Self-Healing Polymers For Aerospace Interiors: Flammability, Smoke/Toxicity And Impact Repair

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Self-Healing Polymer Technology Evolution

Self-healing polymers represent a revolutionary advancement in materials science, with their development trajectory spanning several decades. The concept emerged in the 1980s with pioneering work on reversible polymer networks, but significant breakthroughs only materialized in the early 2000s when the first practical self-healing materials were demonstrated by researchers at the University of Illinois.

The evolution of aerospace self-healing polymers has followed a distinct path driven by the industry's unique requirements. Initial developments focused on structural applications, with early systems utilizing microencapsulated healing agents that would release upon damage. These first-generation systems, while innovative, faced limitations in terms of healing efficiency and compatibility with aerospace environments.

By the mid-2000s, the second generation of self-healing polymers emerged, incorporating vascular networks inspired by biological systems. These networks allowed for continuous supply of healing agents, enabling multiple healing cycles. However, these systems still struggled with the stringent flammability and toxicity requirements specific to aerospace interiors.

The 2010s marked a significant shift toward intrinsic self-healing mechanisms, utilizing reversible chemical bonds such as Diels-Alder reactions, hydrogen bonding, and dynamic covalent chemistry. This approach eliminated the need for separate healing agents, creating more integrated systems better suited for aerospace applications. These materials began addressing the critical flammability concerns through incorporation of flame-retardant chemistries directly into the polymer backbone.

Recent developments (2018-2023) have focused on multi-functional self-healing polymers that simultaneously address flammability, smoke/toxicity, and impact resistance. Advanced systems now incorporate phase-change materials and smart additives that respond to thermal and mechanical stimuli, providing both preventive and reactive protection against fire and impact damage.

The latest frontier in aerospace self-healing polymers involves nanotechnology integration, with carbon nanotubes and graphene enhancing both mechanical properties and self-healing efficiency. These nanomaterials create conductive networks that enable electrical or thermal triggering of healing mechanisms, allowing for controlled and rapid repair processes particularly valuable in time-critical aerospace applications.

Current research is increasingly focused on bio-inspired approaches, mimicking natural systems that demonstrate remarkable healing capabilities while maintaining flame resistance. This biomimetic direction represents a promising pathway toward developing the next generation of aerospace interior materials that can withstand extreme conditions while offering superior safety characteristics and extended service life.

The evolution of aerospace self-healing polymers has followed a distinct path driven by the industry's unique requirements. Initial developments focused on structural applications, with early systems utilizing microencapsulated healing agents that would release upon damage. These first-generation systems, while innovative, faced limitations in terms of healing efficiency and compatibility with aerospace environments.

By the mid-2000s, the second generation of self-healing polymers emerged, incorporating vascular networks inspired by biological systems. These networks allowed for continuous supply of healing agents, enabling multiple healing cycles. However, these systems still struggled with the stringent flammability and toxicity requirements specific to aerospace interiors.

The 2010s marked a significant shift toward intrinsic self-healing mechanisms, utilizing reversible chemical bonds such as Diels-Alder reactions, hydrogen bonding, and dynamic covalent chemistry. This approach eliminated the need for separate healing agents, creating more integrated systems better suited for aerospace applications. These materials began addressing the critical flammability concerns through incorporation of flame-retardant chemistries directly into the polymer backbone.

Recent developments (2018-2023) have focused on multi-functional self-healing polymers that simultaneously address flammability, smoke/toxicity, and impact resistance. Advanced systems now incorporate phase-change materials and smart additives that respond to thermal and mechanical stimuli, providing both preventive and reactive protection against fire and impact damage.

The latest frontier in aerospace self-healing polymers involves nanotechnology integration, with carbon nanotubes and graphene enhancing both mechanical properties and self-healing efficiency. These nanomaterials create conductive networks that enable electrical or thermal triggering of healing mechanisms, allowing for controlled and rapid repair processes particularly valuable in time-critical aerospace applications.

Current research is increasingly focused on bio-inspired approaches, mimicking natural systems that demonstrate remarkable healing capabilities while maintaining flame resistance. This biomimetic direction represents a promising pathway toward developing the next generation of aerospace interior materials that can withstand extreme conditions while offering superior safety characteristics and extended service life.

Market Demand Analysis for Advanced Aerospace Interior Materials

The aerospace interior materials market is experiencing significant growth, driven by increasing air passenger traffic and fleet expansion. According to industry reports, the global aerospace interior market was valued at approximately $29.8 billion in 2022 and is projected to reach $45.2 billion by 2030, growing at a CAGR of 5.3%. Within this sector, advanced materials with self-healing capabilities represent an emerging segment with substantial growth potential.

Airlines and aircraft manufacturers are increasingly prioritizing materials that enhance passenger safety while reducing maintenance costs. The demand for self-healing polymers specifically designed for aerospace interiors stems from stringent safety regulations established by aviation authorities such as the FAA and EASA, particularly regarding flammability, smoke emission, and toxicity standards outlined in FAR 25.853 and similar regulations.

Market research indicates that maintenance and repair operations (MRO) in commercial aviation cost the industry approximately $76 billion annually, with interior components accounting for roughly 16% of these expenses. Self-healing polymers capable of autonomously repairing minor impacts and damage could potentially reduce these costs by 25-30%, representing significant operational savings for airlines.

The push toward more sustainable aviation has also created market demand for materials with extended lifecycles. Self-healing polymers align with this trend by potentially doubling the service life of interior components, thereby reducing waste and replacement frequency. This sustainability aspect is increasingly valued by airlines seeking to improve their environmental credentials.

Regional analysis shows North America and Europe currently dominating the demand for advanced aerospace materials, collectively accounting for 68% of the market. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate at 7.8% annually through 2030 due to expanding domestic aviation markets and increasing manufacturing capabilities.

Customer segmentation reveals that major commercial aircraft manufacturers represent the primary market (62%), followed by business jet manufacturers (21%) and aftermarket suppliers (17%). These stakeholders are increasingly specifying advanced materials in their design requirements, with particular emphasis on materials that can withstand the high-traffic, high-wear environment of aircraft cabins while maintaining safety standards.

The economic value proposition of self-healing polymers is compelling when considering the full lifecycle costs. Although these materials typically command a 30-40% premium over conventional alternatives, the extended service life and reduced maintenance requirements offer a potential ROI within 3-4 years of installation, making them increasingly attractive to cost-conscious operators.

Airlines and aircraft manufacturers are increasingly prioritizing materials that enhance passenger safety while reducing maintenance costs. The demand for self-healing polymers specifically designed for aerospace interiors stems from stringent safety regulations established by aviation authorities such as the FAA and EASA, particularly regarding flammability, smoke emission, and toxicity standards outlined in FAR 25.853 and similar regulations.

Market research indicates that maintenance and repair operations (MRO) in commercial aviation cost the industry approximately $76 billion annually, with interior components accounting for roughly 16% of these expenses. Self-healing polymers capable of autonomously repairing minor impacts and damage could potentially reduce these costs by 25-30%, representing significant operational savings for airlines.

The push toward more sustainable aviation has also created market demand for materials with extended lifecycles. Self-healing polymers align with this trend by potentially doubling the service life of interior components, thereby reducing waste and replacement frequency. This sustainability aspect is increasingly valued by airlines seeking to improve their environmental credentials.

Regional analysis shows North America and Europe currently dominating the demand for advanced aerospace materials, collectively accounting for 68% of the market. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate at 7.8% annually through 2030 due to expanding domestic aviation markets and increasing manufacturing capabilities.

Customer segmentation reveals that major commercial aircraft manufacturers represent the primary market (62%), followed by business jet manufacturers (21%) and aftermarket suppliers (17%). These stakeholders are increasingly specifying advanced materials in their design requirements, with particular emphasis on materials that can withstand the high-traffic, high-wear environment of aircraft cabins while maintaining safety standards.

The economic value proposition of self-healing polymers is compelling when considering the full lifecycle costs. Although these materials typically command a 30-40% premium over conventional alternatives, the extended service life and reduced maintenance requirements offer a potential ROI within 3-4 years of installation, making them increasingly attractive to cost-conscious operators.

Current Challenges in Self-Healing Polymer Development

Despite significant advancements in self-healing polymer technology, several critical challenges persist in developing viable solutions for aerospace interior applications. The stringent safety requirements of the aerospace industry create a complex development environment where multiple competing priorities must be balanced simultaneously.

The foremost challenge lies in achieving self-healing capabilities while maintaining compliance with FAA flammability standards (FAR 25.853). Current self-healing mechanisms often rely on microcapsules containing healing agents or dynamic covalent bonds, which can introduce additional fuel sources that compromise flame retardancy. The healing chemistry must function effectively without increasing heat release rates or flame spread, a balance that remains difficult to achieve.

Smoke and toxicity requirements present another significant hurdle. When exposed to heat or flame, many self-healing polymers release potentially harmful compounds during the healing process. The catalysts and healing agents necessary for repair mechanisms can generate toxic gases when burned, creating a direct conflict between healing efficiency and safety requirements. This is particularly problematic in confined aircraft cabins where evacuation times are critical.

Impact resistance and healing efficiency create a technical paradox. Materials robust enough to withstand the mechanical stresses of aerospace applications often have molecular structures that inhibit efficient healing. Conversely, polymers with excellent healing properties frequently lack the structural integrity required for aerospace interior components. This fundamental materials science challenge has yet to be fully resolved.

Temperature-dependent healing presents operational limitations. Most current self-healing mechanisms function optimally within narrow temperature ranges that do not align with the extreme conditions experienced in aerospace applications (-55°C to +85°C). Developing systems that can heal across this operational temperature spectrum without external intervention remains elusive.

Manufacturing scalability and cost-effectiveness constitute significant barriers to commercial implementation. Many laboratory-demonstrated self-healing systems rely on complex chemistries or processing techniques that are difficult to scale to industrial production levels. The cost premium for self-healing capabilities must be justified by demonstrable improvements in service life or maintenance reduction.

Long-term stability and aging effects remain largely unknown. The aerospace industry requires materials with 15-20 year service lives, but accelerated aging studies on self-healing polymers show degradation of healing efficiency over time. Understanding and mitigating these aging effects is critical for practical implementation.

The foremost challenge lies in achieving self-healing capabilities while maintaining compliance with FAA flammability standards (FAR 25.853). Current self-healing mechanisms often rely on microcapsules containing healing agents or dynamic covalent bonds, which can introduce additional fuel sources that compromise flame retardancy. The healing chemistry must function effectively without increasing heat release rates or flame spread, a balance that remains difficult to achieve.

Smoke and toxicity requirements present another significant hurdle. When exposed to heat or flame, many self-healing polymers release potentially harmful compounds during the healing process. The catalysts and healing agents necessary for repair mechanisms can generate toxic gases when burned, creating a direct conflict between healing efficiency and safety requirements. This is particularly problematic in confined aircraft cabins where evacuation times are critical.

Impact resistance and healing efficiency create a technical paradox. Materials robust enough to withstand the mechanical stresses of aerospace applications often have molecular structures that inhibit efficient healing. Conversely, polymers with excellent healing properties frequently lack the structural integrity required for aerospace interior components. This fundamental materials science challenge has yet to be fully resolved.

Temperature-dependent healing presents operational limitations. Most current self-healing mechanisms function optimally within narrow temperature ranges that do not align with the extreme conditions experienced in aerospace applications (-55°C to +85°C). Developing systems that can heal across this operational temperature spectrum without external intervention remains elusive.

Manufacturing scalability and cost-effectiveness constitute significant barriers to commercial implementation. Many laboratory-demonstrated self-healing systems rely on complex chemistries or processing techniques that are difficult to scale to industrial production levels. The cost premium for self-healing capabilities must be justified by demonstrable improvements in service life or maintenance reduction.

Long-term stability and aging effects remain largely unknown. The aerospace industry requires materials with 15-20 year service lives, but accelerated aging studies on self-healing polymers show degradation of healing efficiency over time. Understanding and mitigating these aging effects is critical for practical implementation.

Current Self-Healing Solutions for Aerospace Applications

01 Flame retardant self-healing polymer compositions

Self-healing polymers can be formulated with flame retardant additives to reduce flammability while maintaining their healing properties. These compositions typically incorporate phosphorus-based compounds, metal hydroxides, or halogenated materials that inhibit combustion processes. The flame retardant components work by creating a char layer, releasing water vapor, or interrupting free radical reactions during burning, thereby reducing heat release and flame spread while preserving the polymer's ability to repair damage.- Flame retardant self-healing polymer compositions: Self-healing polymers can be formulated with flame retardant additives to reduce flammability while maintaining their healing properties. These compositions typically incorporate phosphorus-based compounds, metal hydroxides, or halogenated materials that inhibit combustion processes. The flame retardant components work by creating a char layer during heating that limits oxygen access and heat transfer, while the self-healing mechanisms remain functional to repair mechanical damage.

- Smoke and toxicity reduction in self-healing polymers: Advanced formulations of self-healing polymers address smoke generation and toxicity concerns through incorporation of smoke suppressants and non-toxic healing agents. These polymers utilize environmentally friendly catalysts and healing mechanisms that produce minimal toxic byproducts during thermal decomposition. Some compositions include metal oxides or silica-based additives that trap volatile compounds and reduce smoke density during combustion events while maintaining the polymer's ability to repair damage.

- Impact-responsive healing mechanisms: Self-healing polymers designed specifically for impact repair utilize microencapsulated healing agents that release upon mechanical damage. These systems incorporate force-sensitive microcapsules or vascular networks that rupture during impact, releasing healing agents precisely where needed. The healing components polymerize or cross-link rapidly to restore structural integrity after impact events, with some advanced systems capable of multiple healing cycles without performance degradation.

- Temperature-resistant self-healing polymer systems: High-temperature resistant self-healing polymers combine thermal stability with repair capabilities for applications in extreme environments. These materials utilize thermally stable polymer backbones with reversible cross-linking mechanisms that remain functional across wide temperature ranges. The compositions often incorporate ceramic particles or heat-resistant fibers that enhance both thermal resistance and mechanical properties while allowing the polymer matrix to maintain its healing functionality even after exposure to high temperatures.

- Multi-functional self-healing composite materials: Multi-functional self-healing composites integrate flame retardancy, low smoke emission, and impact repair capabilities within a single material system. These advanced composites typically combine fiber reinforcement with specialized polymer matrices containing multiple healing mechanisms triggered by different stimuli. The materials often incorporate nanomaterials that enhance both mechanical properties and flame resistance while facilitating efficient healing processes through improved thermal conductivity or catalytic activity.

02 Smoke and toxicity reduction in self-healing polymers

Specialized additives can be incorporated into self-healing polymer systems to reduce smoke generation and toxic gas emissions during combustion. These formulations often include smoke suppressants, char-forming agents, and metal compounds that catalyze the conversion of carbon monoxide to less harmful carbon dioxide. By modifying the degradation pathway during thermal decomposition, these additives maintain the polymer's self-healing functionality while significantly improving its safety profile in fire scenarios.Expand Specific Solutions03 Impact-responsive healing mechanisms

Advanced self-healing polymers can be designed with impact-triggered repair mechanisms that activate specifically in response to mechanical damage. These systems utilize microencapsulated healing agents, vascular networks, or dynamic covalent bonds that become reactive upon impact. The healing process begins immediately after damage occurs, restoring mechanical properties and structural integrity without external intervention. This approach is particularly valuable for applications where components are subjected to repeated impact or vibration.Expand Specific Solutions04 Environmentally-friendly self-healing fire-resistant polymers

Sustainable self-healing polymers with enhanced fire resistance can be developed using bio-based materials and environmentally friendly additives. These formulations replace traditional halogenated flame retardants with renewable alternatives such as modified plant oils, cellulose derivatives, or protein-based compounds. The resulting materials offer a combination of self-healing capabilities, reduced environmental impact, and improved fire safety performance, making them suitable for applications where both sustainability and safety are priorities.Expand Specific Solutions05 Multi-functional self-healing polymer systems

Integrated polymer systems can be engineered to simultaneously address flammability, smoke production, toxicity, and impact repair through a single cohesive design. These multi-functional materials incorporate synergistic combinations of additives and structural elements that work together to enhance overall performance. The systems may feature compartmentalized healing agents that remain stable during fire exposure, intumescent components that expand to protect the material, and chemical modifiers that reduce toxic emissions while maintaining the polymer's ability to self-repair after mechanical damage.Expand Specific Solutions

Key Industry Players in Aerospace Polymer Innovation

The self-healing polymer market for aerospace interiors is in an early growth phase, with increasing market potential driven by stringent safety requirements and sustainability concerns. The technology is advancing from laboratory research to commercial applications, with NASA and CIDETEC leading fundamental research while companies like Autonomic Materials and Kaneka develop practical implementations. Technical maturity varies across flammability, smoke/toxicity, and impact repair properties, with major aerospace stakeholders like Leonardo and Boeing (through HRL Laboratories) investing in integration capabilities. Academic institutions including Sichuan University, Louisiana State University, and University of Michigan are contributing significant research to address performance challenges in extreme aerospace environments, positioning this technology for accelerated adoption in premium aerospace applications.

National Aeronautics & Space Administration

Technical Solution: NASA has developed advanced self-healing polymer composites specifically designed for aerospace interiors that address the critical challenges of flammability, smoke/toxicity, and impact repair. Their approach utilizes microcapsule-based healing systems embedded within polymer matrices that contain flame retardant compounds. When damaged, these microcapsules rupture and release healing agents that polymerize upon contact with embedded catalysts, restoring structural integrity while maintaining flame resistance properties. NASA's materials incorporate phosphorus-containing compounds and expandable graphite that form a protective char layer during combustion, significantly reducing heat release rates and flame spread. Their self-healing polymers also feature smoke suppressants and low-toxicity additives that minimize the generation of harmful gases during thermal decomposition. NASA has successfully demonstrated these materials in microgravity environments, showing effective autonomous repair capabilities without compromising the strict aerospace safety requirements for cabin interiors.

Strengths: Exceptional performance in microgravity environments, integration with existing aerospace manufacturing processes, and comprehensive testing protocols that meet stringent aerospace safety standards. Weaknesses: Higher production costs compared to conventional materials, potential weight penalties, and limited commercial availability outside aerospace applications.

Commonwealth Scientific & Industrial Research Organisation

Technical Solution: CSIRO has pioneered a novel approach to self-healing polymers for aerospace applications through their development of intrinsic healing mechanisms based on reversible covalent bonds and supramolecular interactions. Their technology utilizes dynamic Diels-Alder chemistry that enables repeated healing cycles through temperature-controlled bond breaking and reformation. The polymer systems incorporate phosphorus-nitrogen compounds that impart flame retardancy while maintaining the self-healing functionality. CSIRO's materials feature a unique microstructure that compartmentalizes flame retardants, ensuring they remain effective even after multiple healing cycles. Their polymers demonstrate excellent mechanical property recovery (up to 90% of original strength) after impact damage, while simultaneously meeting the stringent FAR 25.853 flammability requirements for aircraft interiors. The materials also incorporate specialized additives that trap free radicals during combustion, significantly reducing smoke density and the release of toxic gases like hydrogen cyanide and carbon monoxide. CSIRO has successfully scaled up production of these materials and demonstrated their application in aircraft panel components.

Strengths: Excellent balance between self-healing efficiency and flame retardancy, multiple healing cycles without performance degradation, and compatibility with existing manufacturing processes. Weaknesses: Temperature-dependent healing mechanism requires external heating for activation, potential for decreased healing efficiency over time, and higher cost compared to conventional non-healing polymers.

Critical Patents in Fire-Resistant Self-Healing Polymers

Self-healing materials for aerospace

PatentPendingIN202411020385A

Innovation

- A self-healing composite material with a fiber-reinforced matrix and microcapsules containing healing agents, integrated with shape memory polymers, which enables autonomous repair and restoration of structural integrity, along with a smart monitoring system for proactive healing and a repair kit for in-situ maintenance.

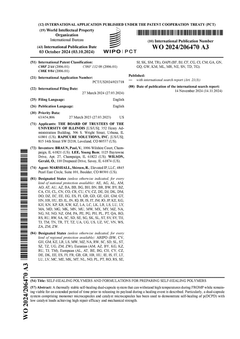

Self-healing polymers and formulations for preparing self-healing polymers

PatentWO2024206470A3

Innovation

- Development of a thermally stable dual-capsule self-healing system capable of withstanding high temperatures during Fiber-Reinforced Organic Matrix Processing (FROMP) while maintaining long-term viability.

- Achievement of high repair efficacy and mechanical strength in poly(dicyclopentadiene) [p(DCPD)] systems using low catalyst loads through a dual-capsule approach combining monomer and catalyst microcapsules.

- Design of a controlled-release mechanism that preserves healing agents until damage occurs, enabling on-demand repair functionality.

Safety Certification Standards for Aerospace Materials

The aerospace industry operates under stringent safety regulations that govern all materials used in aircraft interiors. For self-healing polymers to be viable in this sector, they must comply with comprehensive certification standards established by aviation authorities worldwide. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) have developed detailed requirements specifically addressing flammability, smoke emission, and toxicity characteristics of materials used in aircraft cabins.

FAA regulations, particularly FAR 25.853 and 25.855, establish strict flammability requirements that materials must meet before certification. These include vertical burn tests, heat release rate tests, and smoke density evaluations. Similarly, EASA's CS-25 regulations mirror these requirements with some regional variations. Any self-healing polymer system intended for aerospace applications must demonstrate compliance with these standards without compromise.

The Aircraft Material Fire Test Handbook (DOT/FAA/AR-00/12) provides standardized testing methodologies that manufacturers must follow to validate material performance. For self-healing polymers, these tests present unique challenges as the healing mechanisms must not introduce additional fire hazards or toxic byproducts when activated during emergency scenarios.

Smoke and toxicity testing follows standards such as ABD0031 and BSS7239, which measure the concentration of toxic gases produced during combustion. Self-healing polymers must demonstrate that their healing agents, catalysts, and byproducts do not increase toxicity levels when exposed to heat or flame. The industry standard maximum values for gases like CO, NOx, HCN, HF, and SO2 are strictly enforced.

Impact resistance certification involves demonstrating material durability under dynamic loading conditions. Standards such as ASTM D7136 for impact resistance must be satisfied while maintaining the material's self-healing capabilities. The certification process requires evidence that the healing mechanism remains effective after multiple impact events without degradation of performance.

Material aging and environmental testing are additional certification requirements. Standards like RTCA DO-160 address environmental conditions including temperature cycling, humidity, and fluid resistance. Self-healing polymers must maintain their healing efficacy and safety properties throughout the aircraft's service life, typically 20+ years, while being exposed to these environmental stressors.

Manufacturers seeking certification for self-healing polymers must also provide comprehensive documentation on material composition, manufacturing processes, and quality control procedures. This documentation forms part of the Technical Standard Order (TSO) or European Technical Standard Order (ETSO) approval process, which is mandatory for materials used in critical aerospace applications.

FAA regulations, particularly FAR 25.853 and 25.855, establish strict flammability requirements that materials must meet before certification. These include vertical burn tests, heat release rate tests, and smoke density evaluations. Similarly, EASA's CS-25 regulations mirror these requirements with some regional variations. Any self-healing polymer system intended for aerospace applications must demonstrate compliance with these standards without compromise.

The Aircraft Material Fire Test Handbook (DOT/FAA/AR-00/12) provides standardized testing methodologies that manufacturers must follow to validate material performance. For self-healing polymers, these tests present unique challenges as the healing mechanisms must not introduce additional fire hazards or toxic byproducts when activated during emergency scenarios.

Smoke and toxicity testing follows standards such as ABD0031 and BSS7239, which measure the concentration of toxic gases produced during combustion. Self-healing polymers must demonstrate that their healing agents, catalysts, and byproducts do not increase toxicity levels when exposed to heat or flame. The industry standard maximum values for gases like CO, NOx, HCN, HF, and SO2 are strictly enforced.

Impact resistance certification involves demonstrating material durability under dynamic loading conditions. Standards such as ASTM D7136 for impact resistance must be satisfied while maintaining the material's self-healing capabilities. The certification process requires evidence that the healing mechanism remains effective after multiple impact events without degradation of performance.

Material aging and environmental testing are additional certification requirements. Standards like RTCA DO-160 address environmental conditions including temperature cycling, humidity, and fluid resistance. Self-healing polymers must maintain their healing efficacy and safety properties throughout the aircraft's service life, typically 20+ years, while being exposed to these environmental stressors.

Manufacturers seeking certification for self-healing polymers must also provide comprehensive documentation on material composition, manufacturing processes, and quality control procedures. This documentation forms part of the Technical Standard Order (TSO) or European Technical Standard Order (ETSO) approval process, which is mandatory for materials used in critical aerospace applications.

Environmental Impact Assessment of Polymer Technologies

The environmental impact of self-healing polymers for aerospace interiors represents a critical consideration in their development and implementation. Traditional polymer materials used in aircraft cabins often require frequent replacement due to damage, contributing significantly to waste generation and resource consumption. Self-healing polymers offer a promising alternative by extending product lifecycles through autonomous repair capabilities, thereby reducing the environmental footprint associated with manufacturing replacement components.

When evaluating the environmental profile of these advanced materials, lifecycle assessment (LCA) methodologies reveal notable advantages. The production phase of self-healing polymers typically involves higher energy inputs and potentially more complex chemical processes compared to conventional polymers. However, this initial environmental investment is offset by the extended service life and reduced maintenance requirements, resulting in net positive environmental outcomes over the complete product lifecycle.

The flammability characteristics of self-healing polymers present both challenges and opportunities from an environmental perspective. Fire-resistant formulations often incorporate halogenated compounds that may pose environmental risks if released during production, use, or disposal. Recent innovations focus on developing non-halogenated flame retardants that maintain safety standards while minimizing environmental persistence and bioaccumulation potential.

Smoke and toxicity considerations extend beyond immediate safety concerns to encompass long-term environmental impacts. The combustion byproducts of aerospace polymers can contribute to atmospheric pollution and potential ecosystem damage. Self-healing formulations designed with environmentally benign healing agents demonstrate reduced toxic emissions during thermal degradation compared to conventional alternatives, representing a significant environmental advantage.

End-of-life management presents another dimension for environmental assessment. The complex chemical structures of self-healing polymers may complicate recycling processes, potentially limiting their integration into existing polymer recovery systems. Research indicates that certain self-healing mechanisms based on reversible covalent bonds offer improved recyclability compared to those utilizing encapsulated healing agents, suggesting a pathway toward more environmentally sustainable designs.

Water and energy consumption metrics throughout the production and use phases reveal that while manufacturing self-healing polymers may require additional resources initially, the elimination of repair processes and extended replacement intervals results in substantial resource conservation over time. Quantitative analyses demonstrate potential reductions in carbon footprint by 15-30% compared to traditional aerospace interior materials when accounting for full lifecycle impacts.

When evaluating the environmental profile of these advanced materials, lifecycle assessment (LCA) methodologies reveal notable advantages. The production phase of self-healing polymers typically involves higher energy inputs and potentially more complex chemical processes compared to conventional polymers. However, this initial environmental investment is offset by the extended service life and reduced maintenance requirements, resulting in net positive environmental outcomes over the complete product lifecycle.

The flammability characteristics of self-healing polymers present both challenges and opportunities from an environmental perspective. Fire-resistant formulations often incorporate halogenated compounds that may pose environmental risks if released during production, use, or disposal. Recent innovations focus on developing non-halogenated flame retardants that maintain safety standards while minimizing environmental persistence and bioaccumulation potential.

Smoke and toxicity considerations extend beyond immediate safety concerns to encompass long-term environmental impacts. The combustion byproducts of aerospace polymers can contribute to atmospheric pollution and potential ecosystem damage. Self-healing formulations designed with environmentally benign healing agents demonstrate reduced toxic emissions during thermal degradation compared to conventional alternatives, representing a significant environmental advantage.

End-of-life management presents another dimension for environmental assessment. The complex chemical structures of self-healing polymers may complicate recycling processes, potentially limiting their integration into existing polymer recovery systems. Research indicates that certain self-healing mechanisms based on reversible covalent bonds offer improved recyclability compared to those utilizing encapsulated healing agents, suggesting a pathway toward more environmentally sustainable designs.

Water and energy consumption metrics throughout the production and use phases reveal that while manufacturing self-healing polymers may require additional resources initially, the elimination of repair processes and extended replacement intervals results in substantial resource conservation over time. Quantitative analyses demonstrate potential reductions in carbon footprint by 15-30% compared to traditional aerospace interior materials when accounting for full lifecycle impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!