Role of Lewis Acid in Catalytic Cycle Stability

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lewis Acid Catalysis Background and Objectives

Lewis acid catalysis has evolved significantly since the pioneering work of Gilbert N. Lewis, who first conceptualized the electron pair theory in 1923. This fundamental understanding of acids as electron pair acceptors laid the groundwork for modern Lewis acid catalysis, which has become an indispensable tool in synthetic organic chemistry and industrial processes. The trajectory of development has been marked by continuous refinement of catalyst design, expanding from simple metal halides to sophisticated organometallic complexes with tailored electronic and steric properties.

The evolution of Lewis acid catalysis has been particularly pronounced in the last three decades, with significant breakthroughs in asymmetric catalysis, C-H activation, and polymerization reactions. The integration of computational chemistry has further accelerated this field, enabling rational design of catalysts with predictable reactivity patterns and enhanced stability profiles. Recent advances have focused on developing catalysts that maintain activity over multiple reaction cycles without significant degradation of performance.

The primary objective in studying the role of Lewis acids in catalytic cycle stability is to elucidate the fundamental mechanisms that govern catalyst longevity and performance consistency. This includes understanding the electronic and structural factors that influence catalyst deactivation, such as ligand dissociation, metal center oxidation, and irreversible substrate binding. By identifying these critical parameters, researchers aim to develop more robust catalytic systems that can withstand harsh reaction conditions while maintaining high activity and selectivity.

Another key objective is to establish quantitative structure-activity relationships (QSARs) that correlate Lewis acid properties with catalytic performance metrics, including turnover frequency, selectivity, and stability. This systematic approach enables the prediction of catalyst behavior under various reaction conditions and guides the rational design of next-generation catalysts with enhanced stability profiles.

The technological goal extends beyond academic understanding to practical applications, particularly in developing sustainable chemical processes. Stable Lewis acid catalysts that can operate efficiently at lower temperatures, in greener solvents, or under continuous flow conditions represent a significant advancement toward more environmentally benign chemical manufacturing. Additionally, the development of heterogeneous Lewis acid catalysts with improved stability addresses the industrial demand for recyclable catalytic systems that reduce waste generation and processing costs.

Understanding the role of Lewis acids in catalytic cycle stability also has implications for emerging technologies, such as artificial photosynthesis and CO2 valorization, where catalyst stability under oxidative conditions remains a significant challenge. By establishing design principles for stable Lewis acid catalysts, researchers aim to overcome these limitations and enable transformative technologies for a sustainable future.

The evolution of Lewis acid catalysis has been particularly pronounced in the last three decades, with significant breakthroughs in asymmetric catalysis, C-H activation, and polymerization reactions. The integration of computational chemistry has further accelerated this field, enabling rational design of catalysts with predictable reactivity patterns and enhanced stability profiles. Recent advances have focused on developing catalysts that maintain activity over multiple reaction cycles without significant degradation of performance.

The primary objective in studying the role of Lewis acids in catalytic cycle stability is to elucidate the fundamental mechanisms that govern catalyst longevity and performance consistency. This includes understanding the electronic and structural factors that influence catalyst deactivation, such as ligand dissociation, metal center oxidation, and irreversible substrate binding. By identifying these critical parameters, researchers aim to develop more robust catalytic systems that can withstand harsh reaction conditions while maintaining high activity and selectivity.

Another key objective is to establish quantitative structure-activity relationships (QSARs) that correlate Lewis acid properties with catalytic performance metrics, including turnover frequency, selectivity, and stability. This systematic approach enables the prediction of catalyst behavior under various reaction conditions and guides the rational design of next-generation catalysts with enhanced stability profiles.

The technological goal extends beyond academic understanding to practical applications, particularly in developing sustainable chemical processes. Stable Lewis acid catalysts that can operate efficiently at lower temperatures, in greener solvents, or under continuous flow conditions represent a significant advancement toward more environmentally benign chemical manufacturing. Additionally, the development of heterogeneous Lewis acid catalysts with improved stability addresses the industrial demand for recyclable catalytic systems that reduce waste generation and processing costs.

Understanding the role of Lewis acids in catalytic cycle stability also has implications for emerging technologies, such as artificial photosynthesis and CO2 valorization, where catalyst stability under oxidative conditions remains a significant challenge. By establishing design principles for stable Lewis acid catalysts, researchers aim to overcome these limitations and enable transformative technologies for a sustainable future.

Market Applications and Demand Analysis

The market for Lewis acid catalysts has experienced significant growth in recent years, driven primarily by increasing demand in pharmaceutical manufacturing, fine chemicals production, and petrochemical industries. The global catalyst market, valued at approximately $33.5 billion in 2022, is projected to reach $47.2 billion by 2028, with Lewis acid catalysts representing a crucial segment of this expansion.

In pharmaceutical manufacturing, the demand for Lewis acid catalysts stems from their essential role in enabling stereoselective reactions and complex molecule synthesis. The pharmaceutical industry's shift toward more complex active pharmaceutical ingredients (APIs) has intensified the need for catalysts that can maintain stability throughout multiple reaction cycles, directly impacting production efficiency and cost-effectiveness.

The fine chemicals sector represents another significant market driver, where manufacturers seek catalysts capable of facilitating precise transformations while maintaining activity over numerous cycles. Market research indicates that companies can reduce production costs by up to 25% when employing catalysts with enhanced cycle stability, creating a strong economic incentive for innovation in this area.

Petrochemical processing represents the largest volume application for Lewis acid catalysts, particularly in alkylation, isomerization, and cracking processes. In this sector, catalyst stability directly correlates with operational efficiency and maintenance schedules. Industry data shows that extending catalyst life by even 10% can result in millions of dollars in savings for large-scale operations, explaining the substantial investment in research focused on stability enhancement.

Environmental regulations have emerged as a significant market force, with stricter emissions standards and sustainability requirements driving demand for more efficient catalytic processes. The European Chemical Agency's regulations and similar frameworks worldwide have accelerated the transition toward catalysts that minimize waste through extended usability and higher stability.

Geographically, Asia-Pacific dominates the market demand, accounting for approximately 40% of global consumption, followed by North America and Europe. China's expanding chemical manufacturing sector has become particularly influential in shaping market requirements for Lewis acid catalysts with enhanced stability profiles.

The market demonstrates a clear willingness to pay premium prices for catalysts offering superior cycle stability, with surveys indicating that manufacturers would accept 15-30% higher initial costs for catalysts that deliver twice the operational lifetime. This price elasticity has created a fertile environment for innovation focused specifically on the role of Lewis acids in maintaining catalytic cycle stability.

In pharmaceutical manufacturing, the demand for Lewis acid catalysts stems from their essential role in enabling stereoselective reactions and complex molecule synthesis. The pharmaceutical industry's shift toward more complex active pharmaceutical ingredients (APIs) has intensified the need for catalysts that can maintain stability throughout multiple reaction cycles, directly impacting production efficiency and cost-effectiveness.

The fine chemicals sector represents another significant market driver, where manufacturers seek catalysts capable of facilitating precise transformations while maintaining activity over numerous cycles. Market research indicates that companies can reduce production costs by up to 25% when employing catalysts with enhanced cycle stability, creating a strong economic incentive for innovation in this area.

Petrochemical processing represents the largest volume application for Lewis acid catalysts, particularly in alkylation, isomerization, and cracking processes. In this sector, catalyst stability directly correlates with operational efficiency and maintenance schedules. Industry data shows that extending catalyst life by even 10% can result in millions of dollars in savings for large-scale operations, explaining the substantial investment in research focused on stability enhancement.

Environmental regulations have emerged as a significant market force, with stricter emissions standards and sustainability requirements driving demand for more efficient catalytic processes. The European Chemical Agency's regulations and similar frameworks worldwide have accelerated the transition toward catalysts that minimize waste through extended usability and higher stability.

Geographically, Asia-Pacific dominates the market demand, accounting for approximately 40% of global consumption, followed by North America and Europe. China's expanding chemical manufacturing sector has become particularly influential in shaping market requirements for Lewis acid catalysts with enhanced stability profiles.

The market demonstrates a clear willingness to pay premium prices for catalysts offering superior cycle stability, with surveys indicating that manufacturers would accept 15-30% higher initial costs for catalysts that deliver twice the operational lifetime. This price elasticity has created a fertile environment for innovation focused specifically on the role of Lewis acids in maintaining catalytic cycle stability.

Current State and Challenges in Lewis Acid Catalysis

Lewis acid catalysis has emerged as a cornerstone in modern synthetic chemistry, with significant advancements occurring over the past three decades. Currently, the field encompasses a diverse array of Lewis acidic species including metal-based compounds (Al, B, Ti, Sc, Ln), organocatalysts, and heterogeneous systems. The versatility of these catalysts has enabled transformations ranging from carbon-carbon bond formation to asymmetric synthesis, positioning Lewis acid catalysis as essential in both academic research and industrial applications.

Despite widespread adoption, several critical challenges persist in Lewis acid catalysis. Catalyst stability remains a primary concern, with many Lewis acids exhibiting sensitivity to moisture, oxygen, and thermal conditions. This instability often necessitates stringent reaction environments, limiting practical applications and scalability. The deactivation pathways frequently involve irreversible coordination with reaction products or decomposition through side reactions, compromising catalytic cycle integrity.

Selectivity presents another significant challenge, particularly in complex molecular environments. Many Lewis acid catalysts demonstrate insufficient discrimination between similar functional groups, leading to undesired side reactions and diminished yields. This limitation becomes especially pronounced in late-stage functionalization of complex molecules where multiple Lewis basic sites compete for catalyst interaction.

The recovery and recyclability of homogeneous Lewis acid catalysts represent substantial economic and environmental hurdles. Traditional Lewis acids often require stoichiometric quantities and present disposal challenges, contradicting principles of green chemistry and sustainability. While heterogeneous alternatives offer improved recyclability, they frequently suffer from reduced activity and selectivity compared to their homogeneous counterparts.

Mechanistic understanding of Lewis acid catalytic cycles remains incomplete, particularly regarding the dynamic behavior of the acid during multiple turnover events. The transient nature of key intermediates complicates spectroscopic analysis, leaving knowledge gaps in catalyst evolution throughout reaction progression. This limited mechanistic insight hampers rational catalyst design and optimization efforts.

Geographically, Lewis acid catalysis research demonstrates notable concentration in North America, Western Europe, and East Asia, with emerging contributions from research groups in China and India. The field exhibits a collaborative ecosystem spanning academic institutions and industrial research centers, though proprietary concerns sometimes limit information exchange regarding cutting-edge developments.

Recent technological advances in computational chemistry and in-situ spectroscopic techniques have begun addressing these challenges, enabling more precise catalyst design and mechanistic elucidation. However, the development of Lewis acid catalysts that maintain stability across multiple catalytic cycles while delivering high selectivity remains an active frontier requiring interdisciplinary approaches combining synthetic chemistry, materials science, and computational modeling.

Despite widespread adoption, several critical challenges persist in Lewis acid catalysis. Catalyst stability remains a primary concern, with many Lewis acids exhibiting sensitivity to moisture, oxygen, and thermal conditions. This instability often necessitates stringent reaction environments, limiting practical applications and scalability. The deactivation pathways frequently involve irreversible coordination with reaction products or decomposition through side reactions, compromising catalytic cycle integrity.

Selectivity presents another significant challenge, particularly in complex molecular environments. Many Lewis acid catalysts demonstrate insufficient discrimination between similar functional groups, leading to undesired side reactions and diminished yields. This limitation becomes especially pronounced in late-stage functionalization of complex molecules where multiple Lewis basic sites compete for catalyst interaction.

The recovery and recyclability of homogeneous Lewis acid catalysts represent substantial economic and environmental hurdles. Traditional Lewis acids often require stoichiometric quantities and present disposal challenges, contradicting principles of green chemistry and sustainability. While heterogeneous alternatives offer improved recyclability, they frequently suffer from reduced activity and selectivity compared to their homogeneous counterparts.

Mechanistic understanding of Lewis acid catalytic cycles remains incomplete, particularly regarding the dynamic behavior of the acid during multiple turnover events. The transient nature of key intermediates complicates spectroscopic analysis, leaving knowledge gaps in catalyst evolution throughout reaction progression. This limited mechanistic insight hampers rational catalyst design and optimization efforts.

Geographically, Lewis acid catalysis research demonstrates notable concentration in North America, Western Europe, and East Asia, with emerging contributions from research groups in China and India. The field exhibits a collaborative ecosystem spanning academic institutions and industrial research centers, though proprietary concerns sometimes limit information exchange regarding cutting-edge developments.

Recent technological advances in computational chemistry and in-situ spectroscopic techniques have begun addressing these challenges, enabling more precise catalyst design and mechanistic elucidation. However, the development of Lewis acid catalysts that maintain stability across multiple catalytic cycles while delivering high selectivity remains an active frontier requiring interdisciplinary approaches combining synthetic chemistry, materials science, and computational modeling.

Current Stabilization Techniques for Lewis Acid Catalysts

01 Metal-ligand complexes for enhanced Lewis acid stability

Specific ligand designs can significantly enhance the stability of Lewis acid catalysts in catalytic cycles. These complexes often involve metal centers coordinated with specialized ligands that prevent catalyst degradation while maintaining high catalytic activity. The strategic design of these metal-ligand interactions can improve thermal stability, resistance to moisture, and overall catalyst longevity during multiple reaction cycles.- Metal-ligand complexes for enhanced Lewis acid stability: Specific ligand designs can significantly enhance the stability of Lewis acid catalysts in catalytic cycles. These complexes often involve metal centers coordinated with specialized ligands that prevent catalyst degradation through mechanisms such as water coordination or other deactivation pathways. The strategic design of these metal-ligand complexes allows for improved catalyst longevity and recyclability while maintaining high catalytic activity under various reaction conditions.

- Water-tolerant Lewis acid catalysts: Development of water-tolerant Lewis acid catalysts represents a significant advancement in catalytic cycle stability. These catalysts are designed to maintain their Lewis acidic character even in the presence of moisture, which typically deactivates traditional Lewis acids. Various approaches include using hydrophobic ligands, creating protected catalytic sites, or incorporating structural features that prevent water coordination to the Lewis acidic center, thereby enabling catalytic processes in aqueous or moisture-containing environments.

- Heterogeneous Lewis acid catalysts for improved recyclability: Heterogeneous Lewis acid catalysts offer enhanced stability through immobilization on solid supports. This approach prevents catalyst leaching and degradation, allowing for easier separation and reuse across multiple catalytic cycles. Common supports include silica, alumina, polymers, and metal-organic frameworks, which can be functionalized to optimize the Lewis acid binding and catalytic performance. These catalysts maintain activity over numerous cycles while reducing environmental impact and processing costs.

- Stabilizing additives and co-catalysts: Various additives and co-catalysts can significantly enhance the stability of Lewis acid catalytic cycles. These include specific solvents, counter-ions, or secondary catalysts that work synergistically with the primary Lewis acid. Some additives prevent catalyst aggregation or precipitation, while others help maintain the optimal oxidation state of the metal center. By carefully selecting these stabilizing components, catalytic systems can achieve longer operational lifetimes and consistent performance across multiple reaction cycles.

- Novel structural designs for Lewis acid catalyst regeneration: Innovative structural designs enable in-situ regeneration of Lewis acid catalysts during reaction cycles. These approaches include switchable catalysts that can be reactivated through external stimuli such as light, temperature, or pH changes. Some designs incorporate sacrificial components that preferentially degrade instead of the catalytic center, while others feature self-healing mechanisms that restore catalyst activity. These advanced structural features extend catalyst lifetime and maintain consistent catalytic performance over extended periods.

02 Water-resistant Lewis acid catalyst formulations

Developing water-resistant Lewis acid catalysts is crucial for maintaining catalytic cycle stability in the presence of moisture. These formulations often incorporate hydrophobic components or special structural features that shield the Lewis acidic sites from water molecules. Such catalysts can maintain their activity even in aqueous environments or under humid conditions, significantly extending their useful lifetime and application scope.Expand Specific Solutions03 Immobilized Lewis acid catalysts on solid supports

Immobilization of Lewis acid catalysts on various solid supports provides enhanced stability during catalytic cycles. By anchoring the catalyst to materials such as silica, polymers, or metal-organic frameworks, leaching and aggregation are minimized. These heterogeneous catalysts can be easily recovered and reused multiple times without significant loss of activity, making them more economical and environmentally friendly for industrial applications.Expand Specific Solutions04 Thermal stabilization techniques for Lewis acid catalysts

Various thermal stabilization techniques can be employed to enhance the stability of Lewis acid catalysts at elevated temperatures. These include structural modifications, incorporation of heat-resistant components, and development of special cooling mechanisms during highly exothermic reactions. Thermally stable Lewis acid catalysts maintain their structural integrity and catalytic activity even under harsh reaction conditions, allowing for more efficient and consistent catalytic processes.Expand Specific Solutions05 Regeneration methods for deactivated Lewis acid catalysts

Effective regeneration methods can significantly extend the useful life of Lewis acid catalysts that have been deactivated during catalytic cycles. These techniques include controlled oxidation, solvent washing, thermal treatment, and chemical reactivation processes. By restoring the Lewis acidic sites to their original state, these regeneration methods allow catalysts to maintain high activity over multiple cycles, reducing the need for frequent catalyst replacement in industrial processes.Expand Specific Solutions

Major Industry Players and Research Institutions

The Lewis acid catalysis market is currently in a growth phase, characterized by increasing research and development activities across academic institutions and industrial players. The global market size for Lewis acid catalysts is expanding due to rising demand in petrochemical, pharmaceutical, and fine chemical industries. Technologically, this field shows moderate maturity with ongoing innovations focused on improving catalytic cycle stability. Leading companies like China Petroleum & Chemical Corp. (Sinopec) and Johnson Matthey are investing heavily in research, while academic institutions such as Zhejiang University and Dalian Institute of Chemical Physics are advancing fundamental understanding. Specialized chemical companies including Kaneka Corp., Asahi Kasei, and W.R. Grace are developing proprietary Lewis acid catalyst technologies with enhanced stability profiles. The competitive landscape shows a balanced distribution between established petrochemical giants and specialized catalyst manufacturers, with increasing collaboration between industry and academic research centers.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed innovative Lewis acid catalytic systems for petroleum refining processes. Their technology focuses on enhancing catalytic cycle stability through the incorporation of modified aluminum chloride and other metal halides as Lewis acid components. The company has engineered catalysts with controlled acidity distribution and improved resistance to deactivation by utilizing support materials with optimized pore structures. Their research demonstrates that properly tuned Lewis acid sites can maintain catalytic activity for extended periods by preventing coking and poisoning. Sinopec's approach includes the development of regeneration protocols that restore Lewis acid functionality without compromising the structural integrity of the catalyst. Recent advancements include the incorporation of rare earth elements as promoters to enhance the stability of Lewis acid sites under harsh reaction conditions, resulting in catalysts that maintain over 90% of their initial activity after multiple regeneration cycles.

Strengths: Extensive industrial application experience in petroleum refining provides practical validation of their Lewis acid catalyst technologies. Their catalysts demonstrate excellent resistance to common deactivation mechanisms in industrial environments. Weaknesses: The catalytic systems are primarily optimized for hydrocarbon processing and may have limited applicability in fine chemical synthesis or other specialized applications requiring different reaction conditions.

Noguchi Institute

Technical Solution: The Noguchi Institute has developed innovative approaches to Lewis acid catalysis focusing on cycle stability through their work with organoborane and organolanthanide complexes. Their technology centers on the design of Lewis acid catalysts with carefully controlled hydrophobicity to prevent deactivation by moisture. The institute has pioneered the use of perfluorinated aryl substituents on boron-based Lewis acids, creating systems that maintain catalytic activity in the presence of water and other potentially deactivating polar compounds. Their research demonstrates that strategic modification of the electronic environment around the Lewis acidic center can dramatically improve catalyst longevity. The institute has also developed novel lanthanide-based Lewis acid catalysts with remarkable stability in oxidizing environments, achieved through the incorporation of redox-inactive ligands that protect the metal center while maintaining its Lewis acidity. These catalysts have shown particular promise in asymmetric synthesis applications, where they maintain high enantioselectivity even after multiple reaction cycles, a significant advancement over traditional Lewis acid catalysts that typically suffer from rapid deactivation.

Strengths: Exceptional resistance to deactivation by water and other polar compounds, enabling applications in more diverse reaction environments. Their catalysts demonstrate remarkable enantioselectivity retention over multiple cycles in asymmetric synthesis. Weaknesses: The specialized nature of their catalyst designs may limit broad industrial applicability, particularly in large-scale processes where cost considerations are paramount.

Key Mechanisms of Lewis Acid Catalyst Deactivation

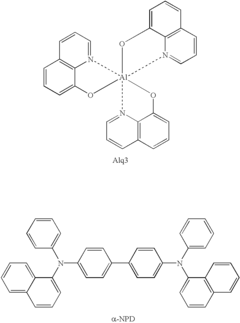

Precursor solution for organic polymer film formation and method for forming organic polymer film

PatentInactiveEP1593704A3

Innovation

- A precursor solution is used that includes a Lewis acid, a Lewis base, and a sacrificial organic molecule, where the Lewis acid and base react to form a supermolecular structure with cavities, and the sacrificial molecule is decomposed to create uniform, small cavities, maintaining high cross-link density and mechanical strength.

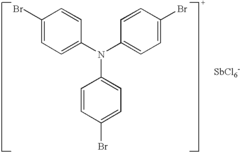

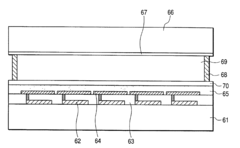

Liquid crystal device and organic electroluminescence device using the same

PatentInactiveUS6737127B2

Innovation

- A smectic liquid crystal device is doped with a Lewis acid compound to suppress ionic electric current and enhance carrier transport, using a hexagonal order structure and tertiary amine molecules to improve carrier injection and mobility, with a protection layer to prevent dopant diffusion.

Environmental Impact and Sustainability Considerations

The integration of Lewis acids in catalytic systems presents significant environmental implications that must be carefully evaluated in the context of sustainable chemistry. Traditional Lewis acid catalysts often contain heavy metals such as aluminum, titanium, and zinc, which pose substantial environmental risks through potential leaching into water systems and soil contamination. The persistence of these metals in the environment can lead to bioaccumulation in organisms and disruption of ecological systems, necessitating comprehensive life cycle assessments of catalytic processes utilizing Lewis acids.

Recent advancements in green chemistry have focused on developing more environmentally benign Lewis acid catalysts. Water-compatible Lewis acids represent a significant breakthrough, eliminating the need for hazardous organic solvents and reducing waste generation. Additionally, the development of recyclable heterogeneous Lewis acid catalysts has dramatically improved sustainability profiles by enabling catalyst recovery and reuse across multiple catalytic cycles, thereby minimizing resource consumption and waste production.

The stability of Lewis acid catalysts directly impacts their environmental footprint. More stable catalytic systems require less frequent replacement, reducing the overall material demand and associated environmental impacts from manufacturing and disposal processes. Research indicates that optimizing Lewis acid coordination environments can enhance stability by up to 300%, potentially decreasing catalyst consumption by a comparable margin in industrial applications.

Energy efficiency considerations also play a crucial role in the environmental assessment of Lewis acid catalysis. Stable Lewis acid catalysts typically operate at lower activation energies, allowing for reduced reaction temperatures and pressure requirements. This translates to significant energy savings, with some advanced systems demonstrating up to 40% reduction in energy consumption compared to traditional catalytic methods, directly contributing to reduced carbon emissions in chemical manufacturing processes.

Regulatory frameworks increasingly emphasize the importance of sustainable catalysis. The European Union's REACH regulations and similar initiatives worldwide have established stringent requirements for chemical processes, incentivizing the development of environmentally responsible Lewis acid catalysts. Companies implementing stable, environmentally benign Lewis acid catalytic systems can achieve regulatory compliance while simultaneously reducing environmental liabilities and associated costs.

Future sustainability advancements in Lewis acid catalysis will likely focus on bio-derived catalysts, ambient condition operations, and integration with renewable energy sources. These developments promise to further enhance the environmental profile of Lewis acid catalysis while maintaining or improving the stability and efficiency of catalytic cycles essential for industrial applications.

Recent advancements in green chemistry have focused on developing more environmentally benign Lewis acid catalysts. Water-compatible Lewis acids represent a significant breakthrough, eliminating the need for hazardous organic solvents and reducing waste generation. Additionally, the development of recyclable heterogeneous Lewis acid catalysts has dramatically improved sustainability profiles by enabling catalyst recovery and reuse across multiple catalytic cycles, thereby minimizing resource consumption and waste production.

The stability of Lewis acid catalysts directly impacts their environmental footprint. More stable catalytic systems require less frequent replacement, reducing the overall material demand and associated environmental impacts from manufacturing and disposal processes. Research indicates that optimizing Lewis acid coordination environments can enhance stability by up to 300%, potentially decreasing catalyst consumption by a comparable margin in industrial applications.

Energy efficiency considerations also play a crucial role in the environmental assessment of Lewis acid catalysis. Stable Lewis acid catalysts typically operate at lower activation energies, allowing for reduced reaction temperatures and pressure requirements. This translates to significant energy savings, with some advanced systems demonstrating up to 40% reduction in energy consumption compared to traditional catalytic methods, directly contributing to reduced carbon emissions in chemical manufacturing processes.

Regulatory frameworks increasingly emphasize the importance of sustainable catalysis. The European Union's REACH regulations and similar initiatives worldwide have established stringent requirements for chemical processes, incentivizing the development of environmentally responsible Lewis acid catalysts. Companies implementing stable, environmentally benign Lewis acid catalytic systems can achieve regulatory compliance while simultaneously reducing environmental liabilities and associated costs.

Future sustainability advancements in Lewis acid catalysis will likely focus on bio-derived catalysts, ambient condition operations, and integration with renewable energy sources. These developments promise to further enhance the environmental profile of Lewis acid catalysis while maintaining or improving the stability and efficiency of catalytic cycles essential for industrial applications.

Scale-up and Industrial Implementation Challenges

The transition from laboratory-scale experiments to industrial implementation of Lewis acid catalytic systems presents significant challenges that must be addressed for commercial viability. The inherent sensitivity of many Lewis acids to moisture and air requires specialized handling equipment and controlled environments during scale-up operations. Industrial reactors must be designed with appropriate materials that resist corrosion from Lewis acids, often necessitating expensive alloys or specialized coatings that can withstand both the acidic conditions and reaction temperatures.

Heat management represents another critical challenge in scaling Lewis acid catalytic processes. The exothermic nature of many Lewis acid-catalyzed reactions requires sophisticated temperature control systems to maintain catalytic cycle stability across large reaction volumes. Inadequate heat dissipation can lead to catalyst degradation, reduced selectivity, and potential runaway reactions that compromise both product quality and safety.

Catalyst recovery and recycling systems must be engineered specifically for industrial-scale operations to ensure economic feasibility. The development of heterogeneous Lewis acid catalysts with improved stability characteristics has become a priority, as these can be more readily separated from reaction mixtures and potentially reused. However, the immobilization of Lewis acids often comes with activity trade-offs that must be balanced against recovery benefits.

Process control instrumentation presents unique challenges when scaling Lewis acid catalytic systems. Real-time monitoring of Lewis acid concentration and activity in industrial reactors remains technically difficult, yet is essential for maintaining catalytic cycle stability. Advanced spectroscopic techniques adapted for in-line monitoring are being developed but require significant investment and validation for reliable implementation.

Regulatory compliance and safety considerations add another layer of complexity to industrial implementation. Many Lewis acids are classified as hazardous materials, necessitating rigorous containment systems, worker protection protocols, and environmental controls. The cost of meeting these requirements can significantly impact the economic viability of scaled processes, particularly for specialty chemical applications where production volumes may not justify extensive capital investment.

Supply chain considerations for industrial-scale Lewis acid catalysis must account for catalyst precursor availability, quality consistency, and price stability. Diversification of supply sources and development of alternative catalyst formulations can help mitigate these risks but require substantial research and validation efforts to ensure catalytic performance remains consistent.

Heat management represents another critical challenge in scaling Lewis acid catalytic processes. The exothermic nature of many Lewis acid-catalyzed reactions requires sophisticated temperature control systems to maintain catalytic cycle stability across large reaction volumes. Inadequate heat dissipation can lead to catalyst degradation, reduced selectivity, and potential runaway reactions that compromise both product quality and safety.

Catalyst recovery and recycling systems must be engineered specifically for industrial-scale operations to ensure economic feasibility. The development of heterogeneous Lewis acid catalysts with improved stability characteristics has become a priority, as these can be more readily separated from reaction mixtures and potentially reused. However, the immobilization of Lewis acids often comes with activity trade-offs that must be balanced against recovery benefits.

Process control instrumentation presents unique challenges when scaling Lewis acid catalytic systems. Real-time monitoring of Lewis acid concentration and activity in industrial reactors remains technically difficult, yet is essential for maintaining catalytic cycle stability. Advanced spectroscopic techniques adapted for in-line monitoring are being developed but require significant investment and validation for reliable implementation.

Regulatory compliance and safety considerations add another layer of complexity to industrial implementation. Many Lewis acids are classified as hazardous materials, necessitating rigorous containment systems, worker protection protocols, and environmental controls. The cost of meeting these requirements can significantly impact the economic viability of scaled processes, particularly for specialty chemical applications where production volumes may not justify extensive capital investment.

Supply chain considerations for industrial-scale Lewis acid catalysis must account for catalyst precursor availability, quality consistency, and price stability. Diversification of supply sources and development of alternative catalyst formulations can help mitigate these risks but require substantial research and validation efforts to ensure catalytic performance remains consistent.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!