strength-to-weight ratios, making them particularly suitable for lightweight automotive components.

Scalability remains a significant challenge for HEA implementation in automotive manufacturing. Current production volumes are primarily limited to laboratory or small batch scales, with costs approximately 3-5 times higher than conventional aluminum alloys. Key barriers include the high cost of raw materials, especially when incorporating elements like titanium and niobium, and the need for precise composition control during large-scale melting operations.

Energy consumption during manufacturing represents another scalability concern. HEAs typically require higher processing temperatures than conventional alloys, increasing production costs and carbon footprint. Recent research has focused on developing lower-temperature processing routes and optimizing thermal cycles to improve energy efficiency while maintaining desired microstructures.

Quality control and reproducibility present additional challenges when scaling up HEA production. The sensitivity of these alloys to minor compositional variations necessitates advanced monitoring systems and strict process controls. Several automotive suppliers are developing specialized quality assurance protocols, including in-line compositional analysis and non-destructive testing methods tailored to HEA components.

Powder metallurgy has emerged as a promising route for HEA component production, offering advantages in controlling microstructure and reducing segregation. The process typically involves mechanical alloying through high-energy ball milling, followed by consolidation via hot isostatic pressing or spark plasma sintering. This approach has demonstrated success in creating HEAs with refined grain structures and enhanced mechanical properties relevant to automotive applications.

Additive manufacturing technologies, particularly selective laser melting and electron beam melting, represent cutting-edge approaches for HEA fabrication. These methods enable complex geometries and functionally graded structures that can be optimized for specific automotive requirements. The rapid solidification inherent in these processes produces unique microstructures that often enhance strength-to-weight ratios, making them particularly suitable for lightweight automotive components.

Scalability remains a significant challenge for HEA implementation in automotive manufacturing. Current production volumes are primarily limited to laboratory or small batch scales, with costs approximately 3-5 times higher than conventional aluminum alloys. Key barriers include the high cost of raw materials, especially when incorporating elements like titanium and niobium, and the need for precise composition control during large-scale melting operations.

Energy consumption during manufacturing represents another scalability concern. HEAs typically require higher processing temperatures than conventional alloys, increasing production costs and carbon footprint. Recent research has focused on developing lower-temperature processing routes and optimizing thermal cycles to improve energy efficiency while maintaining desired microstructures.

Quality control and reproducibility present additional challenges when scaling up HEA production. The sensitivity of these alloys to minor compositional variations necessitates advanced monitoring systems and strict process controls. Several automotive suppliers are developing specialized quality assurance protocols, including in-line compositional analysis and non-destructive testing methods tailored to HEA components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!