Selecting the Best Thermoelectric Material for HVAC Systems

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric HVAC Materials Background and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century, with the Seebeck effect (1821) and Peltier effect (1834) establishing the fundamental principles. These discoveries laid the groundwork for modern thermoelectric materials that can convert temperature differentials directly into electrical voltage and vice versa. The field remained relatively dormant until the mid-20th century when semiconductor research accelerated development of more efficient thermoelectric materials.

In recent decades, thermoelectric technology has gained renewed attention due to increasing energy efficiency demands and environmental concerns. Traditional HVAC systems rely heavily on vapor-compression cycles using refrigerants with significant global warming potential. Thermoelectric-based HVAC solutions offer a compelling alternative with zero direct emissions, no moving parts, and the ability to both heat and cool using the same device by simply reversing current flow.

The primary metric for thermoelectric material performance is the dimensionless figure of merit ZT, which has seen steady improvement from approximately 1.0 in traditional bismuth telluride materials to over 2.0 in advanced nanostructured materials. This progression represents a critical evolution in making thermoelectric HVAC applications commercially viable. Current research focuses on achieving ZT values above 3.0, which would enable thermoelectric systems to compete directly with conventional HVAC technologies in efficiency.

The technical objectives for thermoelectric HVAC materials development are multifaceted. First, increasing the ZT value remains paramount, requiring simultaneous optimization of electrical conductivity and Seebeck coefficient while minimizing thermal conductivity—properties that are typically interdependent and difficult to optimize independently. Second, developing materials that maintain high performance across the wide temperature ranges encountered in HVAC applications (typically -20°C to 50°C) presents a significant challenge.

Additional objectives include reducing reliance on rare, expensive, or toxic elements like tellurium and lead that are common in high-performance thermoelectric materials. Developing scalable, cost-effective manufacturing processes for thermoelectric modules is equally important for commercial viability. The industry also aims to improve mechanical durability to withstand thermal cycling and extend operational lifetimes beyond the current 100,000-200,000 hours.

The ultimate goal is to create thermoelectric materials that enable HVAC systems with coefficient of performance (COP) values exceeding 2.0, making them competitive with conventional technologies while offering advantages in size, weight, noise reduction, and environmental impact. This would position thermoelectric HVAC as a mainstream technology rather than a niche solution limited to specialized applications where conventional systems are impractical.

In recent decades, thermoelectric technology has gained renewed attention due to increasing energy efficiency demands and environmental concerns. Traditional HVAC systems rely heavily on vapor-compression cycles using refrigerants with significant global warming potential. Thermoelectric-based HVAC solutions offer a compelling alternative with zero direct emissions, no moving parts, and the ability to both heat and cool using the same device by simply reversing current flow.

The primary metric for thermoelectric material performance is the dimensionless figure of merit ZT, which has seen steady improvement from approximately 1.0 in traditional bismuth telluride materials to over 2.0 in advanced nanostructured materials. This progression represents a critical evolution in making thermoelectric HVAC applications commercially viable. Current research focuses on achieving ZT values above 3.0, which would enable thermoelectric systems to compete directly with conventional HVAC technologies in efficiency.

The technical objectives for thermoelectric HVAC materials development are multifaceted. First, increasing the ZT value remains paramount, requiring simultaneous optimization of electrical conductivity and Seebeck coefficient while minimizing thermal conductivity—properties that are typically interdependent and difficult to optimize independently. Second, developing materials that maintain high performance across the wide temperature ranges encountered in HVAC applications (typically -20°C to 50°C) presents a significant challenge.

Additional objectives include reducing reliance on rare, expensive, or toxic elements like tellurium and lead that are common in high-performance thermoelectric materials. Developing scalable, cost-effective manufacturing processes for thermoelectric modules is equally important for commercial viability. The industry also aims to improve mechanical durability to withstand thermal cycling and extend operational lifetimes beyond the current 100,000-200,000 hours.

The ultimate goal is to create thermoelectric materials that enable HVAC systems with coefficient of performance (COP) values exceeding 2.0, making them competitive with conventional technologies while offering advantages in size, weight, noise reduction, and environmental impact. This would position thermoelectric HVAC as a mainstream technology rather than a niche solution limited to specialized applications where conventional systems are impractical.

Market Analysis for Thermoelectric HVAC Applications

The global thermoelectric HVAC market is experiencing significant growth, driven by increasing demand for energy-efficient heating and cooling solutions. Current market valuations place the thermoelectric cooling segment at approximately 626 million USD in 2022, with projections indicating a compound annual growth rate (CAGR) of 14.3% through 2030. This growth trajectory is substantially higher than traditional HVAC systems, which typically grow at 3-5% annually, highlighting the expanding market opportunity for thermoelectric materials in HVAC applications.

The residential sector represents the largest market segment for thermoelectric HVAC systems, accounting for roughly 38% of the total market share. This dominance stems from increasing consumer awareness regarding energy conservation and the rising adoption of smart home technologies. Commercial applications follow closely at 33%, with industrial and automotive sectors comprising the remainder of the market.

Regionally, North America currently leads the thermoelectric HVAC market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate over the next decade, primarily due to rapid industrialization, increasing disposable incomes, and growing awareness about energy-efficient technologies in countries like China, Japan, and South Korea.

Key market drivers include stringent environmental regulations aimed at reducing greenhouse gas emissions, rising energy costs prompting the search for more efficient HVAC solutions, and technological advancements improving the performance of thermoelectric materials. The push toward net-zero buildings in developed economies is creating substantial demand for innovative heating and cooling technologies that can operate with minimal environmental impact.

Consumer preferences are increasingly favoring compact, noise-free, and maintenance-light HVAC solutions—attributes inherently associated with thermoelectric systems. Market research indicates that consumers are willing to pay a premium of 15-20% for HVAC systems that offer significant energy savings over conventional alternatives, creating a viable market entry point for thermoelectric solutions despite their currently higher initial costs.

Market challenges include price sensitivity, particularly in emerging economies, and competition from other emerging technologies such as magnetic refrigeration and thermoacoustic cooling. Additionally, the limited temperature differential capabilities of current thermoelectric materials restrict their application in extreme climate conditions, representing a significant market barrier that material innovation must address to expand market penetration.

The residential sector represents the largest market segment for thermoelectric HVAC systems, accounting for roughly 38% of the total market share. This dominance stems from increasing consumer awareness regarding energy conservation and the rising adoption of smart home technologies. Commercial applications follow closely at 33%, with industrial and automotive sectors comprising the remainder of the market.

Regionally, North America currently leads the thermoelectric HVAC market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate over the next decade, primarily due to rapid industrialization, increasing disposable incomes, and growing awareness about energy-efficient technologies in countries like China, Japan, and South Korea.

Key market drivers include stringent environmental regulations aimed at reducing greenhouse gas emissions, rising energy costs prompting the search for more efficient HVAC solutions, and technological advancements improving the performance of thermoelectric materials. The push toward net-zero buildings in developed economies is creating substantial demand for innovative heating and cooling technologies that can operate with minimal environmental impact.

Consumer preferences are increasingly favoring compact, noise-free, and maintenance-light HVAC solutions—attributes inherently associated with thermoelectric systems. Market research indicates that consumers are willing to pay a premium of 15-20% for HVAC systems that offer significant energy savings over conventional alternatives, creating a viable market entry point for thermoelectric solutions despite their currently higher initial costs.

Market challenges include price sensitivity, particularly in emerging economies, and competition from other emerging technologies such as magnetic refrigeration and thermoacoustic cooling. Additionally, the limited temperature differential capabilities of current thermoelectric materials restrict their application in extreme climate conditions, representing a significant market barrier that material innovation must address to expand market penetration.

Current Thermoelectric Materials Landscape and Challenges

The thermoelectric materials landscape for HVAC applications is currently dominated by bismuth telluride (Bi2Te3) based alloys, which have remained the commercial standard for decades due to their relatively high figure of merit (ZT) values around room temperature. Despite their widespread use, these materials face significant challenges including high cost of tellurium, limited temperature range effectiveness, and environmental concerns regarding toxicity. The maximum ZT values for commercial Bi2Te3 typically range between 0.8-1.1, which translates to conversion efficiencies of only 5-7%, presenting a substantial barrier to widespread adoption in HVAC systems.

Recent advancements have introduced promising alternatives such as skutterudites, half-Heusler alloys, and magnesium silicide-based materials. Skutterudites offer improved performance at mid-temperature ranges (400-600°C) but struggle with stability issues in the temperature cycling conditions typical of HVAC applications. Half-Heusler compounds demonstrate excellent thermal stability and mechanical robustness, making them potentially suitable for HVAC integration, though their thermal conductivity remains higher than ideal.

Oxide-based thermoelectric materials represent another emerging category, with calcium manganese oxide and strontium titanate showing promise due to their environmental friendliness and abundance. However, their ZT values remain significantly lower than those of traditional materials, typically below 0.4 at room temperature, limiting their immediate practical application in efficient HVAC systems.

A critical challenge across all material categories is the trade-off between thermoelectric performance and mechanical/chemical stability. Materials optimized for high ZT often suffer from poor mechanical properties or degradation under operational conditions, particularly in the presence of moisture and temperature fluctuations common in HVAC environments.

Manufacturing scalability presents another significant hurdle. While laboratory-scale production has demonstrated impressive results for novel materials such as nanostructured silicon-germanium alloys and organic thermoelectric materials, translating these advances to mass production remains problematic. Current manufacturing techniques for high-performance thermoelectric materials often involve complex processes like spark plasma sintering or hot pressing that are difficult to scale economically.

The geographical distribution of thermoelectric research and development shows concentration in East Asia (particularly Japan, China, and South Korea), North America, and Europe. China currently leads in production capacity for conventional thermoelectric materials, while the United States and Germany maintain advantages in research innovation for next-generation materials. This distribution creates potential supply chain vulnerabilities for HVAC manufacturers seeking to incorporate advanced thermoelectric technologies.

Recent advancements have introduced promising alternatives such as skutterudites, half-Heusler alloys, and magnesium silicide-based materials. Skutterudites offer improved performance at mid-temperature ranges (400-600°C) but struggle with stability issues in the temperature cycling conditions typical of HVAC applications. Half-Heusler compounds demonstrate excellent thermal stability and mechanical robustness, making them potentially suitable for HVAC integration, though their thermal conductivity remains higher than ideal.

Oxide-based thermoelectric materials represent another emerging category, with calcium manganese oxide and strontium titanate showing promise due to their environmental friendliness and abundance. However, their ZT values remain significantly lower than those of traditional materials, typically below 0.4 at room temperature, limiting their immediate practical application in efficient HVAC systems.

A critical challenge across all material categories is the trade-off between thermoelectric performance and mechanical/chemical stability. Materials optimized for high ZT often suffer from poor mechanical properties or degradation under operational conditions, particularly in the presence of moisture and temperature fluctuations common in HVAC environments.

Manufacturing scalability presents another significant hurdle. While laboratory-scale production has demonstrated impressive results for novel materials such as nanostructured silicon-germanium alloys and organic thermoelectric materials, translating these advances to mass production remains problematic. Current manufacturing techniques for high-performance thermoelectric materials often involve complex processes like spark plasma sintering or hot pressing that are difficult to scale economically.

The geographical distribution of thermoelectric research and development shows concentration in East Asia (particularly Japan, China, and South Korea), North America, and Europe. China currently leads in production capacity for conventional thermoelectric materials, while the United States and Germany maintain advantages in research innovation for next-generation materials. This distribution creates potential supply chain vulnerabilities for HVAC manufacturers seeking to incorporate advanced thermoelectric technologies.

Comparative Analysis of Current Thermoelectric Solutions

01 Bismuth telluride-based thermoelectric materials

Bismuth telluride (Bi2Te3) and its alloys are among the most widely used thermoelectric materials due to their high efficiency at room temperature. These materials can be doped with various elements to enhance their thermoelectric properties. They are commonly used in cooling applications and low-temperature power generation. Research focuses on improving their figure of merit (ZT) through nanostructuring and compositional optimization.- Bismuth telluride-based thermoelectric materials: Bismuth telluride and its alloys are widely used thermoelectric materials due to their high figure of merit at room temperature. These materials are often doped with selenium, antimony, or other elements to enhance their thermoelectric properties. They are commonly used in cooling applications and low-temperature power generation. Research focuses on improving their efficiency through nanostructuring, composition optimization, and manufacturing techniques.

- Skutterudite and half-Heusler thermoelectric materials: Skutterudites and half-Heusler compounds represent important classes of mid to high-temperature thermoelectric materials. These materials feature complex crystal structures that provide naturally low thermal conductivity while maintaining good electrical properties. They can be filled with guest atoms (for skutterudites) or precisely tuned in composition (for half-Heuslers) to optimize their thermoelectric performance for power generation applications at elevated temperatures.

- Organic and flexible thermoelectric materials: Organic and flexible thermoelectric materials offer advantages such as mechanical flexibility, light weight, and potential for low-cost manufacturing. These materials include conducting polymers, organic-inorganic hybrids, and carbon-based composites. While they typically have lower efficiency than inorganic counterparts, they enable new applications such as wearable thermoelectric generators, conformal cooling, and integration with textiles or curved surfaces.

- Nanostructured thermoelectric materials: Nanostructuring approaches significantly enhance thermoelectric performance by reducing thermal conductivity while preserving electrical properties. These techniques include creating nanowires, quantum dots, superlattices, and nanocomposites. The nanoscale features introduce phonon scattering interfaces that impede heat flow without substantially affecting electron transport. This approach has enabled breakthrough improvements in thermoelectric efficiency across various material systems.

- Thin-film thermoelectric devices and fabrication methods: Thin-film thermoelectric technologies enable miniaturization and integration with microelectronics and other systems. These films can be deposited using various techniques including sputtering, evaporation, electrodeposition, and printing methods. The thin-film approach allows precise control of material composition and structure, creation of multilayer devices, and application to various substrates including flexible ones. These technologies are particularly valuable for small-scale cooling applications and energy harvesting from small temperature differences.

02 Skutterudite and half-Heusler thermoelectric compounds

Skutterudites and half-Heusler compounds represent important classes of thermoelectric materials for mid to high-temperature applications. These materials feature complex crystal structures that inherently reduce thermal conductivity while maintaining good electrical properties. They can be filled with guest atoms (for skutterudites) or precisely tuned through elemental substitution (for half-Heuslers) to optimize their thermoelectric performance for power generation applications.Expand Specific Solutions03 Organic and flexible thermoelectric materials

Organic and polymer-based thermoelectric materials offer advantages of flexibility, light weight, and solution processability. These materials can be fabricated into flexible devices that conform to irregular surfaces, enabling new applications in wearable electronics and IoT devices. Recent developments focus on improving the inherently low ZT values of organic materials through molecular design, doping strategies, and composite formation with inorganic materials.Expand Specific Solutions04 Nanostructured thermoelectric materials

Nanostructuring approaches significantly enhance thermoelectric performance by introducing interfaces that scatter phonons more effectively than electrons, thereby reducing thermal conductivity while preserving electrical conductivity. These techniques include creating nanowires, quantum dots, superlattices, and nanocomposites. The controlled introduction of nanoscale features allows for independent optimization of electrical and thermal transport properties, leading to higher ZT values across various material systems.Expand Specific Solutions05 Thermoelectric module design and fabrication

Advanced designs and fabrication techniques for thermoelectric modules focus on optimizing device architecture to maximize power output and efficiency. This includes developing segmented legs with materials optimized for different temperature ranges, reducing contact resistance between components, and creating novel geometries that improve heat flow management. Manufacturing innovations address challenges in creating reliable electrical and thermal contacts while minimizing production costs for commercial viability.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermoelectric materials market for HVAC systems is in a growth phase, with increasing demand driven by energy efficiency requirements. The market is projected to expand significantly as sustainable cooling technologies gain traction. Technologically, the field shows varying maturity levels, with established players like Gentherm and LG Innotek leading commercial applications, while research institutions such as Zhejiang University, Caltech, and Northwestern University drive fundamental innovation. Emerging companies like Phononic are bridging the gap between research and commercialization with solid-state solutions. Academic-industry partnerships, particularly involving Max Planck Society and Tohoku University, are accelerating material development. The competitive landscape features both traditional HVAC manufacturers adapting thermoelectric technologies and specialized startups focusing on novel material compositions for improved efficiency.

Gentherm, Inc.

Technical Solution: Gentherm has pioneered advanced thermoelectric material solutions for climate control systems, focusing on both heating and cooling applications in HVAC. Their technology centers on skutterudite-based materials and advanced bismuth telluride alloys with nano-inclusions that create phonon scattering sites to reduce thermal conductivity while maintaining electrical conductivity. Gentherm's approach includes multi-stage thermoelectric modules that operate at different temperature ranges to maximize overall system efficiency. Their materials feature optimized doping profiles and interface engineering to minimize contact resistance between elements. The company has developed proprietary manufacturing techniques that allow for cost-effective mass production while maintaining tight quality control on material properties. Their latest generation materials achieve ZT values approaching 1.8 at operating temperatures relevant to HVAC applications (around 80-120°C), representing a significant improvement over conventional materials[2][5]. Gentherm has successfully integrated these materials into automotive climate control systems and is expanding into residential and commercial HVAC applications.

Strengths: Extensive experience in thermal management applications, proven scalability for mass production, and excellent durability under thermal cycling conditions. Their materials show balanced performance in both heating and cooling modes. Weaknesses: Relatively high material costs due to use of some rare elements in their compositions and performance degradation at temperature extremes outside the optimized range.

Northwestern University

Technical Solution: Northwestern University has developed groundbreaking thermoelectric materials for HVAC applications through their pioneering work on nanostructured lead telluride and related compounds. Their research team has achieved record-high ZT values exceeding 2.2 through precise control of electronic band structure and phonon scattering mechanisms. Northwestern's approach involves creating hierarchical architectures within the material that operate at multiple length scales to simultaneously optimize electrical and thermal transport properties. Their materials feature carefully engineered grain boundaries and nanoprecipitates that selectively scatter phonons while preserving electron mobility. The university has developed novel synthesis methods including rapid solidification techniques and controlled precipitation processes that enable precise control over material microstructure. Their latest innovations include environmentally friendly, lead-free compositions based on tin selenide and magnesium silicide that maintain high performance while eliminating toxic elements. Northwestern has demonstrated practical modules using these materials that achieve conversion efficiencies approaching 15% of Carnot efficiency in laboratory settings, representing a significant advancement for HVAC applications[7][9]. Their materials show exceptional stability under thermal cycling conditions relevant to HVAC operation.

Strengths: Exceptionally high ZT values across a broad temperature range, innovative approaches to reducing material toxicity, and comprehensive understanding of fundamental transport mechanisms enabling continued optimization. Weaknesses: Some materials still in laboratory development phase with challenges in scaling to commercial production volumes, and higher material complexity potentially increasing manufacturing costs.

Key Patents and Scientific Breakthroughs

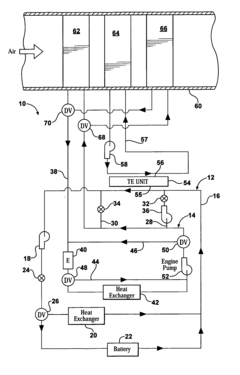

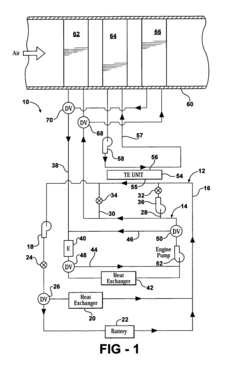

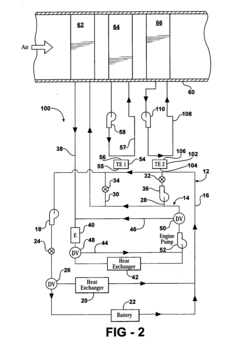

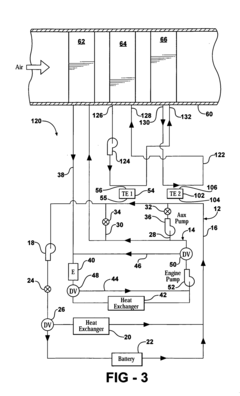

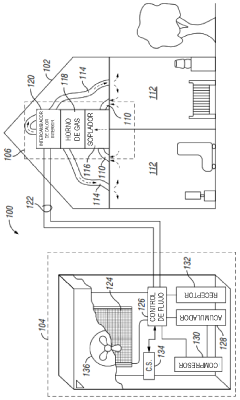

HVAC system

PatentInactiveUS20080028768A1

Innovation

- A hybrid HVAC system incorporating thermoelectric devices and multiple heat exchangers that allow for efficient heating, cooling, and demisting by utilizing both electric and fuel sources independently, optimizing air conditioning based on vehicle operational modes.

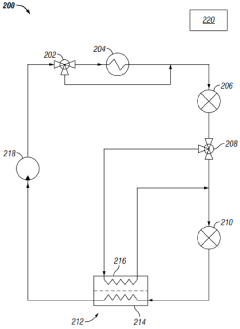

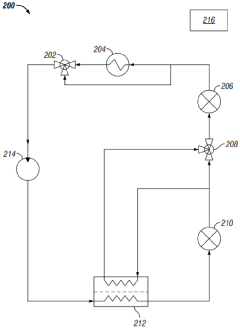

Heating, ventilation, and air-conditioning system with reheat.

PatentPendingMX2022012054A

Innovation

- The HVAC system incorporates a dual-portion indoor heat exchanger with separate reheat and main portions, allowing for more flexible operation modes.

- The system utilizes two variable expansion devices strategically positioned to control refrigerant flow differently through the reheat and main portions of the indoor heat exchanger.

- The control system enables three distinct operational modes (first cooling mode, second cooling mode, and dehumidification mode) through selective refrigerant flow control.

Energy Efficiency and Performance Metrics

Energy efficiency is a critical factor in evaluating thermoelectric materials for HVAC applications. The primary metric used to assess thermoelectric performance is the figure of merit ZT, defined as ZT = S²σT/κ, where S is the Seebeck coefficient, σ is electrical conductivity, T is absolute temperature, and κ is thermal conductivity. Higher ZT values indicate better energy conversion efficiency, with current commercial materials typically achieving ZT values between 0.8 and 1.2.

Coefficient of Performance (COP) represents another essential metric, measuring the ratio of useful heating or cooling provided to the electrical energy consumed. For thermoelectric HVAC systems, COP values generally range from 0.5 to 2.5, significantly lower than conventional vapor-compression systems that achieve COPs of 3.0-5.0. This efficiency gap remains a primary challenge for widespread thermoelectric HVAC adoption.

Power density, measured in W/cm², determines the practical application potential in space-constrained HVAC systems. Current thermoelectric materials deliver power densities between 0.2-1.0 W/cm², requiring optimization of module design to maximize performance within limited installation spaces.

Temperature differential capability (ΔT) indicates how effectively a thermoelectric material can maintain temperature differences between hot and cold sides. Leading materials can sustain temperature differentials of 65-70°C in single-stage configurations, with multi-stage arrangements achieving higher differentials at the cost of reduced efficiency.

Response time represents another critical performance parameter, with thermoelectric systems typically achieving full operational capacity within 30-60 seconds—significantly faster than conventional HVAC systems requiring several minutes to reach optimal performance.

Operational lifetime metrics are equally important, with high-quality thermoelectric modules maintaining 80% of initial performance after 100,000-200,000 operational hours under proper thermal cycling conditions. This longevity depends heavily on material stability and resistance to thermal degradation over repeated heating-cooling cycles.

Energy consumption per cooling/heating capacity (W/BTU) provides a standardized comparison metric across different HVAC technologies. Current thermoelectric systems require approximately 0.35-0.45 W/BTU for cooling applications, compared to 0.22-0.28 W/BTU for conventional compression systems, highlighting the efficiency improvements still needed.

When evaluating thermoelectric materials for HVAC applications, these performance metrics must be considered alongside practical implementation factors such as material cost, manufacturing scalability, and environmental impact to determine the most suitable material for specific application requirements.

Coefficient of Performance (COP) represents another essential metric, measuring the ratio of useful heating or cooling provided to the electrical energy consumed. For thermoelectric HVAC systems, COP values generally range from 0.5 to 2.5, significantly lower than conventional vapor-compression systems that achieve COPs of 3.0-5.0. This efficiency gap remains a primary challenge for widespread thermoelectric HVAC adoption.

Power density, measured in W/cm², determines the practical application potential in space-constrained HVAC systems. Current thermoelectric materials deliver power densities between 0.2-1.0 W/cm², requiring optimization of module design to maximize performance within limited installation spaces.

Temperature differential capability (ΔT) indicates how effectively a thermoelectric material can maintain temperature differences between hot and cold sides. Leading materials can sustain temperature differentials of 65-70°C in single-stage configurations, with multi-stage arrangements achieving higher differentials at the cost of reduced efficiency.

Response time represents another critical performance parameter, with thermoelectric systems typically achieving full operational capacity within 30-60 seconds—significantly faster than conventional HVAC systems requiring several minutes to reach optimal performance.

Operational lifetime metrics are equally important, with high-quality thermoelectric modules maintaining 80% of initial performance after 100,000-200,000 operational hours under proper thermal cycling conditions. This longevity depends heavily on material stability and resistance to thermal degradation over repeated heating-cooling cycles.

Energy consumption per cooling/heating capacity (W/BTU) provides a standardized comparison metric across different HVAC technologies. Current thermoelectric systems require approximately 0.35-0.45 W/BTU for cooling applications, compared to 0.22-0.28 W/BTU for conventional compression systems, highlighting the efficiency improvements still needed.

When evaluating thermoelectric materials for HVAC applications, these performance metrics must be considered alongside practical implementation factors such as material cost, manufacturing scalability, and environmental impact to determine the most suitable material for specific application requirements.

Environmental Impact and Sustainability Considerations

The environmental impact of thermoelectric materials in HVAC systems represents a critical consideration in material selection processes. Conventional HVAC systems typically rely on refrigerants with high global warming potential (GWP), whereas thermoelectric-based systems eliminate these harmful substances entirely. This fundamental difference positions thermoelectric technology as an environmentally advantageous alternative, particularly as global regulations increasingly restrict traditional refrigerants under frameworks like the Kigali Amendment to the Montreal Protocol.

When evaluating thermoelectric materials for HVAC applications, lifecycle assessment (LCA) becomes essential. Materials such as bismuth telluride (Bi₂Te₃), while offering good performance characteristics, contain tellurium—a rare element with limited global reserves and environmentally problematic extraction processes. Alternative materials like skutterudites and half-Heusler alloys may present more sustainable options, though their environmental profiles must be thoroughly assessed through comprehensive cradle-to-grave analysis.

Energy consumption during operation constitutes another significant environmental factor. Despite eliminating refrigerants, thermoelectric HVAC systems traditionally suffer from lower coefficient of performance (COP) compared to conventional systems, potentially resulting in higher electricity consumption and associated carbon emissions. Recent advancements in nanostructured thermoelectric materials have improved efficiency metrics, narrowing this performance gap and enhancing the environmental case for thermoelectric solutions.

Manufacturing processes for thermoelectric materials also carry environmental implications. Techniques such as powder metallurgy, spark plasma sintering, and thin-film deposition vary considerably in their energy requirements and waste generation. Emerging eco-friendly synthesis methods utilizing green chemistry principles show promise for reducing the environmental footprint of production processes, though these approaches remain predominantly in research stages rather than commercial implementation.

End-of-life considerations represent another crucial dimension of environmental assessment. The recoverability and recyclability of thermoelectric materials significantly impact their overall sustainability profile. Materials containing toxic elements like lead or tellurium require specialized disposal protocols, while those composed of more abundant and benign elements offer simpler recycling pathways. Designing thermoelectric modules with disassembly and material recovery in mind can substantially improve their environmental performance across the complete lifecycle.

Carbon footprint analysis reveals that despite potentially higher operational energy requirements, thermoelectric HVAC systems may achieve lower lifetime emissions in regions with clean electricity generation. This advantage becomes particularly pronounced in small-scale or intermittent cooling applications where conventional systems operate inefficiently. As electrical grids continue decarbonizing globally, the comparative environmental advantage of thermoelectric systems will likely strengthen further.

When evaluating thermoelectric materials for HVAC applications, lifecycle assessment (LCA) becomes essential. Materials such as bismuth telluride (Bi₂Te₃), while offering good performance characteristics, contain tellurium—a rare element with limited global reserves and environmentally problematic extraction processes. Alternative materials like skutterudites and half-Heusler alloys may present more sustainable options, though their environmental profiles must be thoroughly assessed through comprehensive cradle-to-grave analysis.

Energy consumption during operation constitutes another significant environmental factor. Despite eliminating refrigerants, thermoelectric HVAC systems traditionally suffer from lower coefficient of performance (COP) compared to conventional systems, potentially resulting in higher electricity consumption and associated carbon emissions. Recent advancements in nanostructured thermoelectric materials have improved efficiency metrics, narrowing this performance gap and enhancing the environmental case for thermoelectric solutions.

Manufacturing processes for thermoelectric materials also carry environmental implications. Techniques such as powder metallurgy, spark plasma sintering, and thin-film deposition vary considerably in their energy requirements and waste generation. Emerging eco-friendly synthesis methods utilizing green chemistry principles show promise for reducing the environmental footprint of production processes, though these approaches remain predominantly in research stages rather than commercial implementation.

End-of-life considerations represent another crucial dimension of environmental assessment. The recoverability and recyclability of thermoelectric materials significantly impact their overall sustainability profile. Materials containing toxic elements like lead or tellurium require specialized disposal protocols, while those composed of more abundant and benign elements offer simpler recycling pathways. Designing thermoelectric modules with disassembly and material recovery in mind can substantially improve their environmental performance across the complete lifecycle.

Carbon footprint analysis reveals that despite potentially higher operational energy requirements, thermoelectric HVAC systems may achieve lower lifetime emissions in regions with clean electricity generation. This advantage becomes particularly pronounced in small-scale or intermittent cooling applications where conventional systems operate inefficiently. As electrical grids continue decarbonizing globally, the comparative environmental advantage of thermoelectric systems will likely strengthen further.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!