Robust electrical feedthrough designs for long-term electrophysiology readouts in neural chips

SEP 2, 20256 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neural Feedthrough Technology Background and Objectives

Neural feedthrough technology has evolved significantly over the past three decades, transitioning from rudimentary wire-based systems to sophisticated hermetically sealed interfaces capable of transmitting electrical signals between the internal components of neural implants and external recording or stimulation equipment. The development trajectory has been driven by the increasing demand for high-density, miniaturized neural interfaces that can maintain signal integrity over extended periods in the challenging physiological environment of the nervous system.

The evolution of feedthrough technology began with simple glass-to-metal seals in the 1990s, progressing through ceramic-based platforms in the early 2000s, to today's advanced microfabricated arrays incorporating novel materials and manufacturing techniques. This progression has been necessitated by the exponential increase in channel counts required for modern neural interfaces, which have grown from single-digit channels to systems supporting hundreds or even thousands of electrodes.

A critical milestone in this technological evolution was the development of biocompatible hermetic packaging solutions that could withstand the corrosive biological environment while maintaining electrical performance. The introduction of platinum-iridium alloys, titanium nitride coatings, and parylene insulation layers represented significant advances in extending device longevity from weeks to years.

The primary objective of robust electrical feedthrough design is to create reliable, high-density signal pathways that maintain electrical isolation between channels while preserving signal fidelity over the intended lifetime of the neural implant. This involves addressing several interconnected challenges: achieving hermeticity to prevent moisture ingress, maintaining biocompatibility to minimize tissue reaction, ensuring mechanical stability against micromotion, and developing manufacturing processes that enable scalable production of high-yield devices.

Current research aims to develop feedthrough technologies capable of supporting channel densities exceeding 1000 electrodes/cm² while maintaining functional stability for periods of 10+ years in vivo. This represents a significant leap from current capabilities, which typically demonstrate reliable performance for 2-5 years with more modest channel counts.

The technological trajectory is now focused on novel materials and fabrication approaches, including atomic layer deposition techniques, carbon-based nanomaterials, and advanced polymer composites that promise to revolutionize the field. These innovations are expected to enable fully implantable, wireless neural interfaces with unprecedented longevity and channel capacity, potentially transforming treatments for neurological conditions and enabling advanced brain-machine interfaces.

The evolution of feedthrough technology began with simple glass-to-metal seals in the 1990s, progressing through ceramic-based platforms in the early 2000s, to today's advanced microfabricated arrays incorporating novel materials and manufacturing techniques. This progression has been necessitated by the exponential increase in channel counts required for modern neural interfaces, which have grown from single-digit channels to systems supporting hundreds or even thousands of electrodes.

A critical milestone in this technological evolution was the development of biocompatible hermetic packaging solutions that could withstand the corrosive biological environment while maintaining electrical performance. The introduction of platinum-iridium alloys, titanium nitride coatings, and parylene insulation layers represented significant advances in extending device longevity from weeks to years.

The primary objective of robust electrical feedthrough design is to create reliable, high-density signal pathways that maintain electrical isolation between channels while preserving signal fidelity over the intended lifetime of the neural implant. This involves addressing several interconnected challenges: achieving hermeticity to prevent moisture ingress, maintaining biocompatibility to minimize tissue reaction, ensuring mechanical stability against micromotion, and developing manufacturing processes that enable scalable production of high-yield devices.

Current research aims to develop feedthrough technologies capable of supporting channel densities exceeding 1000 electrodes/cm² while maintaining functional stability for periods of 10+ years in vivo. This represents a significant leap from current capabilities, which typically demonstrate reliable performance for 2-5 years with more modest channel counts.

The technological trajectory is now focused on novel materials and fabrication approaches, including atomic layer deposition techniques, carbon-based nanomaterials, and advanced polymer composites that promise to revolutionize the field. These innovations are expected to enable fully implantable, wireless neural interfaces with unprecedented longevity and channel capacity, potentially transforming treatments for neurological conditions and enabling advanced brain-machine interfaces.

Market Analysis for Neural Interface Solutions

The neural interface market is experiencing unprecedented growth, driven by advancements in neurotechnology and increasing applications in medical treatments, rehabilitation, and human-computer interaction. The global neural interface market was valued at approximately $2.4 billion in 2022 and is projected to reach $8.6 billion by 2030, representing a compound annual growth rate of 17.3% during the forecast period.

Medical applications currently dominate the market landscape, with neural implants for conditions such as Parkinson's disease, epilepsy, and chronic pain management showing significant clinical adoption. The robust electrical feedthrough designs for long-term electrophysiology readouts represent a critical component of this ecosystem, enabling reliable neural signal acquisition and stimulation capabilities essential for therapeutic efficacy.

Consumer-facing neural interfaces are emerging as a secondary but rapidly expanding market segment. Companies like Neuralink, Kernel, and CTRL-labs (acquired by Meta) are developing non-invasive and minimally invasive neural interface solutions targeting consumer applications. This segment is expected to grow at a faster rate than medical applications, with a projected CAGR of 23.7% through 2030.

Geographically, North America leads the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (22%). The United States maintains technological leadership through substantial public funding initiatives like the BRAIN Initiative and DARPA's Neural Engineering System Design program, which have allocated over $500 million toward advancing neural interface technologies.

Key market drivers include aging populations worldwide, increasing prevalence of neurological disorders, and growing acceptance of implantable medical devices. The demand for long-term stable neural interfaces is particularly strong, as current solutions often suffer from signal degradation over time due to biofouling, micromotion, and material degradation at the electrode-tissue interface.

Customer requirements are evolving toward smaller form factors, wireless capabilities, increased channel counts, and extended longevity. Healthcare providers specifically demand neural chips with robust electrical feedthroughs that can maintain signal integrity for 5+ years post-implantation, representing a significant market opportunity for advanced materials and design solutions.

Reimbursement policies and regulatory pathways are maturing for neural interface technologies, with the FDA having approved several neural stimulation devices through various pathways. However, novel neural recording technologies face more stringent requirements, particularly regarding long-term safety and efficacy data, creating market entry barriers that favor established players with substantial R&D resources.

Medical applications currently dominate the market landscape, with neural implants for conditions such as Parkinson's disease, epilepsy, and chronic pain management showing significant clinical adoption. The robust electrical feedthrough designs for long-term electrophysiology readouts represent a critical component of this ecosystem, enabling reliable neural signal acquisition and stimulation capabilities essential for therapeutic efficacy.

Consumer-facing neural interfaces are emerging as a secondary but rapidly expanding market segment. Companies like Neuralink, Kernel, and CTRL-labs (acquired by Meta) are developing non-invasive and minimally invasive neural interface solutions targeting consumer applications. This segment is expected to grow at a faster rate than medical applications, with a projected CAGR of 23.7% through 2030.

Geographically, North America leads the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (22%). The United States maintains technological leadership through substantial public funding initiatives like the BRAIN Initiative and DARPA's Neural Engineering System Design program, which have allocated over $500 million toward advancing neural interface technologies.

Key market drivers include aging populations worldwide, increasing prevalence of neurological disorders, and growing acceptance of implantable medical devices. The demand for long-term stable neural interfaces is particularly strong, as current solutions often suffer from signal degradation over time due to biofouling, micromotion, and material degradation at the electrode-tissue interface.

Customer requirements are evolving toward smaller form factors, wireless capabilities, increased channel counts, and extended longevity. Healthcare providers specifically demand neural chips with robust electrical feedthroughs that can maintain signal integrity for 5+ years post-implantation, representing a significant market opportunity for advanced materials and design solutions.

Reimbursement policies and regulatory pathways are maturing for neural interface technologies, with the FDA having approved several neural stimulation devices through various pathways. However, novel neural recording technologies face more stringent requirements, particularly regarding long-term safety and efficacy data, creating market entry barriers that favor established players with substantial R&D resources.

Current Challenges in Electrical Feedthrough Reliability

Despite significant advancements in neural interface technologies, electrical feedthrough reliability remains a critical bottleneck in the development of long-term implantable neural chips. Current feedthrough designs face multiple challenges that compromise their performance over extended periods in the harsh physiological environment. The primary issue is hermeticity failure, where micro-cracks develop at the interface between conductive elements and insulating materials, allowing fluid infiltration that leads to electrical shorts and device failure. These failures typically manifest after months of implantation, making them particularly problematic for chronic neural recording applications.

Material biocompatibility presents another significant challenge, as many conventional feedthrough materials exhibit either poor long-term stability in vivo or inadequate electrical properties. Noble metals like platinum and gold offer excellent biocompatibility but present manufacturing challenges when integrated with ceramics or polymers in hermetic packages. Meanwhile, ceramic-to-metal seals often suffer from thermal expansion mismatches that create stress points vulnerable to mechanical failure during temperature fluctuations.

Miniaturization demands compound these issues, as researchers push toward higher channel counts in smaller form factors. Current fabrication techniques struggle to maintain reliable insulation between densely packed conductors while preserving mechanical integrity. The trade-off between channel density and long-term reliability remains poorly optimized in existing solutions, with most high-density arrays showing accelerated failure rates compared to simpler designs.

Environmental factors further exacerbate reliability concerns. Continuous exposure to saline environments accelerates corrosion processes, while mechanical stresses from tissue micromotion gradually degrade interface integrity. Current encapsulation methods provide insufficient protection against these combined effects, particularly at the critical junction where feedthroughs exit the hermetic package.

Manufacturing consistency represents another major challenge, with yield rates for high-quality feedthroughs remaining unacceptably low. Process variations in brazing, glass sealing, or polymer curing lead to inconsistent performance between supposedly identical devices. This variability complicates both research outcomes and potential clinical translation of neural interface technologies.

Testing methodologies for predicting long-term reliability remain inadequate. Accelerated aging protocols poorly correlate with actual in vivo performance, leaving researchers unable to confidently predict feedthrough lifespans without conducting lengthy animal studies. The lack of standardized testing frameworks further hinders comparative evaluation between different technological approaches.

These combined challenges create a significant barrier to the development of truly chronic neural interfaces capable of stable recording over years rather than months. Addressing these limitations requires interdisciplinary approaches spanning materials science, microfabrication techniques, and novel testing methodologies specifically tailored to the unique demands of neural interface applications.

Material biocompatibility presents another significant challenge, as many conventional feedthrough materials exhibit either poor long-term stability in vivo or inadequate electrical properties. Noble metals like platinum and gold offer excellent biocompatibility but present manufacturing challenges when integrated with ceramics or polymers in hermetic packages. Meanwhile, ceramic-to-metal seals often suffer from thermal expansion mismatches that create stress points vulnerable to mechanical failure during temperature fluctuations.

Miniaturization demands compound these issues, as researchers push toward higher channel counts in smaller form factors. Current fabrication techniques struggle to maintain reliable insulation between densely packed conductors while preserving mechanical integrity. The trade-off between channel density and long-term reliability remains poorly optimized in existing solutions, with most high-density arrays showing accelerated failure rates compared to simpler designs.

Environmental factors further exacerbate reliability concerns. Continuous exposure to saline environments accelerates corrosion processes, while mechanical stresses from tissue micromotion gradually degrade interface integrity. Current encapsulation methods provide insufficient protection against these combined effects, particularly at the critical junction where feedthroughs exit the hermetic package.

Manufacturing consistency represents another major challenge, with yield rates for high-quality feedthroughs remaining unacceptably low. Process variations in brazing, glass sealing, or polymer curing lead to inconsistent performance between supposedly identical devices. This variability complicates both research outcomes and potential clinical translation of neural interface technologies.

Testing methodologies for predicting long-term reliability remain inadequate. Accelerated aging protocols poorly correlate with actual in vivo performance, leaving researchers unable to confidently predict feedthrough lifespans without conducting lengthy animal studies. The lack of standardized testing frameworks further hinders comparative evaluation between different technological approaches.

These combined challenges create a significant barrier to the development of truly chronic neural interfaces capable of stable recording over years rather than months. Addressing these limitations requires interdisciplinary approaches spanning materials science, microfabrication techniques, and novel testing methodologies specifically tailored to the unique demands of neural interface applications.

Existing Robust Feedthrough Design Solutions

01 Hermetic sealing techniques for electrical feedthroughs

Hermetic sealing is crucial for ensuring the robustness and long-term stability of electrical feedthroughs. Various techniques are employed to create reliable hermetic seals between the conductor and insulator materials, preventing moisture ingress and maintaining electrical isolation. These techniques include glass-to-metal sealing, ceramic-to-metal bonding, and specialized brazing processes that create strong mechanical bonds while maintaining electrical isolation. Properly sealed feedthroughs can withstand harsh environmental conditions and provide stable electrical connections over extended periods.- Hermetic sealing techniques for electrical feedthroughs: Hermetic sealing is crucial for ensuring the robustness and long-term stability of electrical feedthroughs. Various techniques are employed to create reliable hermetic seals between the conductor and insulator materials, preventing moisture ingress and maintaining electrical isolation. These techniques include glass-to-metal seals, ceramic-to-metal seals, and specialized brazing processes that create strong bonds while accommodating thermal expansion differences. Properly sealed feedthroughs maintain their integrity under extreme conditions and over extended periods.

- Advanced materials for feedthrough components: The selection of advanced materials significantly impacts the robustness and long-term stability of electrical feedthroughs. High-performance ceramics, specialized alloys, and noble metals are utilized for their superior electrical properties, thermal stability, and corrosion resistance. Materials are chosen to withstand harsh environments, including high temperatures, pressure variations, and exposure to corrosive substances. Compatibility between different materials is carefully considered to prevent degradation mechanisms such as galvanic corrosion or thermal stress that could compromise the feedthrough's performance over time.

- Structural design innovations for mechanical stability: Innovative structural designs enhance the mechanical stability of electrical feedthroughs under various stresses. These designs incorporate features such as stress-relief geometries, reinforced connection points, and optimized conductor paths to minimize mechanical fatigue. Some designs employ flexible elements that accommodate thermal expansion or external forces while maintaining electrical continuity. Multi-layer architectures distribute mechanical stresses more evenly across the feedthrough assembly, preventing localized failures and extending operational lifetime even in applications with vibration or physical impacts.

- Environmental protection and insulation strategies: Protecting electrical feedthroughs from environmental factors is essential for long-term stability. Various strategies include applying specialized coatings, implementing redundant sealing systems, and using protective encapsulation materials. Advanced insulation techniques prevent electrical leakage and breakdown under high voltage conditions. Some designs incorporate sacrificial elements or getter materials that absorb contaminants before they can damage sensitive components. These protection strategies ensure that feedthroughs maintain their electrical and mechanical properties despite exposure to moisture, chemicals, radiation, or extreme temperatures.

- Testing and validation methodologies for long-term reliability: Comprehensive testing and validation methodologies are employed to ensure the long-term reliability of electrical feedthrough designs. These include accelerated aging tests, thermal cycling, pressure cycling, and electrical performance verification under simulated operational conditions. Advanced analytical techniques such as finite element analysis predict potential failure modes before physical testing. Some approaches incorporate real-time monitoring capabilities that detect early signs of degradation during operation. These methodologies help establish confidence in feedthrough performance over extended periods, often exceeding decades of continuous operation in critical applications.

02 Material selection for enhanced durability

The choice of materials significantly impacts the robustness and long-term stability of electrical feedthroughs. High-performance ceramics, specialized alloys, and noble metals are selected for their resistance to corrosion, thermal stability, and mechanical strength. Biocompatible materials are essential for medical implant feedthroughs, while high-temperature applications require materials with matching thermal expansion coefficients to prevent stress-induced failures. Advanced composite materials and specialized coatings can further enhance durability by providing additional protection against environmental factors and improving electrical performance over time.Expand Specific Solutions03 Structural design innovations for mechanical stability

Innovative structural designs enhance the mechanical stability of electrical feedthroughs under various stress conditions. These include reinforced pin arrangements, stress-relief features, and optimized geometries that distribute mechanical loads evenly. Some designs incorporate flexible elements to accommodate thermal expansion and contraction, while others feature redundant sealing mechanisms for added reliability. Advanced computer modeling techniques are used to simulate mechanical stresses and optimize designs before manufacturing, ensuring that the feedthroughs can withstand vibration, shock, and thermal cycling without compromising electrical performance.Expand Specific Solutions04 Environmental protection and shielding solutions

Protecting electrical feedthroughs from environmental factors is essential for long-term stability. Various shielding and protection methods are employed, including EMI/RFI shielding to prevent electromagnetic interference, protective housings to guard against physical damage, and specialized coatings that resist corrosion and chemical attack. Some designs incorporate multiple barriers against moisture ingress, while others feature integrated surge protection components. These protective measures ensure that the electrical feedthrough maintains its performance characteristics even when exposed to harsh operating environments, extending its operational lifespan.Expand Specific Solutions05 Testing and qualification methodologies

Rigorous testing and qualification methodologies are critical for verifying the robustness and long-term stability of electrical feedthroughs. These include accelerated aging tests, thermal cycling, pressure cycling, and hermeticity testing to simulate years of operation in compressed timeframes. Electrical performance is evaluated under various environmental conditions to ensure consistent functionality. Some testing protocols involve subjecting feedthroughs to extreme conditions beyond their intended operating parameters to establish safety margins. Advanced monitoring techniques, including real-time impedance measurements and non-destructive evaluation methods, help predict potential failure modes and validate design improvements.Expand Specific Solutions

Leading Companies in Neural Interface Industry

The neural chip electrophysiology feedthrough market is currently in a growth phase, characterized by increasing demand for robust, long-term implantable solutions. The market size is expanding rapidly, driven by applications in neuromodulation and brain-computer interfaces, with projections exceeding $2 billion by 2025. Technologically, the field shows varying maturity levels, with established medical device companies like Medtronic, Cochlear, and Boston Scientific (via Cardiac Pacemakers) leading with commercialized solutions. Infineon and TDK Electronics contribute advanced materials expertise, while academic institutions such as Zhejiang University and UESTC are driving innovation in novel hermetic sealing techniques. SCHOTT AG and Morgan Advanced Ceramics hold specialized positions in glass-to-metal sealing technologies critical for long-term hermeticity, creating a competitive landscape balanced between established medical device manufacturers and materials science specialists.

Medtronic, Inc.

Technical Solution: Medtronic has developed hermetically sealed electrical feedthrough assemblies utilizing platinum-iridium conductors and ceramic insulators for long-term neural implants. Their design incorporates multi-pin feedthroughs with titanium housings and alumina ceramic insulators, creating reliable biocompatible interfaces that maintain signal integrity in physiological environments. The company employs active metallization techniques to create robust metal-ceramic bonds capable of withstanding sterilization processes and long-term implantation. Their latest designs feature nano-structured surface treatments that enhance hermeticity and reduce electrochemical corrosion at the metal-ceramic interfaces[1]. Medtronic has also pioneered the use of platinum-iridium alloys with optimized compositions (90/10 ratio) that balance electrical conductivity with mechanical strength for reliable neural recordings over extended periods[3].

Strengths: Industry-leading hermeticity standards with helium leak rates below 10^-9 atm-cc/sec; extensive clinical validation through decades of implantable medical device experience. Weaknesses: Higher manufacturing costs compared to competitors; designs may be larger than newer miniaturized solutions from specialized neural interface companies.

SCHOTT AG

Technical Solution: SCHOTT AG has pioneered advanced glass-to-metal sealing technology for neural interface applications, developing specialized borosilicate glass compositions with thermal expansion properties matched to titanium and platinum conductors. Their Eternaloc® feedthrough platform utilizes proprietary glass formulations that resist ion migration and maintain hermeticity in biological environments. SCHOTT's manufacturing process employs precision high-temperature vacuum furnaces that create molecular-level bonds between glass and metal components, eliminating microvoids that could compromise long-term performance. Their feedthrough designs incorporate stress-relieving geometries that accommodate thermal cycling without compromising seal integrity. SCHOTT has also developed specialized analytical techniques to validate hermeticity beyond traditional helium leak testing, including mass spectrometry approaches that can detect sub-ppb levels of moisture penetration[5]. Recent innovations include biocompatible glass formulations with reduced alkali content to minimize potential for biocorrosion during long-term implantation[7].

Strengths: World-leading expertise in specialized glass materials and glass-to-metal sealing technology; manufacturing capabilities for high-volume, consistent production with exceptional quality control. Weaknesses: Less experience specifically in neural recording applications compared to dedicated neurotech companies; glass-based solutions may have different mechanical properties than ceramic alternatives.

Critical Patents in Long-term Electrophysiology Feedthroughs

Electrical feedthrough

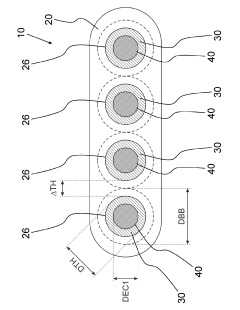

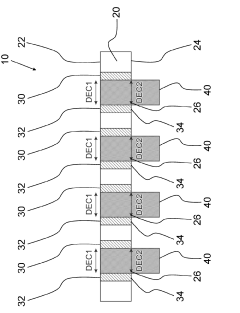

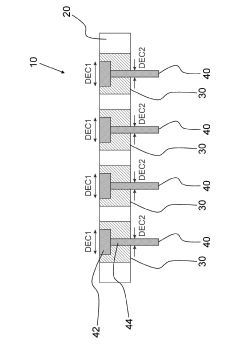

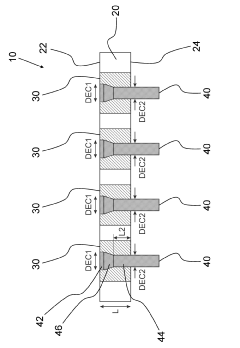

PatentPendingJP2022188003A

Innovation

- The electrical feedthrough design features a conductor with varying diameters (larger at one end than the other), enabling high-density arrangement while maintaining optimal sealing properties.

- The through-hole design with specialized insulating material creates an effective hermetic seal while allowing electrical conductors to pass through the base body.

- The tapered conductor design optimizes the balance between electrical conductivity and sealing effectiveness, particularly beneficial for long-term electrophysiology applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!