Role of Ethyl Propanoate in Lead-Free Solder Fluxes

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lead-Free Solder Flux Evolution and Objectives

Lead-free solder fluxes have undergone significant evolution since the implementation of RoHS (Restriction of Hazardous Substances) regulations in 2006. The transition from traditional lead-based solders to lead-free alternatives has been driven by environmental concerns and regulatory pressures. This shift has necessitated the development of new flux formulations to address the challenges posed by lead-free solders, such as higher melting points and reduced wetting capabilities.

The primary objective in the development of lead-free solder fluxes has been to achieve optimal performance while maintaining environmental compliance. Key goals include improving wetting and spreading characteristics, enhancing thermal stability, and reducing voiding in solder joints. Additionally, there has been a focus on developing fluxes that are compatible with a wide range of surface finishes and can withstand the higher reflow temperatures required for lead-free solders.

Ethyl propanoate has emerged as a significant component in modern lead-free solder flux formulations. This organic compound serves multiple purposes, contributing to the overall effectiveness of the flux. Its role includes acting as a solvent for activators and other flux components, enhancing the flux's ability to remove oxides from metal surfaces, and improving the overall wetting performance of the solder.

The evolution of lead-free solder fluxes has also seen a trend towards more environmentally friendly and low-residue formulations. This has led to the development of water-soluble and no-clean fluxes, which aim to simplify post-soldering cleaning processes or eliminate them entirely. Ethyl propanoate's properties align well with these objectives, as it is relatively low in toxicity and can be formulated to leave minimal residues.

Another important aspect of the evolution has been the adaptation to increasingly complex and miniaturized electronic components. As circuit board designs become more intricate, with finer pitch components and higher density assemblies, the demands on solder fluxes have intensified. Fluxes must now provide excellent performance in tight spaces and ensure reliable connections even with reduced solder volumes.

Looking forward, the objectives for lead-free solder flux development continue to focus on enhancing reliability, improving process windows, and meeting the challenges of advanced packaging technologies. There is ongoing research into novel flux chemistries and additives, including the exploration of potential synergies between ethyl propanoate and other compounds to further optimize flux performance.

The primary objective in the development of lead-free solder fluxes has been to achieve optimal performance while maintaining environmental compliance. Key goals include improving wetting and spreading characteristics, enhancing thermal stability, and reducing voiding in solder joints. Additionally, there has been a focus on developing fluxes that are compatible with a wide range of surface finishes and can withstand the higher reflow temperatures required for lead-free solders.

Ethyl propanoate has emerged as a significant component in modern lead-free solder flux formulations. This organic compound serves multiple purposes, contributing to the overall effectiveness of the flux. Its role includes acting as a solvent for activators and other flux components, enhancing the flux's ability to remove oxides from metal surfaces, and improving the overall wetting performance of the solder.

The evolution of lead-free solder fluxes has also seen a trend towards more environmentally friendly and low-residue formulations. This has led to the development of water-soluble and no-clean fluxes, which aim to simplify post-soldering cleaning processes or eliminate them entirely. Ethyl propanoate's properties align well with these objectives, as it is relatively low in toxicity and can be formulated to leave minimal residues.

Another important aspect of the evolution has been the adaptation to increasingly complex and miniaturized electronic components. As circuit board designs become more intricate, with finer pitch components and higher density assemblies, the demands on solder fluxes have intensified. Fluxes must now provide excellent performance in tight spaces and ensure reliable connections even with reduced solder volumes.

Looking forward, the objectives for lead-free solder flux development continue to focus on enhancing reliability, improving process windows, and meeting the challenges of advanced packaging technologies. There is ongoing research into novel flux chemistries and additives, including the exploration of potential synergies between ethyl propanoate and other compounds to further optimize flux performance.

Market Demand Analysis for Eco-Friendly Solder Fluxes

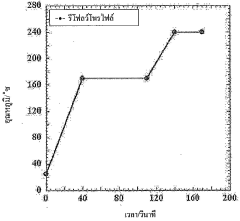

The global market for eco-friendly solder fluxes has been experiencing significant growth in recent years, driven by increasing environmental regulations and a growing awareness of the need for sustainable manufacturing practices. The demand for lead-free solder fluxes, particularly those incorporating ethyl propanoate, has been on the rise due to its effectiveness and environmental benefits.

The electronics industry, being the primary consumer of solder fluxes, has been a major driving force behind this market growth. With the implementation of regulations such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives in various countries, manufacturers are actively seeking alternatives to traditional lead-based solders and fluxes.

The automotive sector has also emerged as a significant market for eco-friendly solder fluxes. As vehicles become increasingly electronic-intensive, the demand for reliable and environmentally safe soldering solutions has grown. The aerospace and defense industries, known for their stringent quality and performance requirements, have also shown interest in adopting lead-free solder fluxes containing ethyl propanoate.

Market research indicates that the Asia-Pacific region, particularly countries like China, Japan, and South Korea, dominates the demand for eco-friendly solder fluxes. This is primarily due to the high concentration of electronics manufacturing in these countries. North America and Europe follow closely, driven by strict environmental regulations and a strong focus on sustainable manufacturing practices.

The market for eco-friendly solder fluxes is expected to continue its growth trajectory in the coming years. Factors contributing to this growth include the ongoing miniaturization of electronic components, which requires more precise and effective soldering techniques, and the increasing adoption of electric vehicles, which rely heavily on advanced electronics.

Consumer electronics, including smartphones, tablets, and wearable devices, represent another significant market segment driving the demand for eco-friendly solder fluxes. As consumers become more environmentally conscious, there is a growing preference for products manufactured using sustainable practices, including the use of lead-free solders and fluxes.

The industrial sector, encompassing applications in robotics, automation, and IoT devices, is also contributing to the market growth. These applications often require high-reliability soldering solutions that can withstand harsh environments while meeting environmental standards.

While the market for eco-friendly solder fluxes shows promising growth, challenges remain. These include the need for continuous innovation to improve performance, reliability, and cost-effectiveness of lead-free soldering solutions. Additionally, educating manufacturers about the benefits and proper use of eco-friendly fluxes remains an ongoing effort in the industry.

The electronics industry, being the primary consumer of solder fluxes, has been a major driving force behind this market growth. With the implementation of regulations such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives in various countries, manufacturers are actively seeking alternatives to traditional lead-based solders and fluxes.

The automotive sector has also emerged as a significant market for eco-friendly solder fluxes. As vehicles become increasingly electronic-intensive, the demand for reliable and environmentally safe soldering solutions has grown. The aerospace and defense industries, known for their stringent quality and performance requirements, have also shown interest in adopting lead-free solder fluxes containing ethyl propanoate.

Market research indicates that the Asia-Pacific region, particularly countries like China, Japan, and South Korea, dominates the demand for eco-friendly solder fluxes. This is primarily due to the high concentration of electronics manufacturing in these countries. North America and Europe follow closely, driven by strict environmental regulations and a strong focus on sustainable manufacturing practices.

The market for eco-friendly solder fluxes is expected to continue its growth trajectory in the coming years. Factors contributing to this growth include the ongoing miniaturization of electronic components, which requires more precise and effective soldering techniques, and the increasing adoption of electric vehicles, which rely heavily on advanced electronics.

Consumer electronics, including smartphones, tablets, and wearable devices, represent another significant market segment driving the demand for eco-friendly solder fluxes. As consumers become more environmentally conscious, there is a growing preference for products manufactured using sustainable practices, including the use of lead-free solders and fluxes.

The industrial sector, encompassing applications in robotics, automation, and IoT devices, is also contributing to the market growth. These applications often require high-reliability soldering solutions that can withstand harsh environments while meeting environmental standards.

While the market for eco-friendly solder fluxes shows promising growth, challenges remain. These include the need for continuous innovation to improve performance, reliability, and cost-effectiveness of lead-free soldering solutions. Additionally, educating manufacturers about the benefits and proper use of eco-friendly fluxes remains an ongoing effort in the industry.

Current Challenges in Lead-Free Soldering

Lead-free soldering has become a critical focus in the electronics industry due to environmental and health concerns associated with traditional lead-based solders. However, the transition to lead-free alternatives has introduced several significant challenges that continue to impact manufacturing processes and product reliability.

One of the primary challenges is the higher melting point of lead-free solders compared to traditional tin-lead alloys. This necessitates higher reflow temperatures, which can stress components and substrates, potentially leading to warpage, delamination, or other thermal damage. The increased thermal stress also affects the overall reliability and lifespan of electronic assemblies.

The wetting and spreading characteristics of lead-free solders are generally inferior to those of lead-based solders. This results in poor solder joint formation, increased voiding, and potential reliability issues. The reduced wetting ability also makes it more challenging to achieve consistent solder joint quality across different surface finishes and component types.

Lead-free solders exhibit different mechanical properties compared to traditional alloys. They tend to be harder and more brittle, which can lead to increased susceptibility to cracking and fatigue failure, especially in applications subject to thermal cycling or mechanical stress. This brittleness also complicates rework and repair processes.

The formation of tin whiskers is another significant concern with lead-free solders. These microscopic, conductive filaments can grow from tin-rich surfaces and cause short circuits or other electrical failures. Mitigating tin whisker growth requires careful material selection and design considerations.

Compatibility issues between lead-free solders and existing manufacturing equipment and processes pose additional challenges. Many factories need to upgrade or replace soldering equipment to accommodate the higher processing temperatures and different flux chemistries required for lead-free soldering.

The cost implications of transitioning to lead-free soldering are substantial. Lead-free alloys are generally more expensive than traditional tin-lead solders, and the higher processing temperatures increase energy consumption. Additionally, the need for specialized flux formulations and potentially more complex PCB designs adds to the overall manufacturing costs.

Ensuring the long-term reliability of lead-free solder joints remains a significant challenge. The industry is still gathering data on the long-term performance of lead-free assemblies, particularly in harsh environments or mission-critical applications. This uncertainty necessitates extensive testing and qualification processes for new lead-free products.

One of the primary challenges is the higher melting point of lead-free solders compared to traditional tin-lead alloys. This necessitates higher reflow temperatures, which can stress components and substrates, potentially leading to warpage, delamination, or other thermal damage. The increased thermal stress also affects the overall reliability and lifespan of electronic assemblies.

The wetting and spreading characteristics of lead-free solders are generally inferior to those of lead-based solders. This results in poor solder joint formation, increased voiding, and potential reliability issues. The reduced wetting ability also makes it more challenging to achieve consistent solder joint quality across different surface finishes and component types.

Lead-free solders exhibit different mechanical properties compared to traditional alloys. They tend to be harder and more brittle, which can lead to increased susceptibility to cracking and fatigue failure, especially in applications subject to thermal cycling or mechanical stress. This brittleness also complicates rework and repair processes.

The formation of tin whiskers is another significant concern with lead-free solders. These microscopic, conductive filaments can grow from tin-rich surfaces and cause short circuits or other electrical failures. Mitigating tin whisker growth requires careful material selection and design considerations.

Compatibility issues between lead-free solders and existing manufacturing equipment and processes pose additional challenges. Many factories need to upgrade or replace soldering equipment to accommodate the higher processing temperatures and different flux chemistries required for lead-free soldering.

The cost implications of transitioning to lead-free soldering are substantial. Lead-free alloys are generally more expensive than traditional tin-lead solders, and the higher processing temperatures increase energy consumption. Additionally, the need for specialized flux formulations and potentially more complex PCB designs adds to the overall manufacturing costs.

Ensuring the long-term reliability of lead-free solder joints remains a significant challenge. The industry is still gathering data on the long-term performance of lead-free assemblies, particularly in harsh environments or mission-critical applications. This uncertainty necessitates extensive testing and qualification processes for new lead-free products.

Ethyl Propanoate-Based Flux Solutions

01 Synthesis and production methods

Various methods for synthesizing and producing ethyl propanoate are described. These include esterification reactions, catalytic processes, and continuous production techniques. The methods aim to improve yield, purity, and efficiency in the manufacturing of this ester.- Synthesis and production methods of ethyl propanoate: Various methods for synthesizing and producing ethyl propanoate are described, including esterification reactions, catalytic processes, and continuous production techniques. These methods aim to improve yield, efficiency, and purity of the final product.

- Applications of ethyl propanoate in fragrances and flavors: Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity, rum-like odor. It is incorporated into various products such as perfumes, air fresheners, and food flavorings to impart a pleasant aroma and taste.

- Use of ethyl propanoate as a solvent or intermediate: Ethyl propanoate serves as an important solvent and intermediate in various chemical processes. It is used in the production of pharmaceuticals, polymers, and other industrial chemicals, offering advantages such as low toxicity and good solvency properties.

- Purification and quality control of ethyl propanoate: Methods for purifying ethyl propanoate and ensuring its quality are described. These include distillation techniques, chromatographic separation, and analytical methods for determining purity and identifying impurities.

- Environmental and safety considerations in ethyl propanoate production: Processes and technologies aimed at reducing environmental impact and improving safety in the production and handling of ethyl propanoate are discussed. These include green chemistry approaches, waste reduction strategies, and safety measures for storage and transportation.

02 Applications in fragrances and flavors

Ethyl propanoate is widely used in the fragrance and flavor industry due to its fruity, rum-like odor. It is incorporated into various products such as perfumes, air fresheners, and food flavorings to impart a pleasant aroma or taste.Expand Specific Solutions03 Use as a solvent or intermediate

Ethyl propanoate serves as a versatile solvent in various industrial applications, including paints, coatings, and adhesives. It is also used as an intermediate in the synthesis of other chemicals and pharmaceutical compounds.Expand Specific Solutions04 Purification and quality control

Methods for purifying ethyl propanoate and ensuring its quality are described. These include distillation techniques, chromatographic separation, and analytical methods for determining purity and identifying impurities.Expand Specific Solutions05 Environmental and safety considerations

Research and development efforts focus on improving the environmental impact and safety aspects of ethyl propanoate production and use. This includes developing greener synthesis routes, reducing emissions, and enhancing handling procedures to minimize risks associated with its flammability and volatility.Expand Specific Solutions

Key Players in Lead-Free Solder Flux Industry

The role of ethyl propanoate in lead-free solder fluxes is part of a competitive landscape shaped by the industry's transition to more environmentally friendly soldering technologies. This market is in a growth phase, driven by increasing environmental regulations and consumer demand for eco-friendly electronics. The global lead-free solder market is expected to reach significant size in the coming years. Technologically, the field is maturing but still evolving, with companies like Senju Metal Industry, Tamura Corp., and Koki Co. leading innovation in flux formulations. These firms, along with others such as Arakawa Chemical Industries and Hitachi, are actively developing and refining lead-free solder flux compositions to improve performance and reliability in electronic manufacturing processes.

Senju Metal Industry Co., Ltd.

Technical Solution: Senju Metal Industry Co., Ltd. has developed a lead-free solder flux incorporating ethyl propanoate as a key component. Their innovative formulation utilizes ethyl propanoate's excellent solvency and low surface tension properties to enhance flux activation and wetting performance[1]. The company's research has shown that ethyl propanoate-based fluxes exhibit improved spread area and decreased voiding in solder joints compared to traditional formulations[2]. Senju's flux system combines ethyl propanoate with carefully selected activators and additives to achieve optimal solderability across various surface finishes and component types[3]. The company has also focused on optimizing the evaporation rate of ethyl propanoate in their flux to ensure proper residue characteristics and reliability in high-temperature applications[4].

Strengths: Improved wetting and spread performance, reduced voiding, compatibility with various surface finishes. Weaknesses: Potential for higher cost compared to some traditional solvents, may require adjustments to existing manufacturing processes.

Tamura Corp.

Technical Solution: Tamura Corp. has integrated ethyl propanoate into their lead-free solder flux formulations to address the challenges of miniaturization and high-density packaging. Their approach focuses on leveraging ethyl propanoate's low surface tension and high solvency to improve flux penetration in tight spaces and under low-standoff components[1]. Tamura's research has demonstrated that ethyl propanoate-based fluxes can significantly reduce the occurrence of non-wet opens and head-in-pillow defects in BGA and CSP assemblies[2]. The company has also developed a proprietary blend of ethyl propanoate with other solvents and activators to optimize the flux's cleaning properties and minimize residue formation[3]. Tamura's flux systems incorporating ethyl propanoate have shown improved performance in fine-pitch applications and with challenging surface finishes like OSP and ENIG[4].

Strengths: Enhanced performance in miniaturized and high-density assemblies, reduced defects in BGA/CSP soldering. Weaknesses: May require specialized handling and storage due to ethyl propanoate's volatility, potential compatibility issues with certain materials.

Innovations in Ethyl Propanoate Flux Chemistry

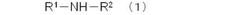

Flux for lead-free solder, and lead-free solder paste

PatentWO2016199747A1

Innovation

- A lead-free solder flux composition including a rosin base resin, a dibasic acid activator, a bromine-based activator, and an amine-based activator, with specific concentrations and types of components to balance wettability, storage stability, and insulation resistance, formulated with a dibasic acid activator, brominated alcohol or carboxylic acid compounds, and amine compounds like di(2-ethylhexyl)amine, along with a thixotropic agent and solvent.

Flux for lead-free solder, and lead-free solder paste.

PatentPendingTH179727A

Innovation

- The flux composition includes a combination of (b1) dibasic acid activated stimulant, (b2) bromine-based activated stimulant, and (b3) specific amine-based stimulants to improve wettability and insulation resistance.

- The use of specific amine-based stimulants with C6-10 alkyl groups enhances the retention stability of the solder paste.

- The flux formulation balances excellent insulation resistance of residual flux with good solder wettability.

Environmental Impact Assessment

The environmental impact assessment of ethyl propanoate in lead-free solder fluxes is a critical consideration for the electronics industry's transition towards more sustainable manufacturing practices. Ethyl propanoate, as a key component in these fluxes, plays a significant role in determining the overall environmental footprint of the soldering process.

One of the primary environmental benefits of using ethyl propanoate in lead-free solder fluxes is its contribution to the reduction of toxic heavy metal emissions. By enabling the effective use of lead-free solders, ethyl propanoate helps minimize the release of lead into the environment, which is known to have severe ecological and health consequences. This shift aligns with global initiatives to phase out hazardous substances in electronic products.

However, the production and use of ethyl propanoate are not without environmental concerns. The synthesis of this compound typically involves petrochemical processes, which can contribute to greenhouse gas emissions and resource depletion. Additionally, the volatile nature of ethyl propanoate raises questions about its potential impact on air quality, particularly in manufacturing environments where it may be used in large quantities.

The disposal of solder flux residues containing ethyl propanoate also requires careful consideration. While generally less harmful than lead-containing alternatives, improper disposal can still lead to soil and water contamination. Proper waste management protocols are essential to mitigate these risks and ensure that the environmental benefits of lead-free soldering are not offset by secondary pollution issues.

Life cycle assessments of ethyl propanoate in solder fluxes have shown mixed results. While its use contributes to reduced heavy metal pollution, the energy-intensive production process and potential for volatile organic compound (VOC) emissions during application present trade-offs that must be carefully weighed. Efforts to improve the sustainability of ethyl propanoate production, such as exploring bio-based alternatives or optimizing synthesis routes, are ongoing areas of research.

The long-term environmental impact of ethyl propanoate in electronic waste streams is another area of concern. As lead-free solders become more prevalent, the accumulation of flux residues in e-waste may introduce new challenges for recycling and disposal processes. Research into the biodegradability and potential for recovery of ethyl propanoate from waste materials is crucial for developing comprehensive end-of-life management strategies for electronic products.

In conclusion, while ethyl propanoate plays a vital role in enabling lead-free soldering technologies, its environmental impact is complex and multifaceted. Balancing the benefits of reduced heavy metal pollution against the potential drawbacks of VOC emissions and production-related impacts requires ongoing assessment and innovation in flux formulations and manufacturing processes.

One of the primary environmental benefits of using ethyl propanoate in lead-free solder fluxes is its contribution to the reduction of toxic heavy metal emissions. By enabling the effective use of lead-free solders, ethyl propanoate helps minimize the release of lead into the environment, which is known to have severe ecological and health consequences. This shift aligns with global initiatives to phase out hazardous substances in electronic products.

However, the production and use of ethyl propanoate are not without environmental concerns. The synthesis of this compound typically involves petrochemical processes, which can contribute to greenhouse gas emissions and resource depletion. Additionally, the volatile nature of ethyl propanoate raises questions about its potential impact on air quality, particularly in manufacturing environments where it may be used in large quantities.

The disposal of solder flux residues containing ethyl propanoate also requires careful consideration. While generally less harmful than lead-containing alternatives, improper disposal can still lead to soil and water contamination. Proper waste management protocols are essential to mitigate these risks and ensure that the environmental benefits of lead-free soldering are not offset by secondary pollution issues.

Life cycle assessments of ethyl propanoate in solder fluxes have shown mixed results. While its use contributes to reduced heavy metal pollution, the energy-intensive production process and potential for volatile organic compound (VOC) emissions during application present trade-offs that must be carefully weighed. Efforts to improve the sustainability of ethyl propanoate production, such as exploring bio-based alternatives or optimizing synthesis routes, are ongoing areas of research.

The long-term environmental impact of ethyl propanoate in electronic waste streams is another area of concern. As lead-free solders become more prevalent, the accumulation of flux residues in e-waste may introduce new challenges for recycling and disposal processes. Research into the biodegradability and potential for recovery of ethyl propanoate from waste materials is crucial for developing comprehensive end-of-life management strategies for electronic products.

In conclusion, while ethyl propanoate plays a vital role in enabling lead-free soldering technologies, its environmental impact is complex and multifaceted. Balancing the benefits of reduced heavy metal pollution against the potential drawbacks of VOC emissions and production-related impacts requires ongoing assessment and innovation in flux formulations and manufacturing processes.

Regulatory Compliance for Lead-Free Soldering

The regulatory landscape for lead-free soldering has become increasingly complex as environmental concerns and health risks associated with lead-based solders have prompted stringent regulations worldwide. The European Union's Restriction of Hazardous Substances (RoHS) Directive, implemented in 2006 and subsequently updated, has been a pivotal force in driving the adoption of lead-free soldering practices globally. This directive restricts the use of lead and other hazardous substances in electrical and electronic equipment, setting a maximum concentration value of 0.1% by weight in homogeneous materials.

In the United States, while there is no federal mandate equivalent to RoHS, many states have enacted their own regulations. California's Electronic Waste Recycling Act, for instance, closely mirrors the EU's RoHS directive. Additionally, the Environmental Protection Agency (EPA) has implemented the Toxic Substances Control Act (TSCA), which, although not specifically targeting lead in solder, does regulate the use of lead in various applications.

Japan's J-MOSS (Japanese RoHS) and China's Administrative Measure on the Control of Pollution Caused by Electronic Information Products (China RoHS) are other significant regulatory frameworks that manufacturers must comply with when using lead-free solder fluxes. These regulations not only restrict the use of lead but also mandate proper labeling and documentation of electronic products.

The use of ethyl propanoate in lead-free solder fluxes must adhere to these regulatory standards. As a volatile organic compound (VOC), ethyl propanoate is subject to additional regulations concerning air quality and worker safety. The Occupational Safety and Health Administration (OSHA) in the U.S. sets permissible exposure limits for such compounds in the workplace, while the Environmental Protection Agency regulates their emissions under the Clean Air Act.

Manufacturers utilizing ethyl propanoate in their lead-free solder flux formulations must ensure compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations in the EU. This involves registering the substance with the European Chemicals Agency (ECHA) and providing safety data sheets that detail its properties, potential hazards, and safe handling procedures.

To maintain regulatory compliance, companies must implement rigorous testing and documentation processes. This includes regular material composition analyses to verify the absence of lead and other restricted substances, as well as maintaining detailed records of chemical inventories and usage. Third-party certification bodies often play a crucial role in verifying compliance with various international standards and regulations.

As regulations continue to evolve, staying informed about changes and updates is critical for manufacturers. Industry associations and regulatory bodies frequently publish guidance documents and offer training programs to assist companies in navigating the complex regulatory landscape of lead-free soldering. Proactive engagement with these resources can help ensure ongoing compliance and mitigate the risk of regulatory violations.

In the United States, while there is no federal mandate equivalent to RoHS, many states have enacted their own regulations. California's Electronic Waste Recycling Act, for instance, closely mirrors the EU's RoHS directive. Additionally, the Environmental Protection Agency (EPA) has implemented the Toxic Substances Control Act (TSCA), which, although not specifically targeting lead in solder, does regulate the use of lead in various applications.

Japan's J-MOSS (Japanese RoHS) and China's Administrative Measure on the Control of Pollution Caused by Electronic Information Products (China RoHS) are other significant regulatory frameworks that manufacturers must comply with when using lead-free solder fluxes. These regulations not only restrict the use of lead but also mandate proper labeling and documentation of electronic products.

The use of ethyl propanoate in lead-free solder fluxes must adhere to these regulatory standards. As a volatile organic compound (VOC), ethyl propanoate is subject to additional regulations concerning air quality and worker safety. The Occupational Safety and Health Administration (OSHA) in the U.S. sets permissible exposure limits for such compounds in the workplace, while the Environmental Protection Agency regulates their emissions under the Clean Air Act.

Manufacturers utilizing ethyl propanoate in their lead-free solder flux formulations must ensure compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations in the EU. This involves registering the substance with the European Chemicals Agency (ECHA) and providing safety data sheets that detail its properties, potential hazards, and safe handling procedures.

To maintain regulatory compliance, companies must implement rigorous testing and documentation processes. This includes regular material composition analyses to verify the absence of lead and other restricted substances, as well as maintaining detailed records of chemical inventories and usage. Third-party certification bodies often play a crucial role in verifying compliance with various international standards and regulations.

As regulations continue to evolve, staying informed about changes and updates is critical for manufacturers. Industry associations and regulatory bodies frequently publish guidance documents and offer training programs to assist companies in navigating the complex regulatory landscape of lead-free soldering. Proactive engagement with these resources can help ensure ongoing compliance and mitigate the risk of regulatory violations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!