Solid oxide electrolysis cells’ role in global energy transitions

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SOEC Technology Background and Objectives

Solid oxide electrolysis cells (SOECs) represent a transformative technology in the global energy landscape, with roots dating back to the 1980s when researchers first explored high-temperature electrolysis for hydrogen production. The evolution of SOEC technology has accelerated significantly over the past decade, driven by the urgent need for sustainable energy solutions and decarbonization strategies across industrial sectors.

The fundamental principle of SOECs involves the electrochemical conversion of steam and/or carbon dioxide into hydrogen and/or carbon monoxide using electricity at elevated temperatures (700-900°C). This reverse operation of solid oxide fuel cells enables efficient energy storage and conversion pathways that are increasingly critical for renewable energy integration.

The primary technical objective of SOEC development is to achieve high conversion efficiency exceeding 80% electricity-to-hydrogen, significantly outperforming alternative electrolysis technologies such as alkaline or PEM electrolyzers which typically operate at 60-70% efficiency. Additionally, SOECs aim to demonstrate exceptional durability with degradation rates below 1% per 1000 operating hours and operational lifetimes exceeding 40,000 hours for commercial viability.

Current technological trajectories indicate a strong push toward multi-functional SOEC systems capable of co-electrolysis (simultaneous H2O and CO2 electrolysis) to produce syngas for downstream synthetic fuel production. This versatility positions SOECs as a cornerstone technology for sector coupling between electricity, transportation, and industrial chemical production.

The global energy transition context provides a compelling backdrop for SOEC advancement. As renewable electricity generation continues its exponential growth trajectory, the intermittency challenges create an urgent need for large-scale energy storage solutions. SOECs offer a unique value proposition by converting surplus renewable electricity into storable chemical energy carriers like hydrogen or synthetic natural gas.

Furthermore, hard-to-abate sectors such as steel production, ammonia synthesis, and high-temperature industrial processes require carbon-neutral alternatives to fossil fuels. SOECs present a viable pathway for these industries by providing clean hydrogen and carbon monoxide as feedstocks for industrial processes.

The technology development aims to address several critical challenges, including material stability under thermal cycling, cost reduction of ceramic components, and system integration with renewable energy sources. Recent breakthroughs in electrode materials and cell architecture design have demonstrated promising performance improvements, setting the stage for accelerated commercialization efforts in the coming decade.

The fundamental principle of SOECs involves the electrochemical conversion of steam and/or carbon dioxide into hydrogen and/or carbon monoxide using electricity at elevated temperatures (700-900°C). This reverse operation of solid oxide fuel cells enables efficient energy storage and conversion pathways that are increasingly critical for renewable energy integration.

The primary technical objective of SOEC development is to achieve high conversion efficiency exceeding 80% electricity-to-hydrogen, significantly outperforming alternative electrolysis technologies such as alkaline or PEM electrolyzers which typically operate at 60-70% efficiency. Additionally, SOECs aim to demonstrate exceptional durability with degradation rates below 1% per 1000 operating hours and operational lifetimes exceeding 40,000 hours for commercial viability.

Current technological trajectories indicate a strong push toward multi-functional SOEC systems capable of co-electrolysis (simultaneous H2O and CO2 electrolysis) to produce syngas for downstream synthetic fuel production. This versatility positions SOECs as a cornerstone technology for sector coupling between electricity, transportation, and industrial chemical production.

The global energy transition context provides a compelling backdrop for SOEC advancement. As renewable electricity generation continues its exponential growth trajectory, the intermittency challenges create an urgent need for large-scale energy storage solutions. SOECs offer a unique value proposition by converting surplus renewable electricity into storable chemical energy carriers like hydrogen or synthetic natural gas.

Furthermore, hard-to-abate sectors such as steel production, ammonia synthesis, and high-temperature industrial processes require carbon-neutral alternatives to fossil fuels. SOECs present a viable pathway for these industries by providing clean hydrogen and carbon monoxide as feedstocks for industrial processes.

The technology development aims to address several critical challenges, including material stability under thermal cycling, cost reduction of ceramic components, and system integration with renewable energy sources. Recent breakthroughs in electrode materials and cell architecture design have demonstrated promising performance improvements, setting the stage for accelerated commercialization efforts in the coming decade.

Market Demand Analysis for Green Hydrogen Production

The global market for green hydrogen production is experiencing unprecedented growth, driven by the urgent need for decarbonization across multiple sectors. Solid oxide electrolysis cells (SOECs) are emerging as a critical technology in this landscape, offering higher efficiency compared to conventional alkaline and PEM electrolyzers. Current market projections indicate the green hydrogen market could reach $300 billion by 2050, with SOECs potentially capturing 25-30% of this market due to their superior energy conversion capabilities.

Industrial sectors represent the primary demand drivers for green hydrogen produced via SOECs. Heavy industries including steel manufacturing, chemical production, and ammonia synthesis collectively account for approximately 20% of global carbon emissions and are increasingly seeking decarbonization pathways. The steel industry alone could consume up to 40 million tons of hydrogen annually by 2050 if widespread adoption occurs, creating substantial market pull for efficient hydrogen production technologies like SOECs.

Transportation represents another significant market segment, particularly in applications where battery electrification faces limitations. Long-haul trucking, maritime shipping, and aviation are exploring hydrogen as a zero-carbon fuel alternative, with the maritime sector potentially requiring 160 million tons of green hydrogen equivalent by 2050. Countries with established shipping industries are already investing in hydrogen infrastructure development, creating immediate market opportunities for SOEC technology deployment.

Energy storage applications present a rapidly expanding market for SOEC-produced hydrogen. The intermittent nature of renewable energy sources necessitates efficient storage solutions, with hydrogen increasingly viewed as complementary to battery storage for longer duration requirements. Grid operators in regions with high renewable penetration are exploring power-to-gas-to-power pathways, with several European countries targeting 10-15% hydrogen blending in existing natural gas networks by 2030.

Regional market analysis reveals varying adoption trajectories. The European Union leads in policy support through its Hydrogen Strategy, targeting 40GW of electrolyzer capacity by 2030. Japan and South Korea are focusing on hydrogen for industrial applications and transportation, while China is rapidly scaling manufacturing capacity for electrolysis technologies. The Middle East is leveraging abundant solar resources to position itself as a future green hydrogen export hub.

Market barriers include high production costs, currently estimated at $4-6/kg compared to $1-2/kg for gray hydrogen. However, cost reduction pathways through technological improvements, economies of scale, and increasing carbon prices are expected to make green hydrogen competitive in many applications by 2030, significantly expanding the addressable market for SOEC technology.

Industrial sectors represent the primary demand drivers for green hydrogen produced via SOECs. Heavy industries including steel manufacturing, chemical production, and ammonia synthesis collectively account for approximately 20% of global carbon emissions and are increasingly seeking decarbonization pathways. The steel industry alone could consume up to 40 million tons of hydrogen annually by 2050 if widespread adoption occurs, creating substantial market pull for efficient hydrogen production technologies like SOECs.

Transportation represents another significant market segment, particularly in applications where battery electrification faces limitations. Long-haul trucking, maritime shipping, and aviation are exploring hydrogen as a zero-carbon fuel alternative, with the maritime sector potentially requiring 160 million tons of green hydrogen equivalent by 2050. Countries with established shipping industries are already investing in hydrogen infrastructure development, creating immediate market opportunities for SOEC technology deployment.

Energy storage applications present a rapidly expanding market for SOEC-produced hydrogen. The intermittent nature of renewable energy sources necessitates efficient storage solutions, with hydrogen increasingly viewed as complementary to battery storage for longer duration requirements. Grid operators in regions with high renewable penetration are exploring power-to-gas-to-power pathways, with several European countries targeting 10-15% hydrogen blending in existing natural gas networks by 2030.

Regional market analysis reveals varying adoption trajectories. The European Union leads in policy support through its Hydrogen Strategy, targeting 40GW of electrolyzer capacity by 2030. Japan and South Korea are focusing on hydrogen for industrial applications and transportation, while China is rapidly scaling manufacturing capacity for electrolysis technologies. The Middle East is leveraging abundant solar resources to position itself as a future green hydrogen export hub.

Market barriers include high production costs, currently estimated at $4-6/kg compared to $1-2/kg for gray hydrogen. However, cost reduction pathways through technological improvements, economies of scale, and increasing carbon prices are expected to make green hydrogen competitive in many applications by 2030, significantly expanding the addressable market for SOEC technology.

SOEC Development Status and Technical Barriers

Solid oxide electrolysis cells (SOECs) have emerged as a promising technology for clean hydrogen production and carbon utilization, yet their widespread deployment faces significant technical barriers. Currently, SOECs operate at commercial scale in limited installations globally, with demonstration projects primarily concentrated in Europe, North America, and East Asia. Leading countries in SOEC development include Germany, Denmark, the United States, Japan, and China, with research institutions and companies forming collaborative networks to advance the technology.

Despite progress, SOECs face substantial technical challenges that hinder their commercial viability. The high operating temperatures (700-850°C) necessary for efficient operation create materials degradation issues, with components experiencing thermal stress, chemical incompatibility, and mechanical failure during thermal cycling. Current SOEC systems demonstrate degradation rates of 1-2% per 1000 hours, significantly higher than the 0.1-0.2% target needed for commercial applications requiring 5+ years of stable operation.

Durability remains a critical barrier, with electrode delamination, electrolyte cracking, and interconnect corrosion occurring during extended operation. The oxygen electrode particularly suffers from chromium poisoning and microstructural changes that reduce electrochemical performance over time. These degradation mechanisms accelerate at higher current densities, creating a trade-off between production efficiency and system longevity.

Cost factors present another significant obstacle, with current SOEC stack costs exceeding $2000/kW, substantially higher than the $500/kW threshold considered necessary for market competitiveness. The expensive ceramic materials, complex manufacturing processes, and specialized balance-of-plant components contribute to this cost barrier. Additionally, the need for high-temperature operation requires expensive heat management systems and specialized materials that can withstand extreme conditions.

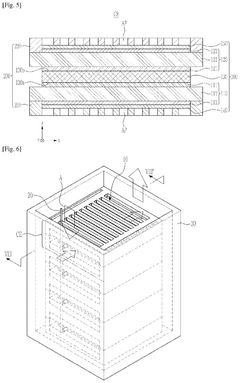

Scale-up challenges persist in transitioning from laboratory to industrial implementation. Current SOEC systems typically operate at kilowatt scale, while commercial viability requires megawatt-scale operations. Manufacturing processes for large-area cells with consistent quality and performance remain underdeveloped, and system integration issues emerge when scaling up, including thermal management, gas distribution, and electrical connections.

The technical complexity of SOEC systems also creates operational challenges. Current systems require specialized expertise for maintenance and operation, limiting their adoption in diverse energy contexts. The integration with variable renewable energy sources introduces additional complexities in managing load variations and maintaining optimal operating conditions during fluctuating power inputs.

Despite progress, SOECs face substantial technical challenges that hinder their commercial viability. The high operating temperatures (700-850°C) necessary for efficient operation create materials degradation issues, with components experiencing thermal stress, chemical incompatibility, and mechanical failure during thermal cycling. Current SOEC systems demonstrate degradation rates of 1-2% per 1000 hours, significantly higher than the 0.1-0.2% target needed for commercial applications requiring 5+ years of stable operation.

Durability remains a critical barrier, with electrode delamination, electrolyte cracking, and interconnect corrosion occurring during extended operation. The oxygen electrode particularly suffers from chromium poisoning and microstructural changes that reduce electrochemical performance over time. These degradation mechanisms accelerate at higher current densities, creating a trade-off between production efficiency and system longevity.

Cost factors present another significant obstacle, with current SOEC stack costs exceeding $2000/kW, substantially higher than the $500/kW threshold considered necessary for market competitiveness. The expensive ceramic materials, complex manufacturing processes, and specialized balance-of-plant components contribute to this cost barrier. Additionally, the need for high-temperature operation requires expensive heat management systems and specialized materials that can withstand extreme conditions.

Scale-up challenges persist in transitioning from laboratory to industrial implementation. Current SOEC systems typically operate at kilowatt scale, while commercial viability requires megawatt-scale operations. Manufacturing processes for large-area cells with consistent quality and performance remain underdeveloped, and system integration issues emerge when scaling up, including thermal management, gas distribution, and electrical connections.

The technical complexity of SOEC systems also creates operational challenges. Current systems require specialized expertise for maintenance and operation, limiting their adoption in diverse energy contexts. The integration with variable renewable energy sources introduces additional complexities in managing load variations and maintaining optimal operating conditions during fluctuating power inputs.

Current SOEC System Architectures and Solutions

01 Electrode materials and structures for solid oxide electrolysis cells

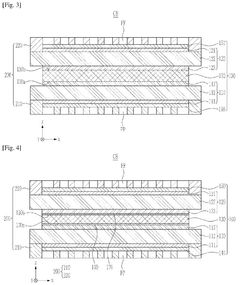

Various electrode materials and structures can be used in solid oxide electrolysis cells to improve performance and durability. These include specialized cathode and anode materials that enhance electrochemical reactions, reduce degradation, and improve conductivity. Advanced electrode structures such as porous designs facilitate gas diffusion and increase active reaction sites, while composite electrodes combining multiple materials can provide synergistic benefits for electrolysis efficiency.- Electrode materials and structures for SOECs: The choice of electrode materials and their structural design significantly impacts the performance of solid oxide electrolysis cells. Advanced materials such as perovskites, cermets, and composite electrodes can enhance electrochemical activity and durability. Optimized electrode microstructures with controlled porosity and thickness improve gas diffusion and reaction kinetics, leading to higher efficiency in hydrogen or syngas production through electrolysis.

- Electrolyte development for high-temperature operation: Specialized electrolyte materials enable efficient ion transport at high operating temperatures in solid oxide electrolysis cells. Yttria-stabilized zirconia (YSZ) and gadolinium-doped ceria (GDC) are commonly used for their excellent oxygen ion conductivity. Thin-film electrolytes reduce ohmic resistance while maintaining mechanical integrity, allowing for lower operating temperatures and improved overall system efficiency.

- System integration and stack design: Innovative stack designs and system integration approaches enhance the performance and durability of solid oxide electrolysis cells. Optimized flow field configurations improve reactant distribution and product removal. Advanced sealing technologies prevent gas leakage and maintain electrical isolation between cells. Thermal management systems ensure uniform temperature distribution, reducing thermal stress and extending operational lifetime of the stack.

- Reversible operation and co-electrolysis capabilities: Reversible solid oxide cells can function in both electrolysis and fuel cell modes, providing flexibility for energy storage and conversion applications. These systems can efficiently switch between hydrogen production and electricity generation based on demand. Co-electrolysis capabilities allow simultaneous reduction of steam and carbon dioxide to produce syngas, which can be further processed into various hydrocarbon fuels and chemicals, enhancing the versatility of solid oxide electrolysis technology.

- Degradation mechanisms and durability enhancement: Understanding and mitigating degradation mechanisms is crucial for improving the long-term stability of solid oxide electrolysis cells. Common degradation issues include electrode delamination, chromium poisoning, and microstructural changes during operation. Protective coatings, dopants, and compositional modifications can enhance material stability under high-temperature electrolysis conditions. Advanced manufacturing techniques and quality control processes help minimize defects that could lead to premature failure.

02 Electrolyte compositions for high-temperature operation

Specialized electrolyte compositions are developed for solid oxide electrolysis cells operating at high temperatures. These electrolytes typically feature enhanced ionic conductivity, thermal stability, and mechanical strength to withstand the harsh operating conditions. Materials such as yttria-stabilized zirconia (YSZ), gadolinium-doped ceria (GDC), and other ceramic composites are engineered to maintain performance while reducing operating temperatures and extending cell lifetime.Expand Specific Solutions03 System integration and stack design for solid oxide electrolysis

System integration and stack design are critical for efficient solid oxide electrolysis operation. This includes optimized cell stacking configurations, sealing technologies, and interconnect designs that minimize electrical resistance and thermal stress. Advanced stack architectures incorporate thermal management systems, gas distribution channels, and modular designs that allow for scalability while maintaining uniform performance across all cells in the stack.Expand Specific Solutions04 Co-electrolysis processes for syngas production

Co-electrolysis processes using solid oxide electrolysis cells enable simultaneous reduction of carbon dioxide and water vapor to produce syngas (a mixture of hydrogen and carbon monoxide). This approach offers an efficient pathway for converting renewable electricity into valuable chemical feedstocks. The technology involves specialized catalysts, optimized operating conditions, and electrode materials that selectively promote the desired reactions while minimizing side reactions and carbon deposition.Expand Specific Solutions05 Degradation mechanisms and durability enhancement

Understanding and mitigating degradation mechanisms is essential for improving the durability of solid oxide electrolysis cells. Research focuses on addressing issues such as chromium poisoning, electrode delamination, and electrolyte cracking that occur during long-term operation. Protective coatings, dopants, and compositional modifications are developed to enhance chemical stability, reduce thermal expansion mismatches, and prevent microstructural changes that lead to performance loss over time.Expand Specific Solutions

Leading Organizations in SOEC Research and Commercialization

Solid oxide electrolysis cells (SOECs) are emerging as a critical technology in global energy transitions, currently in the early commercialization phase with a rapidly growing market projected to reach significant scale by 2030. The technology demonstrates increasing maturity, with companies like Topsoe, DynElectro, and Elcogen leading commercial deployment while academic institutions such as Tsinghua University and Technical University of Denmark drive fundamental research. Chinese players including Sinopec and Chinese Academy of Sciences are making substantial investments, while established corporations like Phillips 66 and Nissan are exploring integration opportunities. The competitive landscape reflects a blend of specialized startups, research institutions, and industrial conglomerates working to overcome durability challenges and reduce costs for green hydrogen production and carbon utilization applications.

Topsoe A/S

Technical Solution: Topsoe has developed advanced solid oxide electrolysis cell (SOEC) technology through their eCOs™ platform, which converts electricity, steam, and CO2 into syngas for sustainable fuel production. Their SOEC systems operate at high temperatures (700-850°C), achieving electrical efficiencies exceeding 90% [1]. Topsoe's technology utilizes proprietary ceramic materials and specialized manufacturing processes to create robust cells with extended operational lifetimes. Their integrated stack design incorporates nickel-based electrodes and yttria-stabilized zirconia electrolytes, optimized for high current density operations. The company has demonstrated industrial-scale implementation with their SynCOR™ technology, which combines SOEC with downstream processing to produce green methanol and sustainable aviation fuels. Topsoe's systems are designed for integration with renewable energy sources, allowing for efficient utilization of intermittent power while providing grid balancing services [2]. Their technology roadmap includes scaling to gigawatt-level electrolysis plants by 2030 to support global decarbonization efforts.

Strengths: Industry-leading electrical efficiency (>90%) reduces operational costs; proven integration with downstream synthesis processes for e-fuels; established manufacturing capacity for commercial deployment. Weaknesses: High operating temperatures require specialized materials and thermal management; initial capital costs remain higher than alternative electrolysis technologies; system complexity necessitates skilled operation and maintenance personnel.

DynElectro ApS

Technical Solution: DynElectro has pioneered a dynamic solid oxide electrolysis cell (SOEC) technology that operates in reversible mode, functioning as both an electrolyzer and fuel cell as needed. Their proprietary DynElectro cells utilize a novel ceramic composite structure with enhanced ionic conductivity at intermediate temperatures (600-700°C), reducing material degradation while maintaining high efficiency. The company's modular stack design incorporates advanced sealing technology that allows for thermal cycling without performance loss, addressing a key challenge in SOEC deployment. DynElectro's systems feature integrated thermal management that captures waste heat for steam generation, creating a self-sustaining process once operational temperature is reached [3]. Their technology achieves hydrogen production at system efficiencies of 85-90% (LHV), with demonstrated degradation rates below 0.5% per 1000 hours of operation. The company has developed specialized electrode materials with nano-structured catalysts that resist carbon deposition and sulfur poisoning, enabling direct electrolysis of biogas and other carbon-containing feedstocks [4]. Their control systems incorporate machine learning algorithms to optimize operation based on electricity price signals and grid demands.

Strengths: Reversible operation provides flexibility for grid balancing and energy storage applications; intermediate temperature operation reduces material costs and thermal stress; modular design enables scalable deployment from kilowatt to megawatt installations. Weaknesses: Limited commercial-scale demonstration compared to larger competitors; technology still requires specialized manufacturing processes; integration with existing energy infrastructure presents standardization challenges.

Critical Materials and Cell Design Innovations

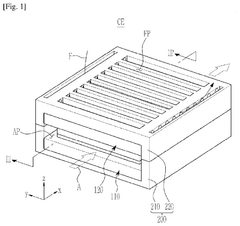

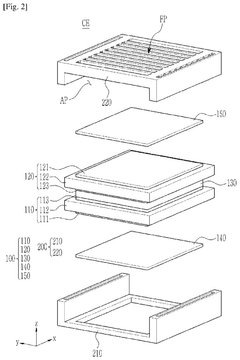

Solid oxide cell systems

PatentPendingEP4611079A1

Innovation

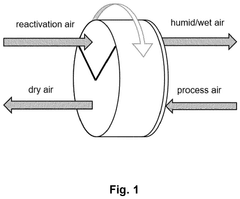

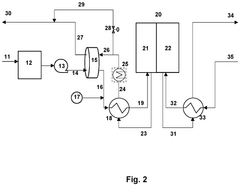

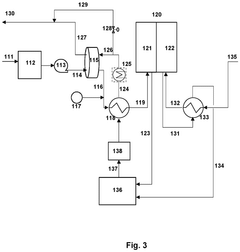

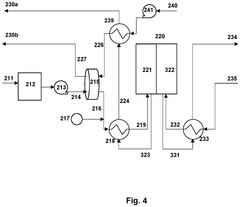

- Integration of a low-pressure desiccant dehumidifier and air recuperator in the SOC system, utilizing waste heat for desiccant regeneration and eliminating the need for separate heaters or blowers, with optimized thermal management to dehumidify process air and prevent chromium migration.

Solid oxide electrolysis cell and cell assembly including the same

PatentPendingUS20250051932A1

Innovation

- The design includes a unit comprising two unit cells with a porous conductive layer in between, along with a separator outside the unit, allowing for parallel electrical connection of multiple units to prevent high voltage application and incorporating circuit breakers for individual unit control.

Economic Viability and Cost Reduction Strategies

The economic viability of Solid Oxide Electrolysis Cells (SOECs) remains a significant challenge despite their promising role in global energy transitions. Current capital costs for SOEC systems range between $800-1,500/kW, substantially higher than conventional hydrogen production methods. This cost barrier primarily stems from expensive ceramic materials, complex manufacturing processes, and the need for high-temperature operation systems.

Material costs represent approximately 40% of total SOEC expenses, with specialized ceramics like yttria-stabilized zirconia and lanthanum strontium manganite commanding premium prices. Manufacturing complexity adds another 30% to costs, while balance-of-plant components for high-temperature operation contribute the remaining 30%.

Several cost reduction strategies show promise for improving SOEC economic competitiveness. Material innovation represents the most impactful approach, with research focusing on alternative ceramic compositions that maintain performance while reducing rare earth element content. Advanced manufacturing techniques, including 3D printing and roll-to-roll processing, demonstrate potential to reduce production costs by 25-35% while improving cell uniformity and reducing defect rates.

Scale economies present another critical pathway to cost reduction. Current SOEC production remains largely subscale, but analysis suggests that gigawatt-scale manufacturing could reduce unit costs by 60-70% through improved process efficiency and supply chain optimization. This transition from laboratory to industrial scale production represents a crucial inflection point for SOEC economic viability.

System integration improvements offer additional cost reduction potential. Co-locating SOECs with renewable energy sources eliminates transmission costs and enables direct utilization of excess renewable electricity. Heat integration with industrial processes can further improve efficiency by utilizing waste heat streams, potentially reducing operational costs by 15-25%.

Policy support mechanisms significantly impact SOEC economic viability. Carbon pricing, renewable energy subsidies, and hydrogen production incentives can dramatically alter the competitive landscape. Models suggest that carbon prices above $50-70/ton could make SOEC hydrogen production cost-competitive with steam methane reforming in many markets.

The learning curve for SOEC technology indicates that costs could decrease by 15-20% with each doubling of deployed capacity, suggesting that early deployment support mechanisms could accelerate cost reduction through accumulated production experience and continuous improvement processes.

Material costs represent approximately 40% of total SOEC expenses, with specialized ceramics like yttria-stabilized zirconia and lanthanum strontium manganite commanding premium prices. Manufacturing complexity adds another 30% to costs, while balance-of-plant components for high-temperature operation contribute the remaining 30%.

Several cost reduction strategies show promise for improving SOEC economic competitiveness. Material innovation represents the most impactful approach, with research focusing on alternative ceramic compositions that maintain performance while reducing rare earth element content. Advanced manufacturing techniques, including 3D printing and roll-to-roll processing, demonstrate potential to reduce production costs by 25-35% while improving cell uniformity and reducing defect rates.

Scale economies present another critical pathway to cost reduction. Current SOEC production remains largely subscale, but analysis suggests that gigawatt-scale manufacturing could reduce unit costs by 60-70% through improved process efficiency and supply chain optimization. This transition from laboratory to industrial scale production represents a crucial inflection point for SOEC economic viability.

System integration improvements offer additional cost reduction potential. Co-locating SOECs with renewable energy sources eliminates transmission costs and enables direct utilization of excess renewable electricity. Heat integration with industrial processes can further improve efficiency by utilizing waste heat streams, potentially reducing operational costs by 15-25%.

Policy support mechanisms significantly impact SOEC economic viability. Carbon pricing, renewable energy subsidies, and hydrogen production incentives can dramatically alter the competitive landscape. Models suggest that carbon prices above $50-70/ton could make SOEC hydrogen production cost-competitive with steam methane reforming in many markets.

The learning curve for SOEC technology indicates that costs could decrease by 15-20% with each doubling of deployed capacity, suggesting that early deployment support mechanisms could accelerate cost reduction through accumulated production experience and continuous improvement processes.

Policy Frameworks Supporting SOEC Deployment

The global transition to sustainable energy systems requires robust policy frameworks to support emerging technologies like Solid Oxide Electrolysis Cells (SOECs). Currently, several nations have implemented strategic policies that accelerate SOEC deployment through financial incentives, regulatory mechanisms, and research funding initiatives.

The European Union leads with its comprehensive Hydrogen Strategy, allocating substantial resources through the Horizon Europe program specifically for SOEC research and commercialization. This is complemented by the European Green Deal, which establishes favorable market conditions for green hydrogen production. Member states like Germany and Denmark have further enhanced these frameworks with national hydrogen strategies that include tax exemptions for green hydrogen producers and subsidies for SOEC installation.

In North America, the United States has recently strengthened its policy support through the Inflation Reduction Act, which provides production tax credits for clean hydrogen and investment incentives for electrolyzer manufacturing. The Department of Energy's Hydrogen Shot initiative specifically targets cost reduction for hydrogen production technologies, including SOECs, with ambitious goals to reduce clean hydrogen costs by 80% within the decade.

Japan and South Korea have implemented technology-specific roadmaps that position SOECs as critical components in their national decarbonization strategies. These Asian frameworks typically combine direct research grants with market creation policies, such as mandatory hydrogen blending quotas in industrial applications and preferential procurement policies.

Carbon pricing mechanisms represent another crucial policy tool supporting SOEC deployment. Regions with established carbon markets or carbon taxes create economic advantages for low-carbon hydrogen production methods. The effectiveness of these mechanisms varies significantly based on carbon price levels, with the EU's Emissions Trading System currently providing the strongest market signals.

Regulatory harmonization remains a challenge, as technical standards and safety regulations for hydrogen production and utilization differ across jurisdictions. International organizations like the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) are working to establish consistent global frameworks that would facilitate technology transfer and reduce market fragmentation.

Future policy development will likely focus on creating demand-pull mechanisms alongside the current supply-push incentives. This balanced approach would establish sustainable market conditions for SOEC technologies beyond the initial deployment phase, ensuring their long-term contribution to global energy transitions.

The European Union leads with its comprehensive Hydrogen Strategy, allocating substantial resources through the Horizon Europe program specifically for SOEC research and commercialization. This is complemented by the European Green Deal, which establishes favorable market conditions for green hydrogen production. Member states like Germany and Denmark have further enhanced these frameworks with national hydrogen strategies that include tax exemptions for green hydrogen producers and subsidies for SOEC installation.

In North America, the United States has recently strengthened its policy support through the Inflation Reduction Act, which provides production tax credits for clean hydrogen and investment incentives for electrolyzer manufacturing. The Department of Energy's Hydrogen Shot initiative specifically targets cost reduction for hydrogen production technologies, including SOECs, with ambitious goals to reduce clean hydrogen costs by 80% within the decade.

Japan and South Korea have implemented technology-specific roadmaps that position SOECs as critical components in their national decarbonization strategies. These Asian frameworks typically combine direct research grants with market creation policies, such as mandatory hydrogen blending quotas in industrial applications and preferential procurement policies.

Carbon pricing mechanisms represent another crucial policy tool supporting SOEC deployment. Regions with established carbon markets or carbon taxes create economic advantages for low-carbon hydrogen production methods. The effectiveness of these mechanisms varies significantly based on carbon price levels, with the EU's Emissions Trading System currently providing the strongest market signals.

Regulatory harmonization remains a challenge, as technical standards and safety regulations for hydrogen production and utilization differ across jurisdictions. International organizations like the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) are working to establish consistent global frameworks that would facilitate technology transfer and reduce market fragmentation.

Future policy development will likely focus on creating demand-pull mechanisms alongside the current supply-push incentives. This balanced approach would establish sustainable market conditions for SOEC technologies beyond the initial deployment phase, ensuring their long-term contribution to global energy transitions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!