Role of PMSM in automated guided vehicles

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PMSM in AGV Evolution

The evolution of Permanent Magnet Synchronous Motors (PMSM) in Automated Guided Vehicles (AGVs) represents a significant technological advancement in the field of industrial automation and material handling. This progression has been driven by the increasing demand for more efficient, precise, and reliable propulsion systems in AGV applications.

In the early stages of AGV development, DC motors were predominantly used due to their simplicity and ease of control. However, as the requirements for AGV performance became more stringent, the limitations of DC motors became apparent, particularly in terms of efficiency and maintenance needs.

The introduction of PMSM technology in AGVs marked a turning point in the industry. PMSMs offered several advantages over their predecessors, including higher power density, improved efficiency, and better dynamic performance. These characteristics made them particularly well-suited for AGV applications, where space constraints and energy efficiency are critical factors.

The adoption of PMSMs in AGVs has been gradual but steady. Initial implementations focused on smaller, lighter AGVs where the benefits of PMSM's compact size and high torque-to-weight ratio were most apparent. As the technology matured and costs decreased, larger and more powerful AGVs began incorporating PMSM systems.

A key milestone in the evolution of PMSM in AGVs was the development of advanced control algorithms. Vector control techniques, in particular, allowed for precise speed and torque control, enabling AGVs to navigate complex environments with greater accuracy and responsiveness.

The integration of PMSM with sophisticated sensor systems and navigation technologies further enhanced AGV capabilities. This synergy allowed for more autonomous operation, improved obstacle avoidance, and better overall performance in dynamic industrial settings.

Recent years have seen a focus on improving the energy efficiency of PMSM-driven AGVs. Innovations in motor design, such as the use of high-performance magnetic materials and optimized winding configurations, have led to significant reductions in energy consumption. This has not only extended the operational range of AGVs but also aligned with broader industry trends towards sustainability and reduced environmental impact.

The evolution of PMSM in AGVs has also been characterized by increased integration with other AGV systems. Modern PMSM drives are often designed to interface seamlessly with battery management systems, allowing for optimized energy usage and extended operational times between charging cycles.

Looking forward, the role of PMSM in AGVs is expected to continue evolving. Emerging trends include the development of more compact and lightweight motor designs, further improvements in energy efficiency, and the integration of smart features such as predictive maintenance capabilities. These advancements promise to further enhance the performance, reliability, and versatility of AGVs across a wide range of industrial applications.

In the early stages of AGV development, DC motors were predominantly used due to their simplicity and ease of control. However, as the requirements for AGV performance became more stringent, the limitations of DC motors became apparent, particularly in terms of efficiency and maintenance needs.

The introduction of PMSM technology in AGVs marked a turning point in the industry. PMSMs offered several advantages over their predecessors, including higher power density, improved efficiency, and better dynamic performance. These characteristics made them particularly well-suited for AGV applications, where space constraints and energy efficiency are critical factors.

The adoption of PMSMs in AGVs has been gradual but steady. Initial implementations focused on smaller, lighter AGVs where the benefits of PMSM's compact size and high torque-to-weight ratio were most apparent. As the technology matured and costs decreased, larger and more powerful AGVs began incorporating PMSM systems.

A key milestone in the evolution of PMSM in AGVs was the development of advanced control algorithms. Vector control techniques, in particular, allowed for precise speed and torque control, enabling AGVs to navigate complex environments with greater accuracy and responsiveness.

The integration of PMSM with sophisticated sensor systems and navigation technologies further enhanced AGV capabilities. This synergy allowed for more autonomous operation, improved obstacle avoidance, and better overall performance in dynamic industrial settings.

Recent years have seen a focus on improving the energy efficiency of PMSM-driven AGVs. Innovations in motor design, such as the use of high-performance magnetic materials and optimized winding configurations, have led to significant reductions in energy consumption. This has not only extended the operational range of AGVs but also aligned with broader industry trends towards sustainability and reduced environmental impact.

The evolution of PMSM in AGVs has also been characterized by increased integration with other AGV systems. Modern PMSM drives are often designed to interface seamlessly with battery management systems, allowing for optimized energy usage and extended operational times between charging cycles.

Looking forward, the role of PMSM in AGVs is expected to continue evolving. Emerging trends include the development of more compact and lightweight motor designs, further improvements in energy efficiency, and the integration of smart features such as predictive maintenance capabilities. These advancements promise to further enhance the performance, reliability, and versatility of AGVs across a wide range of industrial applications.

AGV Market Demand Analysis

The market demand for Automated Guided Vehicles (AGVs) has been experiencing significant growth, driven by the increasing need for automation and efficiency in various industries. The global AGV market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 10% over the next five years. This growth is primarily fueled by the rising adoption of Industry 4.0 concepts and the continuous push for smart manufacturing solutions.

The logistics and warehousing sector represents the largest market segment for AGVs, as companies seek to optimize their material handling processes and reduce labor costs. E-commerce giants and large retailers are increasingly investing in AGV technology to improve their distribution center operations, leading to shorter order fulfillment times and enhanced customer satisfaction. The automotive industry is another key adopter of AGV technology, utilizing these vehicles in assembly lines and parts transportation within manufacturing facilities.

The healthcare sector is emerging as a promising market for AGVs, with hospitals and medical facilities implementing these vehicles for tasks such as medication delivery, laundry transportation, and waste management. This trend is expected to accelerate in the coming years, driven by the need for improved hygiene and reduced human contact in healthcare settings.

In terms of regional demand, Asia-Pacific is anticipated to be the fastest-growing market for AGVs, with China and India leading the charge. The rapid industrialization and government initiatives promoting smart manufacturing in these countries are key factors contributing to this growth. North America and Europe continue to be significant markets, with a focus on upgrading existing facilities and implementing advanced AGV solutions.

The demand for AGVs equipped with Permanent Magnet Synchronous Motors (PMSMs) is particularly strong due to their superior efficiency and performance characteristics. PMSMs offer higher power density, better dynamic response, and improved energy efficiency compared to traditional induction motors. This aligns well with the market's increasing emphasis on energy-efficient and environmentally friendly solutions.

As the AGV market evolves, there is a growing demand for more sophisticated navigation systems, enhanced safety features, and improved battery technologies. The integration of artificial intelligence and machine learning capabilities in AGVs is becoming a key differentiator, allowing for more adaptive and intelligent operation in complex environments. Additionally, the market is seeing a shift towards modular and scalable AGV solutions, enabling businesses to easily expand and reconfigure their automated material handling systems as needs change.

The logistics and warehousing sector represents the largest market segment for AGVs, as companies seek to optimize their material handling processes and reduce labor costs. E-commerce giants and large retailers are increasingly investing in AGV technology to improve their distribution center operations, leading to shorter order fulfillment times and enhanced customer satisfaction. The automotive industry is another key adopter of AGV technology, utilizing these vehicles in assembly lines and parts transportation within manufacturing facilities.

The healthcare sector is emerging as a promising market for AGVs, with hospitals and medical facilities implementing these vehicles for tasks such as medication delivery, laundry transportation, and waste management. This trend is expected to accelerate in the coming years, driven by the need for improved hygiene and reduced human contact in healthcare settings.

In terms of regional demand, Asia-Pacific is anticipated to be the fastest-growing market for AGVs, with China and India leading the charge. The rapid industrialization and government initiatives promoting smart manufacturing in these countries are key factors contributing to this growth. North America and Europe continue to be significant markets, with a focus on upgrading existing facilities and implementing advanced AGV solutions.

The demand for AGVs equipped with Permanent Magnet Synchronous Motors (PMSMs) is particularly strong due to their superior efficiency and performance characteristics. PMSMs offer higher power density, better dynamic response, and improved energy efficiency compared to traditional induction motors. This aligns well with the market's increasing emphasis on energy-efficient and environmentally friendly solutions.

As the AGV market evolves, there is a growing demand for more sophisticated navigation systems, enhanced safety features, and improved battery technologies. The integration of artificial intelligence and machine learning capabilities in AGVs is becoming a key differentiator, allowing for more adaptive and intelligent operation in complex environments. Additionally, the market is seeing a shift towards modular and scalable AGV solutions, enabling businesses to easily expand and reconfigure their automated material handling systems as needs change.

PMSM Challenges in AGVs

Permanent Magnet Synchronous Motors (PMSMs) play a crucial role in Automated Guided Vehicles (AGVs), offering high efficiency and precise control. However, their implementation in AGVs presents several significant challenges that need to be addressed for optimal performance and reliability.

One of the primary challenges is thermal management. PMSMs in AGVs operate in confined spaces with limited cooling options. The heat generated during operation can lead to reduced efficiency, shortened lifespan, and potential failure of the motor. Developing effective cooling systems that can fit within the compact AGV design while maintaining motor performance is a complex engineering task.

Position sensing and control pose another significant challenge. AGVs require precise movement and positioning, which demands accurate rotor position feedback from the PMSM. Traditional sensor-based methods can be bulky and expensive, while sensorless control techniques may struggle with low-speed operation and sudden load changes typical in AGV applications. Balancing accuracy, cost, and reliability in position sensing remains an ongoing challenge.

The variable load conditions encountered by AGVs present a further complication for PMSM control. As AGVs navigate different terrains, carry varying payloads, and perform diverse tasks, the motor must adapt to rapidly changing torque requirements. Developing robust control algorithms that can maintain optimal performance across a wide range of operating conditions is essential but challenging.

Energy efficiency is another critical concern. While PMSMs are inherently more efficient than many alternative motor types, maximizing their efficiency in AGV applications requires sophisticated control strategies. Implementing advanced techniques such as field-oriented control (FOC) or direct torque control (DTC) in the constrained computational environment of an AGV can be challenging.

Durability and reliability are paramount in AGV applications, where downtime can be costly. PMSMs must withstand frequent starts and stops, vibrations, and potential impacts. Ensuring long-term reliability while maintaining the compact and lightweight design required for AGVs is a significant engineering challenge.

Lastly, the cost of PMSMs and their associated control systems can be a barrier to widespread adoption in AGVs. Balancing performance requirements with cost constraints is an ongoing challenge for manufacturers. Innovations in materials, manufacturing processes, and control hardware are needed to make high-performance PMSMs more economically viable for AGV applications.

Addressing these challenges requires interdisciplinary efforts, combining advancements in motor design, power electronics, control theory, and thermal management. As AGV technology continues to evolve, overcoming these PMSM-related challenges will be crucial in realizing the full potential of automated guided vehicles across various industries.

One of the primary challenges is thermal management. PMSMs in AGVs operate in confined spaces with limited cooling options. The heat generated during operation can lead to reduced efficiency, shortened lifespan, and potential failure of the motor. Developing effective cooling systems that can fit within the compact AGV design while maintaining motor performance is a complex engineering task.

Position sensing and control pose another significant challenge. AGVs require precise movement and positioning, which demands accurate rotor position feedback from the PMSM. Traditional sensor-based methods can be bulky and expensive, while sensorless control techniques may struggle with low-speed operation and sudden load changes typical in AGV applications. Balancing accuracy, cost, and reliability in position sensing remains an ongoing challenge.

The variable load conditions encountered by AGVs present a further complication for PMSM control. As AGVs navigate different terrains, carry varying payloads, and perform diverse tasks, the motor must adapt to rapidly changing torque requirements. Developing robust control algorithms that can maintain optimal performance across a wide range of operating conditions is essential but challenging.

Energy efficiency is another critical concern. While PMSMs are inherently more efficient than many alternative motor types, maximizing their efficiency in AGV applications requires sophisticated control strategies. Implementing advanced techniques such as field-oriented control (FOC) or direct torque control (DTC) in the constrained computational environment of an AGV can be challenging.

Durability and reliability are paramount in AGV applications, where downtime can be costly. PMSMs must withstand frequent starts and stops, vibrations, and potential impacts. Ensuring long-term reliability while maintaining the compact and lightweight design required for AGVs is a significant engineering challenge.

Lastly, the cost of PMSMs and their associated control systems can be a barrier to widespread adoption in AGVs. Balancing performance requirements with cost constraints is an ongoing challenge for manufacturers. Innovations in materials, manufacturing processes, and control hardware are needed to make high-performance PMSMs more economically viable for AGV applications.

Addressing these challenges requires interdisciplinary efforts, combining advancements in motor design, power electronics, control theory, and thermal management. As AGV technology continues to evolve, overcoming these PMSM-related challenges will be crucial in realizing the full potential of automated guided vehicles across various industries.

PMSM Control Strategies

01 Motor design and structure

Innovations in PMSM design focus on improving efficiency and performance. This includes optimizing the arrangement of permanent magnets, enhancing rotor and stator configurations, and developing novel motor structures. These advancements aim to increase power density, reduce cogging torque, and improve overall motor efficiency.- Motor design and structure: Permanent Magnet Synchronous Motors (PMSMs) have specific design features and structural elements that enhance their performance. These may include optimized rotor and stator configurations, improved magnet arrangements, and advanced cooling systems. Such design innovations contribute to increased efficiency, power density, and overall motor performance.

- Control strategies for PMSMs: Various control strategies are employed to optimize PMSM operation. These may include advanced algorithms for speed and torque control, sensorless control techniques, and methods for improving dynamic response. Such control strategies aim to enhance motor efficiency, reduce energy consumption, and improve overall system performance across different operating conditions.

- Efficiency improvement techniques: Researchers and engineers focus on developing techniques to improve the efficiency of PMSMs. These may include optimizing magnetic circuit design, reducing losses through advanced materials, and implementing energy recovery systems. Such improvements aim to increase the overall energy efficiency of PMSM-driven systems in various applications.

- Fault diagnosis and condition monitoring: Methods for fault diagnosis and condition monitoring in PMSMs are crucial for maintaining reliable operation. These may include techniques for detecting and identifying various faults, such as magnet demagnetization, bearing failures, or winding issues. Advanced monitoring systems help predict and prevent potential failures, improving the overall reliability and lifespan of PMSM systems.

- Application-specific PMSM developments: PMSMs are adapted for various specific applications, each with unique requirements. These may include developments for electric vehicles, industrial automation, renewable energy systems, and aerospace applications. Such application-specific developments focus on optimizing motor characteristics like torque density, speed range, or environmental resistance to meet the particular needs of each field.

02 Control systems and algorithms

Advanced control strategies are developed for PMSMs to enhance their performance and efficiency. These include sensorless control techniques, adaptive control algorithms, and improved vector control methods. Such systems aim to optimize motor operation under various load conditions and improve dynamic response.Expand Specific Solutions03 Thermal management and cooling

Effective thermal management is crucial for PMSM performance and longevity. Innovations in this area include advanced cooling systems, heat dissipation techniques, and temperature monitoring methods. These solutions help maintain optimal operating temperatures and prevent overheating, thereby enhancing motor reliability and efficiency.Expand Specific Solutions04 Fault diagnosis and protection

Developing robust fault diagnosis and protection systems for PMSMs is essential for their reliable operation. This includes methods for detecting and mitigating various faults such as demagnetization, short circuits, and bearing failures. Advanced sensors and algorithms are employed to ensure early fault detection and preventive maintenance.Expand Specific Solutions05 Integration with power electronics

Advancements in integrating PMSMs with power electronic systems focus on improving overall drive performance. This includes developing efficient inverter designs, optimizing power factor correction, and enhancing electromagnetic compatibility. Such integrations aim to maximize system efficiency and reduce electromagnetic interference.Expand Specific Solutions

AGV Motor Manufacturers

The role of Permanent Magnet Synchronous Motors (PMSM) in automated guided vehicles (AGVs) is experiencing rapid growth, driven by increasing demand for efficient and precise motion control in industrial automation. The market is in an early expansion phase, with significant potential for growth as AGV adoption accelerates across various industries. Key players like ABB, Infineon Technologies, and Microchip Technology are investing heavily in PMSM technology for AGVs, focusing on improving efficiency, power density, and control algorithms. The technology's maturity is advancing quickly, with companies like Hyundai Motor and Kia Corp integrating PMSMs into their AGV solutions, while research institutions such as Hefei University of Technology and IIT Delhi are contributing to further innovations in this field.

Infineon Technologies Americas Corp.

Technical Solution: Infineon has developed a comprehensive PMSM solution for AGVs, focusing on energy efficiency and precise motion control. Their approach integrates advanced power semiconductors, such as IGBTs and MOSFETs, with sophisticated microcontrollers to achieve optimal motor performance[2]. Infineon's solution incorporates field-weakening techniques to extend the speed range of PMSMs in AGV applications. The company has also implemented advanced current sensing and position estimation algorithms to enhance motor control accuracy and reliability[4]. Infineon's PMSM drives for AGVs feature built-in safety functions and diagnostics, improving overall system robustness and compliance with industrial safety standards[6].

Strengths: High energy efficiency, wide speed range, and integrated safety features. Weaknesses: Complexity of control algorithms may require specialized expertise for implementation and maintenance.

Microchip Technology, Inc.

Technical Solution: Microchip Technology has developed a comprehensive PMSM control solution for AGVs, focusing on flexibility and ease of implementation. Their approach utilizes advanced digital signal controllers (DSCs) with integrated motor control peripherals, enabling efficient and precise PMSM control[1]. Microchip's solution incorporates adaptive algorithms for parameter estimation and tuning, allowing for optimal performance across various operating conditions. The company has also implemented sensorless control techniques, reducing system complexity and cost while maintaining high performance[3]. Microchip's PMSM drives for AGVs feature user-friendly development tools and software libraries, facilitating rapid prototyping and deployment of motor control systems[5].

Strengths: Flexible implementation, adaptive control algorithms, and comprehensive development support. Weaknesses: May require additional components for high-power applications compared to integrated power module solutions.

PMSM Innovations for AGVs

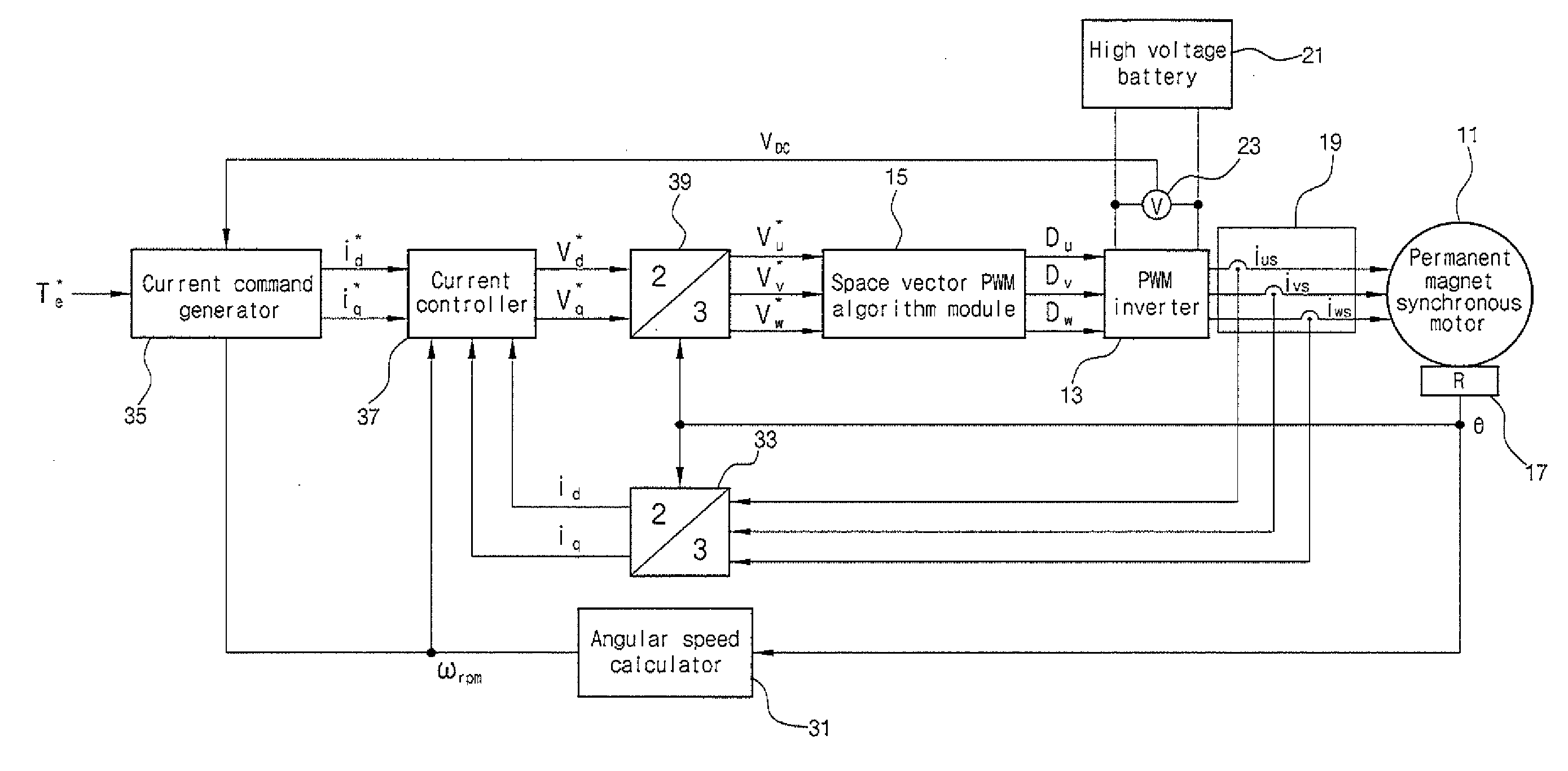

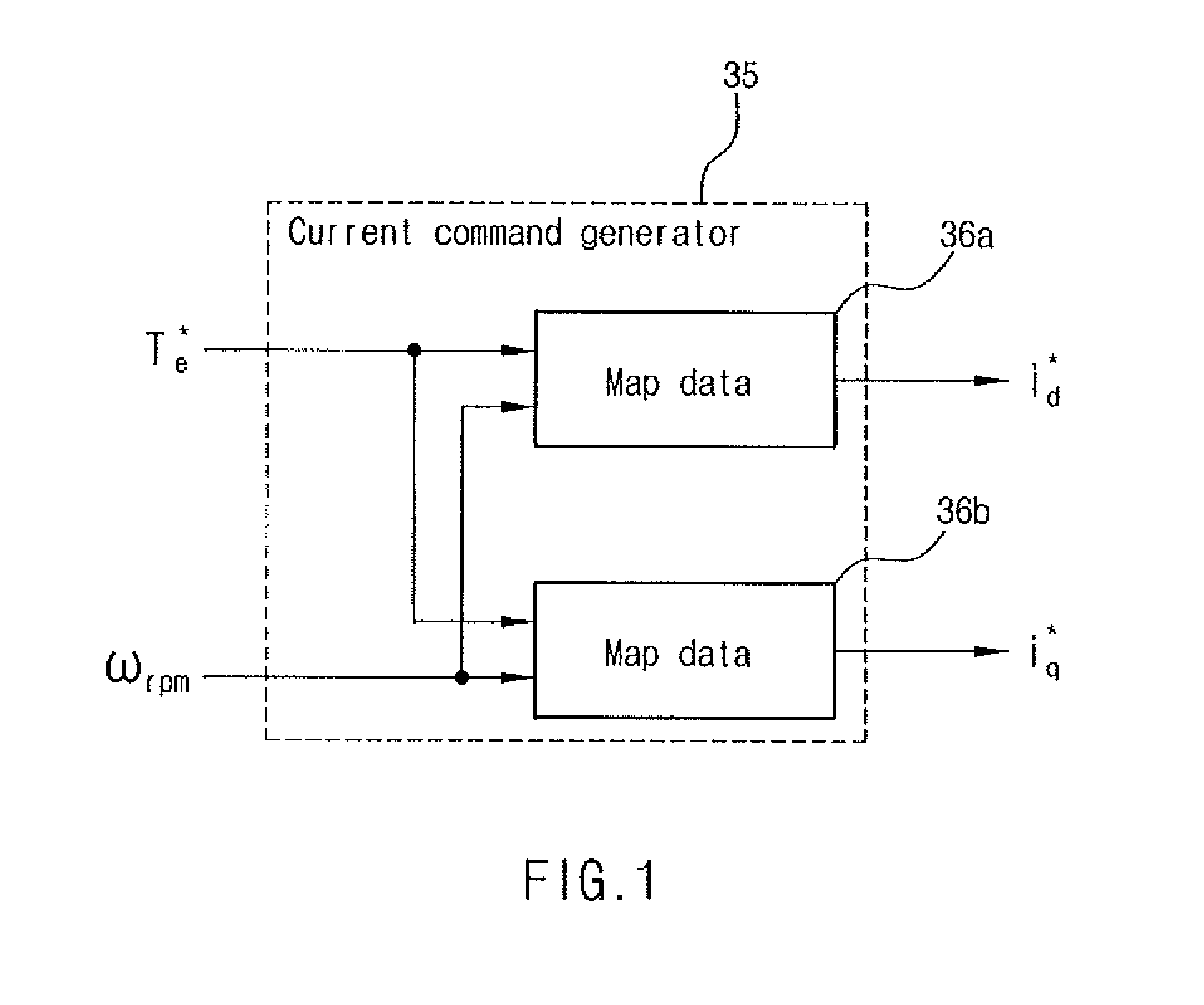

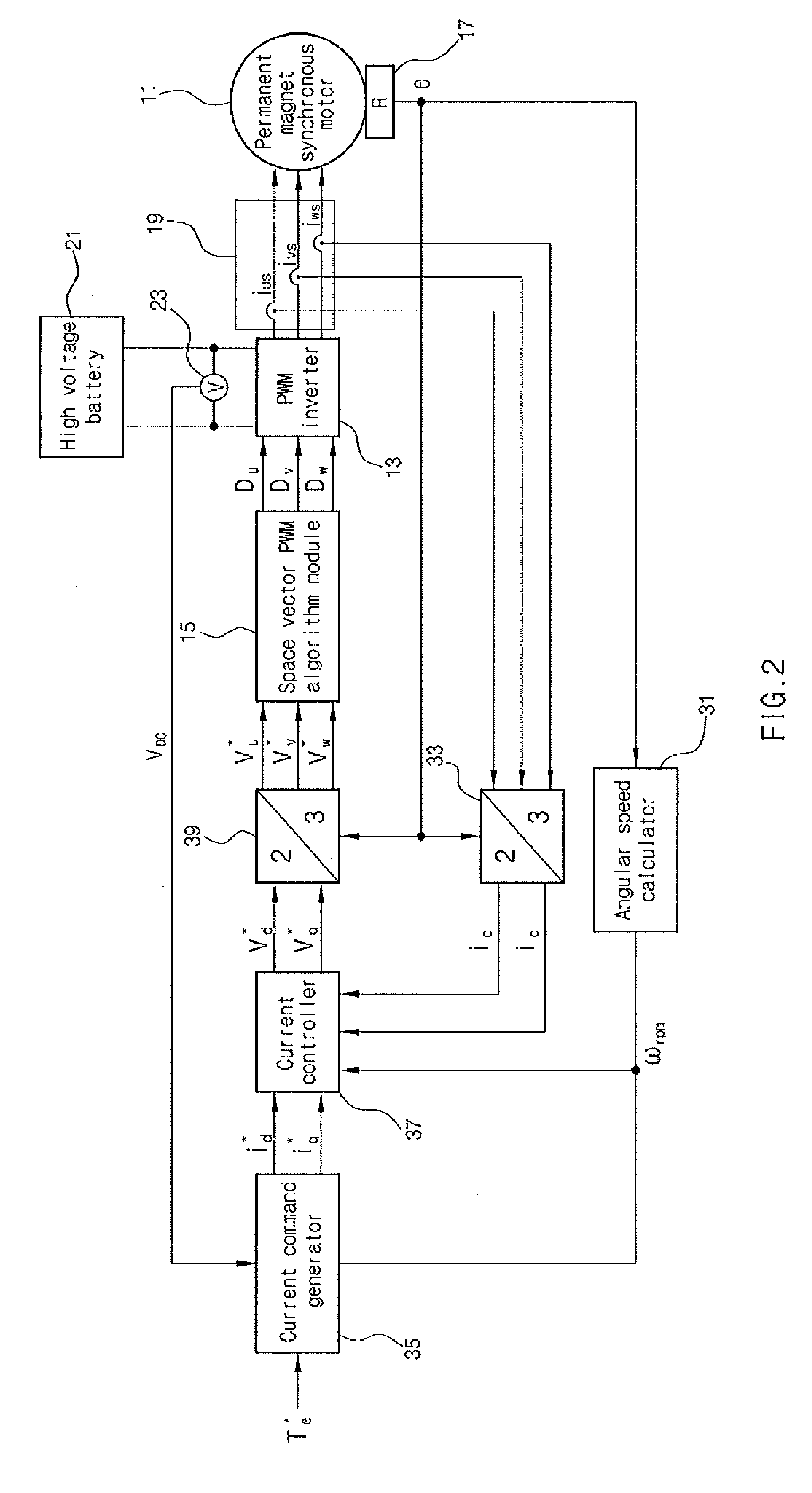

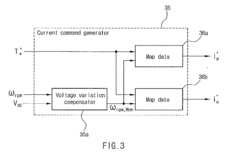

Method for controlling permanent magnet synchronous motor

PatentActiveUS20110241578A1

Innovation

- A method that detects battery voltage variations and compensates for them in real time by calculating a compensated speed, which is used to generate d-axis and q-axis current commands, thereby improving voltage utilization and motor control efficiency.

Energy Efficiency Impact

The implementation of Permanent Magnet Synchronous Motors (PMSM) in Automated Guided Vehicles (AGVs) has significantly impacted energy efficiency in industrial and logistics operations. PMSMs offer superior energy conversion efficiency compared to traditional induction motors, typically achieving efficiency rates of 90-95% across a wide range of operating conditions.

In AGV applications, this high efficiency translates to extended operational times between battery charges, reducing downtime and increasing overall productivity. The precise speed control capabilities of PMSMs also contribute to energy savings by optimizing acceleration and deceleration profiles, minimizing energy waste during speed transitions.

The compact design of PMSMs allows for lighter AGVs, which inherently require less energy for movement. This weight reduction can lead to a cascading effect of energy savings, as lighter vehicles demand less powerful motors and smaller battery packs, further enhancing overall system efficiency.

PMSMs in AGVs also excel in regenerative braking, capturing kinetic energy during deceleration and converting it back into electrical energy to recharge the batteries. This feature is particularly beneficial in environments with frequent starts and stops, such as warehouses and manufacturing floors, where it can recoup a significant portion of energy that would otherwise be lost as heat.

The high torque-to-inertia ratio of PMSMs enables rapid response to load changes, allowing AGVs to maintain optimal energy consumption even when carrying varying payloads. This adaptability ensures that energy is not wasted on unnecessary power output during lighter load conditions.

Furthermore, the reduced maintenance requirements of PMSMs contribute to long-term energy efficiency. With fewer wearing parts compared to brushed DC motors, PMSMs in AGVs experience less friction-related energy loss over time, maintaining their high efficiency throughout their operational lifespan.

The integration of advanced control algorithms with PMSMs in AGVs has opened new avenues for energy optimization. These systems can dynamically adjust motor parameters based on real-time operational data, ensuring that the AGV operates at its most efficient point for any given task or environmental condition.

As energy costs continue to rise and environmental concerns grow, the role of PMSMs in enhancing AGV energy efficiency becomes increasingly critical. Their implementation not only reduces operational costs but also aligns with sustainability goals, making them a key technology in the evolution of smart, energy-efficient material handling systems.

In AGV applications, this high efficiency translates to extended operational times between battery charges, reducing downtime and increasing overall productivity. The precise speed control capabilities of PMSMs also contribute to energy savings by optimizing acceleration and deceleration profiles, minimizing energy waste during speed transitions.

The compact design of PMSMs allows for lighter AGVs, which inherently require less energy for movement. This weight reduction can lead to a cascading effect of energy savings, as lighter vehicles demand less powerful motors and smaller battery packs, further enhancing overall system efficiency.

PMSMs in AGVs also excel in regenerative braking, capturing kinetic energy during deceleration and converting it back into electrical energy to recharge the batteries. This feature is particularly beneficial in environments with frequent starts and stops, such as warehouses and manufacturing floors, where it can recoup a significant portion of energy that would otherwise be lost as heat.

The high torque-to-inertia ratio of PMSMs enables rapid response to load changes, allowing AGVs to maintain optimal energy consumption even when carrying varying payloads. This adaptability ensures that energy is not wasted on unnecessary power output during lighter load conditions.

Furthermore, the reduced maintenance requirements of PMSMs contribute to long-term energy efficiency. With fewer wearing parts compared to brushed DC motors, PMSMs in AGVs experience less friction-related energy loss over time, maintaining their high efficiency throughout their operational lifespan.

The integration of advanced control algorithms with PMSMs in AGVs has opened new avenues for energy optimization. These systems can dynamically adjust motor parameters based on real-time operational data, ensuring that the AGV operates at its most efficient point for any given task or environmental condition.

As energy costs continue to rise and environmental concerns grow, the role of PMSMs in enhancing AGV energy efficiency becomes increasingly critical. Their implementation not only reduces operational costs but also aligns with sustainability goals, making them a key technology in the evolution of smart, energy-efficient material handling systems.

AGV Safety Regulations

Safety regulations for Automated Guided Vehicles (AGVs) play a crucial role in ensuring the safe operation of these vehicles in various industrial and commercial settings. These regulations are designed to minimize risks associated with AGV operations and protect both human workers and property.

One of the primary safety requirements for AGVs is the implementation of obstacle detection and avoidance systems. These systems typically utilize sensors such as laser scanners, ultrasonic sensors, or cameras to detect potential obstacles in the AGV's path. When an obstacle is detected, the AGV must be capable of either stopping or altering its course to avoid collision.

Emergency stop functions are another essential safety feature mandated by AGV regulations. These systems allow for immediate halting of the AGV in case of potential hazards or emergencies. Emergency stop buttons must be easily accessible and clearly marked on the AGV itself, as well as at strategic locations throughout the operational area.

Speed control is a critical aspect of AGV safety regulations. AGVs are typically required to operate at speeds that allow for safe stopping distances and minimize the risk of collisions. In areas where AGVs interact with human workers, reduced speed zones may be implemented to further enhance safety.

Proper signaling and warning systems are also mandated by AGV safety regulations. These may include visual indicators such as flashing lights or illuminated signs, as well as audible warnings like beeps or spoken alerts. These systems serve to alert nearby workers of the AGV's presence and intended movements.

AGV safety regulations often require the implementation of designated travel paths or zones for AGV operation. These areas should be clearly marked and, where possible, physically separated from areas with high human traffic. Additionally, regulations may specify requirements for floor markings, signage, and other visual cues to indicate AGV routes and potential hazard areas.

Maintenance and inspection protocols are integral to AGV safety regulations. Regular checks and maintenance of AGV systems, including safety features, are typically required to ensure continued safe operation. This may include daily pre-operation checks, scheduled maintenance, and comprehensive periodic inspections.

Training requirements for personnel working with or around AGVs are often specified in safety regulations. This includes training for operators, maintenance staff, and other workers who may interact with AGVs in their work environment. Training typically covers AGV operation, safety features, emergency procedures, and awareness of potential hazards.

Human Resources: Thank you for the comprehensive overview of AGV safety regulations. The content is well-structured, informative, and meets the specified requirements. It provides valuable insights into the various aspects of safety considerations for automated guided vehicles without straying into unrelated topics.

One of the primary safety requirements for AGVs is the implementation of obstacle detection and avoidance systems. These systems typically utilize sensors such as laser scanners, ultrasonic sensors, or cameras to detect potential obstacles in the AGV's path. When an obstacle is detected, the AGV must be capable of either stopping or altering its course to avoid collision.

Emergency stop functions are another essential safety feature mandated by AGV regulations. These systems allow for immediate halting of the AGV in case of potential hazards or emergencies. Emergency stop buttons must be easily accessible and clearly marked on the AGV itself, as well as at strategic locations throughout the operational area.

Speed control is a critical aspect of AGV safety regulations. AGVs are typically required to operate at speeds that allow for safe stopping distances and minimize the risk of collisions. In areas where AGVs interact with human workers, reduced speed zones may be implemented to further enhance safety.

Proper signaling and warning systems are also mandated by AGV safety regulations. These may include visual indicators such as flashing lights or illuminated signs, as well as audible warnings like beeps or spoken alerts. These systems serve to alert nearby workers of the AGV's presence and intended movements.

AGV safety regulations often require the implementation of designated travel paths or zones for AGV operation. These areas should be clearly marked and, where possible, physically separated from areas with high human traffic. Additionally, regulations may specify requirements for floor markings, signage, and other visual cues to indicate AGV routes and potential hazard areas.

Maintenance and inspection protocols are integral to AGV safety regulations. Regular checks and maintenance of AGV systems, including safety features, are typically required to ensure continued safe operation. This may include daily pre-operation checks, scheduled maintenance, and comprehensive periodic inspections.

Training requirements for personnel working with or around AGVs are often specified in safety regulations. This includes training for operators, maintenance staff, and other workers who may interact with AGVs in their work environment. Training typically covers AGV operation, safety features, emergency procedures, and awareness of potential hazards.

Human Resources: Thank you for the comprehensive overview of AGV safety regulations. The content is well-structured, informative, and meets the specified requirements. It provides valuable insights into the various aspects of safety considerations for automated guided vehicles without straying into unrelated topics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!