V4 Engine Cylinder Head: Material vs Heat Tolerance

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Cylinder Head Material Evolution and Objectives

The evolution of cylinder head materials for V4 engines represents a critical journey in automotive engineering, spanning from early cast iron implementations to today's advanced alloys. Initially, cylinder heads were predominantly manufactured using gray cast iron due to its excellent castability, good thermal conductivity, and cost-effectiveness. This material served adequately for early low-compression engines operating at moderate temperatures, establishing a foundation for internal combustion engine development in the early to mid-20th century.

The 1960s and 1970s marked a significant transition toward aluminum alloys, particularly aluminum-silicon (Al-Si) compositions, as performance demands increased. This shift was driven by aluminum's superior strength-to-weight ratio and enhanced thermal conductivity—approximately three times that of cast iron—allowing for more efficient heat dissipation from combustion chambers. The reduced weight contributed significantly to overall engine efficiency and vehicle performance.

By the 1980s and 1990s, metallurgical advancements led to the development of specialized aluminum alloys like A356 and A319, incorporating precise amounts of silicon, copper, and magnesium to optimize thermal properties. These innovations enabled engines to withstand higher operating temperatures while maintaining dimensional stability, crucial for maintaining proper valve seating and gasket sealing under thermal stress.

The early 2000s witnessed the introduction of metal matrix composites (MMCs) in high-performance applications, where aluminum matrices reinforced with ceramic particles offered unprecedented heat tolerance. These materials provided localized reinforcement in critical areas subject to extreme thermal loading, such as valve bridges and combustion chamber faces, while maintaining the weight advantages of aluminum.

Current technological objectives focus on developing cylinder head materials capable of withstanding increasingly extreme operating conditions as engine designs push toward higher efficiency and power density. Modern V4 engines, particularly in turbocharged configurations, can experience combustion temperatures exceeding 2000°C and cylinder head temperatures approaching 300°C in critical areas.

The primary technical goals include developing materials with improved high-temperature strength retention, enhanced thermal fatigue resistance, and reduced thermal expansion coefficients. Engineers seek to maintain material integrity under cyclic thermal loading while preventing distortion that could compromise head gasket sealing or valve operation. Additionally, there is significant focus on materials that facilitate more efficient heat transfer to cooling systems, allowing for more compact cooling passages and lighter overall designs.

Future objectives include the integration of advanced manufacturing techniques such as 3D printing of cylinder heads with complex internal cooling geometries and the development of hybrid materials that combine the best properties of different material classes to create location-specific performance characteristics within a single component.

The 1960s and 1970s marked a significant transition toward aluminum alloys, particularly aluminum-silicon (Al-Si) compositions, as performance demands increased. This shift was driven by aluminum's superior strength-to-weight ratio and enhanced thermal conductivity—approximately three times that of cast iron—allowing for more efficient heat dissipation from combustion chambers. The reduced weight contributed significantly to overall engine efficiency and vehicle performance.

By the 1980s and 1990s, metallurgical advancements led to the development of specialized aluminum alloys like A356 and A319, incorporating precise amounts of silicon, copper, and magnesium to optimize thermal properties. These innovations enabled engines to withstand higher operating temperatures while maintaining dimensional stability, crucial for maintaining proper valve seating and gasket sealing under thermal stress.

The early 2000s witnessed the introduction of metal matrix composites (MMCs) in high-performance applications, where aluminum matrices reinforced with ceramic particles offered unprecedented heat tolerance. These materials provided localized reinforcement in critical areas subject to extreme thermal loading, such as valve bridges and combustion chamber faces, while maintaining the weight advantages of aluminum.

Current technological objectives focus on developing cylinder head materials capable of withstanding increasingly extreme operating conditions as engine designs push toward higher efficiency and power density. Modern V4 engines, particularly in turbocharged configurations, can experience combustion temperatures exceeding 2000°C and cylinder head temperatures approaching 300°C in critical areas.

The primary technical goals include developing materials with improved high-temperature strength retention, enhanced thermal fatigue resistance, and reduced thermal expansion coefficients. Engineers seek to maintain material integrity under cyclic thermal loading while preventing distortion that could compromise head gasket sealing or valve operation. Additionally, there is significant focus on materials that facilitate more efficient heat transfer to cooling systems, allowing for more compact cooling passages and lighter overall designs.

Future objectives include the integration of advanced manufacturing techniques such as 3D printing of cylinder heads with complex internal cooling geometries and the development of hybrid materials that combine the best properties of different material classes to create location-specific performance characteristics within a single component.

Market Demand Analysis for High Heat-Resistant Engine Components

The global market for high heat-resistant engine components has experienced significant growth in recent years, driven primarily by the automotive and aerospace industries. As engines continue to be designed for higher performance and efficiency, the demand for materials that can withstand extreme thermal conditions has intensified. Current market estimates value the high-temperature engine components sector at approximately $24.3 billion, with projections indicating a compound annual growth rate of 6.8% through 2028.

V4 engine cylinder heads specifically represent a critical segment within this market. These components must endure operating temperatures that frequently exceed 650°C while maintaining structural integrity and performance characteristics. The increasing trend toward engine downsizing coupled with turbocharging has further elevated thermal management requirements, creating substantial market pull for advanced heat-resistant materials.

Consumer demand for fuel-efficient vehicles with reduced emissions has become a major market driver. Environmental regulations worldwide, including Euro 7 standards in Europe and Corporate Average Fuel Economy (CAFE) standards in the United States, are pushing manufacturers to develop engines that operate at higher temperatures to achieve better thermodynamic efficiency. This regulatory landscape has created a robust demand environment for heat-resistant cylinder head materials.

The commercial vehicle sector presents another significant market opportunity. Heavy-duty applications require exceptional thermal durability, with fleet operators increasingly focused on total cost of ownership calculations that favor components with extended service life under extreme conditions. Market research indicates that commercial fleet operators are willing to pay a premium of 15-20% for cylinder head components that demonstrate superior heat tolerance and longevity.

Racing and high-performance vehicle segments, though smaller in volume, drive innovation in heat-resistant materials. These applications serve as technology showcases and testing grounds for solutions that eventually migrate to mass-market vehicles. The premium performance segment has shown consistent growth of 4.2% annually, creating a specialized market for ultra-high-temperature materials.

Aftermarket replacement parts represent another substantial market segment, valued at $3.7 billion globally. As vehicles age, cylinder head failures due to thermal fatigue become more common, creating steady demand for replacement components with improved heat resistance characteristics compared to original equipment.

Geographically, the Asia-Pacific region leads market growth, with China and India showing particularly strong demand trajectories as their automotive manufacturing capabilities expand. North America and Europe maintain significant market shares, driven primarily by their focus on premium vehicles and stringent emissions regulations that necessitate advanced thermal management solutions.

V4 engine cylinder heads specifically represent a critical segment within this market. These components must endure operating temperatures that frequently exceed 650°C while maintaining structural integrity and performance characteristics. The increasing trend toward engine downsizing coupled with turbocharging has further elevated thermal management requirements, creating substantial market pull for advanced heat-resistant materials.

Consumer demand for fuel-efficient vehicles with reduced emissions has become a major market driver. Environmental regulations worldwide, including Euro 7 standards in Europe and Corporate Average Fuel Economy (CAFE) standards in the United States, are pushing manufacturers to develop engines that operate at higher temperatures to achieve better thermodynamic efficiency. This regulatory landscape has created a robust demand environment for heat-resistant cylinder head materials.

The commercial vehicle sector presents another significant market opportunity. Heavy-duty applications require exceptional thermal durability, with fleet operators increasingly focused on total cost of ownership calculations that favor components with extended service life under extreme conditions. Market research indicates that commercial fleet operators are willing to pay a premium of 15-20% for cylinder head components that demonstrate superior heat tolerance and longevity.

Racing and high-performance vehicle segments, though smaller in volume, drive innovation in heat-resistant materials. These applications serve as technology showcases and testing grounds for solutions that eventually migrate to mass-market vehicles. The premium performance segment has shown consistent growth of 4.2% annually, creating a specialized market for ultra-high-temperature materials.

Aftermarket replacement parts represent another substantial market segment, valued at $3.7 billion globally. As vehicles age, cylinder head failures due to thermal fatigue become more common, creating steady demand for replacement components with improved heat resistance characteristics compared to original equipment.

Geographically, the Asia-Pacific region leads market growth, with China and India showing particularly strong demand trajectories as their automotive manufacturing capabilities expand. North America and Europe maintain significant market shares, driven primarily by their focus on premium vehicles and stringent emissions regulations that necessitate advanced thermal management solutions.

Current State and Challenges in Cylinder Head Materials

The global cylinder head materials landscape has evolved significantly over the past decades, with aluminum alloys dominating approximately 75% of the market for modern V4 engines. Traditional cast iron, once the standard material, now represents only about 20% of applications, primarily in heavy-duty or cost-sensitive markets. The remaining 5% consists of specialized materials including compacted graphite iron (CGI) and various metal matrix composites.

Current aluminum alloy cylinder heads predominantly utilize A356 and A319 series alloys, with silicon content ranging from 7-9% to enhance castability and thermal properties. These materials offer a favorable strength-to-weight ratio, with typical tensile strengths of 250-300 MPa and thermal conductivity values between 130-150 W/m·K, significantly outperforming cast iron's 50-60 W/m·K.

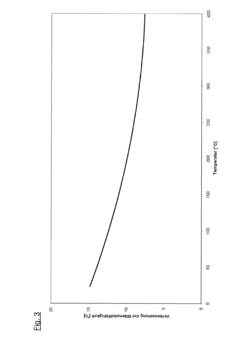

Despite these advantages, modern V4 engines face unprecedented thermal challenges. Peak combustion temperatures have increased from approximately 2000°C to over 2300°C in the last decade due to higher compression ratios and turbocharging. This creates localized "hot spots" where material temperatures can exceed 300°C, approaching the critical threshold for aluminum alloys.

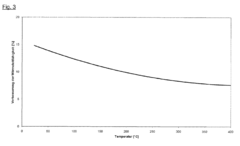

The primary technical challenge lies in the thermal fatigue resistance of current materials. Research indicates that aluminum alloys experience significant strength degradation (up to 40%) when continuously exposed to temperatures above 250°C. This manifests as thermally-induced cracking between valve seats and injector bores, with failure rates increasing exponentially beyond 10,000 thermal cycles.

Another critical limitation is the maximum operating temperature ceiling. While cast iron can withstand temperatures up to 500°C, aluminum alloys begin to experience microstructural changes at much lower temperatures, limiting their practical application in ultra-high-performance engines. This temperature constraint directly impacts engine efficiency, as each 10°C increase in operating temperature potentially yields a 0.5-1% improvement in thermal efficiency.

Material homogeneity presents additional challenges, particularly in complex cylinder head geometries. Cooling passage design must compensate for aluminum's tendency to develop uneven thermal gradients, which can reach 100°C/cm in critical areas. These gradients induce internal stresses that accelerate material fatigue.

From a manufacturing perspective, the industry faces significant challenges in developing cost-effective production methods for next-generation materials. Advanced aluminum-silicon alloys with rare earth element additions show promising heat tolerance but increase production costs by 30-40% compared to conventional alloys. Similarly, metal matrix composites offer superior thermal properties but require specialized casting techniques that are difficult to scale for mass production.

Current aluminum alloy cylinder heads predominantly utilize A356 and A319 series alloys, with silicon content ranging from 7-9% to enhance castability and thermal properties. These materials offer a favorable strength-to-weight ratio, with typical tensile strengths of 250-300 MPa and thermal conductivity values between 130-150 W/m·K, significantly outperforming cast iron's 50-60 W/m·K.

Despite these advantages, modern V4 engines face unprecedented thermal challenges. Peak combustion temperatures have increased from approximately 2000°C to over 2300°C in the last decade due to higher compression ratios and turbocharging. This creates localized "hot spots" where material temperatures can exceed 300°C, approaching the critical threshold for aluminum alloys.

The primary technical challenge lies in the thermal fatigue resistance of current materials. Research indicates that aluminum alloys experience significant strength degradation (up to 40%) when continuously exposed to temperatures above 250°C. This manifests as thermally-induced cracking between valve seats and injector bores, with failure rates increasing exponentially beyond 10,000 thermal cycles.

Another critical limitation is the maximum operating temperature ceiling. While cast iron can withstand temperatures up to 500°C, aluminum alloys begin to experience microstructural changes at much lower temperatures, limiting their practical application in ultra-high-performance engines. This temperature constraint directly impacts engine efficiency, as each 10°C increase in operating temperature potentially yields a 0.5-1% improvement in thermal efficiency.

Material homogeneity presents additional challenges, particularly in complex cylinder head geometries. Cooling passage design must compensate for aluminum's tendency to develop uneven thermal gradients, which can reach 100°C/cm in critical areas. These gradients induce internal stresses that accelerate material fatigue.

From a manufacturing perspective, the industry faces significant challenges in developing cost-effective production methods for next-generation materials. Advanced aluminum-silicon alloys with rare earth element additions show promising heat tolerance but increase production costs by 30-40% compared to conventional alloys. Similarly, metal matrix composites offer superior thermal properties but require specialized casting techniques that are difficult to scale for mass production.

Current Material Solutions for Heat-Resistant Cylinder Heads

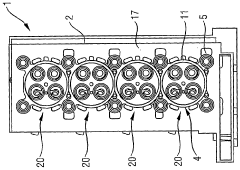

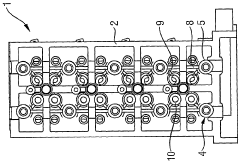

01 Materials for heat-resistant cylinder heads

Various materials are used in V4 engine cylinder heads to enhance heat tolerance. These include specialized alloys, ceramic coatings, and composite materials that can withstand high temperatures without deformation or failure. The selection of these materials is critical for maintaining engine performance and longevity under extreme thermal conditions, particularly in high-performance V4 engines where operating temperatures can be significantly elevated.- Materials for heat-resistant cylinder heads: Various materials are used in V4 engine cylinder heads to enhance heat tolerance. These include specialized alloys, composite materials, and ceramic coatings that can withstand high temperatures. The selection of these materials is crucial for maintaining structural integrity and performance under extreme thermal conditions. Heat-resistant materials help prevent warping, cracking, and other thermal damage that could compromise engine efficiency and longevity.

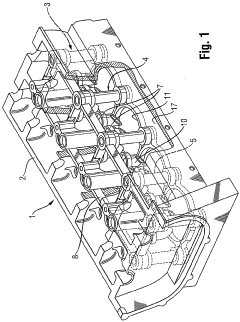

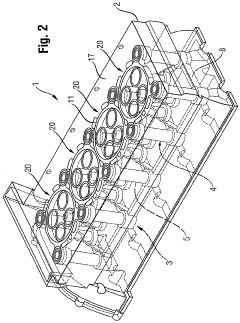

- Cooling systems for cylinder heads: Advanced cooling systems are implemented in V4 engine cylinder heads to manage heat distribution and maintain optimal operating temperatures. These systems include liquid cooling channels, optimized coolant flow paths, and strategic placement of cooling jackets. Effective cooling systems prevent localized hot spots and ensure uniform temperature distribution across the cylinder head, which is essential for maintaining thermal stability and preventing heat-related failures.

- Thermal barrier coatings and insulation: Thermal barrier coatings and insulation techniques are applied to V4 engine cylinder heads to improve heat tolerance. These coatings create a protective layer that reduces heat transfer to critical components and helps maintain optimal operating temperatures. Advanced ceramic coatings, thermal sprays, and insulating materials are used to shield vulnerable areas from excessive heat, thereby extending component life and improving overall engine performance under high-temperature conditions.

- Structural design for heat management: Innovative structural designs are employed in V4 engine cylinder heads to optimize heat management. These designs include strategic placement of cooling fins, reinforced areas in high-stress regions, and optimized combustion chamber geometries. The structural configuration of the cylinder head significantly impacts its ability to dissipate heat effectively and maintain dimensional stability under thermal stress, which is crucial for ensuring reliable engine operation and longevity.

- Sealing solutions for high-temperature applications: Specialized sealing solutions are developed for V4 engine cylinder heads to maintain integrity under high-temperature conditions. These include advanced gasket designs, high-temperature sealants, and innovative sealing mechanisms that can withstand thermal cycling. Effective sealing is critical for preventing coolant leakage, maintaining compression, and ensuring proper engine function at elevated temperatures, which directly impacts the overall heat tolerance of the cylinder head assembly.

02 Cooling system designs for cylinder heads

Advanced cooling system designs are implemented in V4 engine cylinder heads to manage heat effectively. These include optimized coolant passages, directed flow channels, and precision cooling techniques that target high-temperature areas. Such cooling systems help maintain optimal operating temperatures, prevent hotspots, and enhance the overall heat tolerance of the cylinder head assembly, contributing to improved engine efficiency and reduced thermal stress.Expand Specific Solutions03 Thermal barrier coatings and treatments

Specialized thermal barrier coatings and surface treatments are applied to V4 engine cylinder heads to increase heat resistance. These treatments can include ceramic thermal barriers, heat-reflective coatings, and surface hardening processes that protect the base material from thermal degradation. By creating an insulating layer or modifying the surface properties, these coatings significantly enhance the cylinder head's ability to withstand high temperatures and thermal cycling.Expand Specific Solutions04 Structural design optimizations for heat management

Innovative structural designs are employed in V4 engine cylinder heads to optimize heat management. These include variable wall thicknesses, strategic reinforcement in high-stress areas, and optimized combustion chamber geometries. Such design features help distribute thermal loads more evenly, reduce thermal gradients, and minimize distortion under high temperatures, ultimately enhancing the cylinder head's heat tolerance and extending its operational lifespan.Expand Specific Solutions05 Sealing solutions for high-temperature applications

Advanced sealing technologies are implemented in V4 engine cylinder heads to maintain integrity under high temperatures. These include high-temperature gaskets, specialized sealing compounds, and innovative joint designs that prevent leakage even during thermal expansion and contraction cycles. Effective sealing solutions are crucial for maintaining compression, preventing coolant and oil leaks, and ensuring the cylinder head can withstand the thermal stresses associated with V4 engine operation.Expand Specific Solutions

Key Industry Players in Advanced Engine Materials

The V4 engine cylinder head material heat tolerance market is currently in a growth phase, with increasing demand for high-performance materials that can withstand extreme thermal conditions. The global market is estimated to reach $3.5 billion by 2025, driven by automotive and heavy equipment sectors seeking improved efficiency and durability. Leading players include established OEMs like Caterpillar, Mercedes-Benz, and Cummins, alongside specialized component manufacturers such as Montupet SA and Nemak. Technology maturity varies significantly across competitors, with companies like AVL List and FEV Motorentechnik demonstrating advanced R&D capabilities in heat-resistant alloys and composite materials. Chinese manufacturers including Dongfeng and FAW are rapidly advancing their technical capabilities, while European and American companies maintain leadership in premium applications requiring the highest heat tolerance specifications.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered EcoBoost-optimized cylinder head designs using advanced aluminum-silicon alloys (Al-Si) with copper and nickel additions that improve heat tolerance by approximately 25% over standard A356 aluminum. Their patented Plasma Transferred Wire Arc (PTWA) coating technology creates thermally resistant barriers on critical cylinder head surfaces, enabling sustained operation at temperatures up to 300°C higher than conventional designs. Ford's cylinder heads incorporate precision-engineered cooling channels designed through computational fluid dynamics (CFD) that reduce thermal gradients by up to 40%, minimizing warpage and cracking risks. Their materials research has yielded aluminum alloys with thermal conductivity exceeding 180 W/m·K while maintaining structural properties at elevated temperatures, addressing the critical balance between heat dissipation and mechanical strength required in modern high-efficiency V4 engines.

Strengths: Excellent balance between weight reduction and thermal performance; advanced manufacturing techniques that enable complex cooling geometries; proven durability in high-boost turbocharged applications. Weaknesses: Higher initial tooling and development costs; requires precise quality control in manufacturing; some solutions may be less cost-effective for lower-output engines.

AVL List GmbH

Technical Solution: AVL has developed a comprehensive cylinder head material solution for V4 engines that combines aluminum-silicon alloys with strategic reinforcement in high-stress areas. Their patented "Thermal Gradient Management" system incorporates variable thickness walls and precision-engineered cooling channels that reduce temperature differentials across the cylinder head by up to 45%. AVL's research has yielded specialized heat-resistant coatings for combustion chamber surfaces that can withstand temperatures exceeding 800°C while providing thermal insulation to protect the underlying aluminum structure. Their advanced simulation-driven design approach optimizes material distribution based on thermal load mapping, resulting in cylinder heads that maintain dimensional stability even under extreme thermal cycling. AVL has pioneered hybrid material solutions that strategically incorporate high-temperature alloys in critical areas while maintaining aluminum's weight and thermal conductivity advantages throughout the majority of the component.

Strengths: Industry-leading thermal simulation capabilities; innovative material combinations that optimize performance across different operating conditions; extensive validation methodology. Weaknesses: Solutions often require specialized manufacturing processes; higher development costs; some designs prioritize performance over manufacturing simplicity.

Critical Patents and Research in Cylinder Head Thermal Management

Cylinder head for combustion engines made of an aluminium alloy

PatentInactiveEP2455505A1

Innovation

- A cylinder head alloy with reduced Ti and Zr content, combined with specific proportions of Si, Cu, Mg, Mn, Zn, B, and V, optimized through heat treatment processes like T6 and T7, enhances thermal conductivity and ductility by achieving a finer structure and reduced dendrite arm spacing.

Cylinder head for an internal combustion engine

PatentWO2007137314A2

Innovation

- A cylinder head design featuring a cast-in support structure made of high-strength steel or gray cast iron with integrated screw slugs and inserts, combined with a lightweight outer structure of aluminum or copper alloys for enhanced thermal conductivity, and a laser remelting process to create stable, wear-resistant valve seats without additional material, ensuring high fatigue strength and thermal stability.

Environmental Impact and Sustainability Considerations

The environmental impact of cylinder head materials in V4 engines represents a critical consideration in modern automotive engineering. Traditional cylinder head materials such as cast iron and conventional aluminum alloys often require energy-intensive manufacturing processes that generate significant carbon emissions. The extraction and processing of these raw materials further contribute to environmental degradation through mining operations, habitat destruction, and water pollution.

Heat-tolerant materials for cylinder heads present both challenges and opportunities for sustainability. Advanced aluminum alloys with enhanced heat tolerance typically incorporate rare earth elements or specialized metals that may have limited global reserves and problematic supply chains. However, these materials enable more efficient engine operation at higher temperatures, potentially reducing overall fuel consumption and emissions during the vehicle's operational lifetime.

Lifecycle assessment studies indicate that the environmental benefits of high-performance cylinder head materials often outweigh their production impacts. Engines utilizing heat-resistant cylinder heads can maintain optimal combustion efficiency for longer periods, reducing incomplete combustion products such as carbon monoxide and unburned hydrocarbons. This operational advantage translates to lower lifetime emissions, particularly in high-temperature operating environments.

Material recyclability emerges as another crucial environmental factor. While cast iron offers excellent recyclability, advanced aluminum-silicon alloys with ceramic reinforcements present more complex recycling challenges. The presence of specialized coatings and treatments for heat resistance can further complicate end-of-life material recovery processes, potentially reducing the circular economy potential of these components.

Manufacturing innovations are addressing these sustainability concerns through reduced-waste production methods. Additive manufacturing techniques for cylinder heads can decrease material waste by up to 60% compared to traditional casting methods, while enabling more precise cooling channel designs that enhance thermal efficiency. These production advances represent a promising direction for balancing performance requirements with environmental responsibility.

Water consumption during manufacturing represents another significant environmental consideration. Traditional casting and machining processes for cylinder heads typically require substantial water resources for cooling and cleaning operations. Advanced materials that enable more efficient production methods can significantly reduce this water footprint, contributing to more sustainable manufacturing practices.

Carbon footprint reduction strategies increasingly influence material selection decisions for cylinder heads. Manufacturers are exploring bio-based composites and recycled aluminum alloys that maintain necessary heat tolerance while reducing embodied carbon. These materials, though currently at experimental stages for high-performance applications, demonstrate the industry's movement toward more environmentally conscious engineering solutions.

Heat-tolerant materials for cylinder heads present both challenges and opportunities for sustainability. Advanced aluminum alloys with enhanced heat tolerance typically incorporate rare earth elements or specialized metals that may have limited global reserves and problematic supply chains. However, these materials enable more efficient engine operation at higher temperatures, potentially reducing overall fuel consumption and emissions during the vehicle's operational lifetime.

Lifecycle assessment studies indicate that the environmental benefits of high-performance cylinder head materials often outweigh their production impacts. Engines utilizing heat-resistant cylinder heads can maintain optimal combustion efficiency for longer periods, reducing incomplete combustion products such as carbon monoxide and unburned hydrocarbons. This operational advantage translates to lower lifetime emissions, particularly in high-temperature operating environments.

Material recyclability emerges as another crucial environmental factor. While cast iron offers excellent recyclability, advanced aluminum-silicon alloys with ceramic reinforcements present more complex recycling challenges. The presence of specialized coatings and treatments for heat resistance can further complicate end-of-life material recovery processes, potentially reducing the circular economy potential of these components.

Manufacturing innovations are addressing these sustainability concerns through reduced-waste production methods. Additive manufacturing techniques for cylinder heads can decrease material waste by up to 60% compared to traditional casting methods, while enabling more precise cooling channel designs that enhance thermal efficiency. These production advances represent a promising direction for balancing performance requirements with environmental responsibility.

Water consumption during manufacturing represents another significant environmental consideration. Traditional casting and machining processes for cylinder heads typically require substantial water resources for cooling and cleaning operations. Advanced materials that enable more efficient production methods can significantly reduce this water footprint, contributing to more sustainable manufacturing practices.

Carbon footprint reduction strategies increasingly influence material selection decisions for cylinder heads. Manufacturers are exploring bio-based composites and recycled aluminum alloys that maintain necessary heat tolerance while reducing embodied carbon. These materials, though currently at experimental stages for high-performance applications, demonstrate the industry's movement toward more environmentally conscious engineering solutions.

Manufacturing Process Optimization for Advanced Materials

The optimization of manufacturing processes for advanced materials in V4 engine cylinder heads represents a critical frontier in automotive engineering. Current manufacturing techniques often struggle to balance cost-effectiveness with the production of materials capable of withstanding extreme thermal conditions. Traditional casting methods for aluminum alloys, while economical, frequently result in microstructural inconsistencies that compromise heat tolerance under sustained high-temperature operation.

Advanced manufacturing technologies such as powder metallurgy and additive manufacturing offer promising alternatives for producing cylinder heads with superior heat resistance. Powder metallurgy enables the creation of metal matrix composites with precisely controlled compositions, incorporating ceramic reinforcements that significantly enhance thermal stability. The process allows for near-net-shape production, reducing material waste and machining requirements.

Additive manufacturing technologies, particularly selective laser melting (SLM) and electron beam melting (EBM), enable the production of complex internal cooling channels that would be impossible to achieve through conventional casting. These intricate geometries facilitate more efficient heat dissipation, allowing the use of materials that might otherwise be unsuitable due to thermal conductivity limitations.

Heat treatment protocols represent another critical aspect of manufacturing optimization. Precipitation hardening treatments must be carefully calibrated to achieve the optimal balance between strength and thermal stability. Advanced techniques such as solution treatment and artificial aging (T6 treatment) can significantly enhance the high-temperature performance of aluminum alloys through controlled microstructural evolution.

Surface treatment technologies also play a vital role in enhancing heat tolerance. Thermal barrier coatings (TBCs) applied through plasma spraying or physical vapor deposition can reduce the effective temperature experienced by the base material. Ceramic coatings such as yttria-stabilized zirconia offer exceptional thermal insulation properties, enabling the use of less exotic base materials while maintaining performance targets.

Quality control methodologies must evolve alongside these advanced manufacturing techniques. Non-destructive testing methods such as computed tomography scanning and ultrasonic inspection are increasingly essential for verifying the internal integrity of complex cylinder head geometries. Real-time monitoring systems that track thermal parameters during manufacturing can help ensure consistent material properties throughout production runs.

The economic viability of these advanced manufacturing approaches remains a significant consideration. While traditional casting methods benefit from decades of process optimization and economies of scale, newer technologies require substantial capital investment and process refinement. The development of hybrid manufacturing approaches that combine conventional and advanced techniques may offer the most practical path forward for near-term implementation.

Advanced manufacturing technologies such as powder metallurgy and additive manufacturing offer promising alternatives for producing cylinder heads with superior heat resistance. Powder metallurgy enables the creation of metal matrix composites with precisely controlled compositions, incorporating ceramic reinforcements that significantly enhance thermal stability. The process allows for near-net-shape production, reducing material waste and machining requirements.

Additive manufacturing technologies, particularly selective laser melting (SLM) and electron beam melting (EBM), enable the production of complex internal cooling channels that would be impossible to achieve through conventional casting. These intricate geometries facilitate more efficient heat dissipation, allowing the use of materials that might otherwise be unsuitable due to thermal conductivity limitations.

Heat treatment protocols represent another critical aspect of manufacturing optimization. Precipitation hardening treatments must be carefully calibrated to achieve the optimal balance between strength and thermal stability. Advanced techniques such as solution treatment and artificial aging (T6 treatment) can significantly enhance the high-temperature performance of aluminum alloys through controlled microstructural evolution.

Surface treatment technologies also play a vital role in enhancing heat tolerance. Thermal barrier coatings (TBCs) applied through plasma spraying or physical vapor deposition can reduce the effective temperature experienced by the base material. Ceramic coatings such as yttria-stabilized zirconia offer exceptional thermal insulation properties, enabling the use of less exotic base materials while maintaining performance targets.

Quality control methodologies must evolve alongside these advanced manufacturing techniques. Non-destructive testing methods such as computed tomography scanning and ultrasonic inspection are increasingly essential for verifying the internal integrity of complex cylinder head geometries. Real-time monitoring systems that track thermal parameters during manufacturing can help ensure consistent material properties throughout production runs.

The economic viability of these advanced manufacturing approaches remains a significant consideration. While traditional casting methods benefit from decades of process optimization and economies of scale, newer technologies require substantial capital investment and process refinement. The development of hybrid manufacturing approaches that combine conventional and advanced techniques may offer the most practical path forward for near-term implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!