PMSM in electric propulsion for marine vessels

AUG 15, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM Technology Evolution

The evolution of Permanent Magnet Synchronous Motors (PMSM) in electric propulsion for marine vessels has been marked by significant technological advancements over the past few decades. Initially, PMSMs were primarily used in small-scale applications due to limitations in magnet materials and power electronics. However, breakthroughs in rare-earth magnet technology, particularly the development of neodymium-iron-boron (NdFeB) magnets in the 1980s, paved the way for more powerful and efficient PMSMs.

In the 1990s, the marine industry began to explore the potential of PMSMs for electric propulsion systems in smaller vessels. This period saw the introduction of basic vector control techniques, which improved the motor's dynamic performance and efficiency. The early 2000s marked a significant milestone with the implementation of advanced control strategies, such as field-oriented control (FOC) and direct torque control (DTC), which further enhanced the motor's responsiveness and torque output.

The mid-2000s witnessed a surge in research focused on optimizing PMSM designs specifically for marine applications. This led to the development of more robust and corrosion-resistant motor configurations, capable of withstanding harsh maritime environments. Simultaneously, advancements in power electronics, particularly the introduction of high-power insulated-gate bipolar transistors (IGBTs), enabled the creation of more efficient and compact motor drive systems.

From 2010 onwards, the integration of PMSMs in larger vessels became increasingly feasible. This period saw the emergence of modular and scalable PMSM designs, allowing for easier integration into various ship sizes and types. The focus shifted towards improving the power density and thermal management of these motors, resulting in more compact and efficient propulsion systems.

Recent years have seen a growing emphasis on the development of high-torque, low-speed PMSMs, eliminating the need for reduction gears in many marine applications. This direct-drive approach has led to simpler, more reliable propulsion systems with reduced maintenance requirements. Additionally, the integration of advanced materials, such as carbon fiber composites in rotor construction, has further improved the power-to-weight ratio of PMSMs.

The latest technological frontier in PMSM evolution for marine propulsion involves the incorporation of smart features and predictive maintenance capabilities. Sensors and data analytics are being integrated into motor systems to monitor performance, predict potential failures, and optimize operational efficiency in real-time. This trend towards "intelligent" PMSMs is expected to play a crucial role in the future of marine electric propulsion, enhancing reliability and reducing operational costs.

In the 1990s, the marine industry began to explore the potential of PMSMs for electric propulsion systems in smaller vessels. This period saw the introduction of basic vector control techniques, which improved the motor's dynamic performance and efficiency. The early 2000s marked a significant milestone with the implementation of advanced control strategies, such as field-oriented control (FOC) and direct torque control (DTC), which further enhanced the motor's responsiveness and torque output.

The mid-2000s witnessed a surge in research focused on optimizing PMSM designs specifically for marine applications. This led to the development of more robust and corrosion-resistant motor configurations, capable of withstanding harsh maritime environments. Simultaneously, advancements in power electronics, particularly the introduction of high-power insulated-gate bipolar transistors (IGBTs), enabled the creation of more efficient and compact motor drive systems.

From 2010 onwards, the integration of PMSMs in larger vessels became increasingly feasible. This period saw the emergence of modular and scalable PMSM designs, allowing for easier integration into various ship sizes and types. The focus shifted towards improving the power density and thermal management of these motors, resulting in more compact and efficient propulsion systems.

Recent years have seen a growing emphasis on the development of high-torque, low-speed PMSMs, eliminating the need for reduction gears in many marine applications. This direct-drive approach has led to simpler, more reliable propulsion systems with reduced maintenance requirements. Additionally, the integration of advanced materials, such as carbon fiber composites in rotor construction, has further improved the power-to-weight ratio of PMSMs.

The latest technological frontier in PMSM evolution for marine propulsion involves the incorporation of smart features and predictive maintenance capabilities. Sensors and data analytics are being integrated into motor systems to monitor performance, predict potential failures, and optimize operational efficiency in real-time. This trend towards "intelligent" PMSMs is expected to play a crucial role in the future of marine electric propulsion, enhancing reliability and reducing operational costs.

Marine Propulsion Market

The marine propulsion market has been experiencing significant growth and transformation in recent years, driven by increasing global trade, environmental regulations, and technological advancements. The market encompasses various propulsion systems, including diesel engines, gas turbines, and electric propulsion systems, with a growing focus on sustainable and efficient solutions.

Electric propulsion systems, particularly those utilizing Permanent Magnet Synchronous Motors (PMSM), have gained considerable attention in the marine industry. This shift is primarily due to their higher efficiency, reduced emissions, and improved maneuverability compared to traditional propulsion systems. The market for electric propulsion in marine vessels is expected to expand rapidly, with a compound annual growth rate (CAGR) projected to be in the double digits over the next decade.

The demand for electric propulsion systems is being fueled by stringent environmental regulations, such as the International Maritime Organization's (IMO) emissions reduction targets. These regulations aim to reduce greenhouse gas emissions from ships by at least 50% by 2050 compared to 2008 levels. As a result, shipowners and operators are increasingly looking for cleaner propulsion alternatives, creating a favorable market environment for PMSM-based electric propulsion systems.

The market for marine electric propulsion is segmented by vessel type, including commercial vessels, naval vessels, and pleasure crafts. Commercial vessels, such as container ships, tankers, and cruise ships, represent a significant portion of the market due to their high power requirements and the potential for substantial fuel savings. Naval vessels are also adopting electric propulsion systems for improved stealth capabilities and reduced acoustic signatures.

Geographically, Europe and North America are leading the adoption of electric propulsion systems in marine vessels, driven by strict environmental regulations and government support for green technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by increasing shipbuilding activities in countries like China, South Korea, and Japan.

Key market trends include the integration of energy storage systems with electric propulsion, the development of hybrid propulsion solutions, and the increasing use of power electronics for improved control and efficiency. Additionally, there is a growing focus on the development of autonomous and remotely operated vessels, which are expected to further drive the demand for electric propulsion systems.

Electric propulsion systems, particularly those utilizing Permanent Magnet Synchronous Motors (PMSM), have gained considerable attention in the marine industry. This shift is primarily due to their higher efficiency, reduced emissions, and improved maneuverability compared to traditional propulsion systems. The market for electric propulsion in marine vessels is expected to expand rapidly, with a compound annual growth rate (CAGR) projected to be in the double digits over the next decade.

The demand for electric propulsion systems is being fueled by stringent environmental regulations, such as the International Maritime Organization's (IMO) emissions reduction targets. These regulations aim to reduce greenhouse gas emissions from ships by at least 50% by 2050 compared to 2008 levels. As a result, shipowners and operators are increasingly looking for cleaner propulsion alternatives, creating a favorable market environment for PMSM-based electric propulsion systems.

The market for marine electric propulsion is segmented by vessel type, including commercial vessels, naval vessels, and pleasure crafts. Commercial vessels, such as container ships, tankers, and cruise ships, represent a significant portion of the market due to their high power requirements and the potential for substantial fuel savings. Naval vessels are also adopting electric propulsion systems for improved stealth capabilities and reduced acoustic signatures.

Geographically, Europe and North America are leading the adoption of electric propulsion systems in marine vessels, driven by strict environmental regulations and government support for green technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by increasing shipbuilding activities in countries like China, South Korea, and Japan.

Key market trends include the integration of energy storage systems with electric propulsion, the development of hybrid propulsion solutions, and the increasing use of power electronics for improved control and efficiency. Additionally, there is a growing focus on the development of autonomous and remotely operated vessels, which are expected to further drive the demand for electric propulsion systems.

PMSM Challenges in Marine

The implementation of Permanent Magnet Synchronous Motors (PMSM) in marine electric propulsion systems faces several significant challenges. One of the primary obstacles is the harsh marine environment, characterized by high humidity, salt spray, and temperature fluctuations. These conditions can lead to accelerated corrosion and degradation of motor components, particularly affecting the permanent magnets and electrical windings. Ensuring adequate protection and sealing of the motor assembly becomes crucial to maintain long-term reliability and performance.

Another challenge lies in the space constraints and weight limitations inherent to marine vessels. PMSMs need to be compact and lightweight while still delivering high power output and efficiency. This necessitates innovative design approaches and the use of advanced materials to optimize power density without compromising structural integrity or thermal management capabilities.

The dynamic nature of marine propulsion demands also presents unique challenges for PMSM control systems. Rapid load changes, varying sea conditions, and the need for precise maneuvering require sophisticated control algorithms capable of adapting to these fluctuations. Developing robust control strategies that can maintain optimal motor performance across a wide range of operating conditions is essential for effective marine propulsion applications.

Furthermore, the integration of PMSMs with existing shipboard power systems poses significant challenges. Marine vessels often have complex electrical networks, and the introduction of high-power electric propulsion systems can lead to power quality issues, harmonics, and electromagnetic interference. Ensuring compatibility and maintaining overall system stability requires careful consideration of power electronics, filtering techniques, and system-level design approaches.

Reliability and maintenance considerations are also critical challenges in marine PMSM applications. The remote nature of marine operations and the high cost of downtime necessitate motors that can operate for extended periods without failure. This requires not only robust design and construction but also the development of advanced condition monitoring and predictive maintenance techniques to detect potential issues before they lead to system failures.

Lastly, the marine industry's stringent regulatory environment presents additional challenges for PMSM implementation. Compliance with international maritime standards, such as those set by the International Maritime Organization (IMO), requires careful attention to safety, emissions, and efficiency requirements. Balancing these regulatory demands with performance and cost considerations adds another layer of complexity to the design and deployment of PMSM-based marine propulsion systems.

Another challenge lies in the space constraints and weight limitations inherent to marine vessels. PMSMs need to be compact and lightweight while still delivering high power output and efficiency. This necessitates innovative design approaches and the use of advanced materials to optimize power density without compromising structural integrity or thermal management capabilities.

The dynamic nature of marine propulsion demands also presents unique challenges for PMSM control systems. Rapid load changes, varying sea conditions, and the need for precise maneuvering require sophisticated control algorithms capable of adapting to these fluctuations. Developing robust control strategies that can maintain optimal motor performance across a wide range of operating conditions is essential for effective marine propulsion applications.

Furthermore, the integration of PMSMs with existing shipboard power systems poses significant challenges. Marine vessels often have complex electrical networks, and the introduction of high-power electric propulsion systems can lead to power quality issues, harmonics, and electromagnetic interference. Ensuring compatibility and maintaining overall system stability requires careful consideration of power electronics, filtering techniques, and system-level design approaches.

Reliability and maintenance considerations are also critical challenges in marine PMSM applications. The remote nature of marine operations and the high cost of downtime necessitate motors that can operate for extended periods without failure. This requires not only robust design and construction but also the development of advanced condition monitoring and predictive maintenance techniques to detect potential issues before they lead to system failures.

Lastly, the marine industry's stringent regulatory environment presents additional challenges for PMSM implementation. Compliance with international maritime standards, such as those set by the International Maritime Organization (IMO), requires careful attention to safety, emissions, and efficiency requirements. Balancing these regulatory demands with performance and cost considerations adds another layer of complexity to the design and deployment of PMSM-based marine propulsion systems.

Current PMSM Solutions

01 Motor design and structure

Innovations in PMSM design focus on improving efficiency and performance. This includes optimizing the arrangement of permanent magnets, enhancing rotor and stator configurations, and developing novel winding techniques. These advancements aim to increase power density, reduce cogging torque, and improve overall motor efficiency.- Design and optimization of PMSM: This category focuses on the design and optimization of Permanent Magnet Synchronous Motors (PMSM). It includes improvements in motor structure, magnetic circuit design, and performance optimization techniques. These advancements aim to enhance efficiency, power density, and overall performance of PMSMs for various applications.

- Control strategies for PMSM: This point covers various control strategies and algorithms developed for PMSMs. It includes advanced control techniques such as sensorless control, vector control, and adaptive control methods. These strategies aim to improve motor performance, efficiency, and reliability across different operating conditions.

- PMSM applications in electric vehicles: This category focuses on the application of PMSMs in electric vehicles (EVs). It covers specific design considerations, control strategies, and integration techniques for PMSMs in EV powertrains. The advancements in this area aim to improve vehicle performance, range, and energy efficiency.

- Fault diagnosis and condition monitoring of PMSM: This point addresses the development of fault diagnosis and condition monitoring techniques for PMSMs. It includes methods for detecting and identifying various faults, such as rotor eccentricity, demagnetization, and winding faults. These techniques aim to improve the reliability and maintenance of PMSM systems.

- PMSM manufacturing and assembly techniques: This category covers advancements in manufacturing and assembly techniques for PMSMs. It includes innovative methods for magnet placement, winding techniques, and overall motor assembly. These improvements aim to enhance production efficiency, reduce costs, and improve the quality and consistency of PMSM manufacturing.

02 Control systems and algorithms

Advanced control strategies are developed for PMSMs to enhance their operation. These include sensorless control techniques, adaptive control algorithms, and improved vector control methods. Such systems aim to optimize motor performance, reduce energy consumption, and increase reliability across various operating conditions.Expand Specific Solutions03 Thermal management and cooling

Effective thermal management is crucial for PMSM performance and longevity. Innovations in this area include advanced cooling systems, heat dissipation techniques, and temperature monitoring methods. These solutions help maintain optimal operating temperatures, prevent overheating, and extend motor lifespan.Expand Specific Solutions04 Integration with power electronics

Advancements in integrating PMSMs with power electronic systems are being made to improve overall system efficiency. This includes developing compact integrated motor drives, optimizing inverter designs, and implementing advanced power management strategies. Such integrations enhance motor control precision and energy efficiency.Expand Specific Solutions05 Application-specific optimizations

PMSMs are being optimized for specific applications such as electric vehicles, industrial automation, and renewable energy systems. These optimizations involve tailoring motor designs, control strategies, and performance characteristics to meet the unique requirements of each application, improving efficiency and functionality in their intended use cases.Expand Specific Solutions

Key Marine PMSM Players

The research on PMSM in electric propulsion for marine vessels is in a developing stage, with growing market potential due to increasing demand for eco-friendly maritime solutions. The technology is advancing rapidly, but still faces challenges in efficiency and reliability for large-scale marine applications. Key players like Brunswick Corp., Caterpillar Inc., and CRRC Yongji Moto Co., Ltd. are investing heavily in R&D to improve PMSM performance and integration with marine systems. Academic institutions such as Dalian Maritime University and Wuhan University of Technology are also contributing significantly to the field through research collaborations and innovations. As the maritime industry shifts towards electrification, the PMSM market for marine propulsion is expected to expand substantially in the coming years.

Wuhan Research Institute of Marine Electric Propulsion

Technical Solution: The institute has developed a high-performance PMSM control system for marine vessels, utilizing advanced vector control algorithms and real-time optimization techniques. Their solution incorporates a robust sensorless control strategy, enhancing reliability in harsh marine environments. The system achieves high torque density and improved efficiency across a wide speed range, crucial for various marine applications[1][3]. They have also implemented an adaptive flux-weakening control method, allowing for extended operation beyond the base speed while maintaining optimal efficiency[5]. The institute's research includes the development of a fault-tolerant control scheme, ensuring continuous operation even under partial system failures, which is critical for marine safety[7].

Strengths: Specialized expertise in marine electric propulsion, advanced control algorithms, and fault-tolerant systems. Weaknesses: Potentially limited to marine applications, may face challenges in scaling for larger vessels.

Dalian Maritime University

Technical Solution: Dalian Maritime University has focused on developing a novel PMSM design specifically optimized for marine propulsion systems. Their approach includes an innovative rotor structure that reduces cogging torque and minimizes harmonic distortion in the back-EMF, resulting in smoother operation and reduced vibration[2]. The university has also developed an advanced thermal management system, addressing the unique cooling challenges in marine environments. Their PMSM design incorporates a hybrid cooling method, combining liquid cooling for the stator and air cooling for the rotor, significantly improving the motor's power density and continuous operation capabilities[4]. Additionally, they have implemented a predictive maintenance system using machine learning algorithms to monitor motor health and predict potential failures, enhancing overall system reliability[6].

Strengths: Specialized marine-focused PMSM design, advanced thermal management, and predictive maintenance capabilities. Weaknesses: May have limited experience in large-scale commercial production and integration with existing marine systems.

PMSM Innovations Analysis

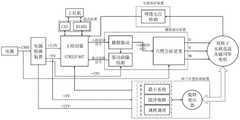

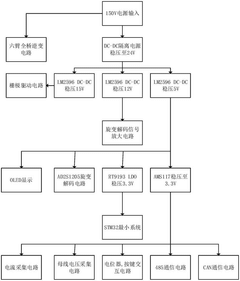

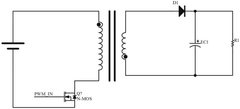

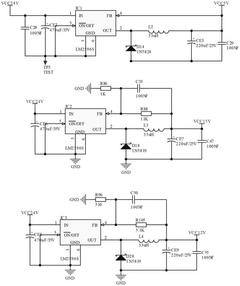

Kilowatt-level double-rotor permanent magnet synchronous motor control system for underwater equipment

PatentPendingCN118868703A

Innovation

- A kilowatt-level dual-rotor permanent magnet synchronous motor control system including a power supply, power conversion device, communication device, rotor position detection device, main controller, gate drive device and circuit protection device is designed. The rotor position is received through the main controller The signal is commutation controlled, the PWM signal is output for SVPWM modulation, and real-time protection is achieved through the circuit protection device. CAN and RS485 communication are used to achieve real-time communication with the host computer.

Environmental Regulations

Environmental regulations play a crucial role in shaping the adoption and development of electric propulsion systems for marine vessels, including those utilizing Permanent Magnet Synchronous Motors (PMSM). These regulations are primarily driven by the need to reduce greenhouse gas emissions and other pollutants from the maritime sector.

The International Maritime Organization (IMO) has set ambitious targets for reducing carbon emissions from ships. By 2050, the IMO aims to cut greenhouse gas emissions from international shipping by at least 50% compared to 2008 levels. This has led to the implementation of stricter emission standards and energy efficiency requirements for marine vessels.

In response to these regulations, many countries and regions have introduced their own environmental policies. The European Union, for instance, has implemented the EU Emissions Trading System (EU ETS) for maritime transport, which includes a gradual introduction of obligations for shipping companies to surrender allowances for a portion of their emissions.

These environmental regulations have significantly accelerated the adoption of electric propulsion systems in the marine industry. PMSM-based electric propulsion offers several advantages in meeting these regulatory requirements, including higher efficiency, reduced emissions, and improved maneuverability.

The regulatory landscape also influences research and development priorities in PMSM technology for marine applications. There is an increased focus on improving the power density, efficiency, and reliability of PMSM systems to meet the stringent environmental standards while maintaining vessel performance.

Furthermore, environmental regulations have spurred innovation in energy storage technologies, such as advanced battery systems and fuel cells, which complement PMSM-based electric propulsion. This has led to the development of hybrid and fully electric vessel designs that can significantly reduce or eliminate emissions during operation.

As regulations continue to evolve, the marine industry is likely to see further advancements in PMSM technology and its integration with other clean energy solutions. This includes research into more efficient motor designs, advanced control strategies, and the use of sustainable materials in motor construction.

The International Maritime Organization (IMO) has set ambitious targets for reducing carbon emissions from ships. By 2050, the IMO aims to cut greenhouse gas emissions from international shipping by at least 50% compared to 2008 levels. This has led to the implementation of stricter emission standards and energy efficiency requirements for marine vessels.

In response to these regulations, many countries and regions have introduced their own environmental policies. The European Union, for instance, has implemented the EU Emissions Trading System (EU ETS) for maritime transport, which includes a gradual introduction of obligations for shipping companies to surrender allowances for a portion of their emissions.

These environmental regulations have significantly accelerated the adoption of electric propulsion systems in the marine industry. PMSM-based electric propulsion offers several advantages in meeting these regulatory requirements, including higher efficiency, reduced emissions, and improved maneuverability.

The regulatory landscape also influences research and development priorities in PMSM technology for marine applications. There is an increased focus on improving the power density, efficiency, and reliability of PMSM systems to meet the stringent environmental standards while maintaining vessel performance.

Furthermore, environmental regulations have spurred innovation in energy storage technologies, such as advanced battery systems and fuel cells, which complement PMSM-based electric propulsion. This has led to the development of hybrid and fully electric vessel designs that can significantly reduce or eliminate emissions during operation.

As regulations continue to evolve, the marine industry is likely to see further advancements in PMSM technology and its integration with other clean energy solutions. This includes research into more efficient motor designs, advanced control strategies, and the use of sustainable materials in motor construction.

Energy Efficiency Metrics

Energy efficiency metrics play a crucial role in evaluating the performance of Permanent Magnet Synchronous Motors (PMSM) in electric propulsion systems for marine vessels. These metrics provide valuable insights into the overall efficiency of the propulsion system and help identify areas for improvement.

One of the primary energy efficiency metrics for PMSM in marine electric propulsion is the motor efficiency, which is typically expressed as a percentage. This metric represents the ratio of mechanical power output to electrical power input. For PMSM used in marine applications, efficiency values often range from 95% to 98%, depending on the motor design and operating conditions.

Power density is another important metric, measured in kilowatts per kilogram (kW/kg) or kilowatts per cubic meter (kW/m³). Higher power density indicates a more compact and lightweight motor, which is particularly beneficial for marine vessels where space and weight are critical factors. PMSM generally offers superior power density compared to other motor types, making them increasingly popular in marine propulsion systems.

The specific fuel consumption (SFC) is a key metric for assessing the overall energy efficiency of the propulsion system. It measures the amount of fuel consumed per unit of power output, typically expressed in grams per kilowatt-hour (g/kWh). Lower SFC values indicate higher energy efficiency and reduced fuel consumption, which is crucial for marine vessels operating over long distances.

Torque density, measured in Newton-meters per kilogram (Nm/kg), is another important metric for PMSM in marine propulsion. Higher torque density allows for better acceleration and maneuverability, which are essential for marine vessels, especially in challenging sea conditions.

The power factor is a metric that indicates how effectively the electrical power is being utilized. A higher power factor, closer to 1, signifies more efficient power usage and reduced electrical losses in the system. PMSM typically operates at high power factors, contributing to overall system efficiency.

Energy efficiency metrics also include thermal efficiency, which measures how effectively the motor converts electrical energy into mechanical energy while minimizing heat losses. This is particularly important in marine environments where cooling can be challenging.

Lastly, the overall system efficiency, which takes into account not only the motor but also the power electronics, transmission, and propeller efficiency, provides a comprehensive view of the entire propulsion system's performance. This metric is crucial for optimizing the complete propulsion chain in marine vessels.

By carefully monitoring and optimizing these energy efficiency metrics, marine vessel operators can significantly reduce fuel consumption, lower operating costs, and minimize environmental impact, all of which are increasingly important in the maritime industry.

One of the primary energy efficiency metrics for PMSM in marine electric propulsion is the motor efficiency, which is typically expressed as a percentage. This metric represents the ratio of mechanical power output to electrical power input. For PMSM used in marine applications, efficiency values often range from 95% to 98%, depending on the motor design and operating conditions.

Power density is another important metric, measured in kilowatts per kilogram (kW/kg) or kilowatts per cubic meter (kW/m³). Higher power density indicates a more compact and lightweight motor, which is particularly beneficial for marine vessels where space and weight are critical factors. PMSM generally offers superior power density compared to other motor types, making them increasingly popular in marine propulsion systems.

The specific fuel consumption (SFC) is a key metric for assessing the overall energy efficiency of the propulsion system. It measures the amount of fuel consumed per unit of power output, typically expressed in grams per kilowatt-hour (g/kWh). Lower SFC values indicate higher energy efficiency and reduced fuel consumption, which is crucial for marine vessels operating over long distances.

Torque density, measured in Newton-meters per kilogram (Nm/kg), is another important metric for PMSM in marine propulsion. Higher torque density allows for better acceleration and maneuverability, which are essential for marine vessels, especially in challenging sea conditions.

The power factor is a metric that indicates how effectively the electrical power is being utilized. A higher power factor, closer to 1, signifies more efficient power usage and reduced electrical losses in the system. PMSM typically operates at high power factors, contributing to overall system efficiency.

Energy efficiency metrics also include thermal efficiency, which measures how effectively the motor converts electrical energy into mechanical energy while minimizing heat losses. This is particularly important in marine environments where cooling can be challenging.

Lastly, the overall system efficiency, which takes into account not only the motor but also the power electronics, transmission, and propeller efficiency, provides a comprehensive view of the entire propulsion system's performance. This metric is crucial for optimizing the complete propulsion chain in marine vessels.

By carefully monitoring and optimizing these energy efficiency metrics, marine vessel operators can significantly reduce fuel consumption, lower operating costs, and minimize environmental impact, all of which are increasingly important in the maritime industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!