Responsible Engineering Through Hydrochloric Acid Initiatives

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl Initiatives Background and Objectives

Hydrochloric acid (HCl) initiatives have emerged as a critical focus in responsible engineering practices, driven by the need to address environmental concerns and optimize industrial processes. The background of these initiatives traces back to the early 20th century when HCl production became widespread due to its versatile applications in various industries. However, the increasing awareness of environmental impacts and safety hazards associated with HCl production and usage has led to a paradigm shift in recent decades.

The evolution of HCl initiatives has been marked by significant milestones in chemical engineering and environmental science. In the 1970s and 1980s, stringent regulations were introduced to control HCl emissions and improve workplace safety. This regulatory landscape prompted industries to invest in research and development of cleaner production methods and more efficient utilization of HCl.

The objectives of current HCl initiatives are multifaceted, aiming to address the challenges posed by traditional HCl production and usage while harnessing its potential benefits. One primary goal is to develop sustainable production methods that minimize environmental impact. This includes exploring alternative synthesis routes, implementing closed-loop systems, and optimizing recovery processes to reduce waste and emissions.

Another key objective is to enhance the safety aspects of HCl handling and transportation. This involves developing advanced containment systems, improving risk assessment methodologies, and implementing robust safety protocols across the supply chain. Additionally, there is a growing focus on exploring novel applications of HCl in emerging fields such as nanotechnology and advanced materials, which could potentially lead to more efficient and environmentally friendly processes.

The technological trajectory of HCl initiatives is closely aligned with the broader trends in green chemistry and circular economy principles. Researchers are investigating catalytic processes that could enable HCl production from renewable resources, as well as exploring the potential of HCl as a key component in energy storage systems and carbon capture technologies.

Furthermore, the objectives extend to improving the overall lifecycle management of HCl, from production to disposal. This encompasses developing more accurate monitoring and control systems, implementing advanced purification techniques, and creating innovative recycling methods to maximize resource efficiency and minimize environmental footprint.

As the field of responsible engineering continues to evolve, HCl initiatives are expected to play a crucial role in shaping sustainable industrial practices. The ongoing research aims to strike a balance between meeting the growing demand for HCl in various sectors and adhering to stringent environmental and safety standards. By addressing these challenges, HCl initiatives are poised to contribute significantly to the advancement of responsible engineering practices in the chemical industry and beyond.

The evolution of HCl initiatives has been marked by significant milestones in chemical engineering and environmental science. In the 1970s and 1980s, stringent regulations were introduced to control HCl emissions and improve workplace safety. This regulatory landscape prompted industries to invest in research and development of cleaner production methods and more efficient utilization of HCl.

The objectives of current HCl initiatives are multifaceted, aiming to address the challenges posed by traditional HCl production and usage while harnessing its potential benefits. One primary goal is to develop sustainable production methods that minimize environmental impact. This includes exploring alternative synthesis routes, implementing closed-loop systems, and optimizing recovery processes to reduce waste and emissions.

Another key objective is to enhance the safety aspects of HCl handling and transportation. This involves developing advanced containment systems, improving risk assessment methodologies, and implementing robust safety protocols across the supply chain. Additionally, there is a growing focus on exploring novel applications of HCl in emerging fields such as nanotechnology and advanced materials, which could potentially lead to more efficient and environmentally friendly processes.

The technological trajectory of HCl initiatives is closely aligned with the broader trends in green chemistry and circular economy principles. Researchers are investigating catalytic processes that could enable HCl production from renewable resources, as well as exploring the potential of HCl as a key component in energy storage systems and carbon capture technologies.

Furthermore, the objectives extend to improving the overall lifecycle management of HCl, from production to disposal. This encompasses developing more accurate monitoring and control systems, implementing advanced purification techniques, and creating innovative recycling methods to maximize resource efficiency and minimize environmental footprint.

As the field of responsible engineering continues to evolve, HCl initiatives are expected to play a crucial role in shaping sustainable industrial practices. The ongoing research aims to strike a balance between meeting the growing demand for HCl in various sectors and adhering to stringent environmental and safety standards. By addressing these challenges, HCl initiatives are poised to contribute significantly to the advancement of responsible engineering practices in the chemical industry and beyond.

Market Analysis for Responsible HCl Engineering

The market for responsible hydrochloric acid (HCl) engineering is experiencing significant growth driven by increasing environmental concerns and stringent regulations. Industries such as chemical manufacturing, metal processing, and water treatment are the primary consumers of HCl, with a growing emphasis on sustainable practices. The global HCl market size was valued at over $7 billion in 2020, with projections indicating steady growth in the coming years.

Responsible HCl engineering initiatives are gaining traction due to the hazardous nature of the chemical and its potential environmental impact. Companies are investing in advanced technologies to minimize HCl emissions, improve handling safety, and optimize production processes. This shift towards responsible practices is creating new market opportunities for equipment manufacturers, process engineering firms, and environmental consultancies.

The demand for closed-loop HCl recycling systems is on the rise, particularly in the semiconductor industry, where ultra-pure HCl is essential. These systems not only reduce waste but also offer cost savings and improved efficiency. Additionally, there is a growing market for HCl recovery from industrial waste streams, driven by both economic and environmental factors.

Geographically, Asia-Pacific dominates the HCl market, accounting for over 40% of global consumption. This region, led by China and India, is also at the forefront of adopting responsible HCl engineering practices due to tightening environmental regulations. North America and Europe follow, with mature markets focusing on innovation in sustainable HCl production and utilization.

The market for HCl alternatives is also expanding, particularly in applications where substitution is feasible. This trend is driving research into less corrosive and more environmentally friendly acids, creating both challenges and opportunities for the HCl industry.

Key market players are investing heavily in research and development to improve HCl production efficiency and reduce environmental impact. This includes the development of catalytic processes that minimize by-product formation and energy consumption. The market is also seeing increased collaboration between industry and academia to address long-standing challenges in HCl handling and disposal.

Emerging technologies such as membrane-based HCl recovery systems and advanced scrubbing techniques are gaining market share. These innovations offer improved efficiency and reduced environmental footprint, aligning with the growing demand for responsible engineering solutions.

The regulatory landscape is a significant driver of market trends, with increasingly stringent emissions standards and waste management requirements shaping industry practices. This regulatory pressure is fostering innovation and creating market opportunities for companies that can provide compliant and cost-effective solutions.

Responsible HCl engineering initiatives are gaining traction due to the hazardous nature of the chemical and its potential environmental impact. Companies are investing in advanced technologies to minimize HCl emissions, improve handling safety, and optimize production processes. This shift towards responsible practices is creating new market opportunities for equipment manufacturers, process engineering firms, and environmental consultancies.

The demand for closed-loop HCl recycling systems is on the rise, particularly in the semiconductor industry, where ultra-pure HCl is essential. These systems not only reduce waste but also offer cost savings and improved efficiency. Additionally, there is a growing market for HCl recovery from industrial waste streams, driven by both economic and environmental factors.

Geographically, Asia-Pacific dominates the HCl market, accounting for over 40% of global consumption. This region, led by China and India, is also at the forefront of adopting responsible HCl engineering practices due to tightening environmental regulations. North America and Europe follow, with mature markets focusing on innovation in sustainable HCl production and utilization.

The market for HCl alternatives is also expanding, particularly in applications where substitution is feasible. This trend is driving research into less corrosive and more environmentally friendly acids, creating both challenges and opportunities for the HCl industry.

Key market players are investing heavily in research and development to improve HCl production efficiency and reduce environmental impact. This includes the development of catalytic processes that minimize by-product formation and energy consumption. The market is also seeing increased collaboration between industry and academia to address long-standing challenges in HCl handling and disposal.

Emerging technologies such as membrane-based HCl recovery systems and advanced scrubbing techniques are gaining market share. These innovations offer improved efficiency and reduced environmental footprint, aligning with the growing demand for responsible engineering solutions.

The regulatory landscape is a significant driver of market trends, with increasingly stringent emissions standards and waste management requirements shaping industry practices. This regulatory pressure is fostering innovation and creating market opportunities for companies that can provide compliant and cost-effective solutions.

Current Challenges in HCl Engineering

The field of hydrochloric acid (HCl) engineering faces several significant challenges that require innovative solutions and responsible practices. One of the primary concerns is the corrosive nature of HCl, which poses risks to both equipment and personnel. This necessitates the development of advanced materials and protective measures to ensure safe handling and storage of the acid.

Environmental impact remains a critical issue in HCl engineering. The production and use of hydrochloric acid can lead to air and water pollution if not properly managed. Emissions control and waste treatment technologies need continuous improvement to meet increasingly stringent environmental regulations and reduce the ecological footprint of HCl-related processes.

Another challenge lies in the energy-intensive nature of HCl production. The chlor-alkali process, which is the primary method for producing HCl, consumes significant amounts of electricity. Enhancing energy efficiency and exploring alternative production methods are crucial for sustainability and cost-effectiveness in the industry.

The transportation of HCl presents logistical challenges due to its hazardous nature. Ensuring safe and efficient transportation while complying with complex regulatory requirements demands ongoing innovation in packaging, containment, and monitoring systems.

In the realm of process engineering, optimizing HCl concentration and purity levels for various applications remains a persistent challenge. Different industries require HCl with specific properties, necessitating precise control over production processes and the development of tailored purification techniques.

The recovery and recycling of HCl from industrial processes present both a challenge and an opportunity. Implementing effective recovery systems can reduce waste and improve resource efficiency, but it requires overcoming technical hurdles related to separation and purification.

Digitalization and automation in HCl engineering processes are areas that demand attention. Integrating advanced sensors, control systems, and data analytics can enhance safety, efficiency, and quality control, but it also introduces challenges in terms of cybersecurity and workforce adaptation.

Lastly, the responsible use of HCl in emerging applications, such as in the production of high-purity silicon for solar panels or in advanced battery technologies, requires ongoing research to balance technological advancements with environmental and safety considerations. Addressing these challenges through responsible engineering initiatives is crucial for the sustainable development of HCl-related technologies and industries.

Environmental impact remains a critical issue in HCl engineering. The production and use of hydrochloric acid can lead to air and water pollution if not properly managed. Emissions control and waste treatment technologies need continuous improvement to meet increasingly stringent environmental regulations and reduce the ecological footprint of HCl-related processes.

Another challenge lies in the energy-intensive nature of HCl production. The chlor-alkali process, which is the primary method for producing HCl, consumes significant amounts of electricity. Enhancing energy efficiency and exploring alternative production methods are crucial for sustainability and cost-effectiveness in the industry.

The transportation of HCl presents logistical challenges due to its hazardous nature. Ensuring safe and efficient transportation while complying with complex regulatory requirements demands ongoing innovation in packaging, containment, and monitoring systems.

In the realm of process engineering, optimizing HCl concentration and purity levels for various applications remains a persistent challenge. Different industries require HCl with specific properties, necessitating precise control over production processes and the development of tailored purification techniques.

The recovery and recycling of HCl from industrial processes present both a challenge and an opportunity. Implementing effective recovery systems can reduce waste and improve resource efficiency, but it requires overcoming technical hurdles related to separation and purification.

Digitalization and automation in HCl engineering processes are areas that demand attention. Integrating advanced sensors, control systems, and data analytics can enhance safety, efficiency, and quality control, but it also introduces challenges in terms of cybersecurity and workforce adaptation.

Lastly, the responsible use of HCl in emerging applications, such as in the production of high-purity silicon for solar panels or in advanced battery technologies, requires ongoing research to balance technological advancements with environmental and safety considerations. Addressing these challenges through responsible engineering initiatives is crucial for the sustainable development of HCl-related technologies and industries.

Existing Responsible HCl Engineering Solutions

01 Production and purification of hydrochloric acid

Various methods and processes for producing and purifying hydrochloric acid, including techniques for improving yield, reducing impurities, and optimizing production efficiency. These processes may involve chemical reactions, distillation, or other separation techniques to obtain high-quality hydrochloric acid.- Production methods of hydrochloric acid: Various methods are employed for the production of hydrochloric acid, including chemical reactions and industrial processes. These methods may involve the use of specific catalysts, reactants, or equipment to efficiently produce hydrochloric acid at different concentrations and purities.

- Applications in chemical processing: Hydrochloric acid is widely used in chemical processing industries for various applications such as pH adjustment, metal treatment, and as a reagent in chemical reactions. Its strong acidic properties make it suitable for diverse industrial processes and manufacturing operations.

- Purification and treatment of hydrochloric acid: Techniques for purifying and treating hydrochloric acid are essential for obtaining high-quality acid suitable for specific applications. These methods may include distillation, filtration, or other separation processes to remove impurities and achieve desired concentrations.

- Storage and handling systems: Specialized storage and handling systems are crucial for the safe management of hydrochloric acid due to its corrosive nature. These systems may include specific container designs, safety features, and materials resistant to acid corrosion to ensure proper storage and transportation.

- Environmental and safety considerations: Environmental and safety aspects are paramount when dealing with hydrochloric acid. This includes methods for neutralization, proper disposal, emission control, and safety measures to protect workers and the environment from potential hazards associated with hydrochloric acid use and production.

02 Applications of hydrochloric acid in industrial processes

Hydrochloric acid is widely used in various industrial applications, such as metal processing, chemical manufacturing, and water treatment. Patents in this category describe specific uses of hydrochloric acid in different industrial processes, including its role as a catalyst, cleaning agent, or reactant.Expand Specific Solutions03 Handling and storage of hydrochloric acid

Innovations related to the safe handling, storage, and transportation of hydrochloric acid. This includes specialized containers, equipment, and systems designed to prevent leaks, corrosion, and accidents associated with the storage and use of this highly corrosive substance.Expand Specific Solutions04 Recovery and recycling of hydrochloric acid

Methods and systems for recovering and recycling hydrochloric acid from industrial processes or waste streams. These technologies aim to reduce environmental impact and improve resource efficiency by reusing or repurposing hydrochloric acid in various applications.Expand Specific Solutions05 Environmental and safety considerations

Inventions focused on mitigating the environmental impact and improving safety aspects related to hydrochloric acid use. This includes technologies for neutralizing acid spills, reducing emissions, and developing safer alternatives or handling methods to minimize risks associated with hydrochloric acid.Expand Specific Solutions

Key Players in HCl Engineering Industry

The research on responsible engineering through hydrochloric acid initiatives is in its early stages, with the market still developing. The global market size for this technology is relatively small but growing, driven by increasing environmental concerns and regulatory pressures. The technology's maturity is evolving, with companies like Vertex Pharmaceuticals, Covestro Deutschland AG, and Arkema France SA leading in research and development. These players are investing in innovative solutions to address the challenges associated with hydrochloric acid use in industrial processes, focusing on sustainability and efficiency. As the industry progresses, collaboration between academic institutions and corporations is expected to accelerate technological advancements and market growth.

Arkema France SA

Technical Solution: Arkema France SA has pioneered responsible engineering in hydrochloric acid initiatives through their innovative ALCA® process. This technology focuses on the recovery and recycling of hydrochloric acid from industrial waste streams[4]. The process utilizes a proprietary catalytic system that converts waste hydrochloric acid into high-value chlorinated compounds, such as vinyl chloride monomer (VCM), while simultaneously producing hydrogen as a clean energy by-product[5]. Arkema has also developed advanced materials for acid-resistant coatings and linings, which extend the lifespan of equipment used in hydrochloric acid production and handling, thereby reducing maintenance needs and improving overall safety[6].

Strengths: Efficient waste acid recovery and conversion to valuable products, production of clean hydrogen. Weaknesses: Process complexity may limit widespread adoption, and it may require significant modifications to existing industrial setups.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed a responsible engineering approach for hydrochloric acid initiatives, focusing on sustainable production and waste reduction. Their process involves using membrane-based electrolysis technology to convert by-product hydrochloric acid into high-purity chlorine and hydrogen[1]. This closed-loop system significantly reduces waste and energy consumption. Additionally, Dow has implemented advanced scrubbing systems and real-time monitoring to minimize environmental impact and ensure worker safety[2]. The company has also invested in developing corrosion-resistant materials and equipment specifically designed for hydrochloric acid handling, improving overall process efficiency and reducing the risk of leaks or spills[3].

Strengths: Closed-loop production system, advanced monitoring, and safety measures. Weaknesses: High initial investment costs and potential limitations in scaling up the technology for larger production volumes.

Innovative HCl Handling Techniques

Methods for the recovery of hcl and for the production of carbohydrates

PatentInactiveUS20130047979A1

Innovation

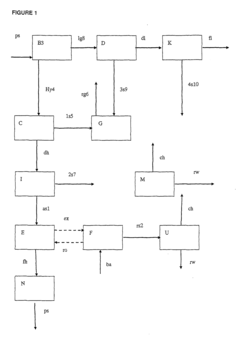

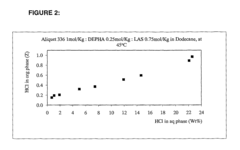

- A method utilizing an organic phase composition comprising quaternary amines, specific organic acids, and hydrocarbons, which selectively extracts HCl from aqueous solutions at controlled temperatures, minimizing solvent use and maintaining product integrity, and a process for recovering HCl through solvent extraction and distillation, ensuring high purity and minimal product loss.

HYDROCHLORIC ACID RECOVERY AND REGENERATION PROCESS WITH SULFATE PRODUCTION

PatentInactiveBR102022004827A2

Innovation

- A process that regenerates hydrochloric acid by reacting exhausted acid with sulfuric acid, producing zinc sulfate and iron sulfate, utilizing a reactor with heating and agitation, followed by concentration and absorption, allowing the acid to be reused and the sulfates to be used in various industries.

Environmental Impact Assessment

The environmental impact assessment of hydrochloric acid initiatives in responsible engineering is a critical component of sustainable industrial practices. These initiatives aim to mitigate the potential adverse effects of hydrochloric acid production and usage on ecosystems and human health. The assessment process involves a comprehensive evaluation of air, water, and soil quality in areas surrounding production facilities and application sites.

Air quality monitoring is a primary focus, as hydrochloric acid emissions can contribute to acid rain and atmospheric pollution. Advanced scrubbing technologies and emission control systems are implemented to minimize the release of acid vapors and chlorine gas. Continuous monitoring of air quality parameters, including pH levels and particulate matter concentrations, helps ensure compliance with environmental regulations and identifies areas for improvement.

Water resource protection is another crucial aspect of the environmental impact assessment. Hydrochloric acid can significantly alter the pH of water bodies if released untreated. Stringent wastewater management protocols are established, including neutralization processes and advanced filtration systems. Regular water quality testing in nearby rivers, lakes, and groundwater sources is conducted to detect any potential contamination and implement remedial measures promptly.

Soil contamination risks are also carefully evaluated, particularly in areas where hydrochloric acid is used in industrial processes or for soil treatment. Soil pH monitoring, along with assessments of soil structure and microbial activity, helps identify any long-term impacts on soil health and agricultural productivity. Remediation strategies, such as soil washing and pH adjustment techniques, are developed to address any detected contamination.

Biodiversity impact studies form an integral part of the assessment, examining the effects of hydrochloric acid-related activities on local flora and fauna. This includes monitoring sensitive species and habitats, assessing potential disruptions to ecosystems, and implementing conservation measures where necessary. The goal is to maintain ecological balance while allowing for responsible industrial development.

Lifecycle analysis of hydrochloric acid production and usage is conducted to identify opportunities for reducing environmental footprint throughout the supply chain. This involves evaluating raw material sourcing, production processes, transportation, and end-of-life disposal or recycling. Emphasis is placed on developing closed-loop systems and exploring alternative, more environmentally friendly production methods.

The assessment also considers the potential for accidental releases and implements robust emergency response plans. This includes the installation of containment systems, training of personnel in spill management, and coordination with local emergency services. Regular drills and simulations ensure preparedness for potential environmental incidents.

Air quality monitoring is a primary focus, as hydrochloric acid emissions can contribute to acid rain and atmospheric pollution. Advanced scrubbing technologies and emission control systems are implemented to minimize the release of acid vapors and chlorine gas. Continuous monitoring of air quality parameters, including pH levels and particulate matter concentrations, helps ensure compliance with environmental regulations and identifies areas for improvement.

Water resource protection is another crucial aspect of the environmental impact assessment. Hydrochloric acid can significantly alter the pH of water bodies if released untreated. Stringent wastewater management protocols are established, including neutralization processes and advanced filtration systems. Regular water quality testing in nearby rivers, lakes, and groundwater sources is conducted to detect any potential contamination and implement remedial measures promptly.

Soil contamination risks are also carefully evaluated, particularly in areas where hydrochloric acid is used in industrial processes or for soil treatment. Soil pH monitoring, along with assessments of soil structure and microbial activity, helps identify any long-term impacts on soil health and agricultural productivity. Remediation strategies, such as soil washing and pH adjustment techniques, are developed to address any detected contamination.

Biodiversity impact studies form an integral part of the assessment, examining the effects of hydrochloric acid-related activities on local flora and fauna. This includes monitoring sensitive species and habitats, assessing potential disruptions to ecosystems, and implementing conservation measures where necessary. The goal is to maintain ecological balance while allowing for responsible industrial development.

Lifecycle analysis of hydrochloric acid production and usage is conducted to identify opportunities for reducing environmental footprint throughout the supply chain. This involves evaluating raw material sourcing, production processes, transportation, and end-of-life disposal or recycling. Emphasis is placed on developing closed-loop systems and exploring alternative, more environmentally friendly production methods.

The assessment also considers the potential for accidental releases and implements robust emergency response plans. This includes the installation of containment systems, training of personnel in spill management, and coordination with local emergency services. Regular drills and simulations ensure preparedness for potential environmental incidents.

Safety Protocols and Regulations

Safety protocols and regulations are paramount in responsible engineering practices involving hydrochloric acid initiatives. The handling, storage, and use of hydrochloric acid require strict adherence to established guidelines to ensure the safety of personnel and the environment. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) have set forth comprehensive standards for the management of hazardous chemicals, including hydrochloric acid.

These regulations typically cover various aspects of acid handling, including proper storage conditions, containment measures, and personal protective equipment (PPE) requirements. Storage facilities must be designed with corrosion-resistant materials and adequate ventilation to prevent the accumulation of potentially harmful fumes. Containment systems, such as secondary containment structures, are essential to prevent accidental spills from contaminating the surrounding environment.

Personal protective equipment is a critical component of safety protocols when working with hydrochloric acid. This includes chemical-resistant gloves, goggles or face shields, and appropriate respiratory protection. Training programs must be implemented to ensure that all personnel are familiar with the proper use of PPE and emergency procedures in case of exposure or spills.

Emergency response plans are another crucial element of safety protocols. These plans should outline specific procedures for addressing acid spills, including neutralization techniques, containment strategies, and evacuation protocols. Regular drills and simulations help maintain readiness and identify potential weaknesses in emergency response procedures.

Waste management is an integral part of responsible engineering practices involving hydrochloric acid. Proper disposal methods must be employed to prevent environmental contamination and comply with local and federal regulations. This may include neutralization processes, specialized waste treatment facilities, or recycling initiatives to minimize the environmental impact of acid-related activities.

Monitoring and documentation play a vital role in ensuring compliance with safety protocols and regulations. Regular inspections of storage facilities, equipment, and safety systems should be conducted and documented. Detailed records of acid usage, disposal, and any incidents or near-misses must be maintained to facilitate continuous improvement of safety practices and demonstrate regulatory compliance.

In conclusion, the implementation of comprehensive safety protocols and strict adherence to regulations are essential for responsible engineering practices involving hydrochloric acid initiatives. These measures not only protect personnel and the environment but also contribute to the overall sustainability and efficiency of industrial processes utilizing hydrochloric acid.

These regulations typically cover various aspects of acid handling, including proper storage conditions, containment measures, and personal protective equipment (PPE) requirements. Storage facilities must be designed with corrosion-resistant materials and adequate ventilation to prevent the accumulation of potentially harmful fumes. Containment systems, such as secondary containment structures, are essential to prevent accidental spills from contaminating the surrounding environment.

Personal protective equipment is a critical component of safety protocols when working with hydrochloric acid. This includes chemical-resistant gloves, goggles or face shields, and appropriate respiratory protection. Training programs must be implemented to ensure that all personnel are familiar with the proper use of PPE and emergency procedures in case of exposure or spills.

Emergency response plans are another crucial element of safety protocols. These plans should outline specific procedures for addressing acid spills, including neutralization techniques, containment strategies, and evacuation protocols. Regular drills and simulations help maintain readiness and identify potential weaknesses in emergency response procedures.

Waste management is an integral part of responsible engineering practices involving hydrochloric acid. Proper disposal methods must be employed to prevent environmental contamination and comply with local and federal regulations. This may include neutralization processes, specialized waste treatment facilities, or recycling initiatives to minimize the environmental impact of acid-related activities.

Monitoring and documentation play a vital role in ensuring compliance with safety protocols and regulations. Regular inspections of storage facilities, equipment, and safety systems should be conducted and documented. Detailed records of acid usage, disposal, and any incidents or near-misses must be maintained to facilitate continuous improvement of safety practices and demonstrate regulatory compliance.

In conclusion, the implementation of comprehensive safety protocols and strict adherence to regulations are essential for responsible engineering practices involving hydrochloric acid initiatives. These measures not only protect personnel and the environment but also contribute to the overall sustainability and efficiency of industrial processes utilizing hydrochloric acid.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!