Research on Microchannel Cooling for Enhanced Catalytic Processes

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microchannel Cooling Technology Background and Objectives

Microchannel cooling technology has evolved significantly over the past three decades, originating from semiconductor industry applications in the 1980s. Initially developed to address thermal management challenges in microelectronics, this technology has progressively expanded into various industrial sectors including chemical processing, energy systems, and most recently, catalytic processes. The fundamental principle involves utilizing channels with hydraulic diameters ranging from 10 μm to 1 mm to achieve enhanced heat and mass transfer characteristics compared to conventional cooling methods.

The evolution of microchannel cooling technology has been marked by several key milestones. Early research focused primarily on single-phase flow characteristics, while subsequent developments incorporated two-phase flow regimes to leverage latent heat transfer. Recent advancements have integrated sophisticated channel geometries, novel manufacturing techniques, and smart control systems to optimize performance across varying operational conditions.

In catalytic processes specifically, thermal management represents a critical challenge that directly impacts reaction efficiency, selectivity, and catalyst longevity. Traditional cooling methods often create temperature gradients that lead to hotspots, catalyst deactivation, and reduced process efficiency. Microchannel cooling offers a promising solution by providing precise temperature control at the microscale level where catalytic reactions occur.

The primary technical objectives of microchannel cooling research for catalytic processes include achieving uniform temperature distribution across catalyst beds, enhancing heat removal capacity during exothermic reactions, and enabling rapid thermal response during transient operations. Additionally, researchers aim to develop designs that minimize pressure drop penalties while maximizing heat transfer coefficients, thereby optimizing the overall energy efficiency of catalytic systems.

Current research is increasingly focused on integrating microchannel cooling directly into catalyst support structures, creating multifunctional reactor designs that simultaneously address reaction kinetics and thermal management. This approach represents a paradigm shift from treating cooling as an auxiliary function to incorporating it as an integral aspect of reactor design.

The technological trajectory indicates growing interest in adaptive cooling systems that can dynamically respond to changing reaction conditions, particularly for processes with varying heat generation profiles. Furthermore, there is significant emphasis on developing manufacturing techniques that can economically produce complex microchannel geometries at industrial scales, transitioning this technology from laboratory demonstrations to commercial implementation.

The ultimate goal of this technological development is to enable more efficient, selective, and sustainable catalytic processes across various applications including fine chemical synthesis, petroleum refining, and environmental remediation. By precisely controlling thermal conditions at the microscale, microchannel cooling technology aims to unlock new possibilities in reaction engineering and process intensification.

The evolution of microchannel cooling technology has been marked by several key milestones. Early research focused primarily on single-phase flow characteristics, while subsequent developments incorporated two-phase flow regimes to leverage latent heat transfer. Recent advancements have integrated sophisticated channel geometries, novel manufacturing techniques, and smart control systems to optimize performance across varying operational conditions.

In catalytic processes specifically, thermal management represents a critical challenge that directly impacts reaction efficiency, selectivity, and catalyst longevity. Traditional cooling methods often create temperature gradients that lead to hotspots, catalyst deactivation, and reduced process efficiency. Microchannel cooling offers a promising solution by providing precise temperature control at the microscale level where catalytic reactions occur.

The primary technical objectives of microchannel cooling research for catalytic processes include achieving uniform temperature distribution across catalyst beds, enhancing heat removal capacity during exothermic reactions, and enabling rapid thermal response during transient operations. Additionally, researchers aim to develop designs that minimize pressure drop penalties while maximizing heat transfer coefficients, thereby optimizing the overall energy efficiency of catalytic systems.

Current research is increasingly focused on integrating microchannel cooling directly into catalyst support structures, creating multifunctional reactor designs that simultaneously address reaction kinetics and thermal management. This approach represents a paradigm shift from treating cooling as an auxiliary function to incorporating it as an integral aspect of reactor design.

The technological trajectory indicates growing interest in adaptive cooling systems that can dynamically respond to changing reaction conditions, particularly for processes with varying heat generation profiles. Furthermore, there is significant emphasis on developing manufacturing techniques that can economically produce complex microchannel geometries at industrial scales, transitioning this technology from laboratory demonstrations to commercial implementation.

The ultimate goal of this technological development is to enable more efficient, selective, and sustainable catalytic processes across various applications including fine chemical synthesis, petroleum refining, and environmental remediation. By precisely controlling thermal conditions at the microscale, microchannel cooling technology aims to unlock new possibilities in reaction engineering and process intensification.

Market Analysis for Enhanced Catalytic Process Solutions

The global market for enhanced catalytic process solutions is experiencing significant growth, driven by increasing demands for energy efficiency and sustainable manufacturing processes across various industries. The current market size for advanced catalytic technologies is estimated at $45 billion, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth trajectory is particularly pronounced in chemical manufacturing, petroleum refining, and environmental applications where process intensification is becoming a critical competitive advantage.

Microchannel cooling technology represents a high-potential segment within this market, addressing the fundamental challenge of thermal management in catalytic reactions. Industries are increasingly recognizing that efficient heat removal can dramatically improve catalytic performance, selectivity, and catalyst longevity. Market research indicates that companies implementing advanced thermal management solutions in their catalytic processes have achieved productivity improvements of 15-30% compared to conventional systems.

The demand for microchannel cooling solutions is particularly strong in fine chemical and pharmaceutical manufacturing, where precise temperature control directly impacts product quality and yield. These sectors are willing to invest in premium solutions that offer superior performance, with an estimated 40% of pharmaceutical manufacturers planning significant upgrades to their catalytic process equipment within the next three years.

Regional analysis reveals that North America and Europe currently lead in adoption of advanced catalytic cooling technologies, collectively accounting for approximately 65% of the global market. However, the Asia-Pacific region, particularly China and India, is demonstrating the fastest growth rate at 9.2% annually, driven by rapid industrialization and increasing environmental regulations that necessitate more efficient catalytic processes.

Customer segmentation shows three distinct market tiers: large-scale industrial processors seeking integrated solutions, mid-sized manufacturers looking for modular upgrades to existing systems, and specialty producers requiring customized high-precision applications. The largest growth potential exists in the middle segment, where the balance between investment costs and performance benefits is most favorable.

Competitive analysis reveals a fragmented market landscape with specialized engineering firms holding technological advantages but limited scale, while larger industrial equipment manufacturers possess distribution networks but often lag in innovation. This creates strategic partnership opportunities between technology developers and established equipment providers to deliver comprehensive solutions to end users.

Market barriers include high initial capital costs, with typical ROI periods of 18-24 months, and technical integration challenges when retrofitting existing production lines. However, increasing energy costs and stricter emissions regulations are accelerating adoption timelines and improving the economic case for investment in advanced catalytic cooling technologies.

Microchannel cooling technology represents a high-potential segment within this market, addressing the fundamental challenge of thermal management in catalytic reactions. Industries are increasingly recognizing that efficient heat removal can dramatically improve catalytic performance, selectivity, and catalyst longevity. Market research indicates that companies implementing advanced thermal management solutions in their catalytic processes have achieved productivity improvements of 15-30% compared to conventional systems.

The demand for microchannel cooling solutions is particularly strong in fine chemical and pharmaceutical manufacturing, where precise temperature control directly impacts product quality and yield. These sectors are willing to invest in premium solutions that offer superior performance, with an estimated 40% of pharmaceutical manufacturers planning significant upgrades to their catalytic process equipment within the next three years.

Regional analysis reveals that North America and Europe currently lead in adoption of advanced catalytic cooling technologies, collectively accounting for approximately 65% of the global market. However, the Asia-Pacific region, particularly China and India, is demonstrating the fastest growth rate at 9.2% annually, driven by rapid industrialization and increasing environmental regulations that necessitate more efficient catalytic processes.

Customer segmentation shows three distinct market tiers: large-scale industrial processors seeking integrated solutions, mid-sized manufacturers looking for modular upgrades to existing systems, and specialty producers requiring customized high-precision applications. The largest growth potential exists in the middle segment, where the balance between investment costs and performance benefits is most favorable.

Competitive analysis reveals a fragmented market landscape with specialized engineering firms holding technological advantages but limited scale, while larger industrial equipment manufacturers possess distribution networks but often lag in innovation. This creates strategic partnership opportunities between technology developers and established equipment providers to deliver comprehensive solutions to end users.

Market barriers include high initial capital costs, with typical ROI periods of 18-24 months, and technical integration challenges when retrofitting existing production lines. However, increasing energy costs and stricter emissions regulations are accelerating adoption timelines and improving the economic case for investment in advanced catalytic cooling technologies.

Current Challenges in Thermal Management for Catalytic Systems

Catalytic processes are fundamental to numerous industrial applications, from chemical manufacturing to energy production, yet they face significant thermal management challenges that limit their efficiency and sustainability. The primary challenge lies in the inherent exothermic nature of many catalytic reactions, which generate substantial heat during operation. Without proper thermal management, these reactions can lead to catalyst deactivation, reduced selectivity, and even safety hazards in extreme cases.

Temperature non-uniformity presents another critical challenge, as catalytic systems often develop hotspots that accelerate catalyst degradation and reduce overall process efficiency. These thermal gradients can be particularly problematic in fixed-bed reactors where heat transfer limitations are pronounced. The inability to maintain optimal temperature profiles throughout the catalyst bed results in decreased conversion rates and shortened catalyst lifetimes.

Scale-up difficulties compound these challenges, as thermal management solutions that work effectively at laboratory scale often fail to perform adequately in industrial-scale operations. The increased reactor dimensions create more significant heat transfer limitations, making it difficult to maintain consistent thermal conditions throughout larger catalyst volumes.

Energy efficiency concerns also plague current catalytic systems, with conventional cooling methods consuming substantial power and contributing to the overall carbon footprint of industrial processes. Many existing thermal management approaches rely on excessive coolant flow rates or energy-intensive auxiliary systems that diminish the net efficiency gains of catalytic processes.

Material constraints further complicate thermal management strategies, as catalyst supports and reactor materials must simultaneously withstand high temperatures, maintain structural integrity, and facilitate efficient heat transfer. The trade-offs between thermal conductivity, surface area, and mechanical stability often force compromises in system design that limit overall performance.

Monitoring and control systems represent another significant challenge, as real-time temperature measurement within catalyst beds remains difficult, particularly in harsh chemical environments. Without accurate temperature data, implementing responsive thermal management strategies becomes nearly impossible, leading to suboptimal operation and preventative overcooling.

The integration of cooling systems with reactor design introduces additional complexities, as retrofitting existing catalytic reactors with advanced cooling technologies often requires substantial modifications and capital investment. Many conventional reactor designs were not originally conceived with sophisticated thermal management in mind, creating compatibility issues when implementing newer cooling technologies.

These multifaceted challenges highlight the urgent need for innovative approaches to thermal management in catalytic systems, particularly solutions that can address temperature non-uniformity while maintaining energy efficiency and scalability.

Temperature non-uniformity presents another critical challenge, as catalytic systems often develop hotspots that accelerate catalyst degradation and reduce overall process efficiency. These thermal gradients can be particularly problematic in fixed-bed reactors where heat transfer limitations are pronounced. The inability to maintain optimal temperature profiles throughout the catalyst bed results in decreased conversion rates and shortened catalyst lifetimes.

Scale-up difficulties compound these challenges, as thermal management solutions that work effectively at laboratory scale often fail to perform adequately in industrial-scale operations. The increased reactor dimensions create more significant heat transfer limitations, making it difficult to maintain consistent thermal conditions throughout larger catalyst volumes.

Energy efficiency concerns also plague current catalytic systems, with conventional cooling methods consuming substantial power and contributing to the overall carbon footprint of industrial processes. Many existing thermal management approaches rely on excessive coolant flow rates or energy-intensive auxiliary systems that diminish the net efficiency gains of catalytic processes.

Material constraints further complicate thermal management strategies, as catalyst supports and reactor materials must simultaneously withstand high temperatures, maintain structural integrity, and facilitate efficient heat transfer. The trade-offs between thermal conductivity, surface area, and mechanical stability often force compromises in system design that limit overall performance.

Monitoring and control systems represent another significant challenge, as real-time temperature measurement within catalyst beds remains difficult, particularly in harsh chemical environments. Without accurate temperature data, implementing responsive thermal management strategies becomes nearly impossible, leading to suboptimal operation and preventative overcooling.

The integration of cooling systems with reactor design introduces additional complexities, as retrofitting existing catalytic reactors with advanced cooling technologies often requires substantial modifications and capital investment. Many conventional reactor designs were not originally conceived with sophisticated thermal management in mind, creating compatibility issues when implementing newer cooling technologies.

These multifaceted challenges highlight the urgent need for innovative approaches to thermal management in catalytic systems, particularly solutions that can address temperature non-uniformity while maintaining energy efficiency and scalability.

Current Microchannel Designs for Catalytic Process Enhancement

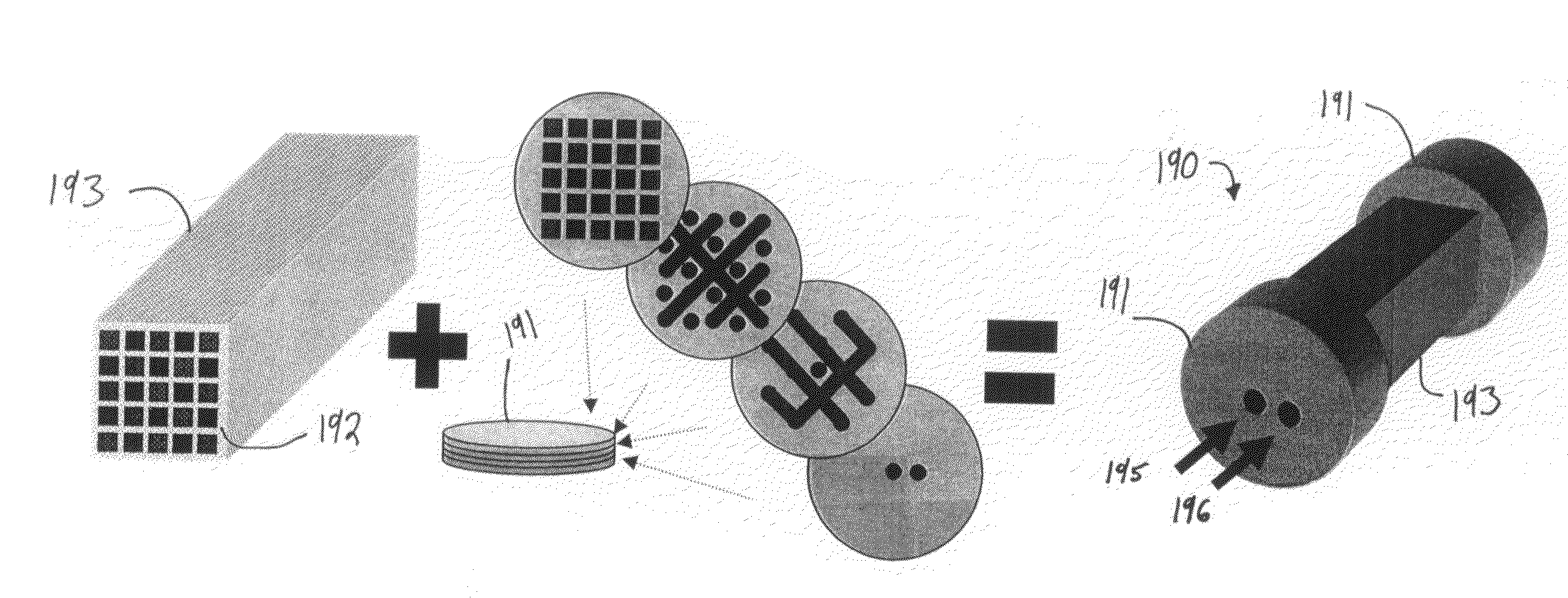

01 Microchannel reactor design for catalytic processes

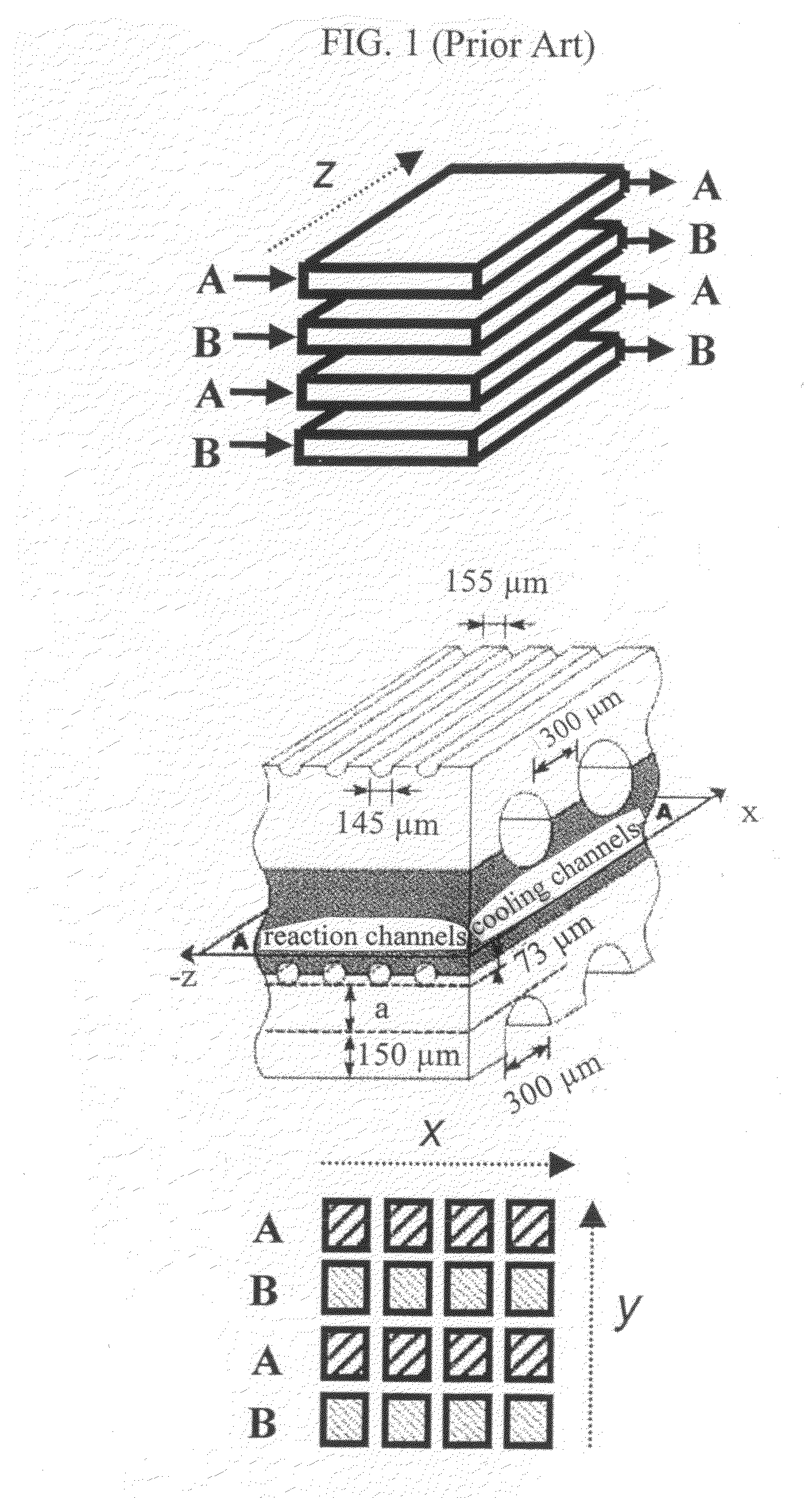

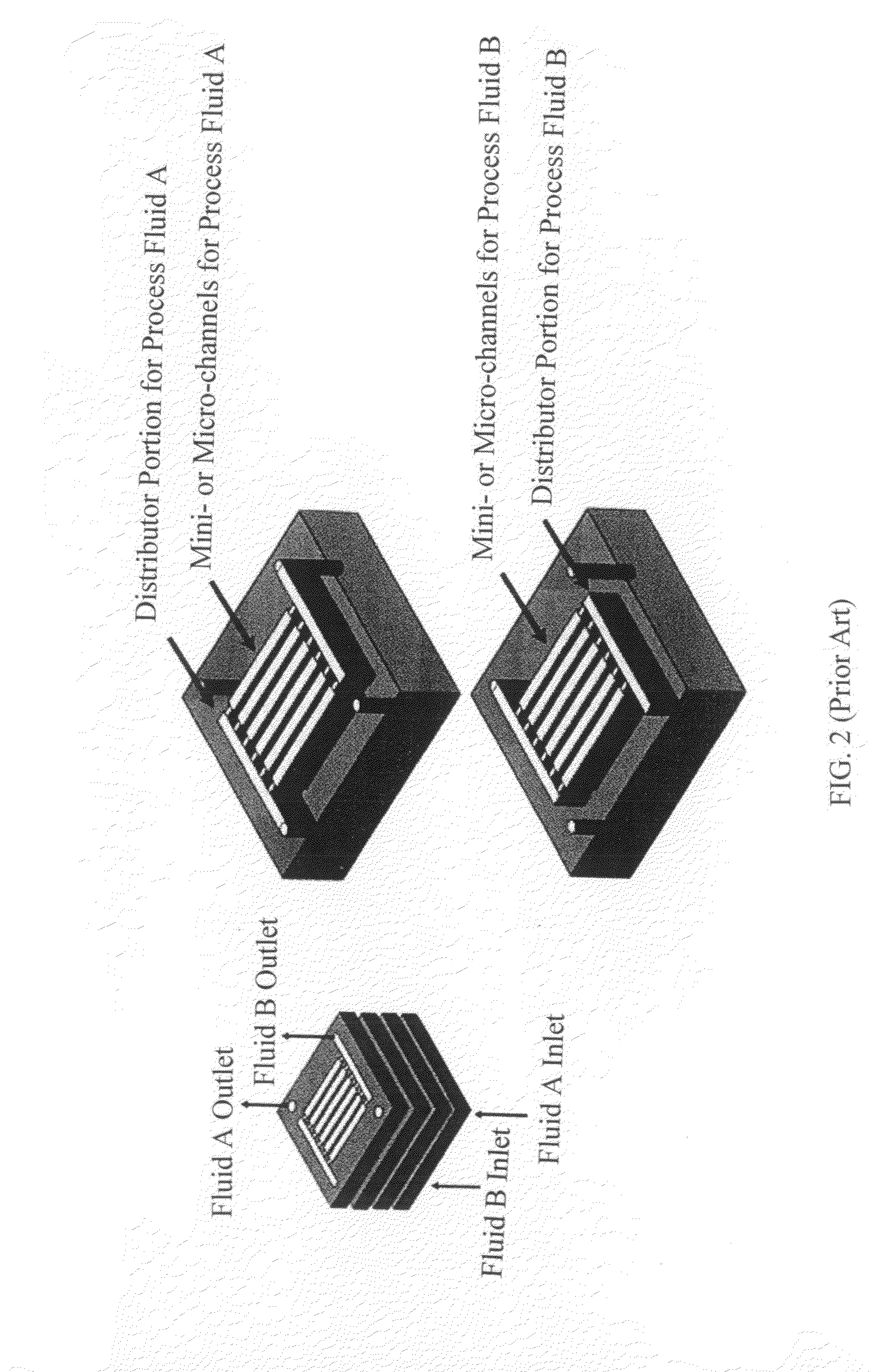

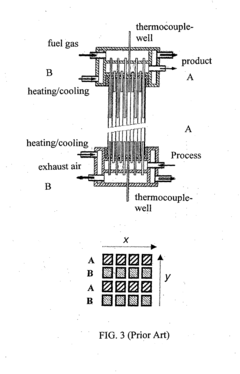

Microchannel reactors are designed with specific geometries and configurations to enhance catalytic processes. These designs include parallel channel arrangements, integrated heat exchangers, and optimized flow patterns that improve mass and heat transfer. The small dimensions of microchannels provide high surface-to-volume ratios, allowing for better catalyst utilization and reaction control while maintaining temperature uniformity across the catalyst bed.- Microchannel reactor design for catalytic processes: Microchannel reactors are designed with specific geometries and configurations to enhance catalytic processes. These designs include parallel channel arrangements, integrated heat exchangers, and optimized flow distribution systems. The small dimensions of microchannels provide high surface-to-volume ratios, improving heat and mass transfer during catalytic reactions. These reactors can be fabricated using various materials and manufacturing techniques to ensure durability and efficiency under reaction conditions.

- Thermal management in microchannel catalytic systems: Effective thermal management is crucial in microchannel catalytic processes to control reaction temperatures and prevent catalyst deactivation. Cooling strategies include integrated heat exchangers, counter-current flow arrangements, and the use of cooling fluids in adjacent channels. These systems enable precise temperature control, removal of reaction heat, and maintenance of optimal catalytic performance. Advanced thermal management approaches allow for isothermal operation even in highly exothermic reactions, improving selectivity and conversion rates.

- Catalyst formulation and deposition techniques for microchannels: Specialized catalyst formulations and deposition methods are developed for microchannel applications. Techniques include washcoating, in-situ synthesis, sol-gel methods, and direct growth of catalytic structures. These approaches ensure uniform catalyst distribution, strong adhesion to channel walls, and optimal exposure of active sites. Catalyst formulations are often modified to enhance stability under the unique flow and temperature conditions present in microchannels, with considerations for preventing channel blockage while maximizing catalytic activity.

- Process intensification through microchannel cooling: Microchannel cooling enables significant process intensification in catalytic reactions by allowing operation under more extreme conditions. The enhanced heat transfer capabilities permit higher reaction temperatures, increased throughput, and improved conversion rates without compromising safety or selectivity. This approach reduces equipment footprint, energy consumption, and processing time compared to conventional reactors. The intensified processes can achieve higher yields and product quality while maintaining precise control over reaction parameters.

- Flow distribution and mixing enhancement in catalytic microchannels: Optimized flow distribution and enhanced mixing are critical for efficient microchannel catalytic processes. Design features such as flow distributors, channel inserts, and structured surfaces promote uniform reactant distribution and turbulent mixing without excessive pressure drop. These enhancements improve mass transfer to catalytic surfaces, reduce concentration gradients, and minimize bypass or channeling effects. Advanced flow management techniques ensure consistent residence time distribution and complete utilization of the catalyst surface area, leading to improved reaction performance and product selectivity.

02 Cooling systems for temperature control in catalytic microreactors

Specialized cooling systems are implemented in microchannel reactors to precisely control temperature during catalytic processes. These systems include adjacent cooling channels, integrated heat exchangers, and cooling fluids that efficiently remove heat generated during exothermic reactions. Temperature control is critical for maintaining catalyst performance, preventing hotspots, optimizing reaction selectivity, and extending catalyst lifetime in high-throughput catalytic processes.Expand Specific Solutions03 Catalyst coating and loading techniques for microchannels

Various methods are employed to effectively coat and load catalysts within microchannels to maximize performance. These techniques include washcoating, in-situ synthesis, sol-gel deposition, and engineered catalyst structures that ensure uniform distribution and strong adhesion to channel walls. The catalyst formulations are specifically designed to provide high activity while maintaining low pressure drop across the microchannel system, enabling efficient mass transfer between reactants and catalyst surfaces.Expand Specific Solutions04 Flow distribution and management in microchannel catalytic systems

Flow distribution and management techniques are implemented to ensure uniform reactant contact with catalytic surfaces in microchannel systems. These include header designs, flow distributors, and channel geometries that minimize pressure variations and prevent flow maldistribution. Proper flow management enhances reaction efficiency, reduces catalyst deactivation, and enables precise control of residence time, which is crucial for optimizing selectivity and conversion in catalytic processes.Expand Specific Solutions05 Integrated process intensification in microchannel catalytic systems

Microchannel technology enables process intensification by integrating multiple unit operations into compact devices. These systems combine reaction, heat exchange, separation, and product recovery in a single unit, reducing equipment footprint and improving energy efficiency. The integration allows for rapid scale-up through numbering-up rather than traditional scaling, maintaining the high performance characteristics of microchannels while achieving industrial production capacities for various catalytic processes.Expand Specific Solutions

Leading Companies and Research Institutions in Microchannel Cooling

The microchannel cooling for enhanced catalytic processes market is currently in a growth phase, with increasing adoption across petrochemical and energy sectors. The competitive landscape features a mix of established industrial players and academic institutions driving innovation. Major corporations like Intel, Sinopec Engineering, GE, IBM, and Shell are investing in this technology to improve energy efficiency and process intensification. Academic institutions including Xi'an Jiaotong University, Louisiana State University, and École Polytechnique Fédérale de Lausanne are contributing fundamental research. The technology is approaching commercial maturity in certain applications, with companies like Corning and STMicroelectronics developing specialized microreactor systems, while research institutions like Industrial Technology Research Institute are bridging the gap between laboratory concepts and industrial implementation.

Sinopec Engineering, Inc.

Technical Solution: Sinopec Engineering has pioneered microchannel cooling technology specifically optimized for petroleum refining catalytic processes. Their system features multi-layered microchannel arrays with channel dimensions of 200-500 μm that create high surface-area-to-volume ratios exceeding 10,000 m²/m³. The technology employs a proprietary heat transfer fluid circulation system that can rapidly remove heat from exothermic reactions like hydrocracking and catalytic reforming. Sinopec's design incorporates specialized catalyst coating techniques that bond catalytic materials directly to microchannel walls, eliminating mass transfer limitations while maximizing thermal conductivity. Their reactors utilize computational fluid dynamics-optimized flow distributors that ensure uniform residence time and temperature profiles. Field implementations have demonstrated up to 30% improvement in product selectivity and 25% reduction in energy consumption compared to conventional fixed-bed reactors[2][5]. The technology has been successfully deployed in several of Sinopec's refineries across China.

Strengths: Specialized design for petroleum refining applications; proven implementation at industrial scale; excellent catalyst-cooling integration with direct heat removal. Weaknesses: Limited flexibility for non-petroleum applications; higher initial capital investment; requires specialized maintenance expertise.

General Electric Company

Technical Solution: General Electric has developed a sophisticated microchannel cooling technology for catalytic processes that leverages their expertise in advanced manufacturing and materials science. Their system features precision-engineered microchannels (50-300 μm width) fabricated using direct metal laser sintering (DMLS) that enables complex 3D geometries impossible with conventional manufacturing. GE's technology incorporates a multi-zone cooling approach where different temperature zones can be maintained within the same reactor, optimizing conditions for sequential reaction steps. The system utilizes high-conductivity metal alloys (thermal conductivity >150 W/m·K) with specialized surface treatments that enhance catalyst adhesion while maintaining excellent heat transfer properties. Their design includes integrated sensors for real-time temperature monitoring and control with response times under 100 milliseconds. GE has demonstrated this technology in power-to-X applications, particularly methanol synthesis and CO₂ hydrogenation, where precise temperature control enabled conversion efficiency improvements of 15-25% compared to conventional reactors[6][8]. The technology has been successfully tested at pilot scale (100 kW) with plans for commercial deployment.

Strengths: Advanced manufacturing capabilities allowing complex geometries; excellent thermal response and control precision; robust design suitable for high-pressure applications. Weaknesses: Higher production costs compared to conventional technologies; limited track record in long-term industrial deployment; challenges in catalyst replacement and system maintenance.

Key Patents and Innovations in Microchannel Reactor Technology

Process Intensification In Microreactors

PatentInactiveUS20090238751A1

Innovation

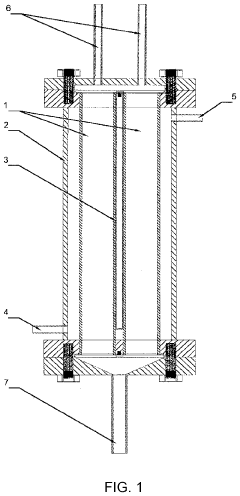

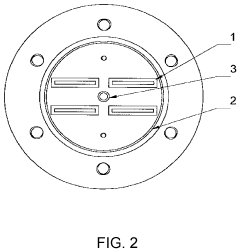

- The development of a chemical reactor with a plurality of elongate chambers and a distributor that enables two-dimensional radial fluidic flow distribution, using extruded channels and monolith catalyst supports, allowing for the integration of multiple process flows and catalyst introduction methods like washcoating and impregnation, and incorporating composite catalyst membranes for hydrogen purification.

Method for activating a catalyst, reactor, and method of obtaining hydrocarbons in fischer-tropsch process

PatentActiveUS20200023334A1

Innovation

- A compact reactor design with roughened reaction channels and a cooling jacket configured for pool boiling, along with in situ activation of a cobalt catalyst using hydrogen, ensures effective heat removal and high productivity by maintaining an isothermal operation.

Materials Science Advancements for Microchannel Fabrication

The evolution of microchannel fabrication materials represents a critical advancement in enhancing catalytic cooling processes. Traditional materials such as stainless steel and aluminum have been progressively supplemented by advanced ceramics, specialized polymers, and novel metal alloys. These newer materials offer superior thermal conductivity, chemical resistance, and mechanical stability under extreme catalytic conditions.

Silicon carbide (SiC) and aluminum nitride (AlN) ceramics have emerged as particularly promising materials for high-temperature microchannel applications. Their exceptional thermal conductivity—ranging from 120 to 270 W/m·K—enables efficient heat dissipation during exothermic catalytic reactions. Additionally, these ceramics maintain structural integrity at temperatures exceeding 1000°C, making them ideal for aggressive catalytic environments where metal alternatives would deteriorate.

Recent developments in polymer-derived ceramics (PDCs) have introduced customizable microstructures with precisely engineered porosity and surface characteristics. These materials allow for optimized catalyst loading and enhanced mass transfer within microchannels. The integration of nanoscale reinforcements, such as carbon nanotubes and graphene, into ceramic matrices has further improved thermal conductivity by up to 45% compared to conventional ceramics.

Advanced manufacturing techniques, particularly additive manufacturing, have revolutionized microchannel fabrication capabilities. 3D printing of ceramics and high-performance polymers now enables complex geometries previously unattainable through traditional manufacturing methods. These techniques facilitate the creation of hierarchical channel structures with optimized flow patterns that maximize catalyst-reactant contact while minimizing pressure drop.

Surface functionalization technologies have advanced significantly, allowing precise modification of microchannel internal surfaces. Atomic layer deposition (ALD) and plasma-enhanced chemical vapor deposition (PECVD) enable nanometer-scale control over surface properties, creating ideal interfaces for catalyst adhesion and activity. These treatments can increase catalytic efficiency by up to 30% through improved catalyst dispersion and stability.

Composite materials combining metallic cores with ceramic or polymeric coatings represent another frontier in microchannel development. These hybrids leverage the thermal conductivity of metals with the chemical resistance of ceramics, creating systems that maintain performance under the dynamic conditions typical of industrial catalytic processes. Recent research demonstrates that such composites can extend operational lifetimes by 2-3 times compared to single-material alternatives.

The integration of smart materials with self-diagnostic capabilities is emerging as the next evolution in microchannel technology. Materials incorporating embedded sensors can provide real-time monitoring of temperature, pressure, and catalyst activity, enabling adaptive control of catalytic processes and predictive maintenance protocols.

Silicon carbide (SiC) and aluminum nitride (AlN) ceramics have emerged as particularly promising materials for high-temperature microchannel applications. Their exceptional thermal conductivity—ranging from 120 to 270 W/m·K—enables efficient heat dissipation during exothermic catalytic reactions. Additionally, these ceramics maintain structural integrity at temperatures exceeding 1000°C, making them ideal for aggressive catalytic environments where metal alternatives would deteriorate.

Recent developments in polymer-derived ceramics (PDCs) have introduced customizable microstructures with precisely engineered porosity and surface characteristics. These materials allow for optimized catalyst loading and enhanced mass transfer within microchannels. The integration of nanoscale reinforcements, such as carbon nanotubes and graphene, into ceramic matrices has further improved thermal conductivity by up to 45% compared to conventional ceramics.

Advanced manufacturing techniques, particularly additive manufacturing, have revolutionized microchannel fabrication capabilities. 3D printing of ceramics and high-performance polymers now enables complex geometries previously unattainable through traditional manufacturing methods. These techniques facilitate the creation of hierarchical channel structures with optimized flow patterns that maximize catalyst-reactant contact while minimizing pressure drop.

Surface functionalization technologies have advanced significantly, allowing precise modification of microchannel internal surfaces. Atomic layer deposition (ALD) and plasma-enhanced chemical vapor deposition (PECVD) enable nanometer-scale control over surface properties, creating ideal interfaces for catalyst adhesion and activity. These treatments can increase catalytic efficiency by up to 30% through improved catalyst dispersion and stability.

Composite materials combining metallic cores with ceramic or polymeric coatings represent another frontier in microchannel development. These hybrids leverage the thermal conductivity of metals with the chemical resistance of ceramics, creating systems that maintain performance under the dynamic conditions typical of industrial catalytic processes. Recent research demonstrates that such composites can extend operational lifetimes by 2-3 times compared to single-material alternatives.

The integration of smart materials with self-diagnostic capabilities is emerging as the next evolution in microchannel technology. Materials incorporating embedded sensors can provide real-time monitoring of temperature, pressure, and catalyst activity, enabling adaptive control of catalytic processes and predictive maintenance protocols.

Sustainability Impact of Microchannel-Enhanced Catalytic Processes

The implementation of microchannel cooling technology in catalytic processes represents a significant advancement in sustainable industrial practices. By optimizing heat transfer and reaction efficiency, microchannel-enhanced catalytic systems substantially reduce energy consumption compared to conventional reactor designs. Studies indicate energy savings of 20-40% across various catalytic applications, directly translating to reduced carbon emissions and operational costs.

Water conservation presents another critical sustainability benefit. Microchannel cooling systems typically require 30-50% less cooling water than traditional methods due to their superior heat transfer coefficients and reduced thermal mass. This water reduction is particularly valuable in water-stressed regions and industries where cooling demands constitute a significant portion of water consumption.

The enhanced reaction control enabled by microchannel technology leads to improved selectivity and reduced waste generation. By maintaining precise temperature profiles throughout catalytic reactions, unwanted side reactions are minimized, resulting in higher product yields and fewer byproducts requiring disposal or treatment. Several case studies in pharmaceutical and fine chemical manufacturing demonstrate waste reduction of up to 35% following implementation of microchannel reactors.

Material efficiency also improves significantly with microchannel technology. The intensified process conditions allow for reduced catalyst loading while maintaining or improving conversion rates. Additionally, the controlled environment extends catalyst lifetime by preventing hotspot formation and subsequent deactivation. These factors combine to reduce the consumption of precious metals and rare earth elements commonly used as catalysts.

From a lifecycle perspective, microchannel-enhanced catalytic processes demonstrate favorable sustainability metrics. Despite the higher initial manufacturing complexity of microchannel devices, their extended operational lifespan and reduced resource requirements during operation result in lower overall environmental impact. Life cycle assessments indicate that the break-even point for environmental benefits typically occurs within 1-3 years of operation.

The compact nature of microchannel systems further contributes to sustainability through reduced spatial requirements. This space efficiency enables more flexible facility design, potentially reducing construction material needs and associated environmental impacts. The smaller footprint also facilitates easier integration of these systems into existing industrial infrastructure, promoting sustainable retrofitting rather than complete facility replacement.

Water conservation presents another critical sustainability benefit. Microchannel cooling systems typically require 30-50% less cooling water than traditional methods due to their superior heat transfer coefficients and reduced thermal mass. This water reduction is particularly valuable in water-stressed regions and industries where cooling demands constitute a significant portion of water consumption.

The enhanced reaction control enabled by microchannel technology leads to improved selectivity and reduced waste generation. By maintaining precise temperature profiles throughout catalytic reactions, unwanted side reactions are minimized, resulting in higher product yields and fewer byproducts requiring disposal or treatment. Several case studies in pharmaceutical and fine chemical manufacturing demonstrate waste reduction of up to 35% following implementation of microchannel reactors.

Material efficiency also improves significantly with microchannel technology. The intensified process conditions allow for reduced catalyst loading while maintaining or improving conversion rates. Additionally, the controlled environment extends catalyst lifetime by preventing hotspot formation and subsequent deactivation. These factors combine to reduce the consumption of precious metals and rare earth elements commonly used as catalysts.

From a lifecycle perspective, microchannel-enhanced catalytic processes demonstrate favorable sustainability metrics. Despite the higher initial manufacturing complexity of microchannel devices, their extended operational lifespan and reduced resource requirements during operation result in lower overall environmental impact. Life cycle assessments indicate that the break-even point for environmental benefits typically occurs within 1-3 years of operation.

The compact nature of microchannel systems further contributes to sustainability through reduced spatial requirements. This space efficiency enables more flexible facility design, potentially reducing construction material needs and associated environmental impacts. The smaller footprint also facilitates easier integration of these systems into existing industrial infrastructure, promoting sustainable retrofitting rather than complete facility replacement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!